Patents

Literature

58results about How to "Reduce the chance of side effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing heavy metal and organic matter composite pollutants in water body by means of zero-valent iron and persulfate

ActiveCN105110448ALarge specific surface areaSimple preparation processWater contaminantsWater/sewage treatment by reductionPotassium persulfateSodium Bentonite

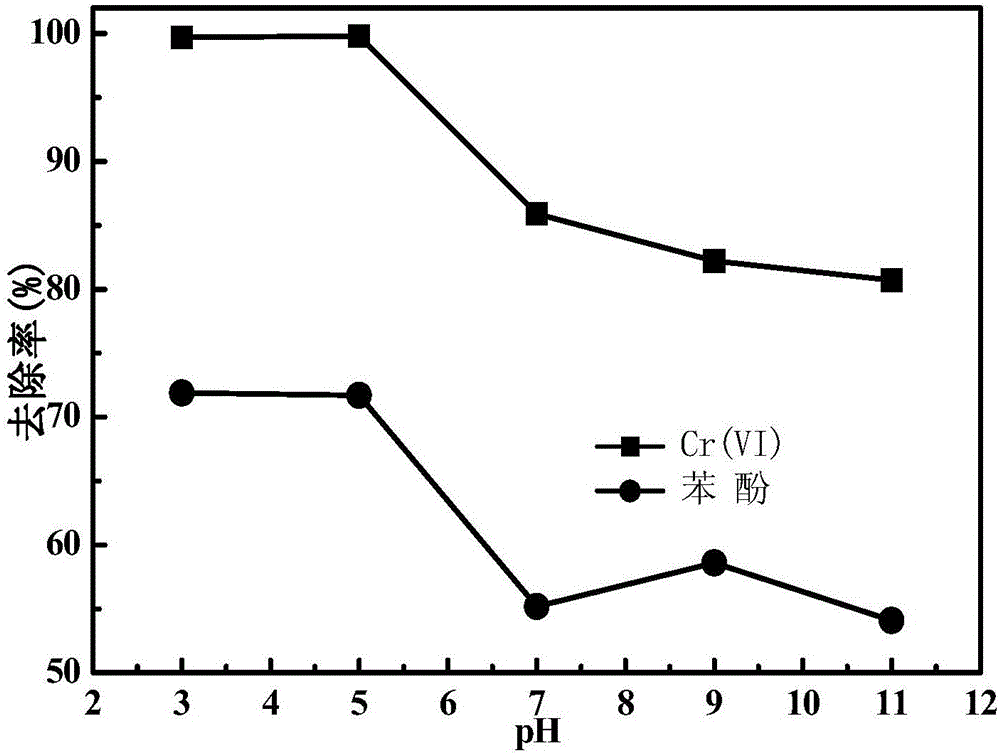

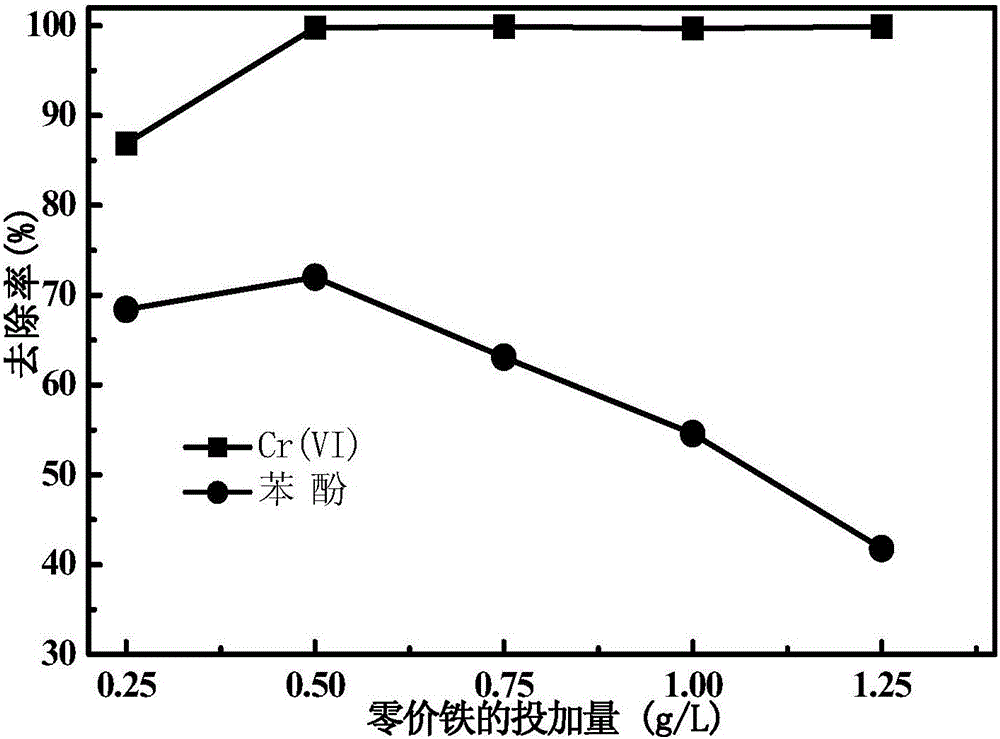

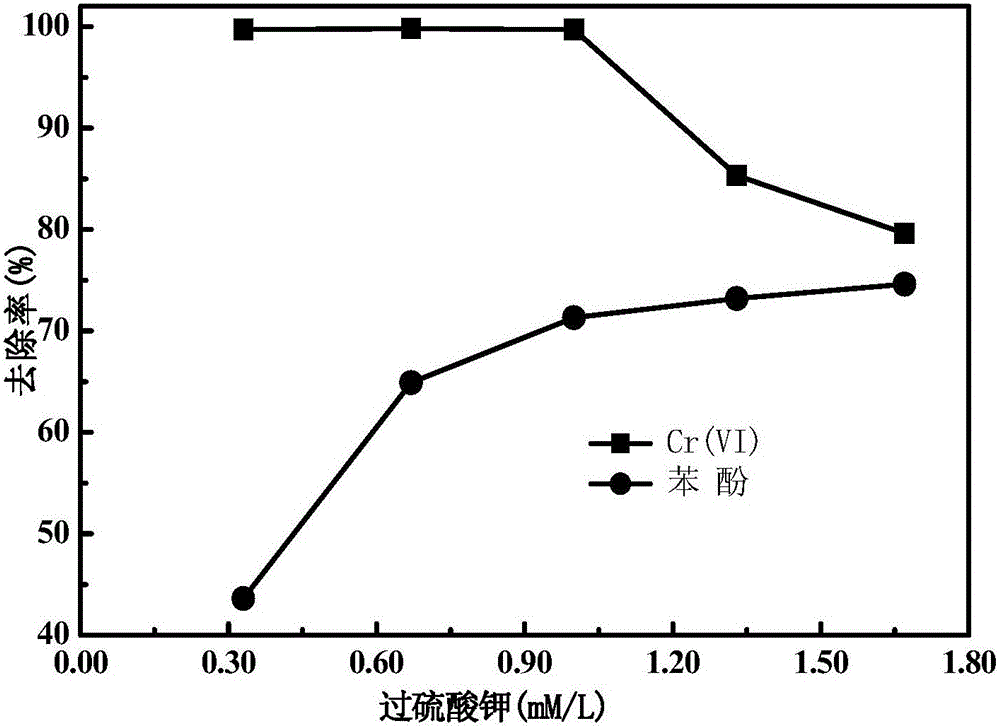

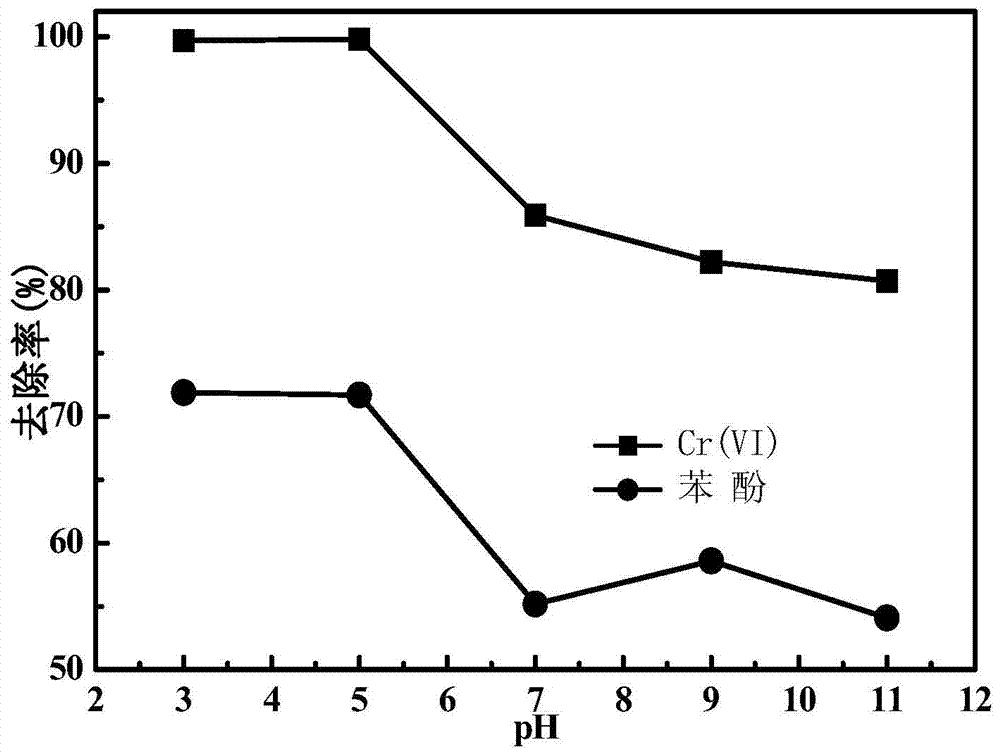

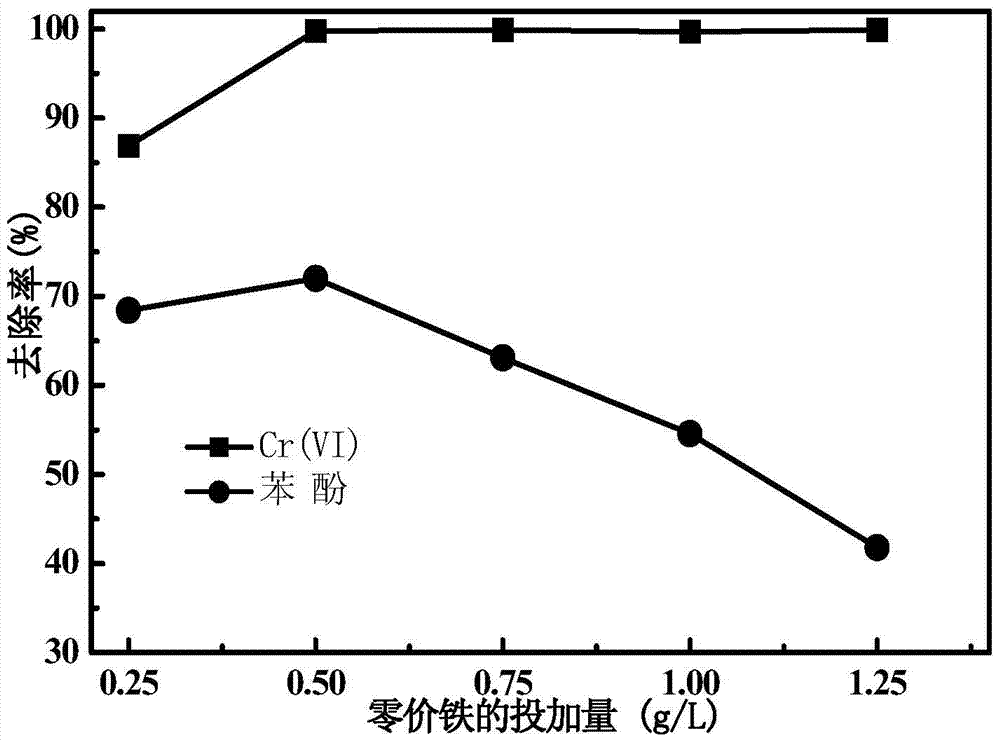

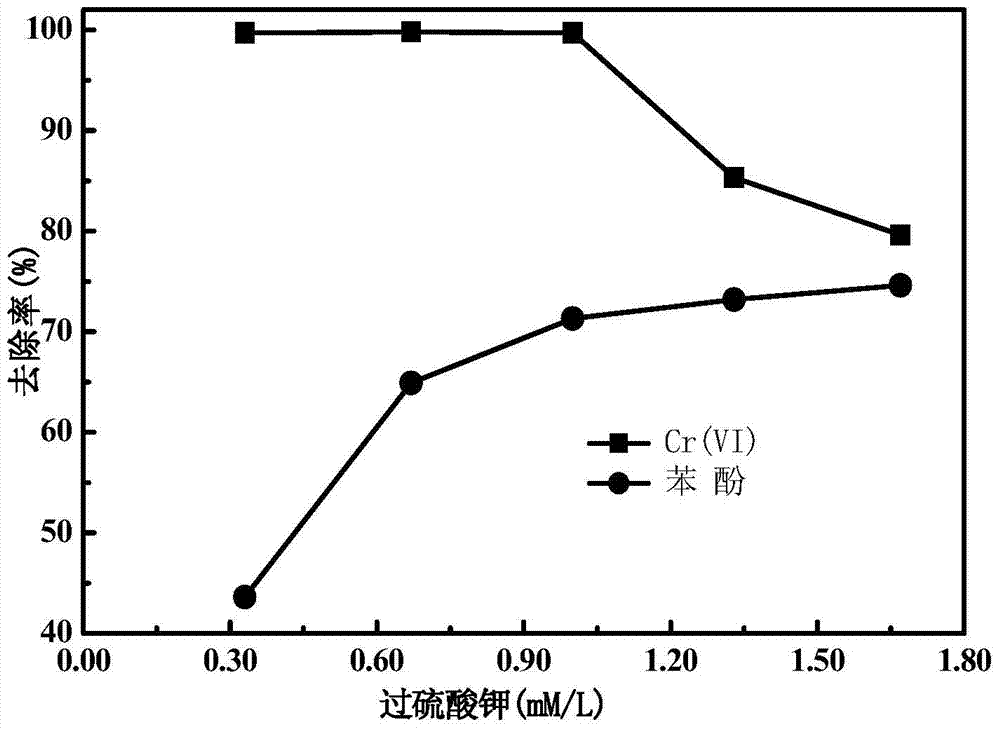

The invention discloses a method for removing heavy metal and organic matter composite pollutants in a water body by means of zero-valent iron and persulfate. According to the method, bentonite-supported nanoscale zero-valent iron and persulfate are added to the water body containing heavy metal and organic matters, a multi-phase coexistent system is formed, and the heavy metal and the organic matters are removed. Cr(VI) and phenol contained in the water body can be removed simultaneously with the bentonite-supported nanoscale zero-valent iron and potassium persulfate combined method, the heavy metal Cr(VI) is removed through the strong reduction performance of the nanosacle zero-valent iron, Fe2+ generated by the nanoscale zero-valent iron in the reaction process is fully used to activate potassium persulfate, so that SO4<->* is continuously generated to oxidize and degrade phenol, and the heavy metal and organic matter composite pollutants in the water body are removed synergistically.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

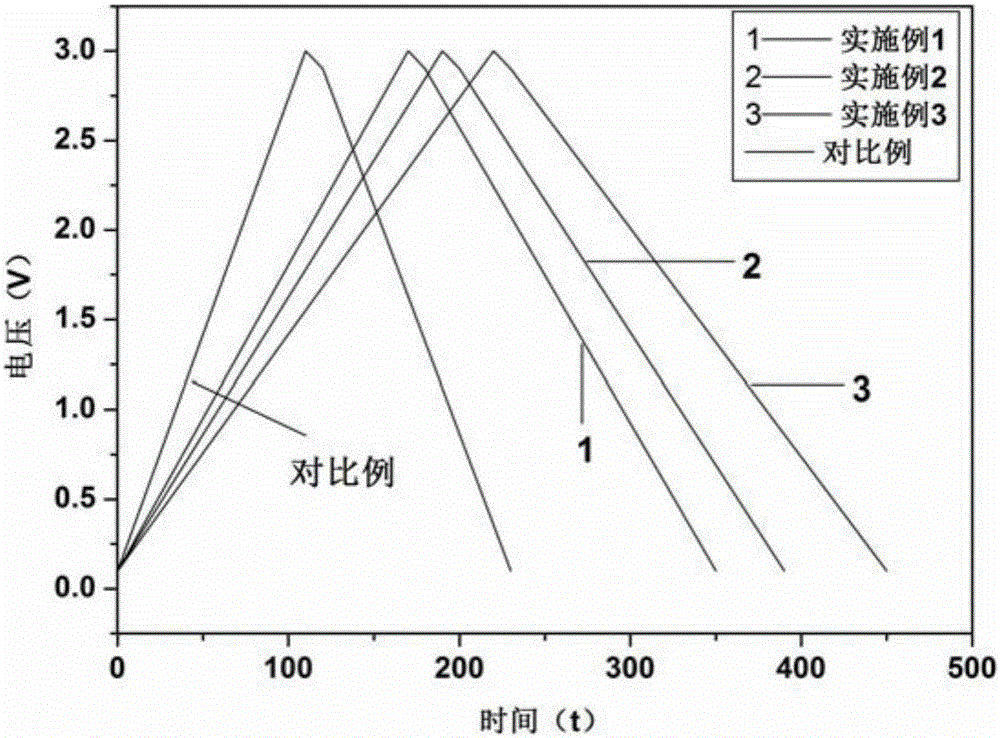

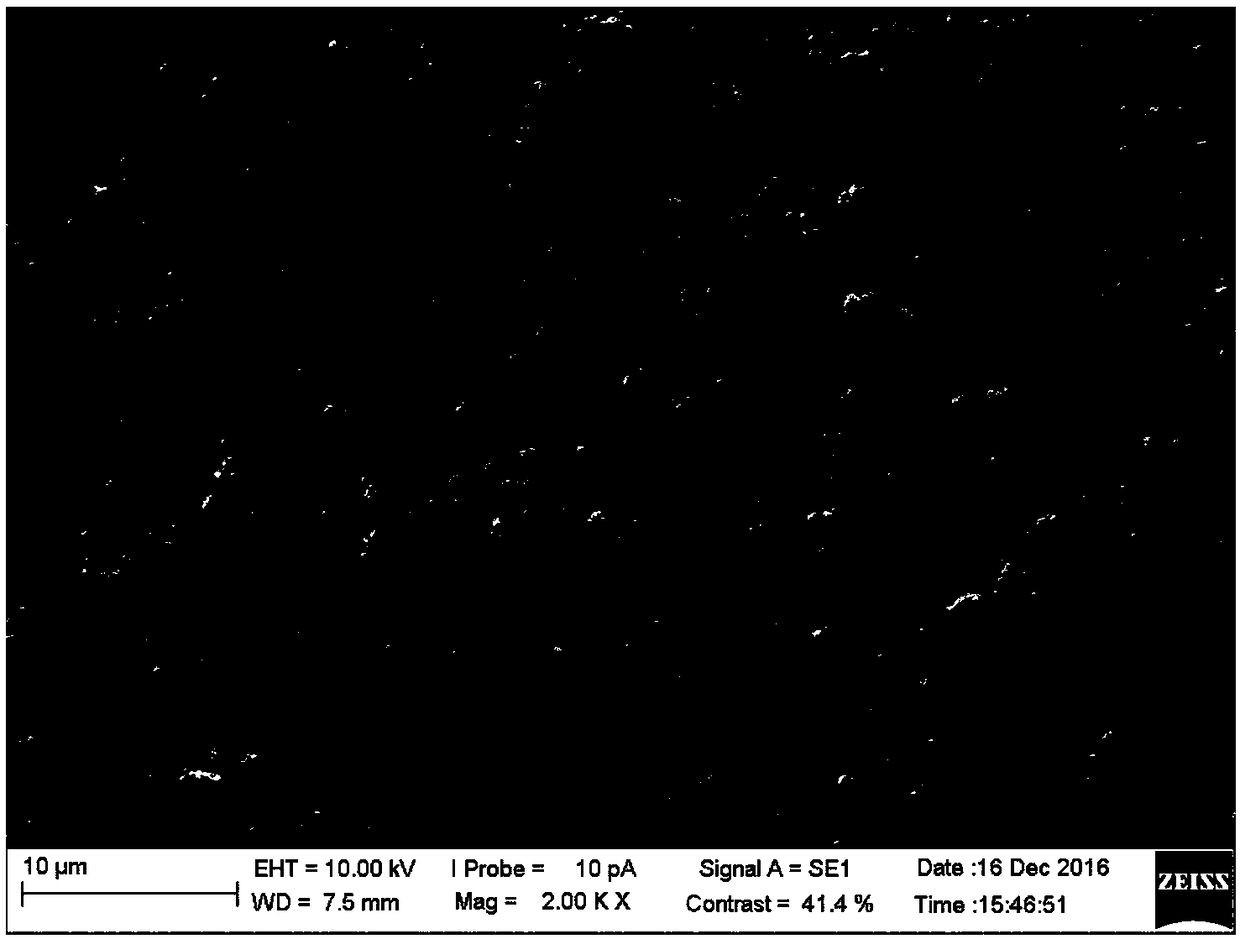

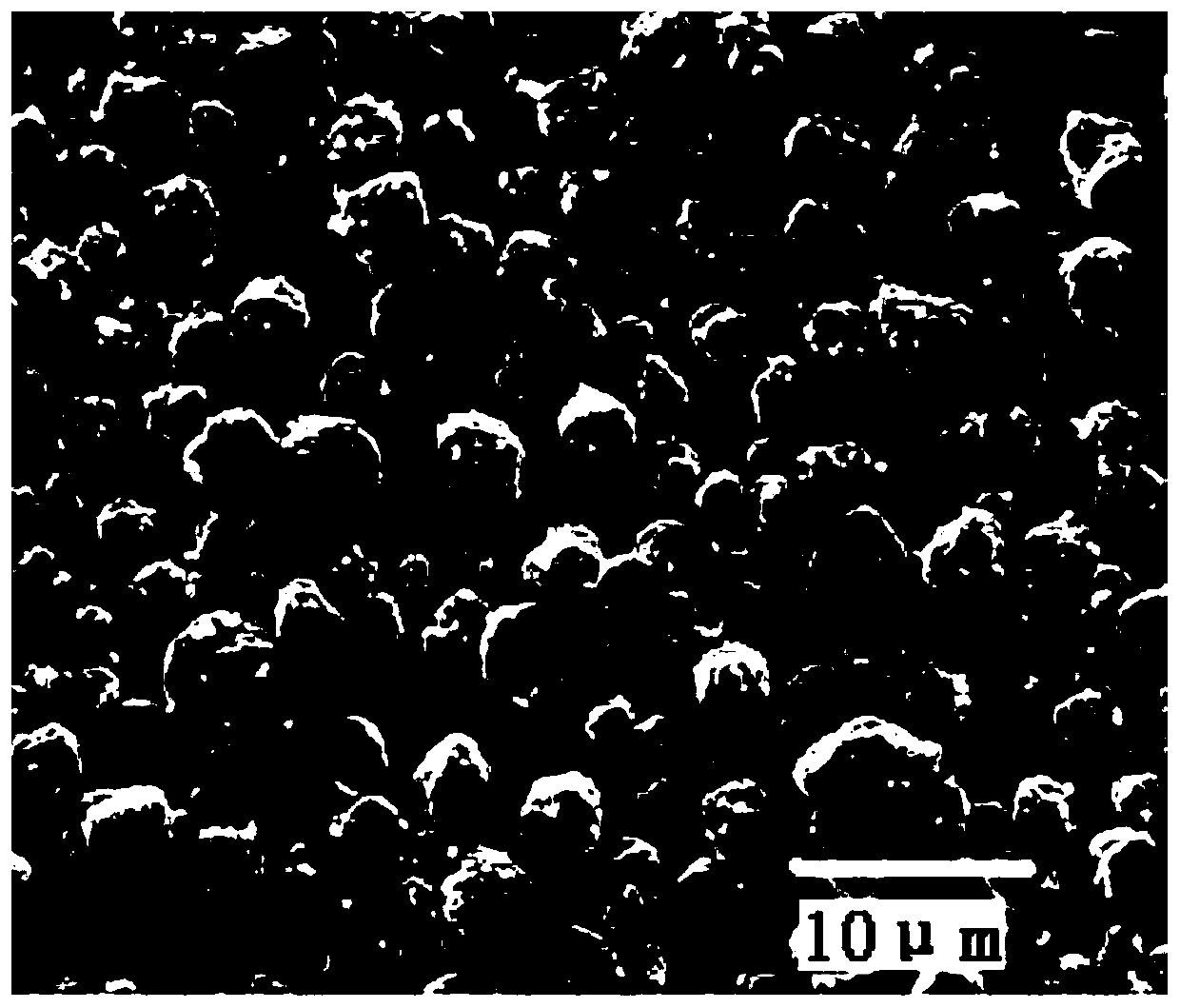

Preparation method of high-compaction density 523-type ternary positive electrode material

InactiveCN107799764AIncrease compaction densityLower pHCell electrodesSecondary cellsManganateSingle crystal

The invention provides a preparation method of a high-compaction density 523-type ternary positive electrode material, and belongs to the technical field of preparation of a lithium ion battery positive electrode material. A high-compaction density and low-pH value lithium nickel cobalt manganate NCM523-type ternary positive electrode is in a spherical shape, grain D50 of secondary agglomeration particle is 10-12 micrometers, and the size of primary single-crystal particle is 1.5-3 micrometers. The preparation method of the high-compaction density 523-type ternary positive electrode material comprises the steps of doping 0.1-1.0% of metal oxide into a mixture of lithium carbonate and a ternary precursor LiNi<0.5>Co<0.2>Mn<0.3>(OH)<2>, performing primary sintering, paste washing, secondarysintering, breakage, iron removal, sieving and mixing, and finally, obtaining an NCM523-type ternary positive electrode material. By the method, the compaction density of the NCM523-type ternary positive electrode material is effectively improved, a pH value is reduced, the compaction density of the prepared NCM523-type ternary positive electrode material is larger than 3.7g / cm<3>, and the pH value is smaller than 10.80.

Owner:JINCHUAN GROUP LIMITED +1

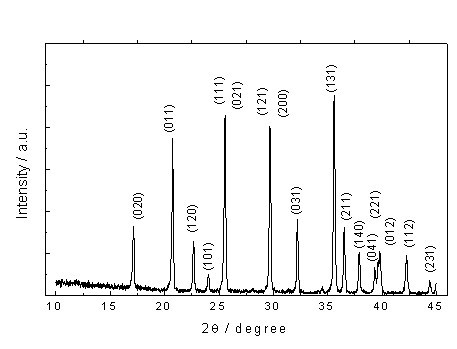

Preparation method of water-heated carbon cladding lithium iron phosphate

InactiveCN102088079AAddressing inhomogeneitySolve loose defectsCell electrodesLithium iron phosphateRoom temperature

The invention discloses a preparation method of water-heated carbon cladding lithium iron phosphate, aiming to provide a preparation method of water-heated carbon cladding lithium iron phosphate, which can overcome the deficiencies of nonuniform and loose cladding and the like of the traditional carbon cladding method. In order to solve the problem, the adopted technical scheme comprises the following steps of: Step 1. mixing lithium iron phosphate powder and organic solution according to the mass ratio of (10-30):100, adding dispersing agent, and carrying out ultrasonic stirring for certain time to obtain well dispersed suspension; Step 2. transferring the well dispersed suspension to a reaction kettle and making the well dispersed suspension react at the temperature of 120 to 300 DEG C for 3 to 10 hours; Step 3. after reaction, cooling the material to the room temperature and then filtering, and washing the material by water and ethanol in sequence; and Step 4. drying the washed material in a vacuum or inert environment at the temperature of 80 to 150 DEG C for 3 to 6 hours to obtain the water-heated carbon cladding lithium iron phosphate powder material. The water-heated carbon cladding lithium iron phosphate prepared by the preparation method has the advantages of uniform and compact cladding, long service life and the like.

Owner:ZHEJIANG RICHPOWER TECH

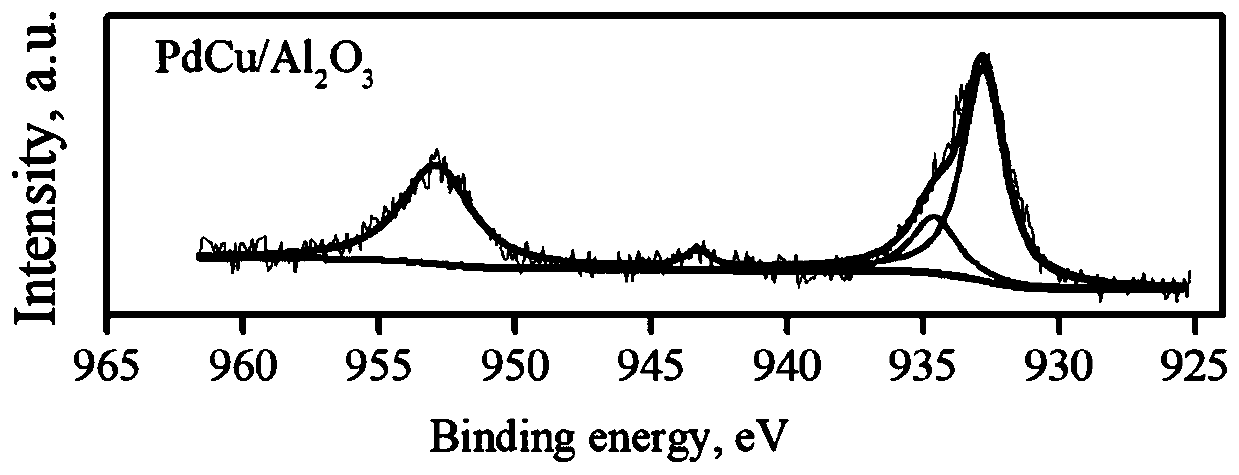

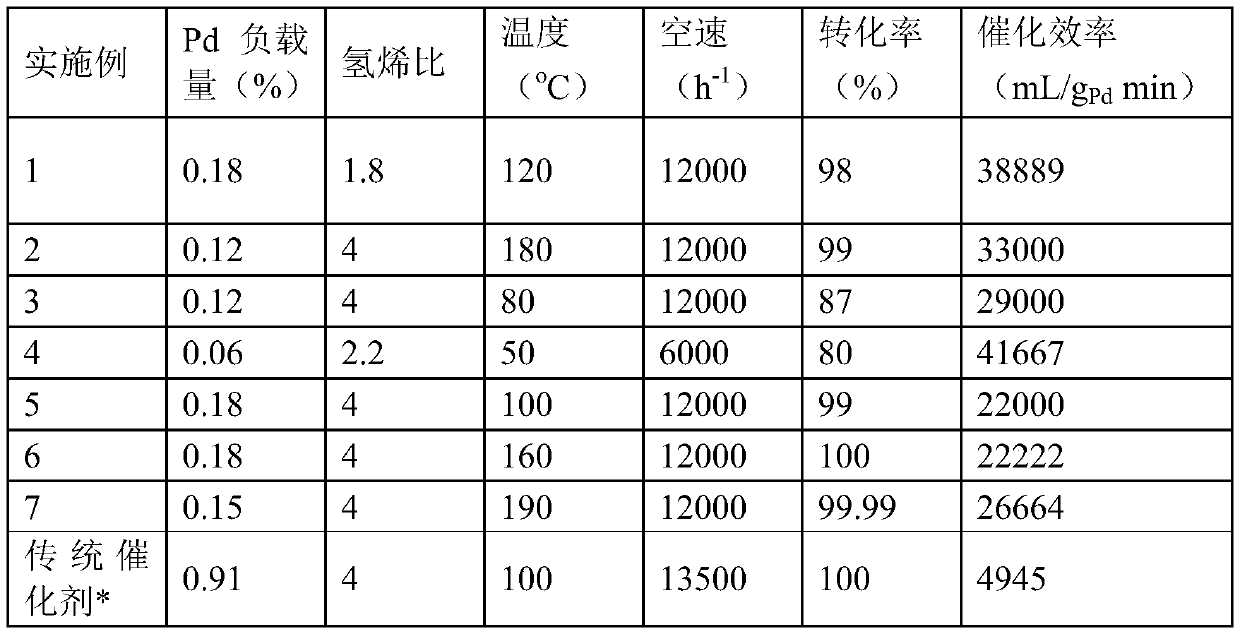

Pdx/Cu monatomic catalyst for selective hydrogenation of C4 and preparation method for Pdx/Cu monatomic catalyst

InactiveCN109806885ATemperature controlEasy to removeHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsButeneAlkyne

The invention relates to an unsaturated C4 selective hydrogenation catalyst and a preparation method and application thereof. The catalyst is prepared from Pd, Cu and a carrier. The catalyst is used for selective hydrogenation removal of C4 alkynes and dienes, unsaturated C4 molecules are converted into butene through hydrogenation, and therefore the purpose of removing unsaturated C4 is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Continuous production method of high-content high-optical-purity lactate

InactiveCN102675102AReduce moisture contentConfiguration flipPreparation by ester-hydroxy reactionOligomerAlcohol

The invention relates to a continuous production method of high-content high-optical-purity lactate. The continuous production method of high-content high-optical-purity lactate includes the steps of adding catalyst in lactic acid to allow for polycondensation to obtain lactic acid oligomer with 1000-2500 molecular weight; adding catalyst into the lactic acid oligomer to allow for depolymerization to obtain crude lactide; and refining the crude lactide, and subjecting the refined lactide and organic alcohol to full-reflux reaction to obtain lactate. The continuous production method is simple in process, easy and simple to operate and suitable for industrial production and application. The materials can all be utilized. No 'three wastes' emission occurs. Content of the synthetized lactate is more than 99.5%, and optical purity of the lactate can reach more than 99%.

Owner:XIAOGAN ESUN NEW MATERIAL

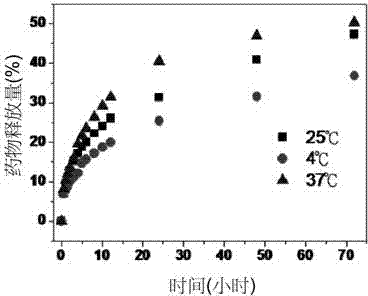

Medicine loading type contact lens and preparation method thereof

ActiveCN102778762AReduce lossesReduce the chance of side effectsSurgeryEye treatmentSide effectBiomedical engineering

Owner:SPRING FOUND OF NCTU

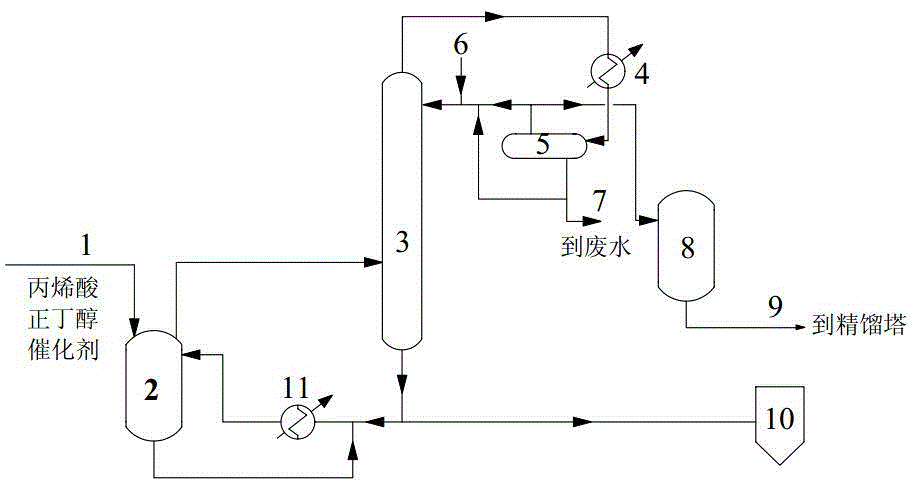

Energy-saving and environmental-protection butyl acrylate production method

InactiveCN104529759AReduce the chance of side effectsSolid alkali has a long service lifeOrganic compound preparationCarboxylic acid esters separation/purificationButyl acrylateButanol

The invention discloses an energy-saving and environmental-protection butyl acrylate production method. The method comprises the following steps: adding reaction raw materials comprising acrylic acid and n-butanol into an esterification kettle according to a molar ratio of 0.8-1:1, adding a catalyst accounting for 0.5-5% of the total mass of the added materials and a polymerization inhibitor accounting for 0.01-0.1% of the total mass of the added materials into the esterification kettle, carrying out a steam heating reaction in the esterification kettle to form an esterification product, allowing the esterification product to enter an esterification tower in an ester-water azeotrope form, separating, extracting from the top of the esterification tower, condensing through a condenser, and adding the obtained condensed product to a phase splitter to layer in order to an ester phase with the content of crude ester of 85-95%; returning most of a kettle liquid of the esterification kettle to the esterification kettle in order to reflux, allowing a small amount of the kettle liquid to enter a cracking system, and carrying out cracking recovery; and carrying out reboiling heating treatment on the returned most kettle liquid, and adjusting a reboiling system to guarantee the full reaction of the raw materials, effectively control the temperature of the esterification kettle and avoid side reactions. The method can effectively reduce the occurrence probability of the side reactions and the wastewater treatment difficulty, saves energy by 5-15%, and is economic and environmentally-friendly.

Owner:谦信化工集团有限公司

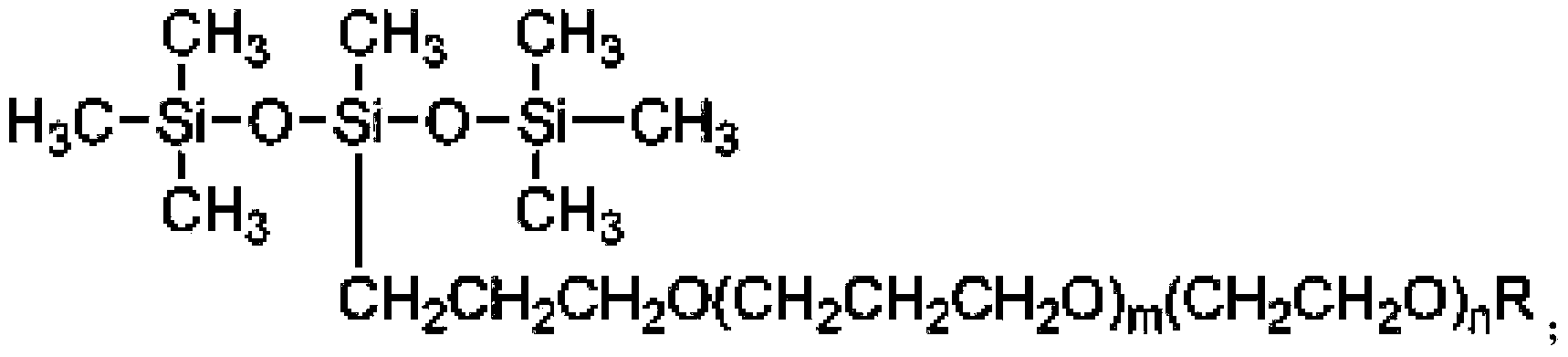

Polyether modified trisiloxane wetting agent and preparation and application methods thereof

ActiveCN104312256AHigh reactivityReduce the chance of side effectsSilicon organic compoundsBiocideLacquerEnvironmental resistance

The invention belongs to the technical field of an organic silicon surface wetting agent and particularly relates to a polyether modified trisiloxane wetting agent and preparation and application methods thereof. According to the polyether modified trisiloxane wetting agent disclosed by the invention, a Pt(0) catalyst is loaded by a nano-pore material; and in a reactor, reaction is performed (the reaction time is shorter than or equal to 2h) to obtain the polyether modified trisiloxane wetting agent. The polyether modified trisiloxane wetting agent disclosed by the invention has a viscosity of 20 to 100cSt and surface tension of smaller than or equal to 21mN / m; when the polyether modified trisiloxane wetting agent is used in a water-based paint, the polyether modified trisiloxane wetting agent can still have excellent wettability on a base material after being aged at a high environment temperature of 40 to 70 DEG C under the alkali condition of pH of 10 for a long time of 200h and no shrinkage cavity or spots are generated on a film; and the polyether modified trisiloxane wetting agent disclosed by the invention can be applied to the field of a water-based leather finishing agent (high-temperature coating), a water-based material, wood lacquer, agricultural chemical reagents and the like and has rapid-extension property, wettability and environmental adaptation. The methods disclosed by the invention have the advantages that the production efficiency is high and the production cost is low, the operation is simple, and the methods are non-toxic and environmental-friendly.

Owner:优美特(北京)环境材料科技股份公司

Lithium cobaltate for positive electrode of lithium ion battery and preparation method of lithium cobaltate for positive electrode of lithium ion battery

InactiveCN104241627AReduce contact areaImprove charge-discharge cycle performanceCell electrodesSecondary cellsLithium electrodeMetal

The invention discloses lithium cobaltate for a positive electrode of a lithium ion battery and a preparation method of the lithium cobaltate for the positive electrode of the lithium ion battery. The proportional formula of the lithium cobaltate prepared by adopting the method is shown as LixCoyMzO2, wherein M represents for one or two of transition metal elements except Co or alkaline earth metals elements; S represents for an average valence of all metal elements of the lithium cobaltate except lithium and cobalt; a mole ratio of four elements in the positive material-lithium cobaltate is x to y to 2 to 2; S is greater than or equal to +2 and less than +2.5; x is greater than or equal to 0.9 and less than or equal to 1.1; y is greater than or equal to 0.8 and less than or equal to 1.1; x plus 3y plus S*z is equal to 4. The lithium cobaltate prepared by adopting the method has the high volume capacity density, the high safety, the stable charge-discharge cycle performances and the high compaction density.

Owner:PULEAD TECH IND

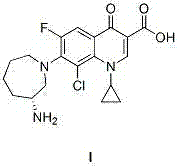

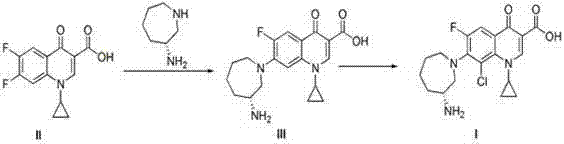

New method for synthesizing besifloxacin

The invention relates to a method for synthesizing an anti-infective drug, namely besifloxacin. The method comprises the steps of taking 2,4,5-trifluorobenzoic acid as a starting material, condensing L-amino caprolactam and 1-cyclopropyl-6,7-difluoro-4-oxo-1,4-dihydro-3-quinoline carboxylic acid to obtain (R)-7-(3-amino hexahydro-1H-azepine-1-yl)-1-cyclopropyl-6-fluorine-1,4-dihydro-4-oxygen-3-cinchoninic acid, and chloridizing with chlorosulfonic acid to obtain the final product besifloxacin. According to the new method for synthesizing the besifloxacin, the preparation method is simple, the reaction is easy to control, an intermediate is stable and easy to obtain, the yield is higher, and industrial production, storage and transportation are facilitated.

Owner:FARMASINO PHARMA ANHUI +1

Industrial preparation method of high-yield cinnamaldehyde

InactiveCN102718638AReduce the chance of oxidationLess side effectsOrganic compound preparationCarbonyl compound preparationDistillationBenzaldehyde

The invention provides an industrial preparation method of high-yield cinnamaldehyde. The method includes the following steps of: A, adding a solid catalyst and a water solution of polyethylene glycol 400 to a reaction vessel, then adding benzaldehyde; B, adding dropwisely 30 % to 50% by mass of an acetaldehyde water solution slowly with stirring, after the dropwisely adding, controlling the temperature from 25 DEG C to 30 DEG C for a reaction for 3 to 5 hours; C, performing washing after the completion of the reaction, and allowing the mixture to stand for delamination; and D, performing distillation after separating out an oil layer to obtain the cinnamaldehyde. The method in the invention is advantaged in operational simplicity, easiness in obtaining raw materials and in preparation of the catalyst, simple recovery, environmental friendliness, continuous operation, fast forward reaction speed compared with common processes, low probability of a side reaction, reduced unit energy consumption of a product as well as stable quality, high yield, and high purity of the produced cinnamaldehyde.

Owner:湖北远成赛创科技有限公司

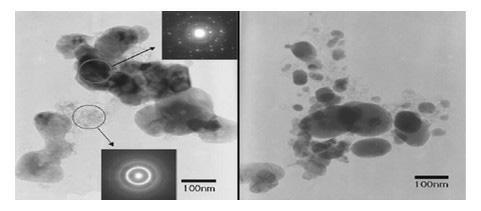

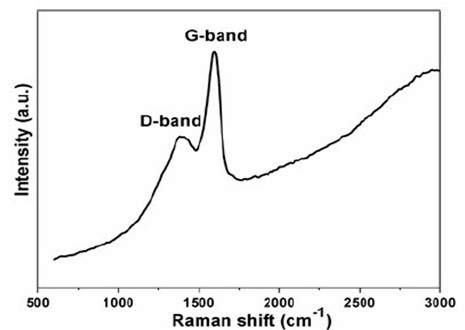

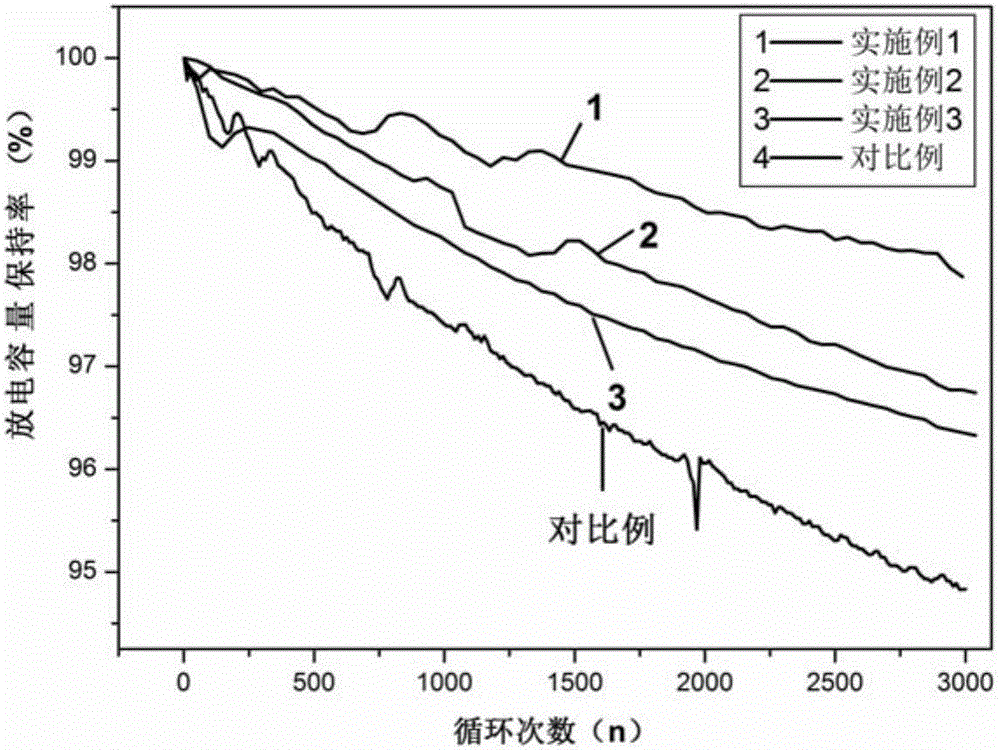

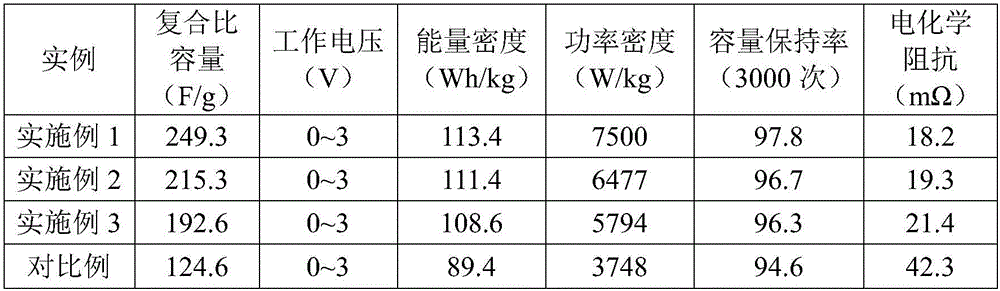

Carbon nano-tube net/Ni(OH)<2>/PPY composite electrode, preparation method and application

InactiveCN106169377AImprove specific energy density characteristicsHigh specific energy density characteristicsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh rate

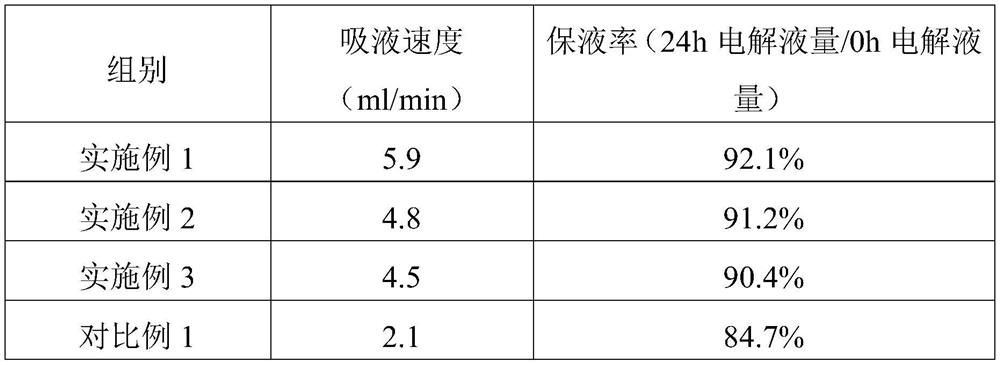

The invention discloses a carbon nano-tube net / Ni(OH)<2> / PPY composite electrode, a preparation method and application, belonging to the technical field of super capacitors. The carbon nano-tube net / Ni(OH)<2> / PPY composite electrode is a core-shell structure; a core is composed of Ni(OH)<2> and a carbon nano-tube net doped therein; and a shell is uniform and compact PPY formed through an electrochemical deposition method. The composite electrode exerts a double-electrode-layer effect by utilizing the carbon nano-tube net having high specific surface area; with the help of the pseudocapacitance characteristic of the nano metallic oxide Ni(OH)<2>, the specific capacity is increased; simultaneously, depending on the high electric conductivity and the high specific energy density of the polymeric conductive polymer PPY, the discharge capability of the super capacitors under a high rate can be improved; the carbon nano-tube net with a connection point in a composite pole piece is doped in Ni(OH)<2>; therefore, the electric conductivity and the liquid sucking and keeping capability of the material are easily improved; and furthermore, the structural stability of the material can be improved through a net type structure.

Owner:深圳博磊达新能源科技有限公司

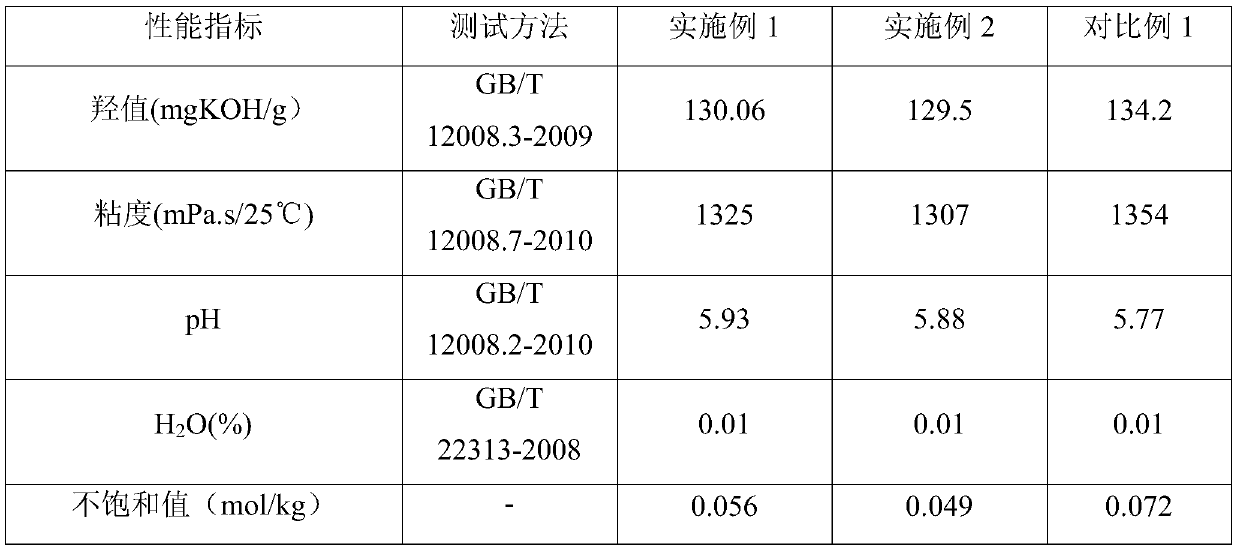

Preparation method of high-functionality polyether polyol

The invention belongs to the technical field of polyether polyol synthesis, and particularly relates to a preparation method of high-functionality polyether polyol, wherein the preparation method comprises the following steps: (1) by using a high-functionality initiator or a mixed initiator containing the high-functionality initiator as an initiator, adding alkylene oxide under the action of a catalyst, and carrying out a polymerization reaction to obtain oligomer polyether polyol; and (2) adding an initiator which is the same as the initiator in the step (1), a catalyst and alkylene oxide into the oligomer polyether polyol obtained in the step (1), and carrying out a polymerization reaction to obtain the high-functionality polyether polyol. According to the invention, a step-by-step secondary feeding mode is adopted, the high-viscosity initiator system is diluted to a certain extent, the olefin oxide addition reaction is easier to start, the problems of long initiation time and non-uniform polymerization are solved, the unsaturated value index of a polyether polyol product is lower, the actual hydroxyl value of the product is closer to the theoretical hydroxyl value, and the product can meet higher use requirements.

Owner:SHANDONG BLUSR DONGDA CHEM

Lithium iron phosphate composite pole piece and preparation method

ActiveCN108258199AIncrease gram capacityImproved magnification performanceElectrode carriers/collectorsSecondary cellsGas phaseLithium metal

The invention discloses a preparation method of a lithium iron phosphate composite pole piece. The preparation method comprises the following steps: firstly dissolving lithium metal into liquid nitrogen to obtain a lithium sol solution, coating the lithium sol solution onto the surface of a spumy current collector, after pressing and high temperature treatment, coating a lithium iron phosphate sizing agent on the surface, and after drying, carrying out vapor deposition on the surface to obtain a graphene layer so as to obtain the positive composite pole piece. The preparation method is simplein process, high in efficiency and easy to control, solves the defects existing in a conventional pole piece coating technology, and is low in cost and excellent in effect. According to the obtained lithium iron phosphate composite pole piece, lithium supplementation is carried out on active substances through pre-lithiation of the current collector, so that the gram volume development and rate performance of a lithium iron phosphate battery can be improved, meanwhile, the cycle performance of the lithium ion battery is improved by using the characteristics that the electric conductivity of external graphene is high and the compatibility with an electrolyte is excellent.

Owner:HEBEI LITAO BATTERY MATERIAL

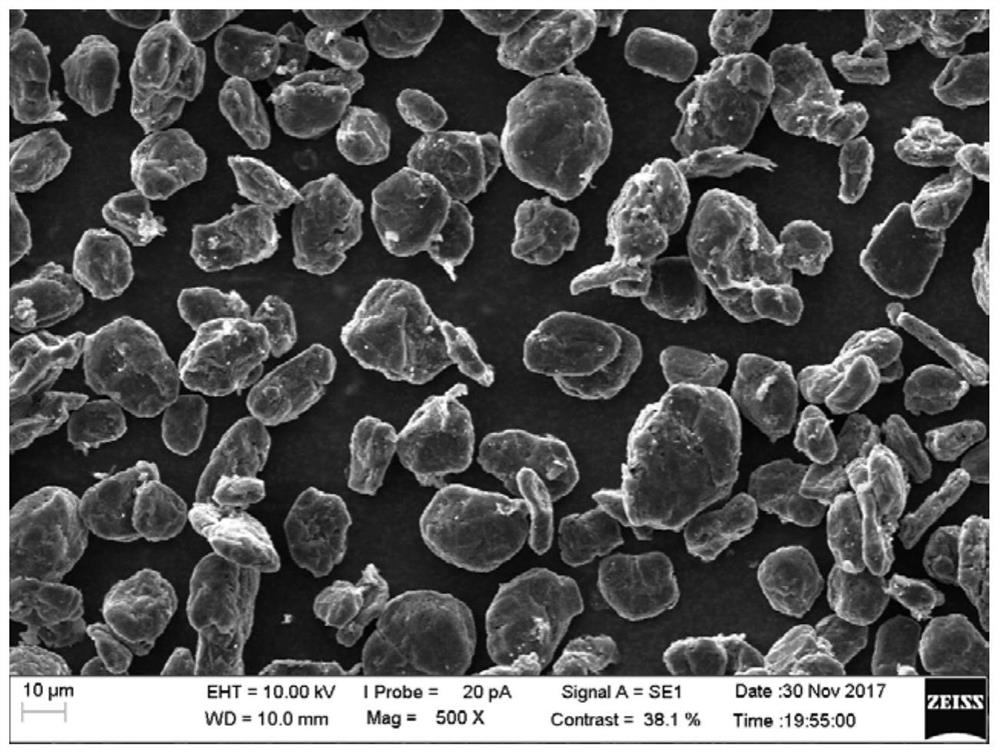

Nano-silicon composite negative electrode material and manufacturing method thereof

ActiveCN112366306AAvoid volumeInhibition of contractionMaterial nanotechnologyNegative electrodesNano siliconCarbon nanotube

The invention relates to a nano-silicon composite negative electrode material and a manufacturing method thereof. The nano-silicon composite negative electrode material comprises multi-coated nano-silicon powder and carbon nanotubes growing in situ, the multi-coated nano-silicon powder is provided with a core part with nano-silicon particles and a composite coating layer arranged on the core part,and the composite coating layer comprises conductive carbon, polyacene and inorganic metal oxide.

Owner:TOMI CHENGDU APPLIED TECH RES INST CO LTD

Catalytic oxidation treatment method of alkali reduction wastewater

InactiveCN107628665AOvercoming the defect of easy reunionMany adsorption sitesWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsAlcoholCatalytic oxidation

The invention discloses a catalytic oxidation treatment method of alkali reduction wastewater and an application thereof. The catalytic oxidation treatment method includes the following steps: at thetemperature of 50-70 DEG C, placing charcoal in nitric acid and soaking, and rinsing until the pH value is no longer changed; dissolving FeSO4.7H2O in deionized water, adding absolute ethyl alcohol toobtain a mixed solution, adding the charcoal to the mixed solution, and continuously stirring to make the charcoal and the solution fully mixed; under the protection of inert gas, dropping a KBH4 solution, after the completion of dropping, carrying out an aging reaction, carrying out washing and drying treatment, and preparing charcoal supported nanoscale zero-valent iron catalyst for standby application; putting the charcoal nanoscale zero-valent iron loaded catalyst into alkali reduction wastewater, then adding Na2S2O8, carrying out a reaction in a normal temperature condition, taking out the mixed solution after the reaction and determining the CODcr concentration. The method is a catalytic oxidation treatment method of the alkali reduction wastewater, wherein the method has the advantages of simple process, high oxidation efficiency and no secondary pollution.

Owner:GUANGDONG UNIV OF TECH

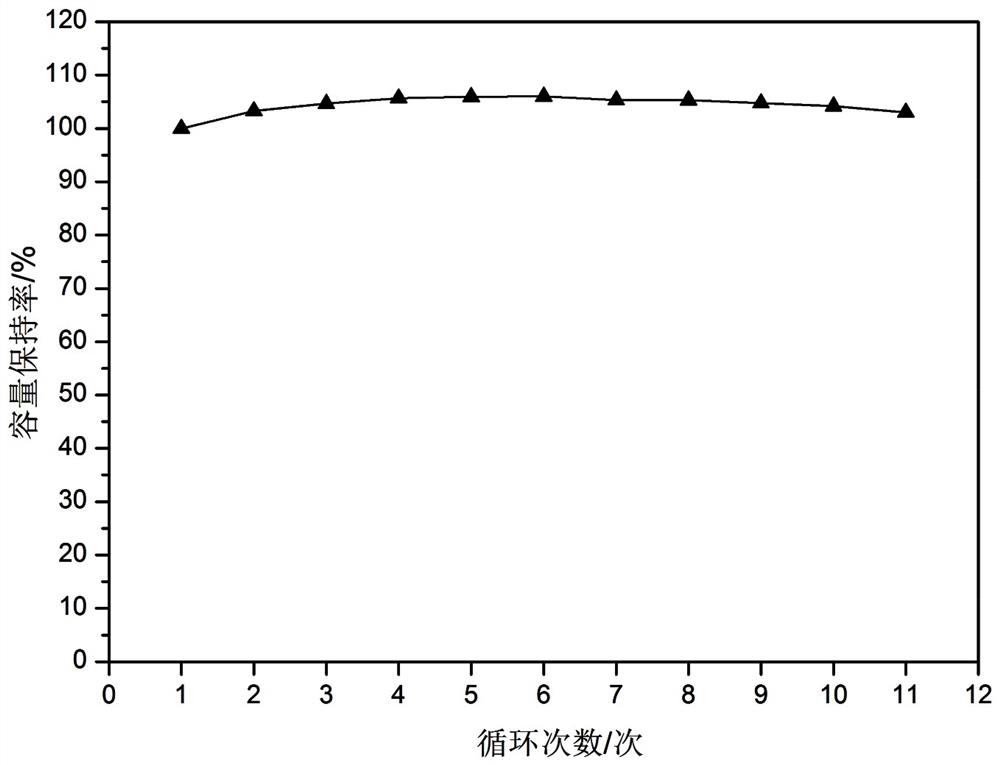

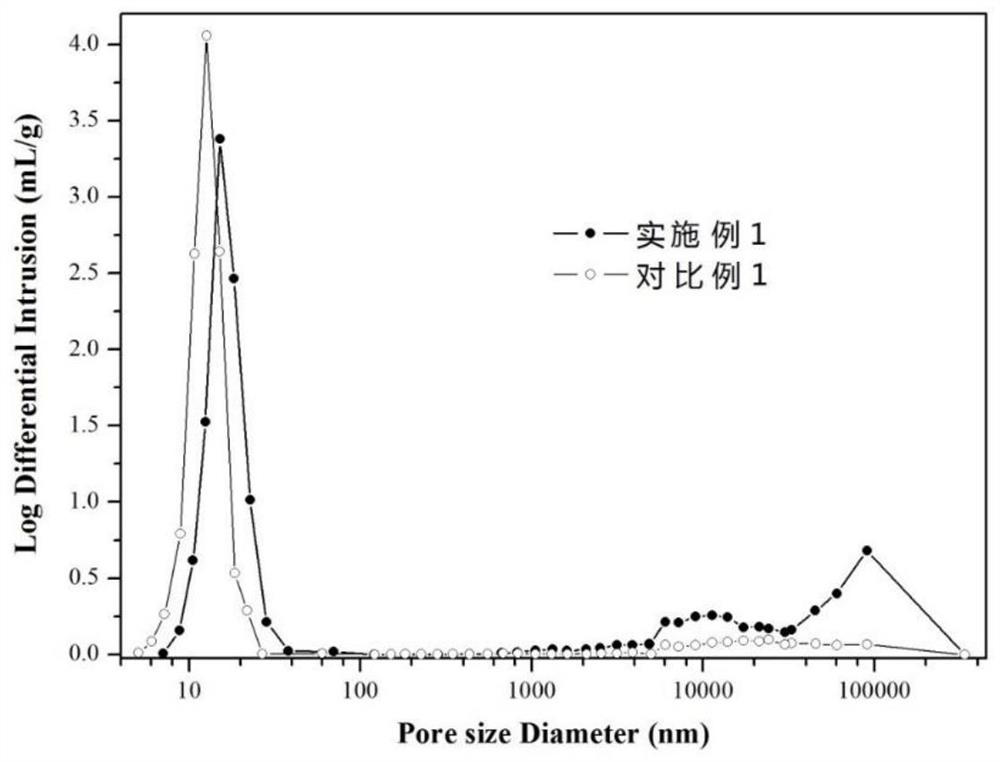

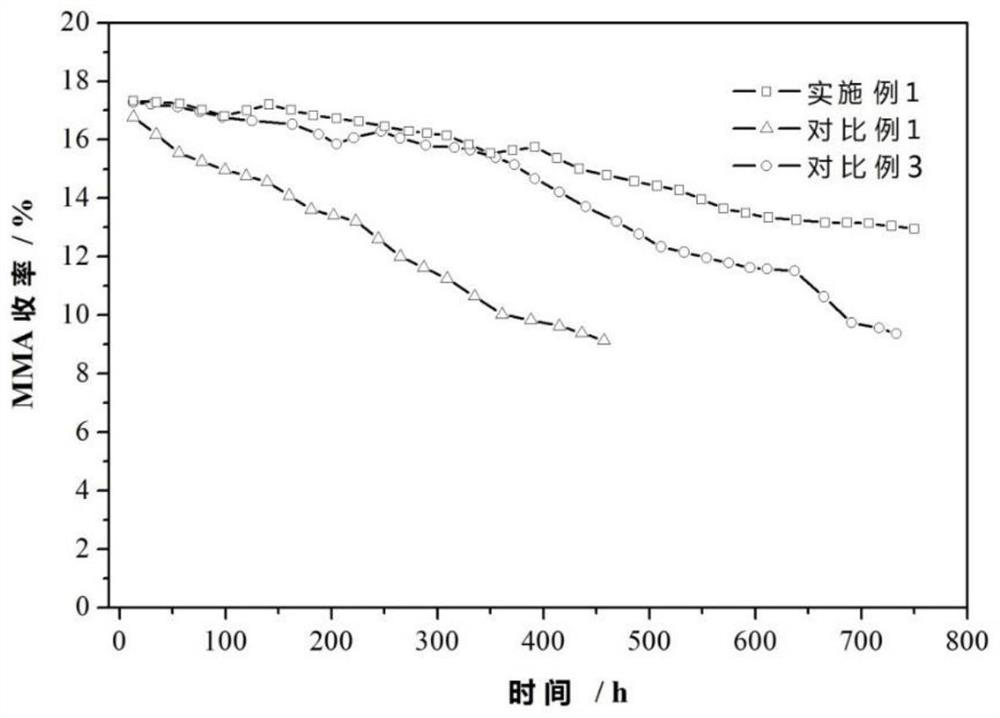

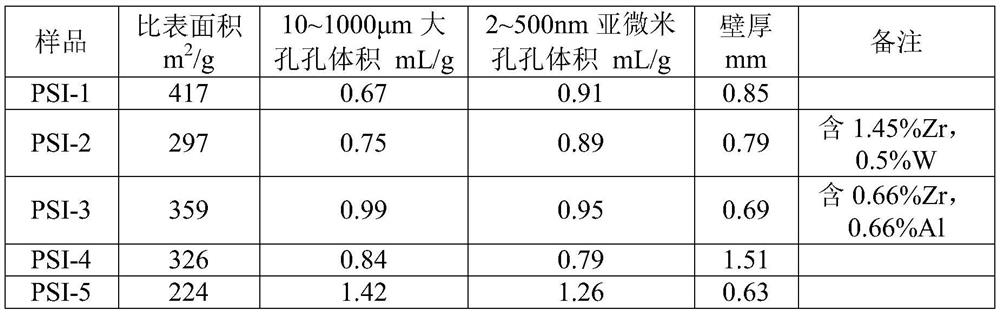

Aldol condensation catalyst, preparation method and method for preparing methyl methacrylate by using aldol condensation catalyst

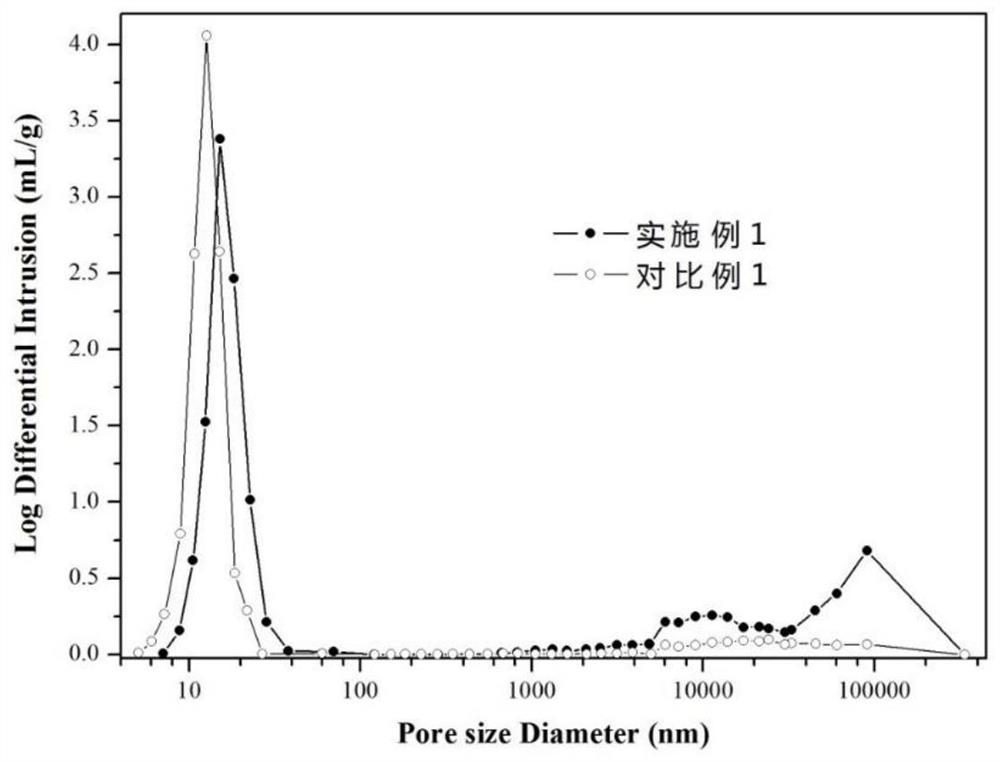

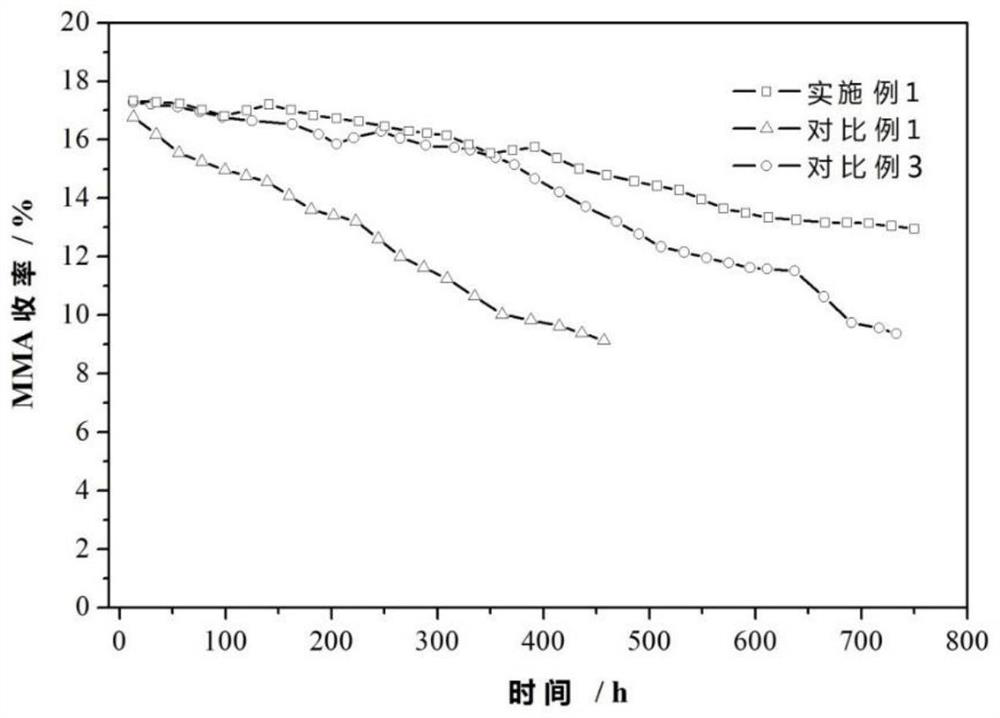

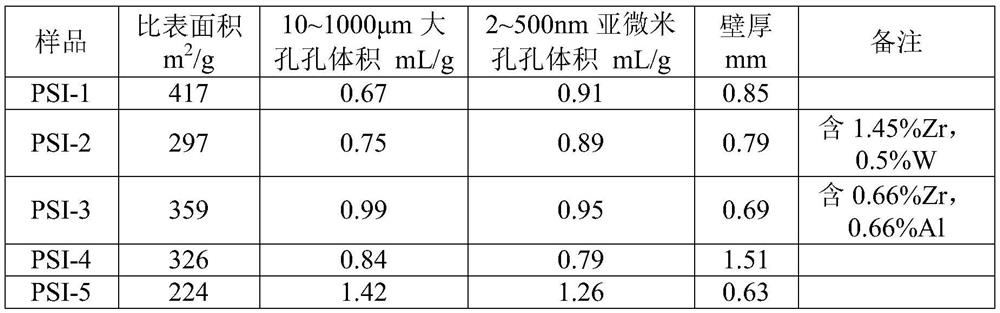

ActiveCN112675830AThin wallNot easy to formOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention provides an aldol condensation catalyst, a preparation method and a method for preparing methyl methacrylate by using the aldol condensation catalyst. The catalyst comprises a modified silicon dioxide carrier and alkali metal elements loaded on the carrier, the modified silicon dioxide carrier is of a foam porous structure and has a first range composed of macropores with the diameter ranging from 10-1000 micrometers and a second range composed of submicron pores with the diameter ranging from 2-500 nanometers; any thickest part of the carrier is less than 1mm; the loading capacity of alkali metal on the catalyst is 4-9wt% (based on alkali metal elements), and the loading capacity of free alkali metal is less than 0.5 wt%; and the total loading capacity of the modifier is 0.5-3wt% (based on modifier elements). The catalyst provided by the invention has excellent water resistance, carbon deposition resistance and long-period activity stability, and is suitable for industrial application of methyl methacrylate prepared by aldol condensation of methyl propionate and formaldehyde.

Owner:WANHUA CHEM GRP CO LTD

A method for simultaneously removing heavy metals-organic compound polluted water bodies using zero-valent iron-persulfate

ActiveCN105110448BLarge specific surface areaSimple preparation processWater contaminantsWater/sewage treatment by reductionPotassium persulfatePersulfate

The invention discloses a method for simultaneously removing heavy metal-organic compound polluted water by using zero-valent iron-persulfate. It is to add bentonite-loaded nanometer zero-valent iron and persulfate to water containing heavy metals and organic matter to form a multi-phase coexistence system to remove heavy metals and organic matter. The present invention utilizes bentonite-loaded nano-zero-valent iron-potassium persulfate combined method to simultaneously remove water containing Cr(VI) and phenol, not only utilizes the strong reducing properties of nano-zero-valent iron to remove heavy metal Cr(VI), but also fully utilizes The Fe2+ generated by nano-zero-valent iron in the reaction process activates potassium persulfate to continuously produce SO4-·oxidative degradation of phenol, and realizes the synergistic removal of heavy metal-organic complex polluted water.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

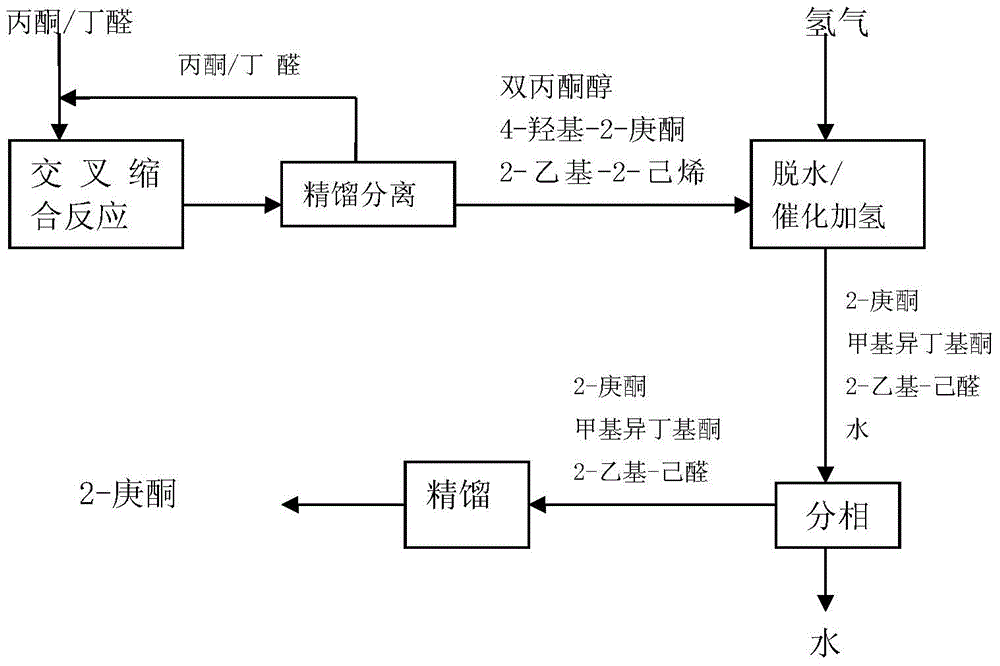

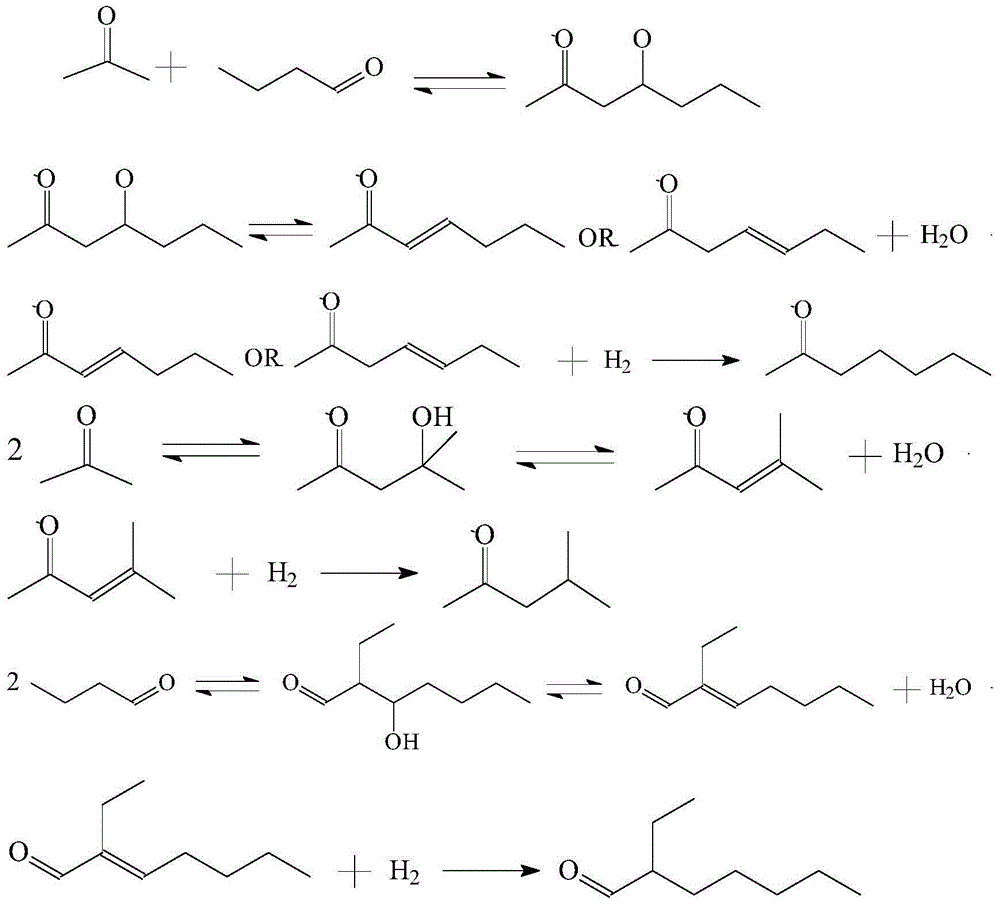

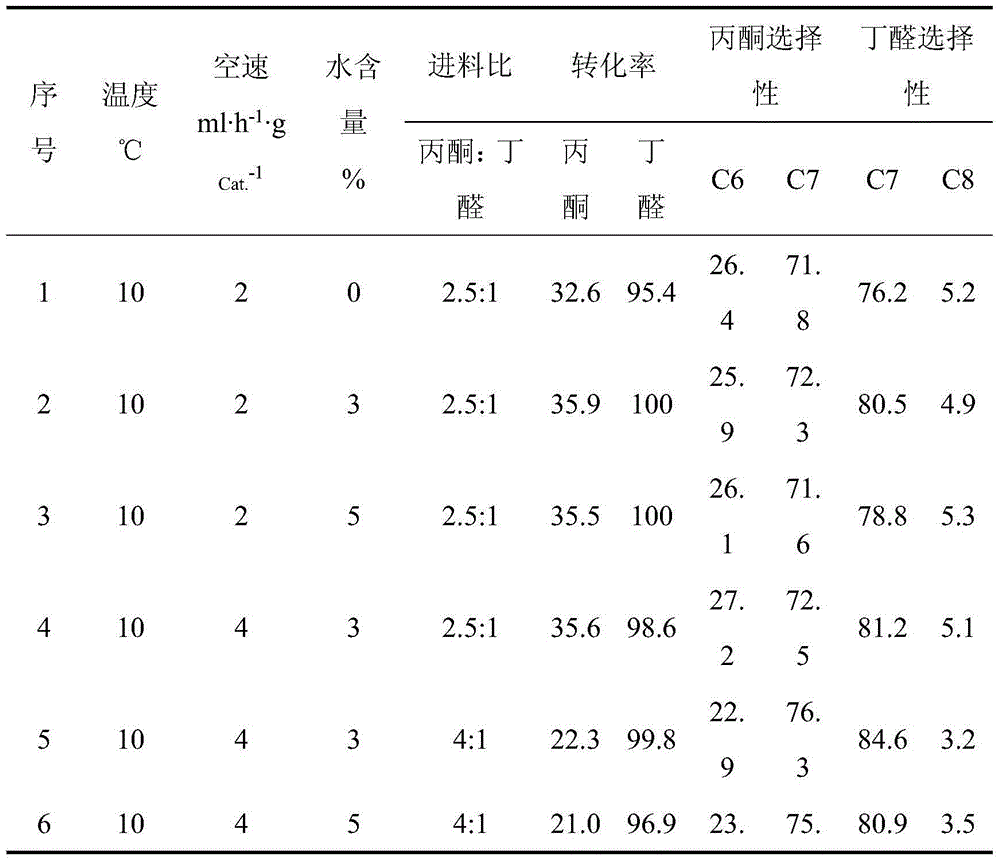

Synthetic method of 2-heptanone

ActiveCN104478683AShort processReduce investmentOrganic compound preparationCarbonyl compound preparation2-HeptanoneSolid base

The invention discloses a chemical synthetic method, specifically a method for synthesizing 2-heptanone by using acetone and butyraldehyde as raw materials. According to the invention, acetone and butyraldehyde which used as raw materials undergo a cross aldol condensation reaction under catalysis of solid base, and reaction products further undergo dehydration and catalytic hydrogenation so as to prepare 2-heptanone. The invention has advantages as follows: technological process is shortened by the technology; generation of an acid-containing waste liquid is avoided; generation of by-products is minimized; investment in equipment is reduced; and production costs of the product are decreased.

Owner:ZHEJIANG XINHUA CHEM

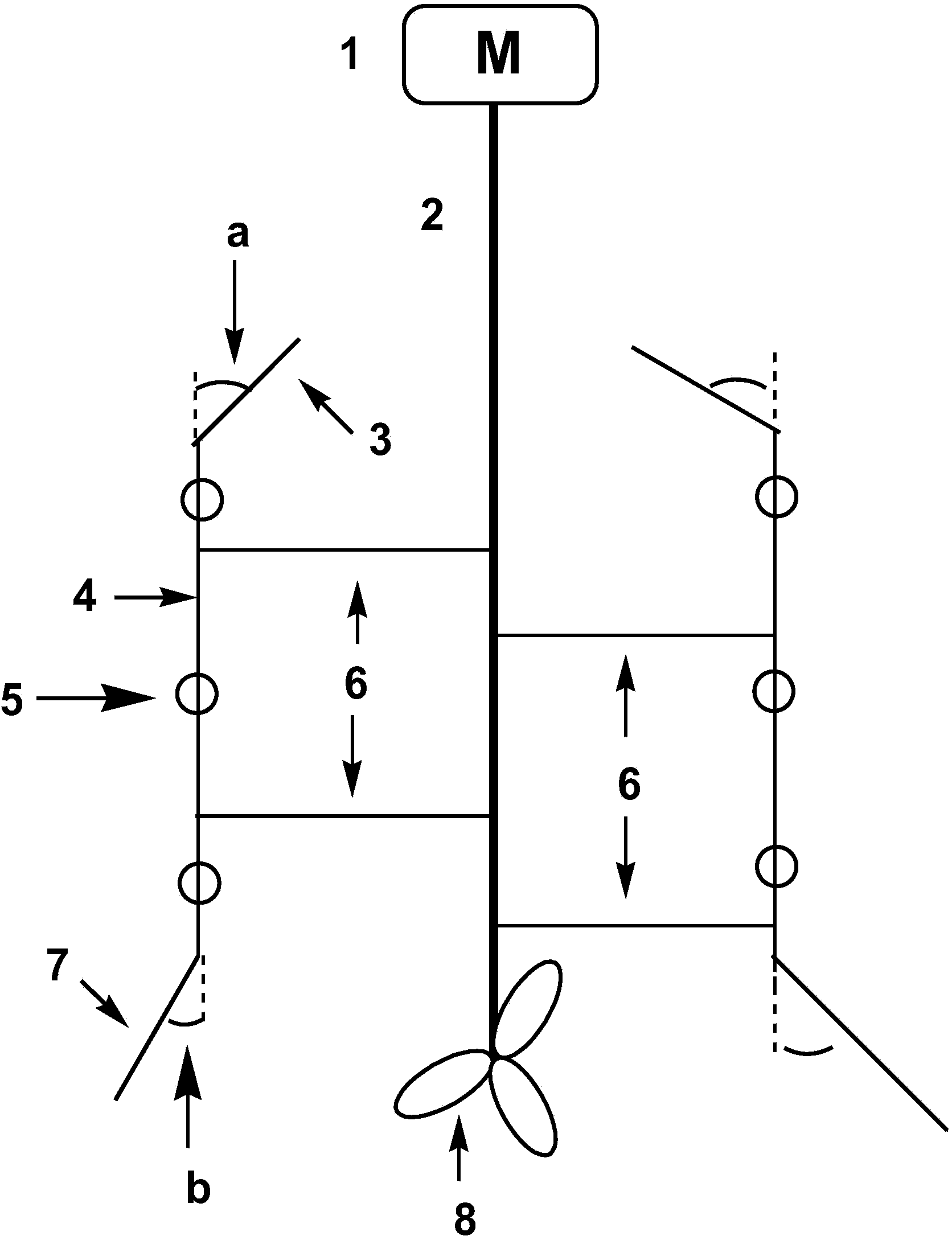

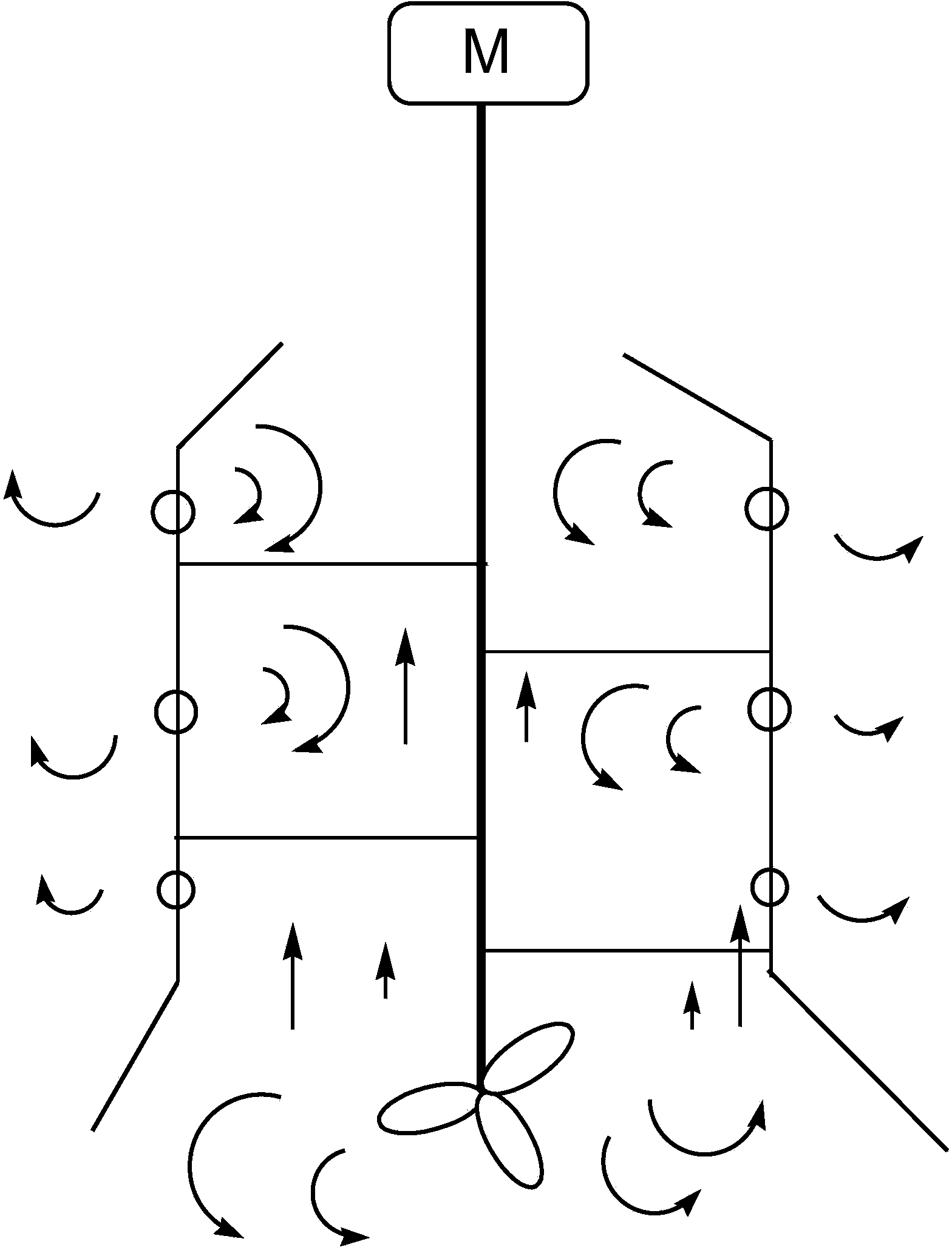

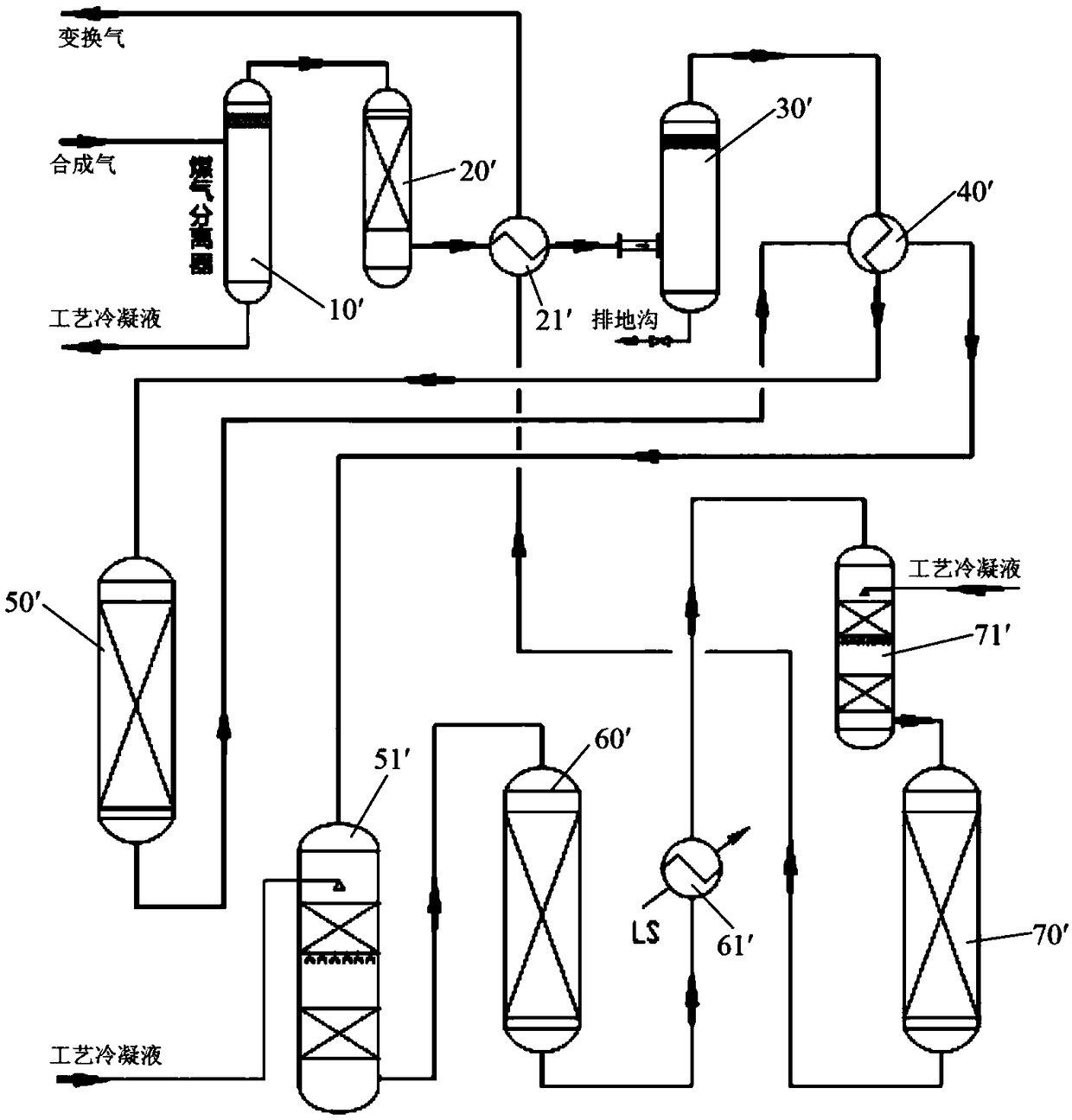

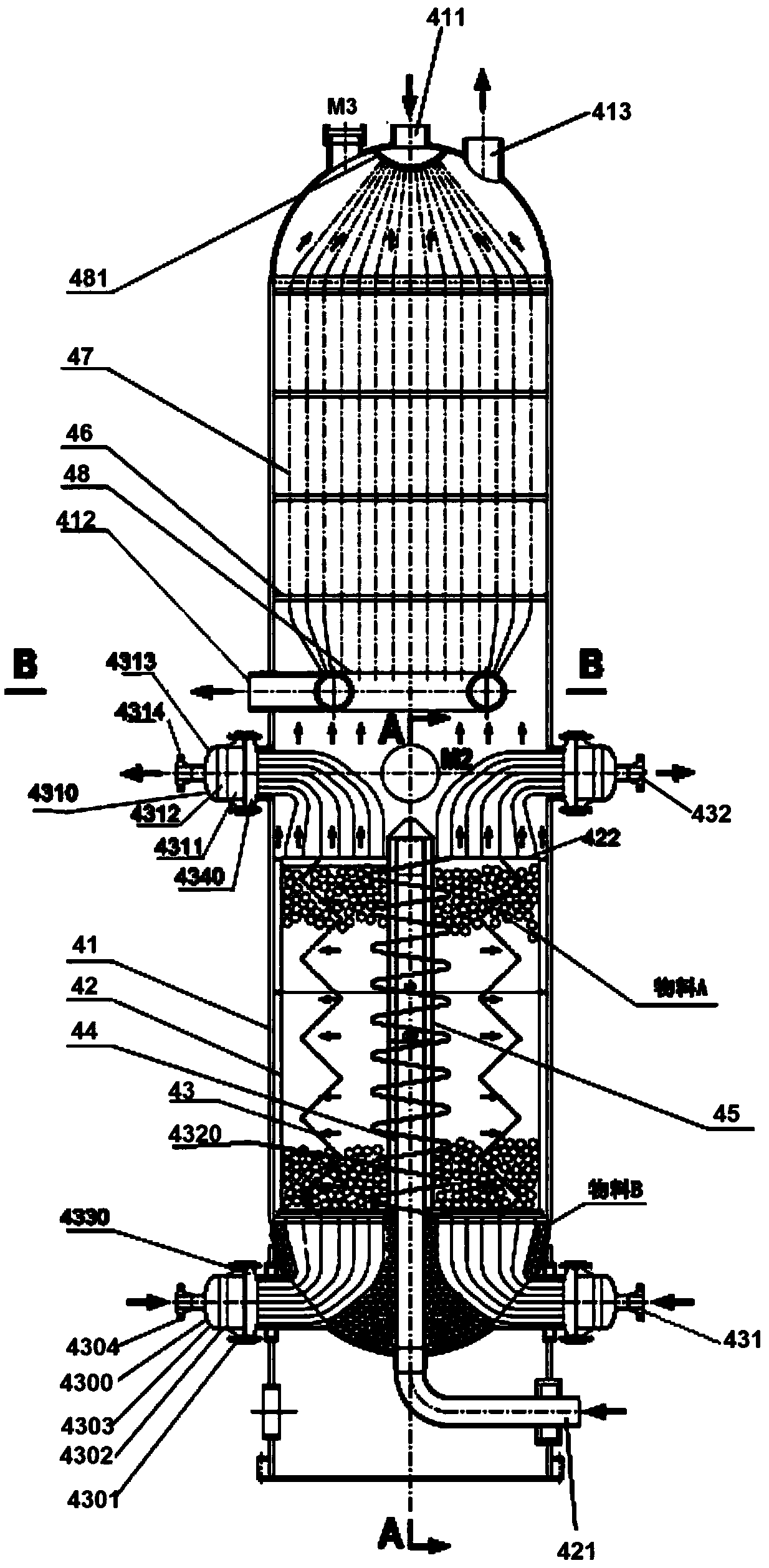

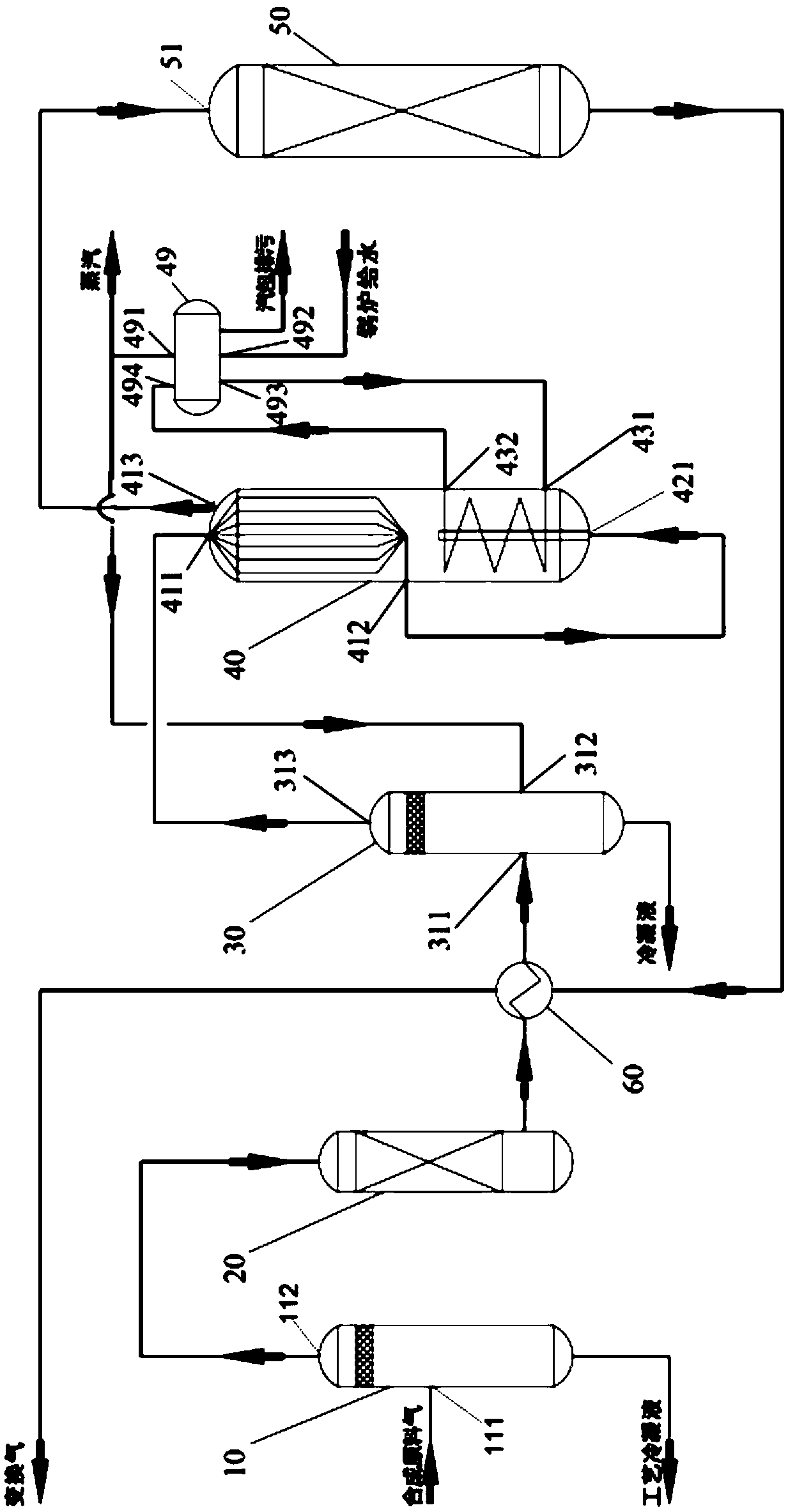

Isothermal conversion device, and syngas complete-conversion reaction system comprising same

ActiveCN109294627AExtended service lifeHigh activityCombustible gas catalytic treatmentSyngasProcess engineering

The invention provides an isothermal conversion device, and a syngas complete-conversion reaction system comprising the same. The isothermal conversion device comprises a shell, a gas collector and atleast one first heat exchange unit, the gas collector is arranged in the shell, the gas collector is provided with a gas-to-be-converted inlet and a converted gas outlet, and is used for performing acomplete-conversion reaction on syngas, and the gas-to-be-converted inlet extends to the external of the shell through a gas-to-be-converted conveying pipeline; and the first heat exchange unit is arranged in the gas collector, and a catalyst is arranged in a space among the gas-to-be-converted conveying pipeline, the first heat exchange unit and the gas collector. The isothermal conversion device can shorten the process route, reduce the resistance of the system and reduce the occupied area of the system when applied to the complete-conversion reaction process of the syngas.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

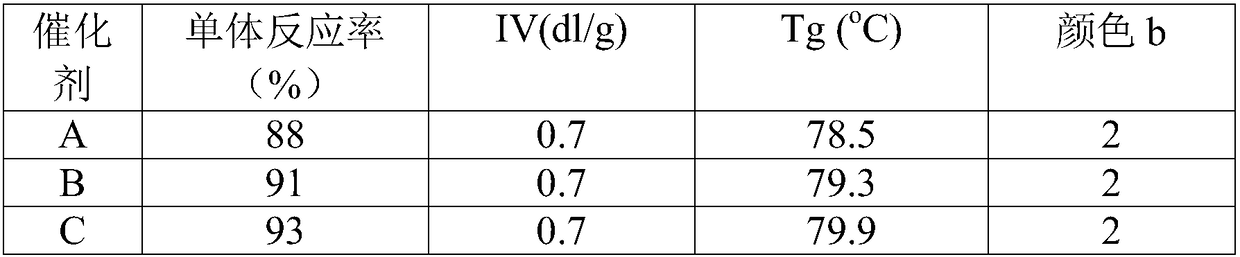

Preparation methods for hydrophobic alcohol metal compound and isosorbide-modified polyester

The invention relates to a preparation method for a hydrophobic alcohol metal compound and application of the same to preparation of isosorbide-modified polyester. According to the invention, a dihydric alcohol mixture of dibasic acid and isosorbide is used as a monomer and the hydrophobic alcohol metal compound is used as a catalyst for preparation of the modified polyester under mild conditions.According to the preparation method for the isosorbide-modified polyester, the used catalyst is low in usage amount and stable in performance, and can effectively reduce esterification time, lower polycondensation temperature, decrease the loss of raw materials and reduce the probability of occurrence of side reactions of a system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

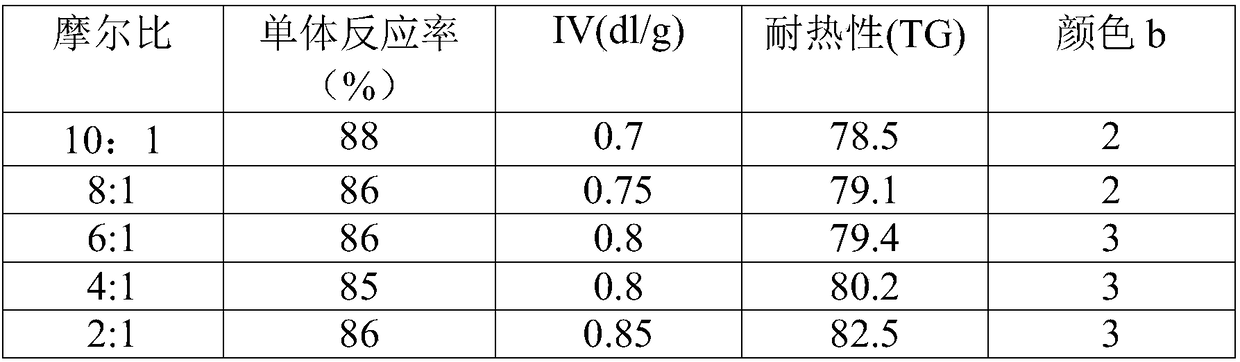

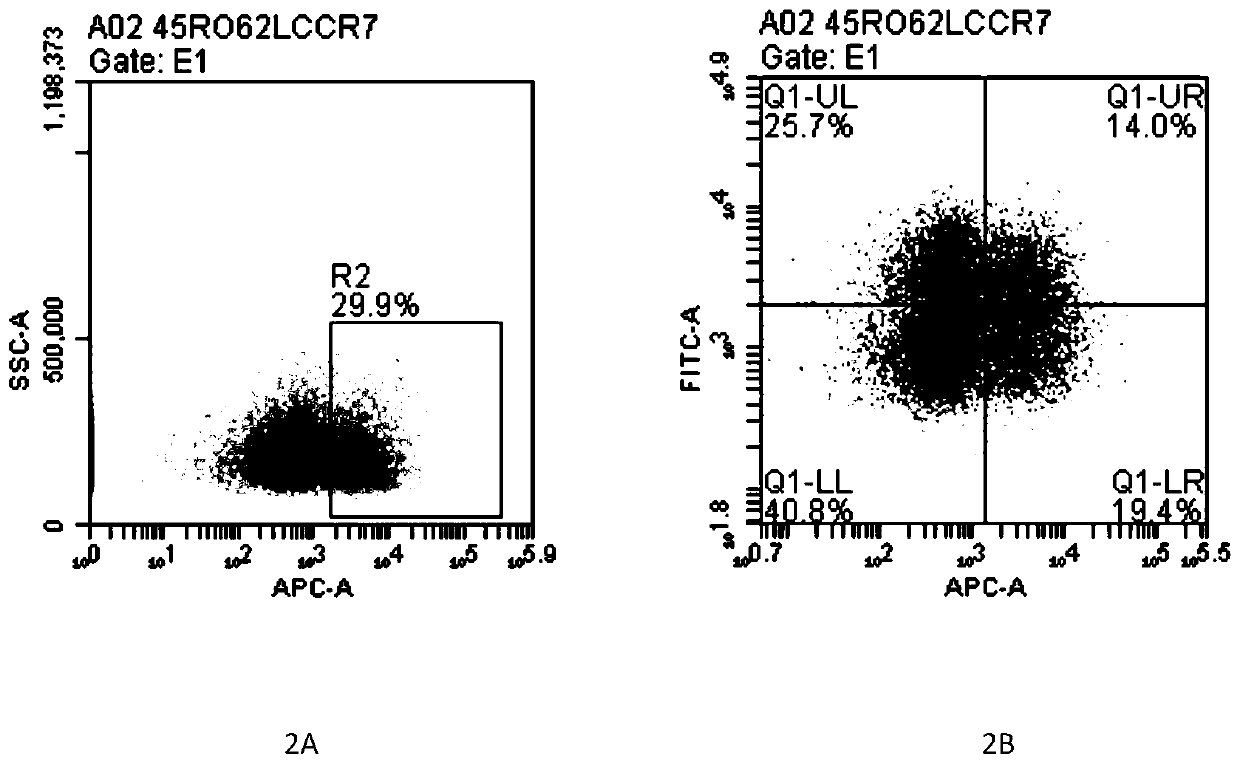

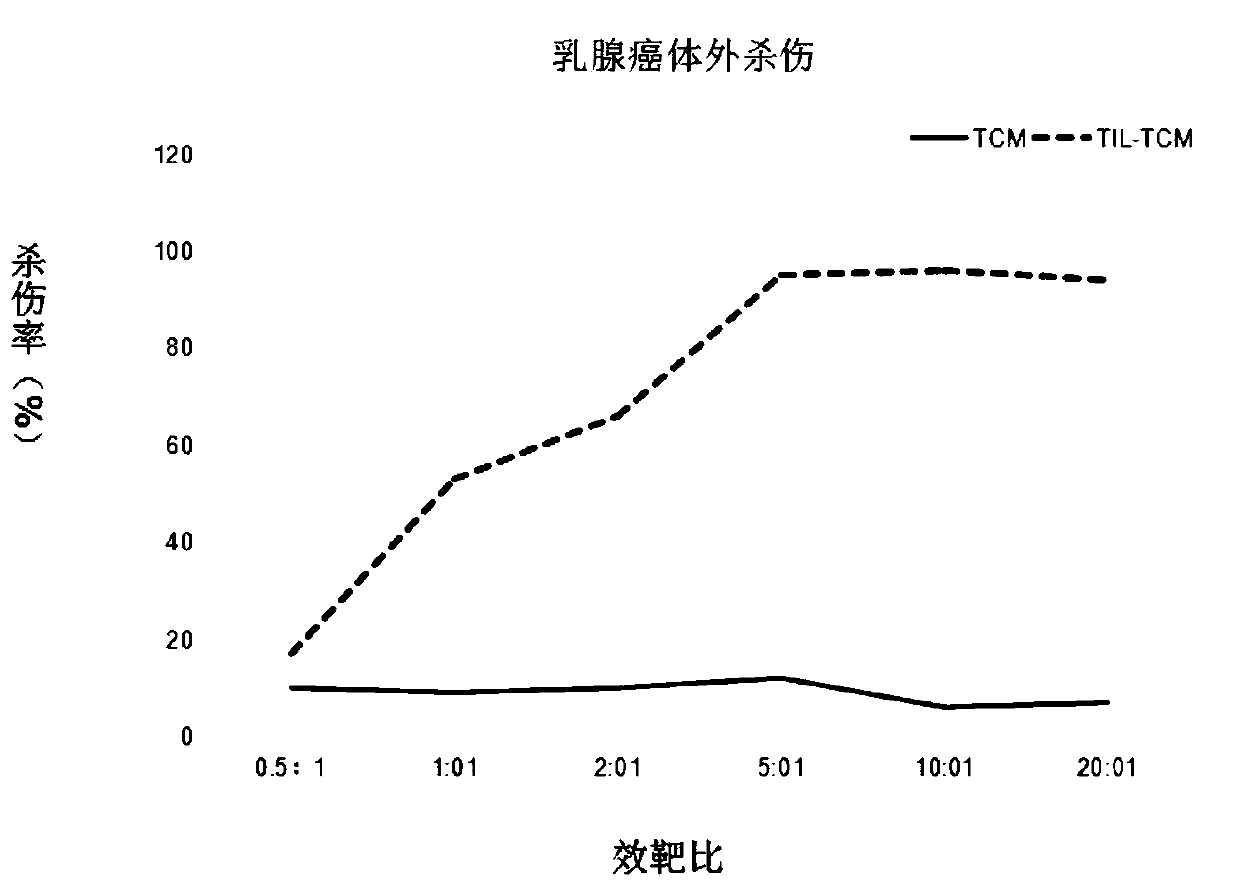

Culture method of wettability T cells

ActiveCN110628717AStrong tumor tropismLong-term anti-tumor effectCulture processBlood/immune system cellsMicrobiologyTumor tropism

The invention relates to a culture method of wettability T cells. The culture method comprises the following steps of (1) preparing and forming effector T cells; (2) using a differentiation culture medium, so that the effector T cells can be subjected to differentiation to TIL-TCM; and (3) amplifying TCM with an amplification culture medium. The cultured TIL-TCM has high tumor tropism, and can home to the position of tumors. Tumor cells can be specifically recognized, and tumors can be specifically killed. The culture method can be adaptive to microenvironment of tumors, can live in bodies fora long time, and can achieve the antitumor effect for a long term. A small quantity of the cells can achieve high antitumor effect, and the cells are short in culture time, low in probability of sideeffects, simple to operate and high in cell proliferation speed.

Owner:SHANGHAI BIOMED UNION BIOTECHNOLOGY CO LTD

Face cream capable of removing spots and preparation method of face cream

InactiveCN108403581AEffective in lightening dark spotsMedicinal effectCosmetic preparationsToilet preparationsSide effectAdditive ingredient

The invention discloses a face cream capable of removing spots and a preparation method of the face cream. The face cream is prepared from the following raw materials in parts by weight: 3-6 parts ofcetanol, 2-4 parts of glycerin monostearate, 1-3 parts of sodium alginate, 4-8 parts of glycerinum, 2-5 parts of polysorbate, 2-5 parts of propanediol, 1-3 parts of triethanolamine, 3-6 parts of composite Chinese herbal medicinal ingredient and 65-85 parts of deionized water. The pH value of the face cream is 7.5-8.0. The composite Chinese herbal medicinal ingredient has the advantages of synergistic interaction, good permeability, easiness in absorption and the like. Metabolism of melanin is accelerated while melanin formation in skin cells is inhibited effectively, and therefore, the spots can rapidly face away or disappear; and the face cream is gentle in effect, is good in spot removing effect, and does not have toxic or side effects.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

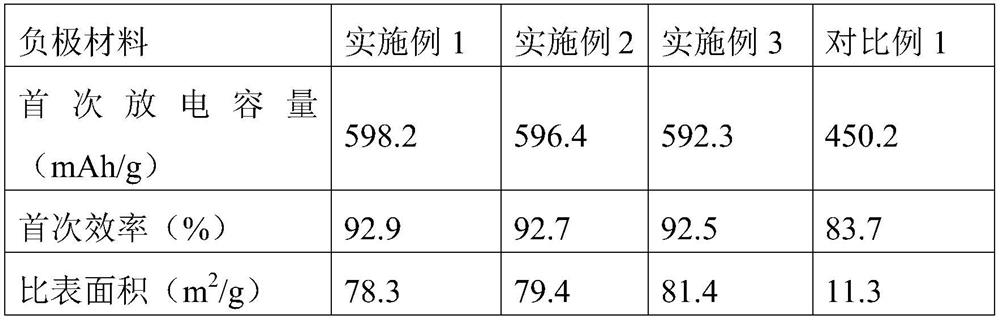

A kind of nitrogen-doped silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN110571426BIncrease gram capacityImprove cycle performanceMaterial nanotechnologySecondary cellsCarbon compositesElectrolytic agent

Owner:石家庄尚太科技股份有限公司 +1

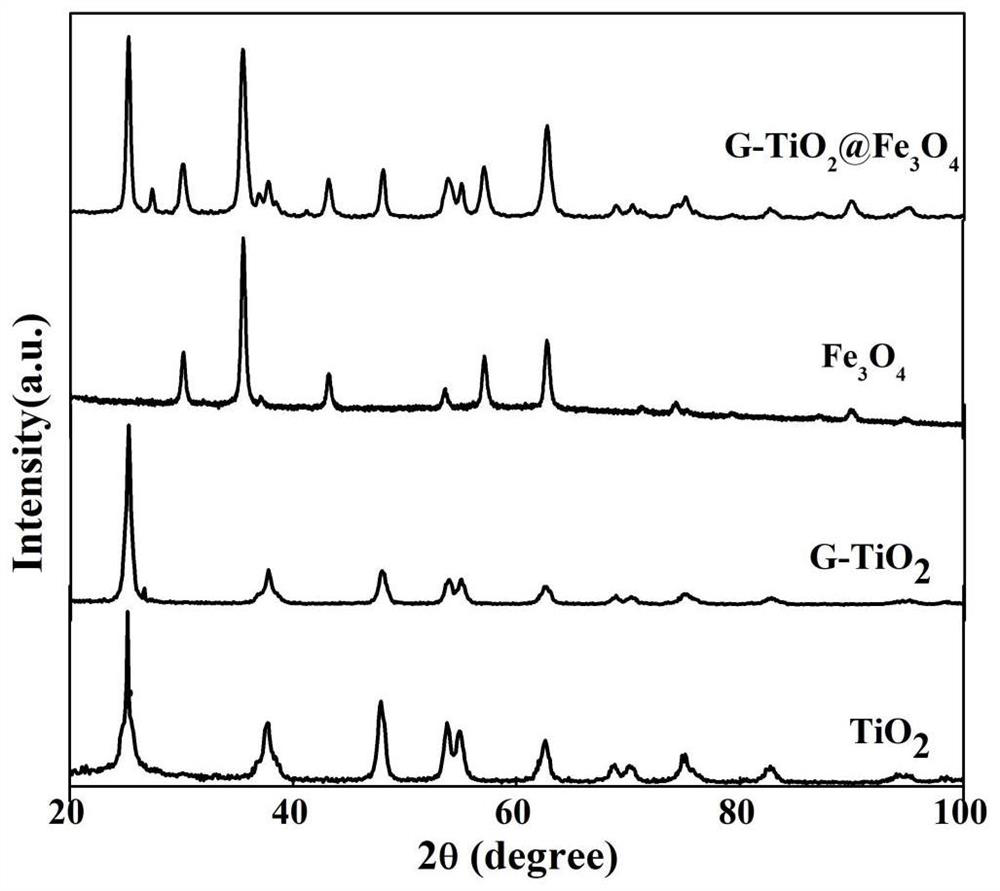

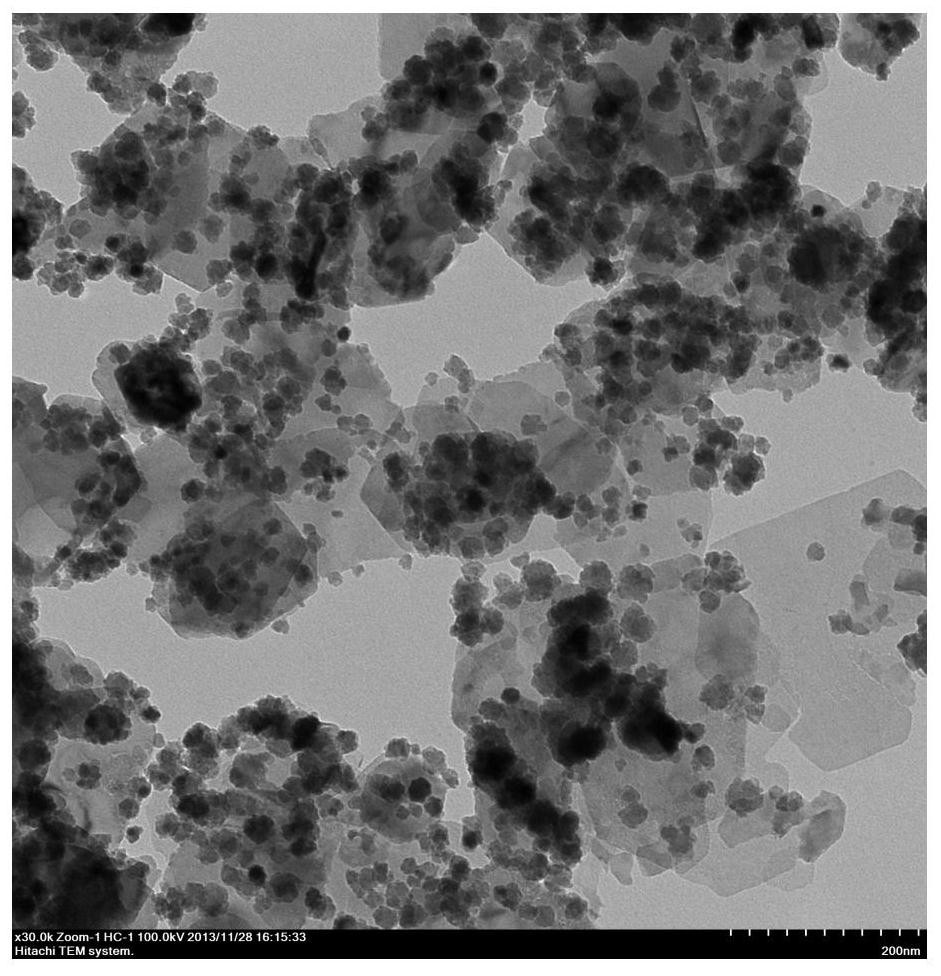

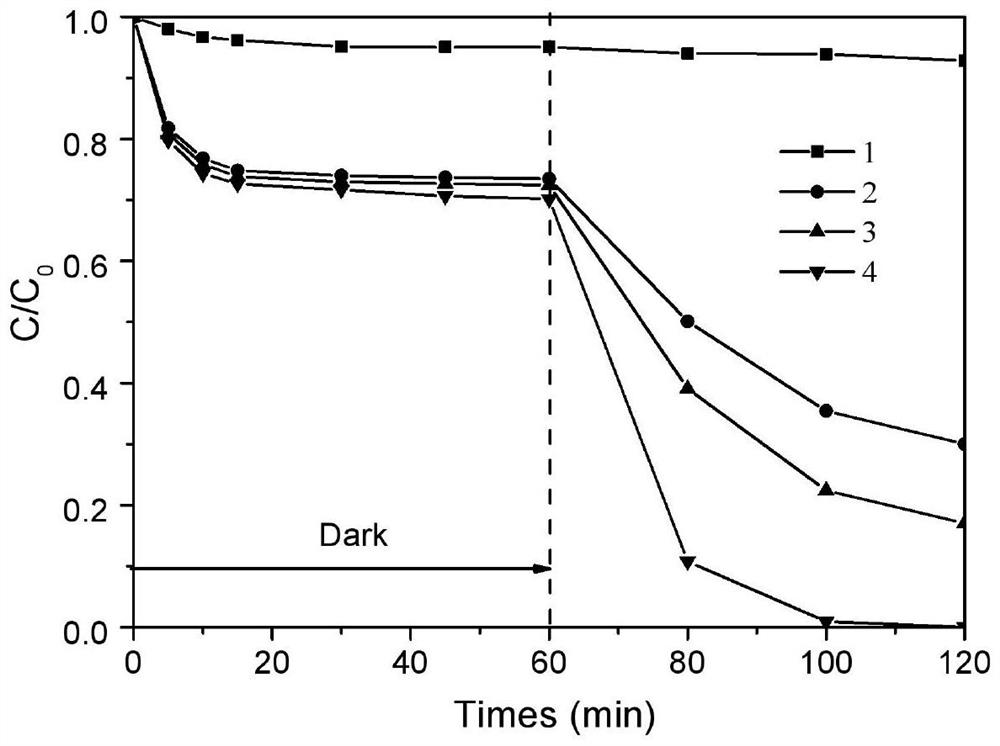

Preparation method of composite photocatalyst, composite photocatalyst and degradation method of dye wastewater

InactiveCN112892536AConductiveIncrease profitWater/sewage treatment by irradiationWater treatment compoundsAlizarinPersulfate

The invention provides a preparation method of a composite photocatalyst, the composite photocatalyst and a degradation method of dye wastewater, and belongs to the field of water pollution treatment. The preparation method of the composite photocatalyst comprises the following steps: mixing butyl titanate, hydrochloric acid and graphite in an ethanol solution, carrying out ultrasonic treatment to obtain gel, drying the gel, grinding into powder, and calcining to obtain graphite-TiO2; and then dispersing the graphite-TiO2 nanoparticles in a mixed solution containing Fe3O4, adding NaOH and polyethylene glycol, and carrying out a reaction to obtain the composite photocatalyst graphite-TiO2@Fe3O4. The composite photocatalyst is high in catalytic activity and high in recovery rate. The composite photocatalyst graphite-TiO2@Fe3O4 and persulfate are synergistically applied to degradation of dye wastewater, and by means of the method, the degradation rate of azo dyes such as alizarin red which are difficult to degrade can reach 90% or above.

Owner:YANSHAN UNIV

Porcine circovirus, porcine pseudorabies virus and mycoplasma triple inactivated vaccine

PendingCN112957460AReduce the chance of side effectsHigh antigen contentAntibacterial agentsBacterial antigen ingredientsUltrafiltrationVirus Protein

The invention discloses a porcine circovirus, porcine pseudorabies virus and mycoplasma triple inactivated vaccine which comprises an antigen and a vaccine adjuvant, the antigen is composed of a porcine circovirus type 2 antigen, a porcine pseudorabies virus antigen and a mycoplasma antigen, the porcine circovirus type 2 antigen is a purified, concentrated and inactivated porcine circovirus type 2 protein antigen solution, and the content of Cap protein is more than or equal to 160 [mu]g / ml; the porcine pseudorabies virus antigen is a purified, concentrated and inactivated porcine pseudorabies virus protein antigen solution, and the content of the Cap protein is more than or equal to 160 [mu]g / ml; the mycoplasma antigen is an inactivated mycoplasma protein antigen solution, and the content of the Cap protein is more than or equal to 160 [mu]g / ml; and the vaccine adjuvant is composed of a water-based high-molecular polymer adjuvant and a composite polysaccharide immunopotentiator. Foreign protein is removed through clarification filtration and ultrafiltration concentration, and the side reaction probability of the vaccine is greatly reduced; and three-proofing can be achieved through one needle, so that the number of immunization times and stress are reduced. The method is economical and practical, the immunization procedure is simplified, and the epidemic prevention cost is reduced.

Owner:JIANGXI ZHENGBANG TECHNOLOGY CO LTD +1

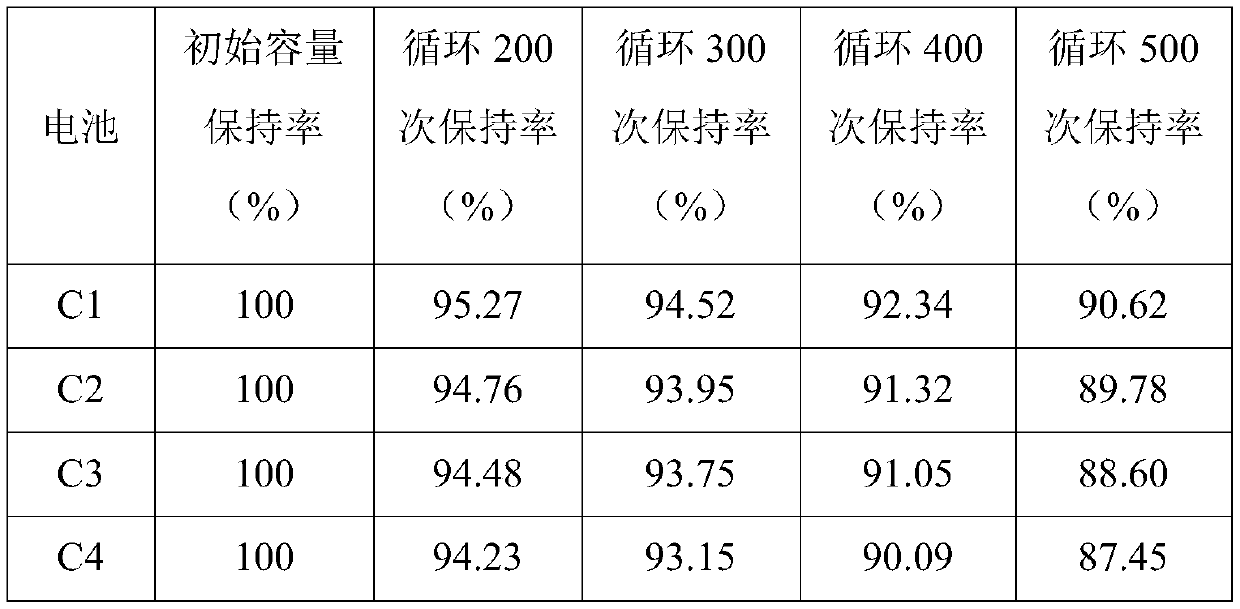

A kind of lithium-ion battery negative electrode material and preparation method thereof, lithium-ion battery

ActiveCN106299314BReduce the chance of side effectsIncrease speedNegative electrodesSecondary cells servicing/maintenanceSolventCarbon nanotube

Owner:JIAOZUO JUNENG ENERGY TECH

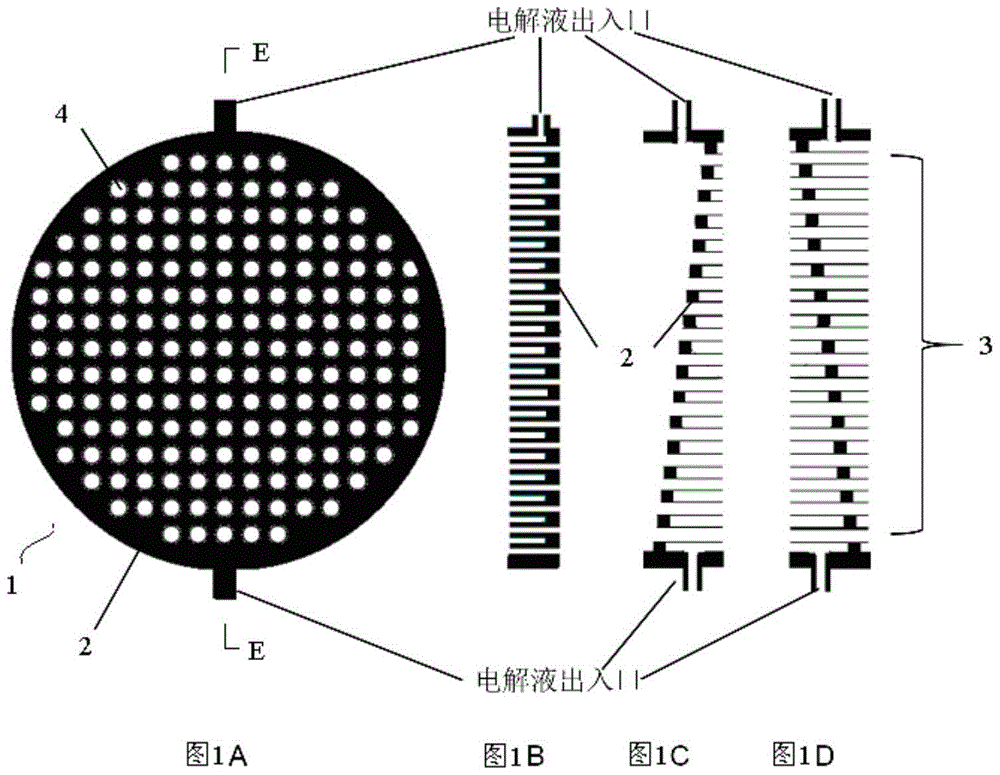

biomimetic electrochemical cell

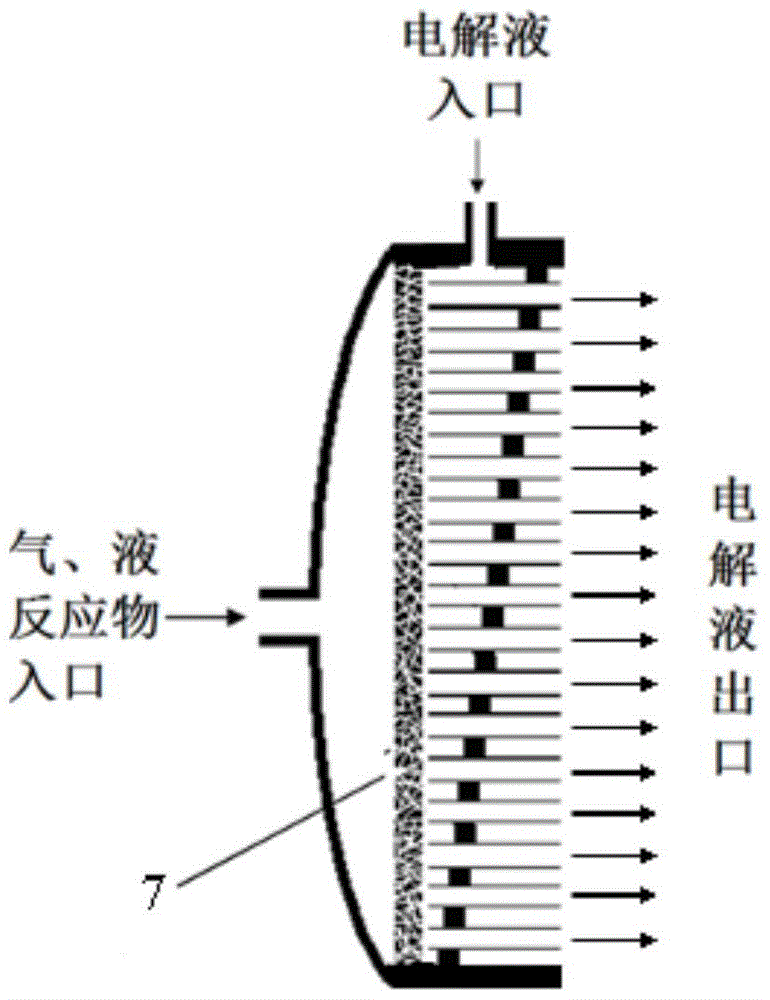

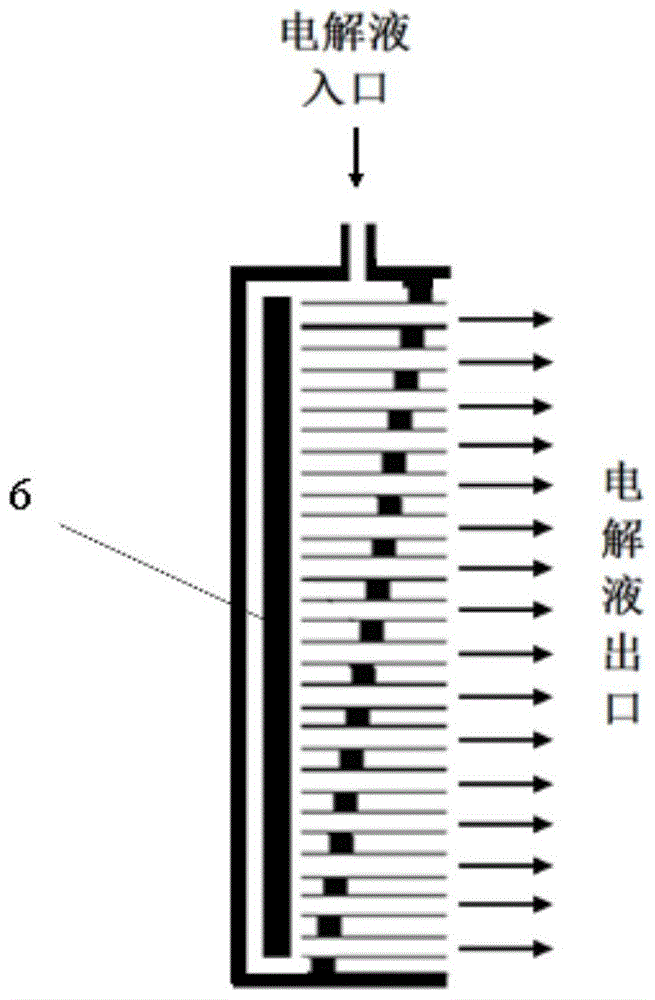

InactiveCN104701563BQuick joinFacilitated DiffusionBiochemical fuel cellsFuel cell detailsElectrochemical responseEngineering

The invention discloses a bionic electrochemical cell. The bionic electrochemical cell comprises two chambers, an anode, a cathode, a flow guide plate, and a pump for pushing electrolyte to flow directionally, wherein electrochemical reaction is generated in the chambers; the anode and the cathode are counter electrodes and are arranged in the two chambers. According to the requirement, each chamber also can be connected with a separator capable of separating products or impurities, and the two chambers are separated away by the flow guide plate which is composed of a flow limiting plate and a pipeline array. The bionic electrochemical cell has the functions that the electrolyte on the surface of an electrode can directionally flow from one electrode zone to the counter electrode zone without backmixing at the equal or similar speed under the pushing by the pump and the restriction of the flow guide plate, and finally flows out from an outlet. The bionic electrochemical cell has the beneficial effects the mass transfer process of substances between electrodes can be accelerated, so that the electrochemical reaction speed can be increased; reactants can be added at proper places, and the products also can be separated timely, so that the interference to the reaction by the products or the consumption of the electrodes can be inhibited, and the probability of side reaction can be reduced greatly.

Owner:SOUTHEAST UNIV

Aldol condensation catalyst, preparation method and method for preparing methyl methacrylate with it

ActiveCN112675830BThin wallNot easy to formOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention provides an aldol condensation catalyst, a preparation method and a method for preparing methyl methacrylate with it. The catalyst of the present invention includes a modified silica carrier and an alkali metal element loaded on the carrier, wherein the modified silica carrier is a foam porous structure, which has the first macropores with a diameter of 10-1000 μm. The first range, and the second range composed of submicron pores of 2nm to 500nm; the thickest part of any part of the support is <1mm; the alkali metal loading on the catalyst is 4 to 9wt% (calculated as alkali metal elements), and the free alkali metal loading The amount is <0.5wt%; the total loading amount of the modifier is 0.5-3wt% (calculated as the modifier element). The catalyst provided by the invention has excellent water resistance, carbon deposition resistance and long-term activity stability, and is suitable for the industrial application of methyl methacrylate prepared by aldol condensation of methyl propionate and formaldehyde.

Owner:WANHUA CHEM GRP CO LTD

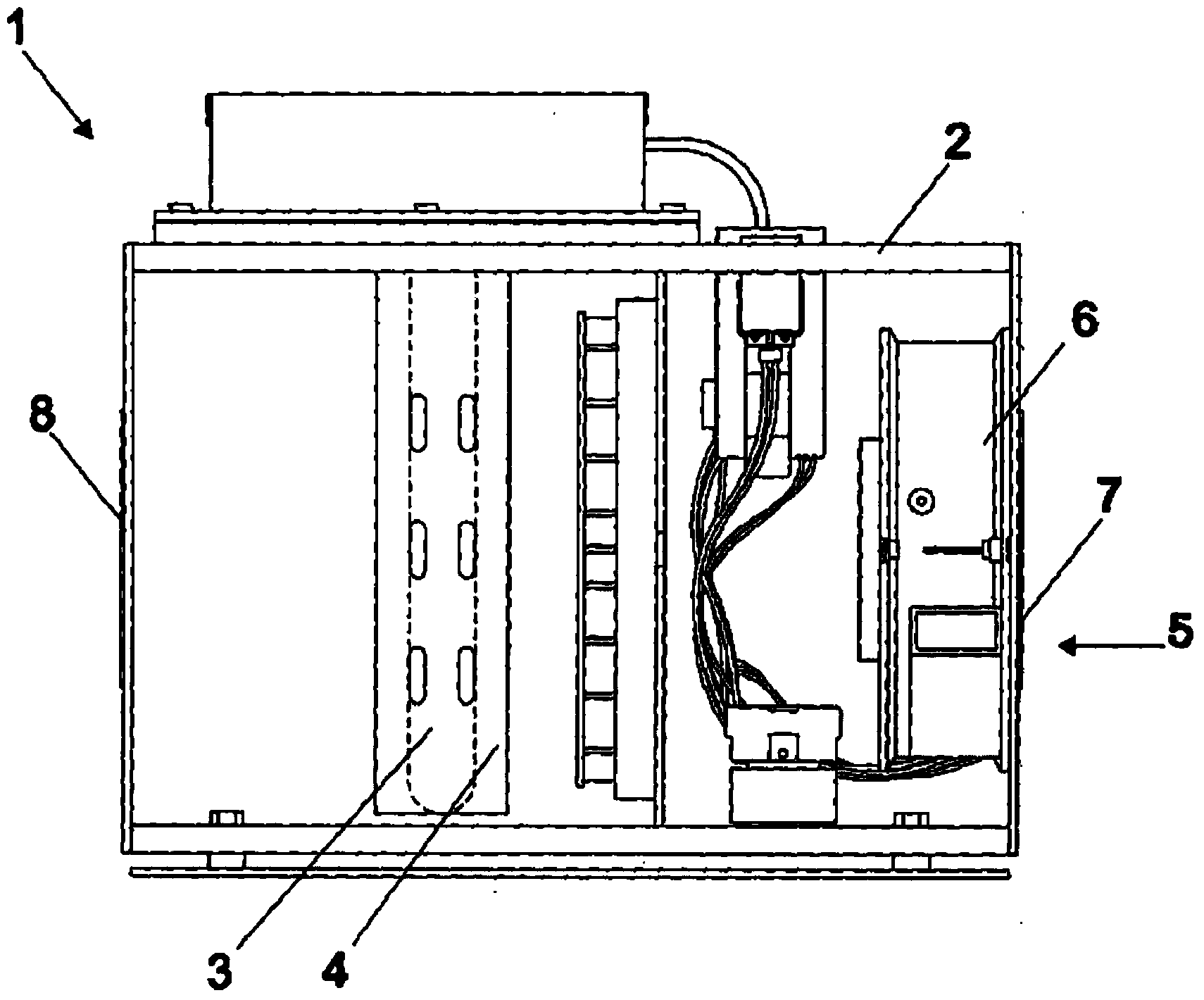

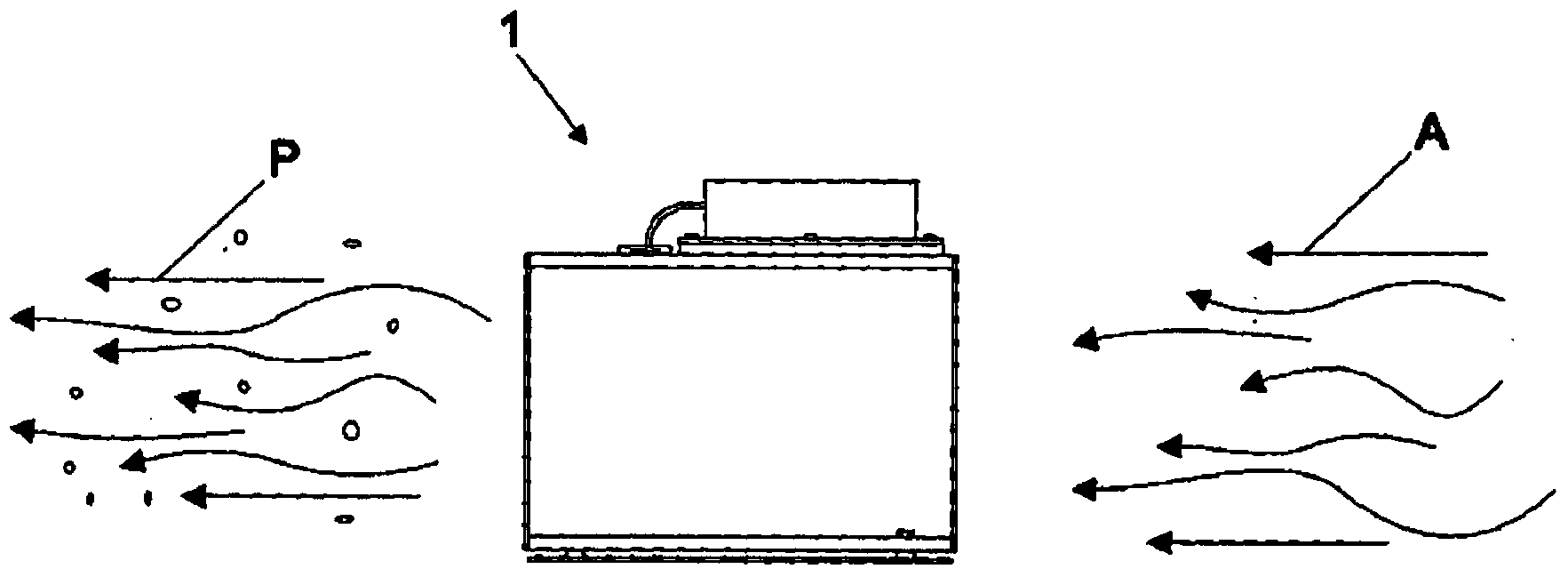

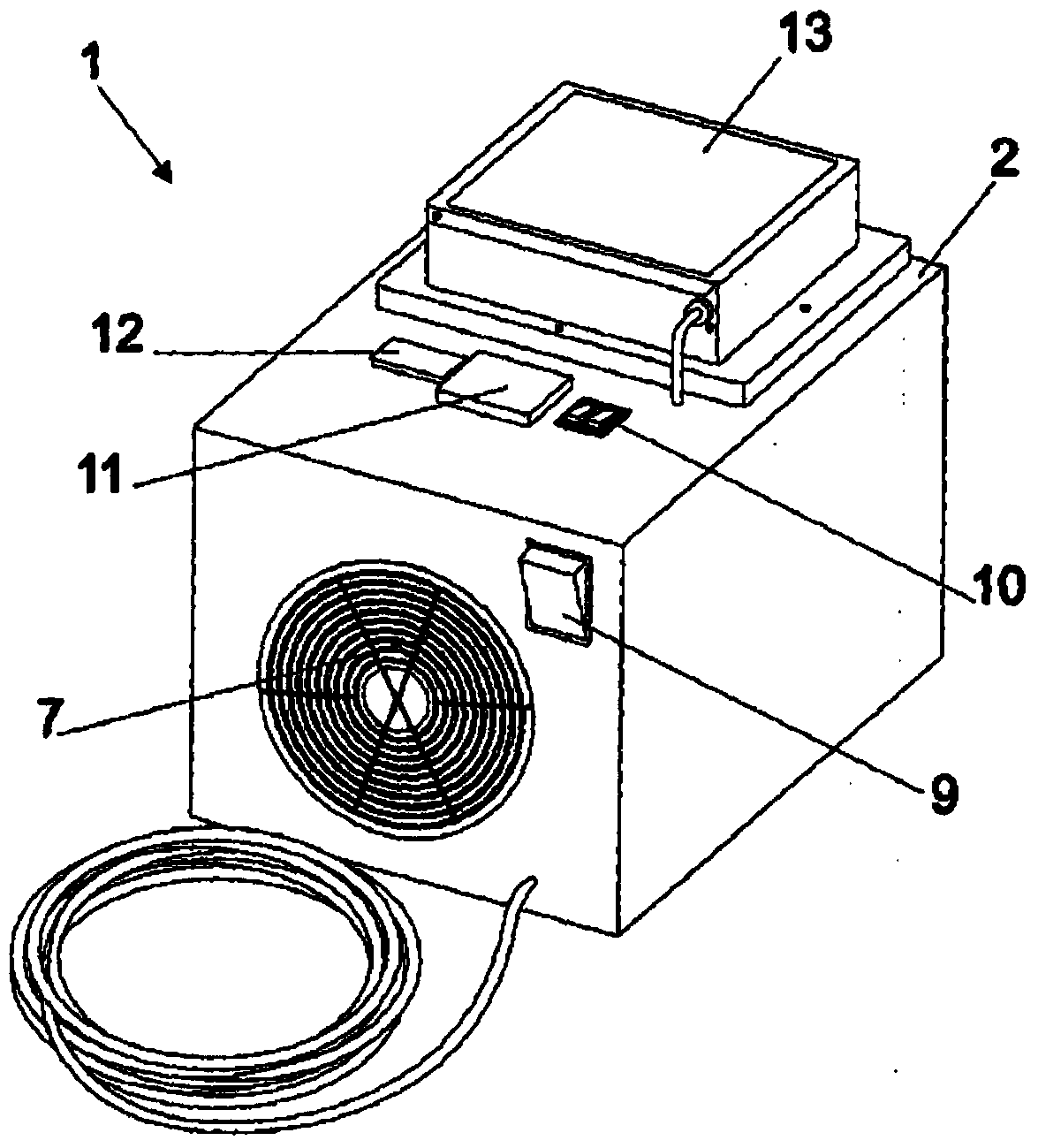

Device for sanitizing the air-conditioning system of vehicles using radiant catalytic ionization

InactiveCN104169654AReduce the chance of side effectsEliminate odorMechanical apparatusAir-treating devicesMetal alloyEngineering

The "DEVICE FOR SANITIZING THE AIR-CONDITIONING SYSTEM OF VEHICLES USING RADIANT CATALYTIC IONIZATION" relates to a device (1) mounted on a casing (2) that includes a UVX lamp (3) surrounded by a metal alloy (4) that converts the air / oxygen (A) into a purifying plasma (P) comprising hydroxyl radicals and hydrogen peroxide.

Owner:巴西生态研发-空气和水净化的进出口贸易和服务有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com