A kind of nitrogen-doped silicon-carbon composite negative electrode material and preparation method thereof

A negative electrode material, carbon composite technology, applied in the direction of negative electrode, nanotechnology for material and surface science, battery electrode, etc. The effect of capacity and cycle performance, strong coating uniformity, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

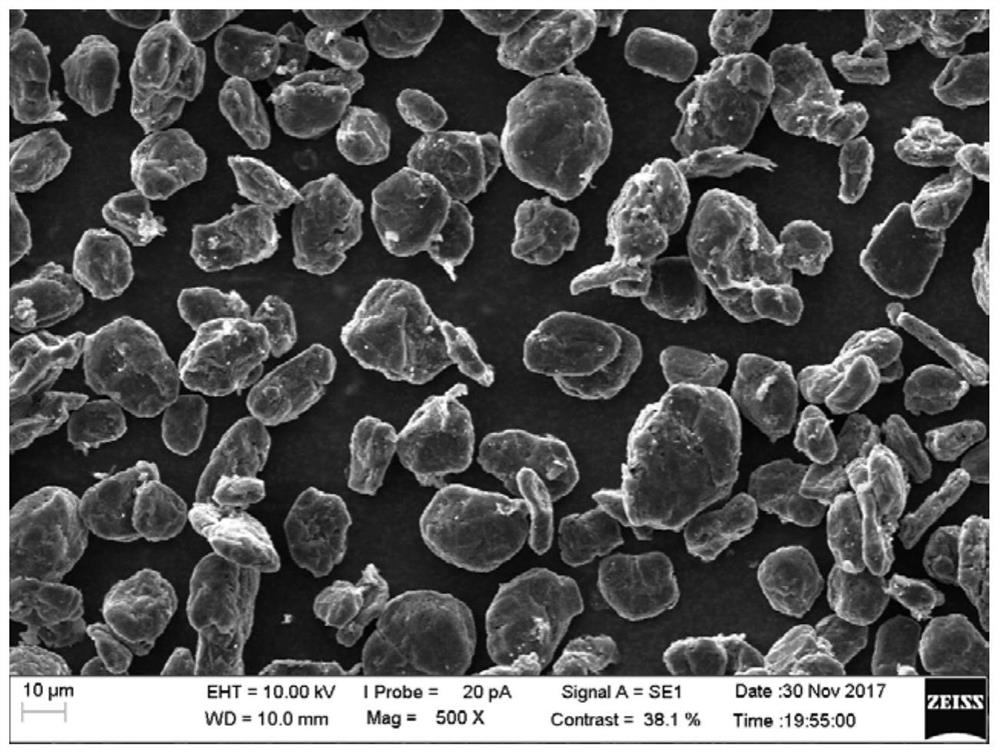

Image

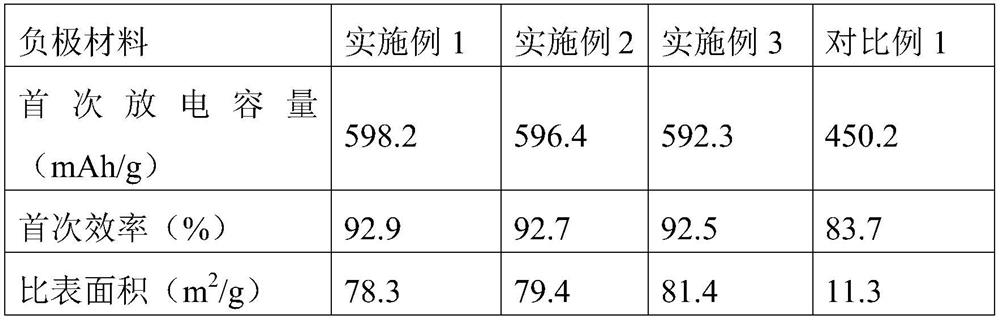

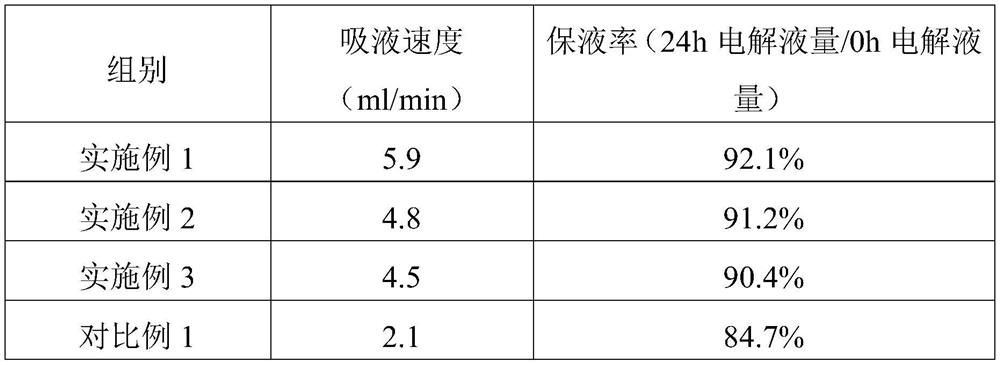

Examples

Embodiment 1

[0032] A nitrogen-doped silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, the core material is porous nano-silicon, the shell material is nitrogen-doped silicon carbide, and the thickness of the shell is 10-200nm;

[0033] The preparation method of the above-mentioned nitrogen-doped silicon-carbon composite negative electrode material comprises the following steps:

[0034] (1) Preparation of porous nano-silicon:

[0035] Dissolve 10g of silicon powder with a particle size of 5 μm in 1000ml of HF solution with a concentration of 5wt% and soak for 2h, filter, wash with water, and dry to obtain a nano-silicon precursor. Ammonia water, then stirred at 70°C for 3h, filtered, and then sintered in argon inert gas, the sintering temperature was 500°C, the time was 2.5h, and the temperature was lowered to room temperature to obtain porous nano-silicon;

[0036] (2) Preparation of nano-silicon / silicon carbide:

[0037] Th...

Embodiment 2

[0039] A nitrogen-doped silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, the core material is porous nano-silicon, the shell material is nitrogen-doped silicon carbide, and the thickness of the shell is 10-200nm;

[0040] The preparation method of the above-mentioned nitrogen-doped silicon-carbon composite negative electrode material comprises the following steps:

[0041] (1) Preparation of porous nano-silicon:

[0042] Dissolve 10g of silicon powder with a particle size of 0.1 μm in 1000ml of HF solution with a concentration of 1wt%, soak for 2h, filter, wash with water, and dry to obtain a nano-silicon precursor. In concentrated ammonia water, then stirred at 60°C for 5h, filtered, and then sintered in argon inert gas, the sintering temperature was 400°C, the time was 3h, and the temperature was cooled to room temperature to obtain porous nano-silicon;

[0043] (2) Preparation of nano-silicon / silicon carbide:

...

Embodiment 3

[0046] A nitrogen-doped silicon-carbon composite negative electrode material, the negative electrode material is a core-shell structure, the core material is porous nano-silicon, the shell material is nitrogen-doped silicon carbide, and the thickness of the shell is 10-200nm;

[0047] The preparation method of the above-mentioned nitrogen-doped silicon-carbon composite negative electrode material comprises the following steps:

[0048] (1) Preparation of porous nano-silicon:

[0049] Dissolve 10g of silicon powder with a particle size of 10 μm in 1000ml of HF solution with a concentration of 10% and soak for 2h, filter, wash with water, and dry to obtain a nano-silicon precursor. Ammonia water, then stirred at 60°C for 1h, filtered, and then sintered in argon inert gas at a sintering temperature of 600°C for 2h, and cooled to room temperature to obtain porous nano-silicon;

[0050] (2) Preparation of nano-silicon / silicon carbide:

[0051] The porous nano-silicon obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com