Preparation method of composite photocatalyst, composite photocatalyst and degradation method of dye wastewater

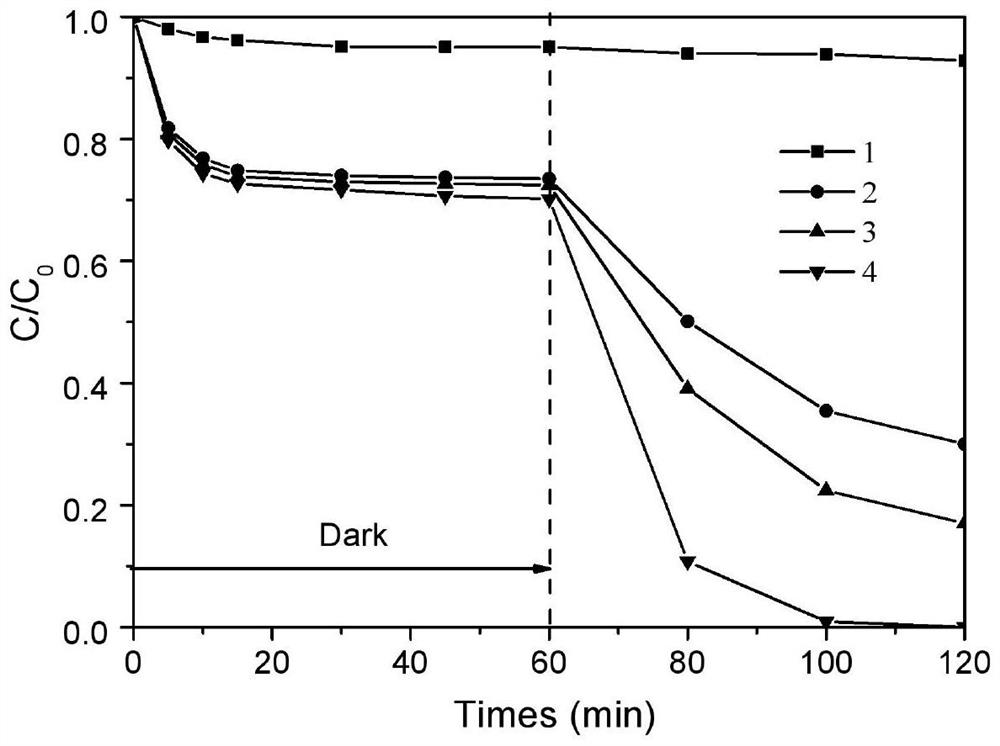

A dye wastewater and catalyst technology, applied in the field of water pollution control, can solve the problems of long degradation time, difficulty in solution storage, and low utilization rate, and achieve the effects of avoiding secondary pollution, improving photocatalytic reaction rate, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

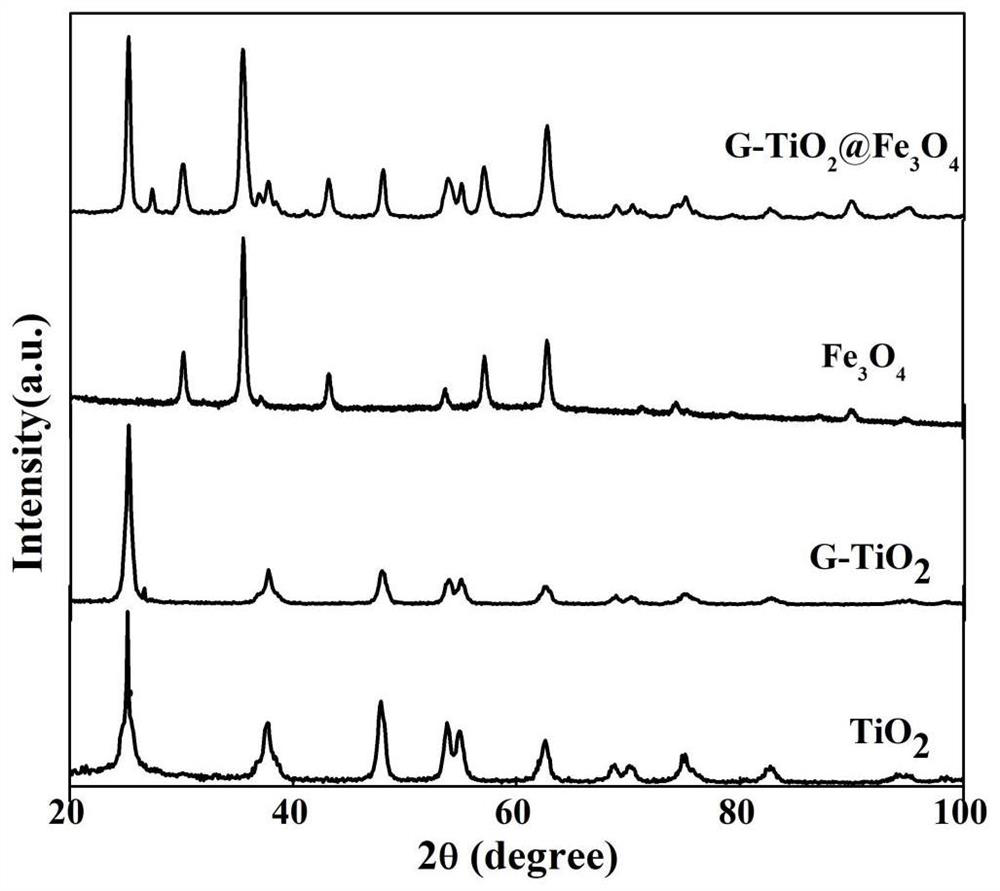

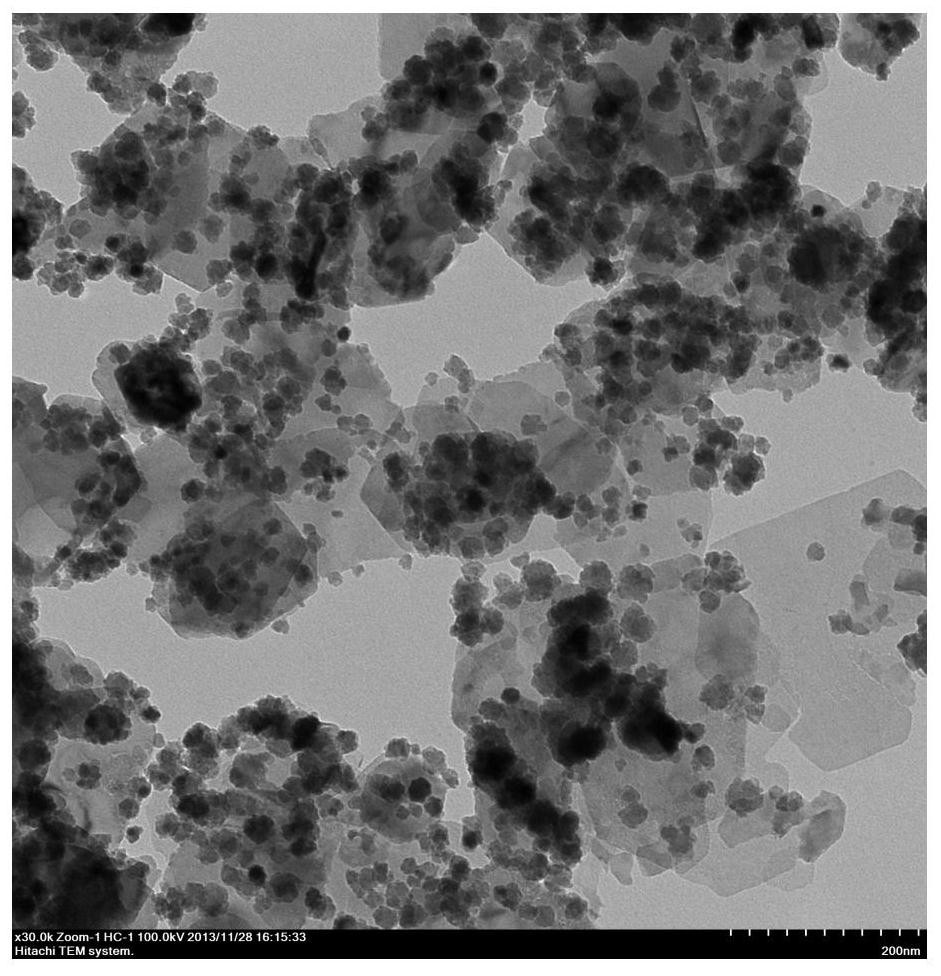

[0036] This embodiment provides a composite photocatalyst graphite-TiO 2 @Fe 3 o 4 , its preparation method is as follows:

[0037] (1) Pipette 6ml of butyl titanate and 0.6ml of 2mol / L hydrochloric acid into 40ml of absolute ethanol, and stir magnetically for 2 minutes. Take 0.012g of graphite, place it in 4ml of ethanol and sonicate for 1 minute, pour it into the above solution, and sonicate for 3-5 minutes. Finally, 3 ml of deionized water was added and stirred at a constant speed on a magnetic stirrer until it turned into a sol, and then turned into a gel by ultrasonication. After drying at room temperature and grinding, the ground powder was finally placed in a muffle furnace and calcined at 450 °C for 3 hours to obtain graphite-TiO 2 Spherical nanoparticles (G-TiO 2 ).

[0038] (2) in N 2 Under the protection of 7.125g FeSO 4 ·7H 2 O and 3.525g Fe 2 (SO 4 ) 3 respectively dissolved in 75ml deionized water, heated in a water bath at 60°C under magnetic stirrin...

Embodiment 2

[0043] This embodiment provides a composite photocatalyst graphite-TiO 2 @Fe 3 o 4 , its preparation method is as follows:

[0044] (1) Pipette 12ml of butyl titanate and 1.2ml of 2mol / L hydrochloric acid into 80ml of absolute ethanol, and stir magnetically for 2 minutes. Take 0.024g of graphite and place it in 4ml of ethanol for 1 minute, pour it into the above solution, and sonicate for 3-5 minutes. Finally, 6 ml of deionized water was added and stirred at a constant speed on a magnetic stirrer until it turned into a sol, and then turned into a gel by ultrasonication. After drying at room temperature and grinding, the ground powder was finally placed in a muffle furnace and calcined at 450 °C for 3 hours to obtain graphite-TiO 2 Spherical nanoparticles (i.e. G-TiO 2 ).

[0045] (2) in N 2 Under the protection of 9.5g FeSO 4 ·7H 2 O and 4.75g Fe 2 (SO 4 ) 3 respectively dissolved in 100ml deionized water, and heated in a water bath at 60°C under magnetic stirring,...

Embodiment 3

[0047] This embodiment provides a composite photocatalyst graphite-TiO 2 @Fe 3 o 4 , its preparation method is as follows:

[0048] (1) Pipette 12ml of butyl titanate and 1.2ml of 2mol / L hydrochloric acid into 80ml of absolute ethanol, and stir magnetically for 2 minutes. Take 0.024g of graphite and place it in 4ml of ethanol for 1 minute, pour it into the above solution, and sonicate for 3 minutes. Finally, 6 ml of deionized water was added and stirred at a constant speed on a magnetic stirrer until it turned into a sol, and then turned into a gel by ultrasonication. After drying at room temperature and grinding, the ground powder was finally placed in a muffle furnace and calcined at 500 °C for 2 hours to obtain graphite-TiO 2 Spherical nanoparticles (i.e. G-TiO 2 ).

[0049] (2) in N 2 Under the protection of 9.5g FeSO 4 ·7H 2 O and 4.75gFe 2 (SO 4 ) 3 respectively dissolved in 100ml deionized water, and heated in a water bath at 65°C under magnetic stirring, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com