Lithium iron phosphate composite pole piece and preparation method

A technology of lithium iron phosphate and composite pole pieces, which is applied in the direction of battery electrodes, electrode carriers/current collectors, electrical components, etc., can solve the problems of difficult control of material consistency, difficult control of coating process, poor consistency of solid phase method, etc. Achieve the effects of reducing the probability of side reactions, low cost, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

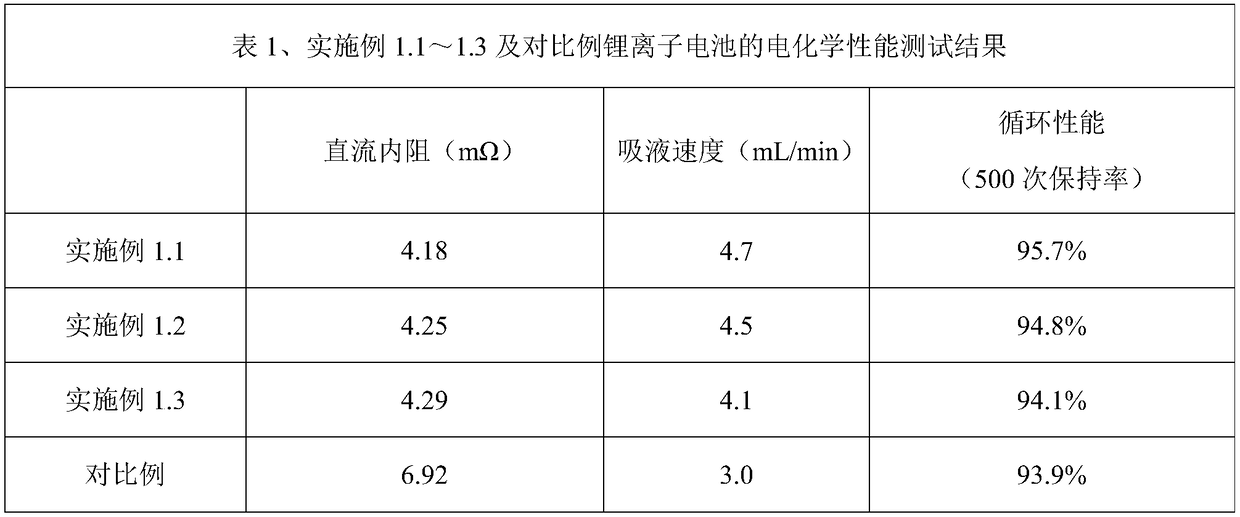

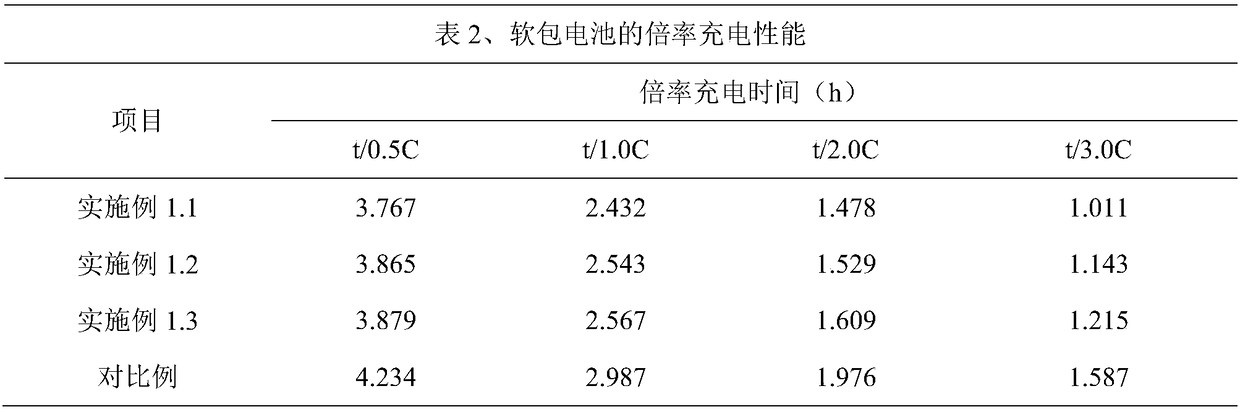

Examples

Embodiment 1

[0030] This embodiment relates to the preparation of a lithium iron phosphate composite pole piece.

Embodiment 11

[0032] Prepare lithium iron phosphate composite pole piece according to the following steps:

[0033] a. Configure metal lithium sol solution:

[0034] Dissolve 5g of lithium metal powder in a steel cylinder containing 710ml of liquid ammonia to form a 1mol / L lithium solution; then add 50g of propylene oxide to the lithium solution under magnetic stirring conditions, and stir evenly to obtain a lithium metal sol;

[0035] b. Preparation of lithium iron phosphate composite pole piece:

[0036] The metal lithium sol solution is scraped and coated on both sides of the aluminum foam current collector. The aluminum foam has a porosity of 80%, a thickness of 30 μm, and a coating thickness of 2 μm. After vacuum drying, it is pressed with a roller press to obtain a composite current collector. The coating machine coats the lithium iron phosphate slurry on the surface of the composite current collector with a coating thickness of 150 μm, and dries to obtain a lithium iron phosphate co...

Embodiment 12

[0041] Prepare lithium iron phosphate composite pole piece according to the following steps:

[0042] a. Configure metal lithium sol solution:

[0043] Dissolve 3.5g of lithium metal powder in a steel cylinder containing 1000ml of liquid ammonia to form a 0.5mol / L lithium solution; then add 40g of acetonitrile to the lithium solution under magnetic stirring conditions, and stir evenly to obtain a lithium metal sol;

[0044] b. Preparation of lithium iron phosphate composite pole piece:

[0045]The metal lithium sol solution is scraped and coated on both sides of the nickel foam current collector. The nickel foam has a porosity of 60%, a thickness of 20 μm, and a coating thickness of 1 μm. After vacuum drying, it is pressed with a roller press to obtain a composite current collector. The coating machine coats the lithium iron phosphate slurry on the surface of the composite current collector with a coating thickness of 100 μm, and dries to obtain a lithium iron phosphate compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com