Energy-saving and environmental-protection butyl acrylate production method

A technology of butyl acrylate and production method, which is applied in the separation/purification of carboxylate, preparation of carboxylate, chemical instruments and methods, etc. It can solve the problems of difficult polymer treatment and excessive waste water, and achieve the service life of solid alkali The effects of long life, saving steam, and reducing the probability of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

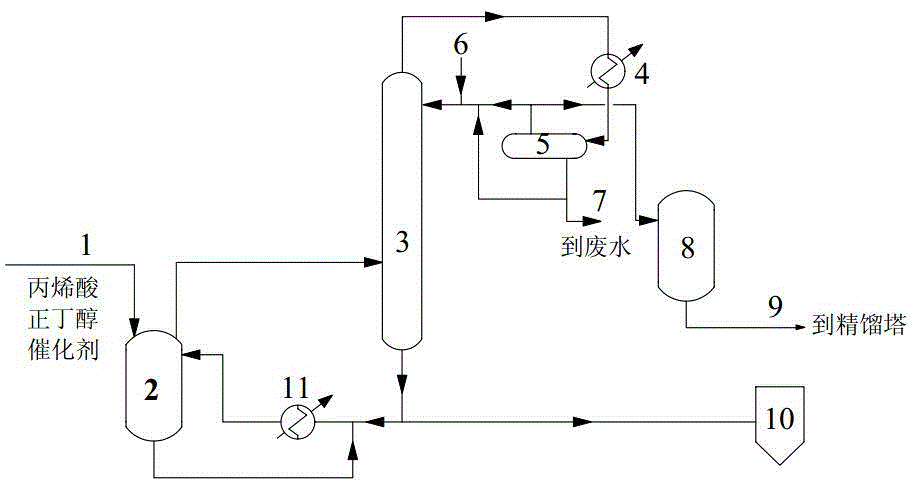

[0018] Such as figure 1 As shown, the equipment of the energy-saving and environment-friendly production method of butyl acrylate in the present embodiment 1 adopts continuous feeding, and the raw materials acrylic acid and n-butanol are dropped into at a molar ratio of 1:1, and the methylsulfonic acid catalyst is directly added to the esterification In the kettle, the total amount of feed is 1800L / h. After the raw materials are heated, the esterification reaction is carried out in the esterification kettle. The temperature of the esterification kettle is 95°C~96°C, and the pressure is 32kpa~38kpa. Keep the circulating flow rate of the tower kettle at about 1300L / h, and the temperature of the reboiler at about 93°C. After the reaction, the product undergoes azeotropic distillation, and the azeotrope enters the esterification tower in binary and ternary forms for separation. The top temperature of the esterification tower is about 68°C and the pressure is about 25kpa. The dis...

Embodiment 2

[0022] Such as figure 1 As shown, the equipment of the energy-saving and environment-friendly production method of butyl acrylate in the present embodiment 2 adopts continuous feeding, and the raw materials acrylic acid and n-butanol are added in a molar ratio of 1:1.1, and the methylsulfonic acid catalyst is directly added to the esterification In the kettle, the total amount of feed is 2500L / h. After the raw materials are heated, the esterification reaction is carried out in the esterification kettle. The temperature of the esterification kettle is 97°C~98°C, and the pressure is 32kpa~38kpa. Keep the circulation flow rate of the tower reactor of the esterification tank at about 2000L / h, and the temperature of the reboiler at about 99°C. After the reaction, the product undergoes azeotropic distillation, and the azeotrope enters the esterification tower in binary and ternary forms for separation. The temperature at the top of the tower is about 69°C and the pressure is about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com