Preparation method of high-functionality polyether polyol

A polyether polyol, high-functionality technology, applied in the field of polyether polyol synthesis, can solve the problems of reaction uniformity, difficulty in initiation of initiator, non-uniform growth, etc. The result is a good effect and the effect of reducing the unsaturation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

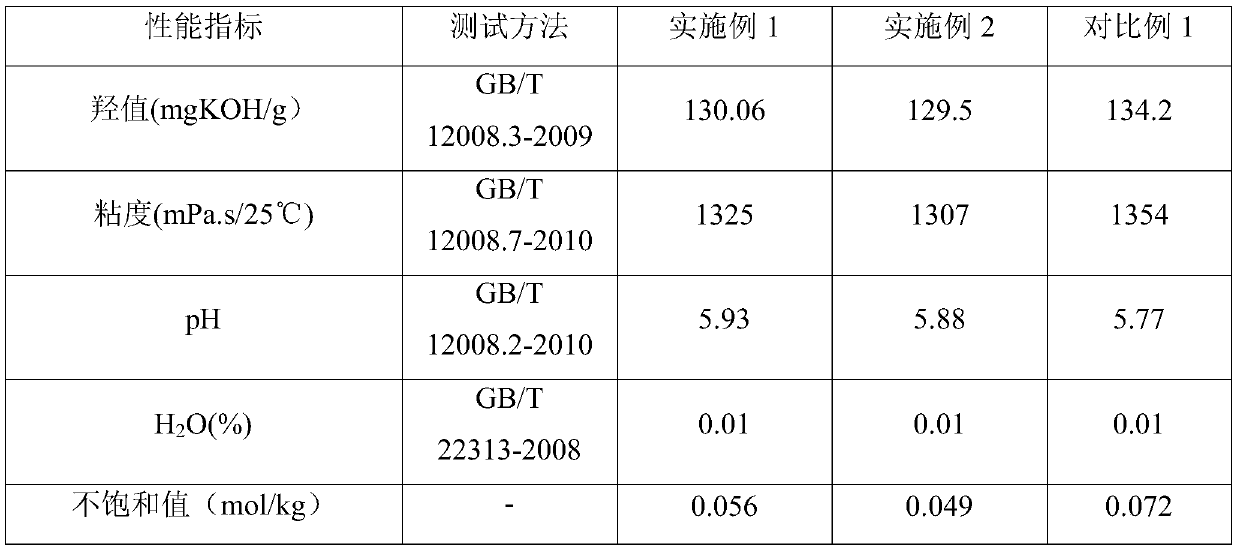

Examples

Embodiment 1

[0026] Add 1,140 parts of liquid sorbitol, 240 parts of glycerin, and 18 parts of potassium hydroxide to a 5L stainless steel reactor, add 2,200 parts of propylene oxide to the storage tank, and the temperature is ≤40°C; start stirring the reactor, and replace it with nitrogen 2-3 times. Vacuumize, heat up to 110°C, and bubble nitrogen for 4 hours; add 2,200 parts of propylene oxide through the storage tank, the initiation time is about 5 hours, and the subsequent addition is completed in about 10 hours. The pressure is controlled at 0.1-0.4 MPa, the temperature is 110-115 Reaction 2h, obtain oligomer polyether polyol;

[0027] Add 190 parts of liquid sorbitol, 40 parts of glycerin, 215 parts of oligomer polyether polyols, and 4.5 parts of potassium hydroxide into a 5L stainless steel reactor, and add 3100 parts of propylene oxide into the storage tank at a temperature of ≤40°C; Start stirring, replace with nitrogen 2-3 times, vacuumize, raise the temperature to 110°C, and bub...

Embodiment 2

[0029] Add 570 parts of liquid sorbitol, 120 parts of glycerin, and 9 parts of potassium hydroxide into a 5L stainless steel reaction kettle, add 2200 parts of propylene oxide into the storage tank, and the temperature is ≤40°C; the reaction kettle is turned on and stirred, and the nitrogen gas is replaced 2-3 times. Vacuumize, heat up to 110°C, and bubble nitrogen for 4 hours; add 2,200 parts of propylene oxide through the storage tank, the initiation time is about 5 hours, and the subsequent addition is completed in about 10 hours. The pressure is controlled at 0.1-0.4 MPa, the temperature is 110-115 Reaction 2h, obtain oligomer polyether polyol;

[0030] Add 190 parts of liquid sorbitol, 40 parts of glycerin, 444 parts of oligomer polyether polyols, and 4.5 parts of potassium hydroxide into a 5L stainless steel reactor, and add 3100 parts of propylene oxide into the storage tank at a temperature of ≤40°C; Start stirring, replace with nitrogen 2-3 times, vacuumize, raise the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com