Carbon nano-tube net/Ni(OH)<2>/PPY composite electrode, preparation method and application

A technology of carbon nanotubes and composite electrodes, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology, etc., can solve problems such as complex preparation processes, achieve uniform coating layer, reduce the probability of side reactions, high power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

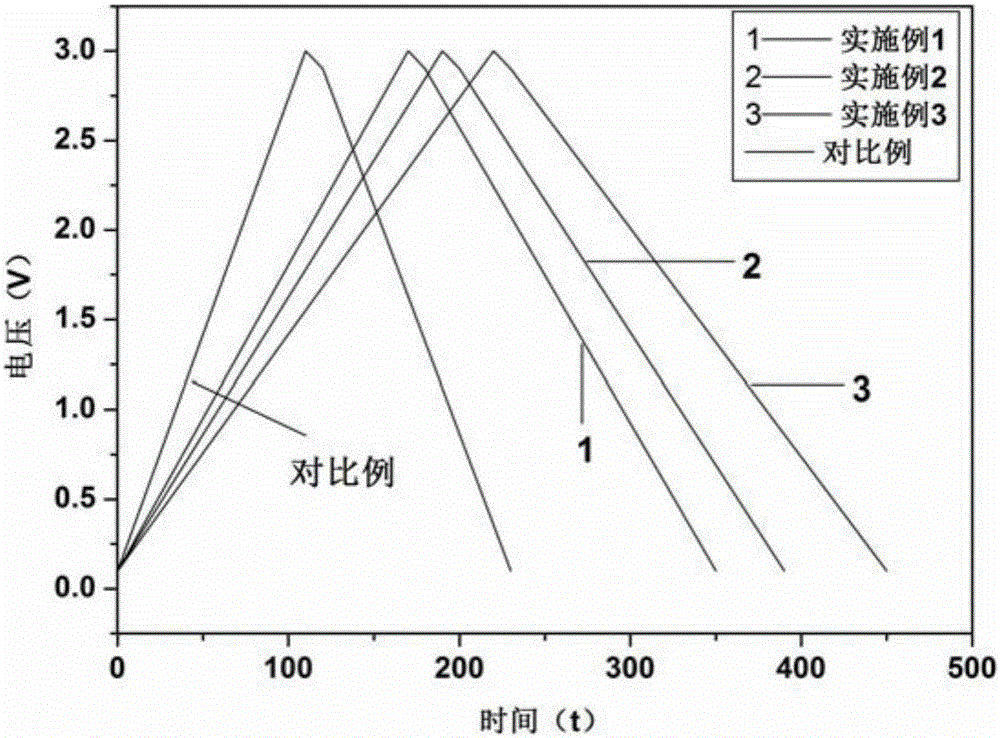

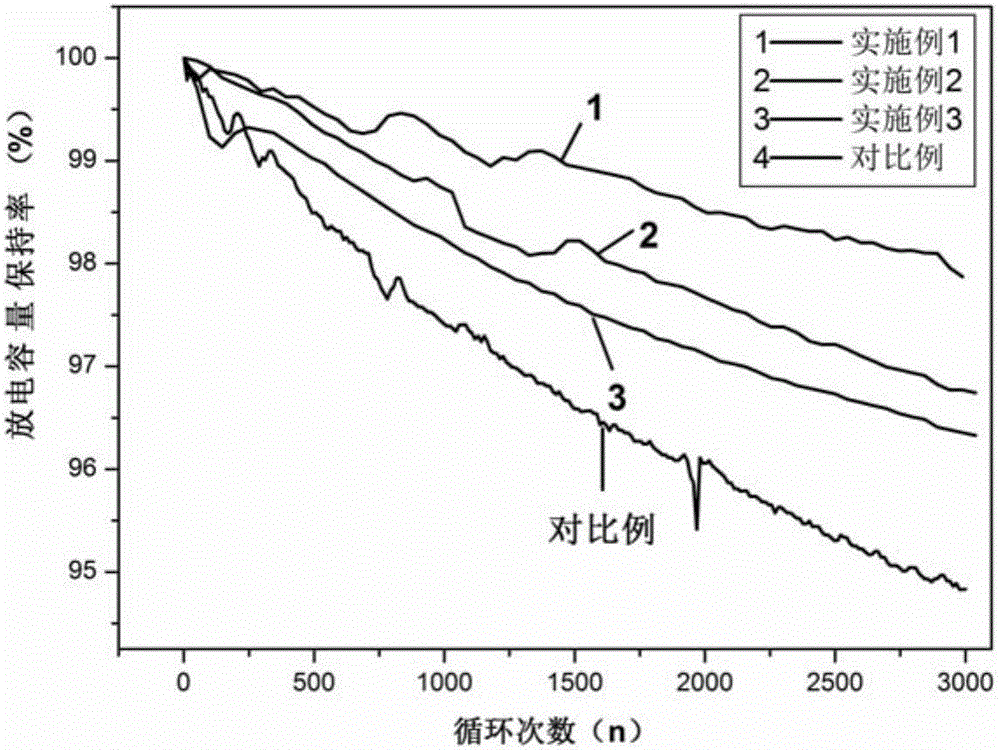

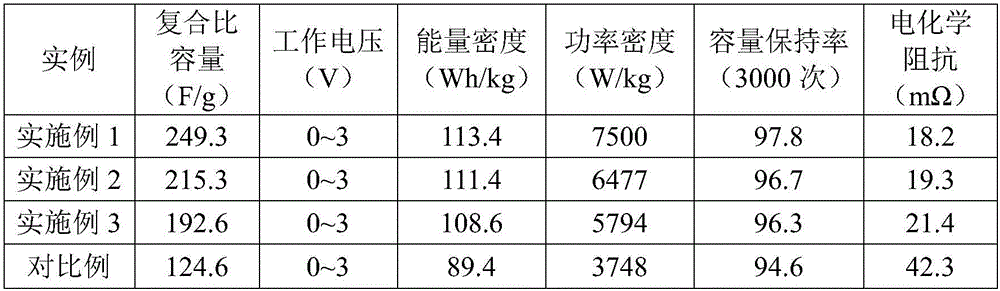

Embodiment 1

[0033] Carbon nanotube network / Ni(OH) 2 / PPY composite electrode is made of carbon nanotube network / Ni(OH) 2 The basic electrode formed by the composite material is obtained by electrodepositing polypyrrole on the surface, and the preparation steps are as follows:

[0034] 1) Preparation of basic electrodes

[0035] Disperse 3g of carbon nanotube networks (CNTN) with connection points into 250mL Ni(NO 3 ) 2 ·6H 2 In the O solution, slowly add 150 mL of KOH solution with a concentration of 0.1 mol / L dropwise under the condition of magnetic stirring. After 30 minutes, the dropwise addition is completed. 2 composite materials;

[0036] The 9g carbon nanotube network / Ni(OH) that will weigh 2Composite material, 5g acetylene black and 5g polytetrafluoroethylene emulsion (PTFE, solid content 60%) are mixed, add 15g N-methylpyrrolidone and stir evenly, obtain electrode slurry; Electrode slurry is coated on foamed nickel current collector The surface is pressed and formed with a...

Embodiment 2

[0041] Carbon nanotube network / Ni(OH) 2 / PPY composite electrode is made of carbon nanotube network / Ni(OH) 2 The basic electrode formed by the composite material is obtained by electrodepositing polypyrrole on the surface, and the preparation steps are as follows:

[0042] 1) Preparation of basic electrodes

[0043] Disperse the weighed 1g carbon nanotube network with connection points into 250mL Ni(NO 3 ) 2 ·6H 2 In the O solution, slowly add 50 mL of KOH solution with a concentration of 0.1 mol / L dropwise under the condition of magnetic stirring, and the dropwise addition is completed in 10 minutes. 2 composite materials;

[0044] The 9.5g carbon nanotube network / Ni(OH) 2 Composite material, 2g acetylene black and 3g polytetrafluoroethylene emulsion (solid content 60%) are mixed, add 15g N-methylpyrrolidone and stir evenly, obtain electrode slurry; Electrode slurry is coated on foamed nickel current collector surface, Press and form with a roller press (pressure 5MPa)...

Embodiment 3

[0049] Carbon nanotube network / Ni(OH) 2 / PPY composite electrode is made of carbon nanotube network / Ni(OH) 2 The basic electrode formed by the composite material is obtained by electrodepositing polypyrrole on the surface, and the preparation steps are as follows:

[0050] 1) Preparation of basic electrodes

[0051] Disperse 5 g of carbon nanotube networks with connection points into 250 mL of Ni(NO) with a concentration of 0.1 mol / L 3 ) 2 ·6H 2 In the O solution, slowly add 250 mL of KOH solution with a concentration of 0.1 mol / L dropwise under the condition of magnetic stirring, and the dropwise addition is completed in 50 minutes. 2 composite materials;

[0052] The 9.2g carbon nanotube network / Ni(OH) 2 After composite material, 3.5g acetylene black and 4g polytetrafluoroethylene emulsion (solid content 60%) are mixed, add 15g N-methylpyrrolidone and stir evenly, obtain electrode slurry; Electrode slurry is coated on foamed nickel current collector surface , press an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com