A kind of lithium-ion battery negative electrode material and preparation method thereof, lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as unimproved charge and discharge rates, poor rate performance, and reduced safety performance, so as to improve rate performance and Fast charge and discharge rate, excellent performance, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

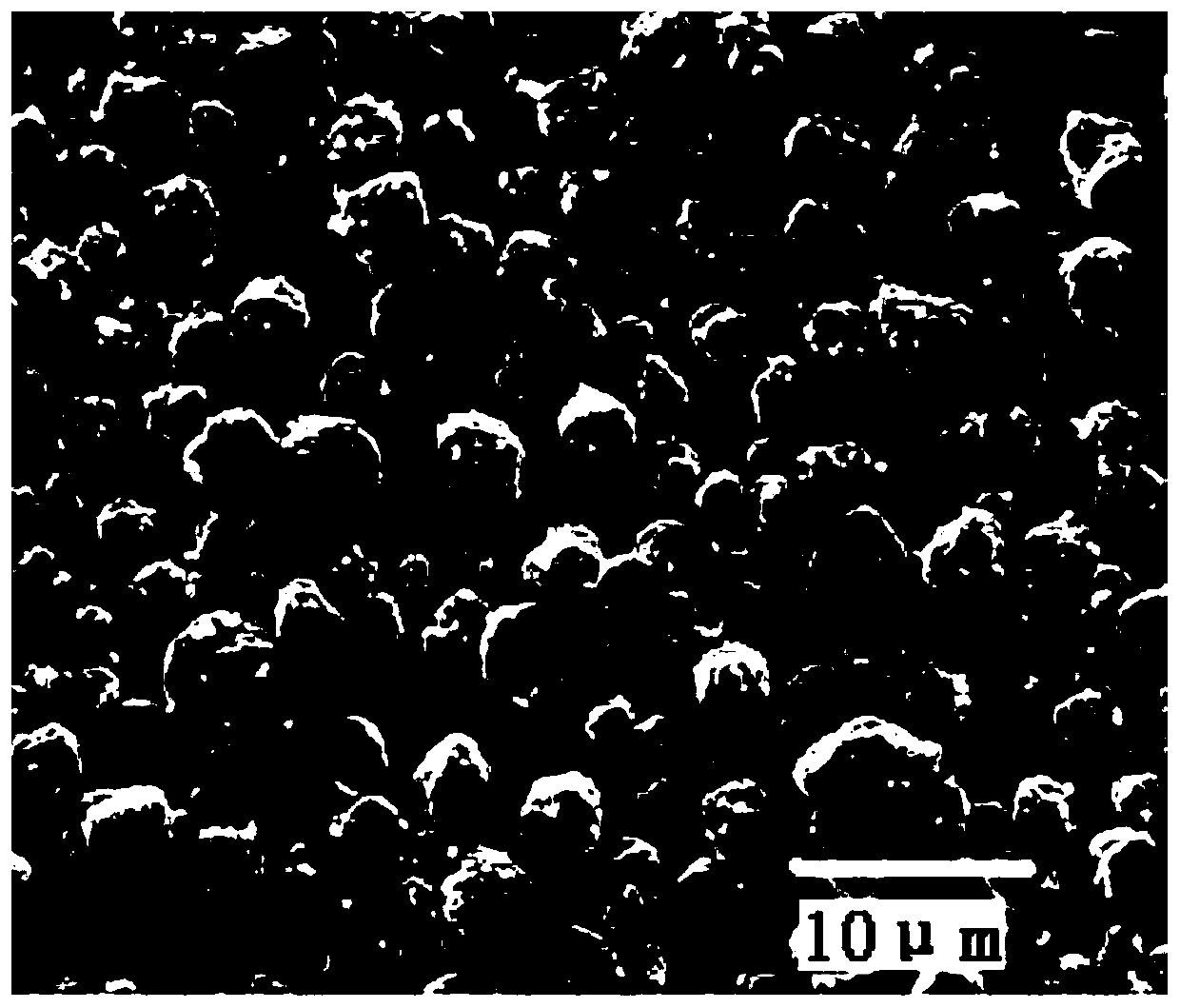

Image

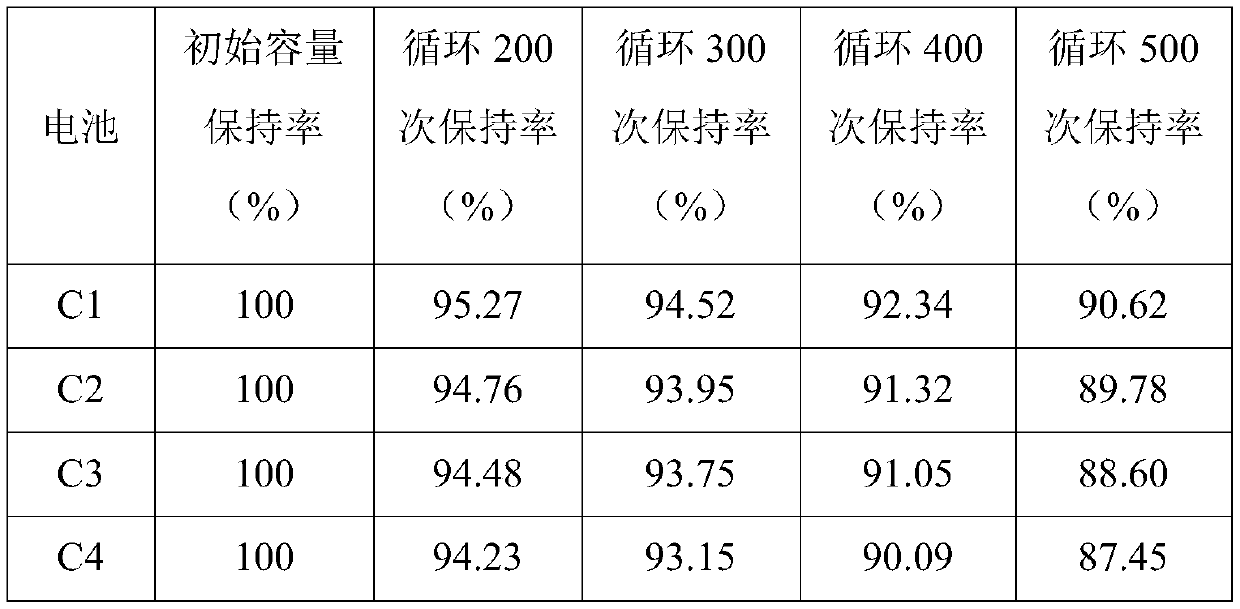

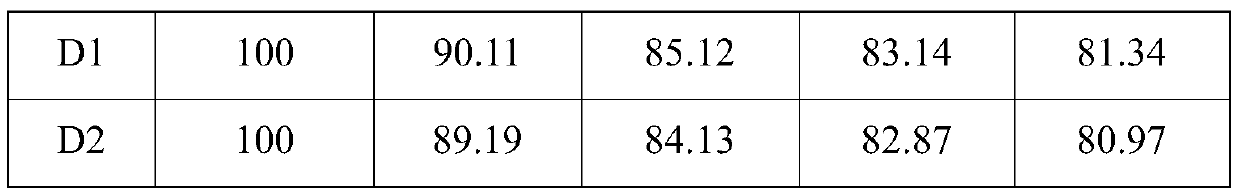

Examples

Embodiment 1

[0028] The lithium-ion battery negative electrode material in this embodiment presents a core-shell structure, the inner core is graphite, and the outer shell is a double-layer structure. From the inside to the outside, there are lithium zirconate layer and organic lithium composite layer, the core: lithium zirconate layer: organic lithium composite layer The thickness ratio of the layers is 100:5:1.

[0029] The concrete preparation method of this lithium-ion battery negative electrode material is:

[0030] 1) Configuration of inorganic lithium composite liquid and organic lithium composite liquid

[0031] a. Configuration of inorganic lithium composite solution: Weigh 100g of lithium zirconate, 1.5g of organic dispersant polyvinyl alcohol, 3g of binder polyvinylidene fluoride, and 1.5g of graphene and add them to 800g of N-methylpyrrolidone, and disperse evenly at high speed instant;

[0032] b. Configuration of organic lithium composite liquid: Weigh 100g methyllithium, 1...

Embodiment 2

[0038]The lithium-ion battery negative electrode material in this embodiment presents a core-shell structure, the inner core is graphite, and the outer shell is a double-layer structure. From the inside to the outside, there are lithium zirconate layer and organic lithium composite layer, the core: lithium zirconate layer: organic lithium composite layer The layer thickness ratio is 100:7:3.

[0039] The concrete preparation method of this lithium-ion battery negative electrode material is:

[0040] 1) Configuration of inorganic lithium composite liquid and organic lithium composite liquid

[0041] a. Configuration of inorganic lithium composite solution: Weigh 100g of lithium zirconate, 1g of organic dispersant polyvinyl alcohol, 2g of binder polyvinylidene fluoride, and 1g of graphene, add them to 500g of N-methylpyrrolidone, and disperse evenly at high speed. ;

[0042] b. Configuration of organic lithium composite solution: Weigh 100g butyllithium, 0.5g dispersant sec-oc...

Embodiment 3

[0048] The lithium-ion battery negative electrode material in this embodiment presents a core-shell structure, the inner core is graphite, and the outer shell is a double-layer structure. From the inside to the outside, there are lithium zirconate layer and organic lithium composite layer, the core: lithium zirconate layer: organic lithium composite layer The layer thickness ratio was 20:2:1.

[0049] The concrete preparation method of this lithium-ion battery negative electrode material is:

[0050] 1) Configuration of inorganic lithium composite liquid and organic lithium composite liquid

[0051] a. Configuration of inorganic lithium composite solution: Weigh 100g of lithium zirconate, 2g of organic dispersant polyvinyl alcohol, 4g of binder polyvinylidene fluoride, and 2g of graphene, add them to 1000g of N-methylpyrrolidone, and disperse evenly at high speed. ;

[0052] b. Configuration of organic lithium composite liquid: Weigh 100g butyllithium, 0.75g dispersant sec-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com