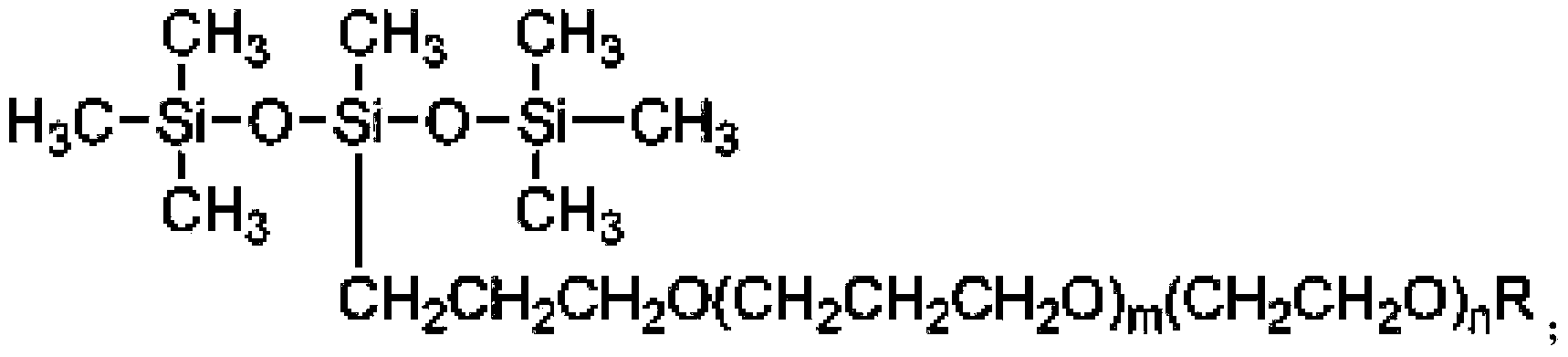

Polyether modified trisiloxane wetting agent and preparation and application methods thereof

A technology of trisiloxane wetting agent and polyether modification, applied in the direction of botanical equipment and methods, applications, biocides, etc., can solve the problems of high temperature resistance and poor alkali resistance, and achieve good alkali resistance and high content Less, the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

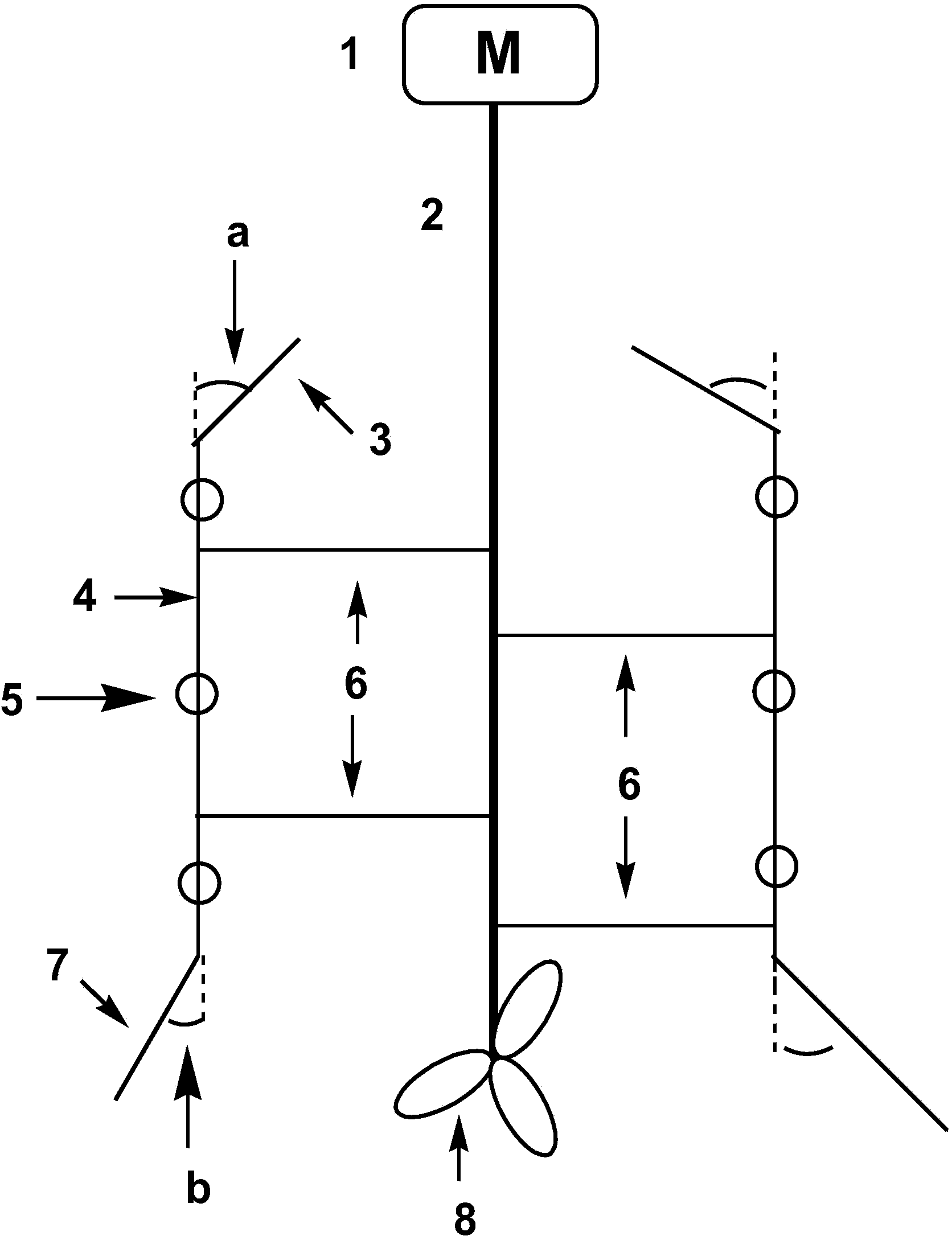

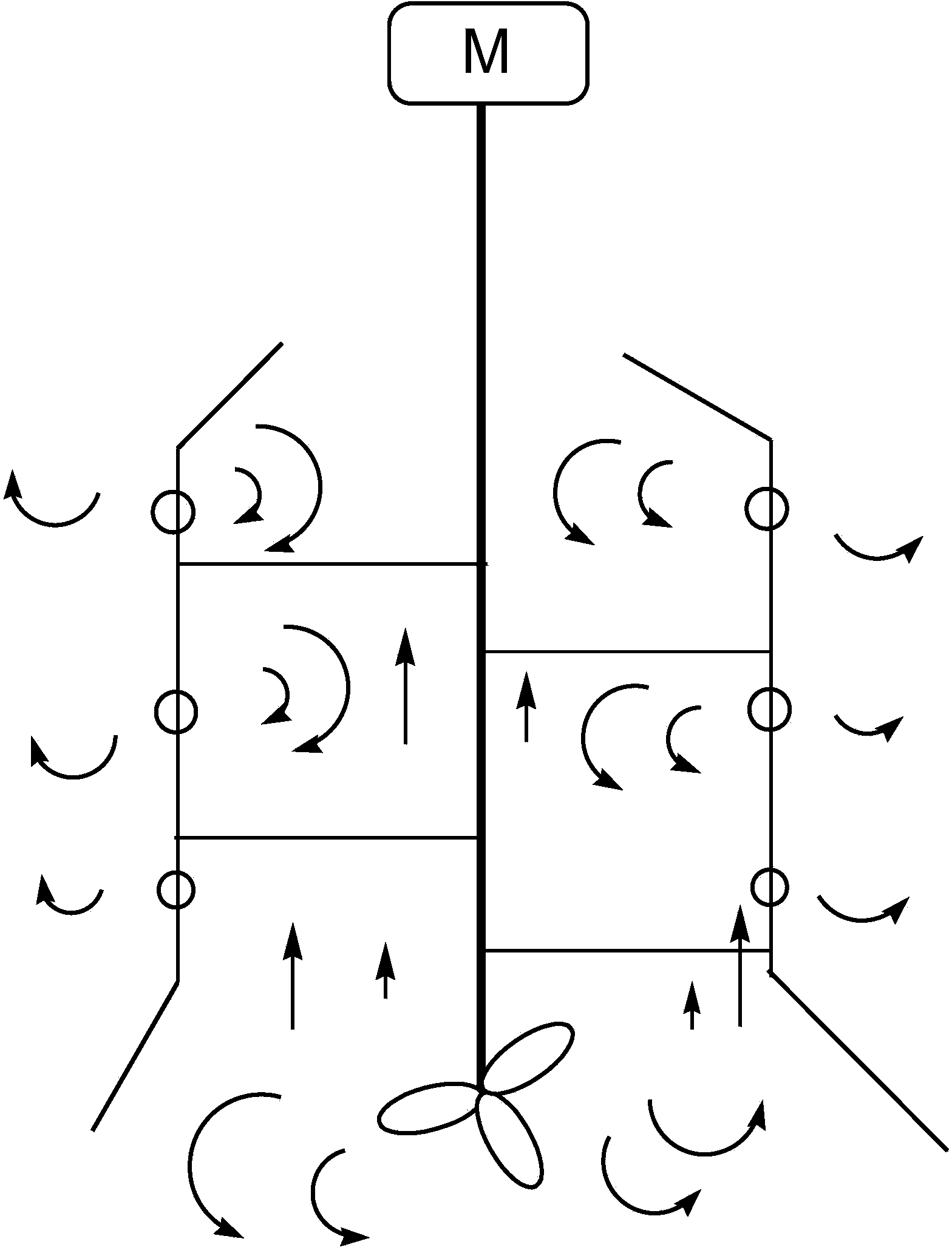

Method used

Image

Examples

Embodiment 1

[0041] In a three-necked flask reactor with a volume of 3000mL, add 1000g vinyl-terminated polyether (the repeating unit number m of propoxy group is 0, the repeating unit number n of ethoxy group is 5, and the other end is methyl-terminated) and Porous Al 2 o 3 Material-supported Pt(0) catalyst (the mass of Pt element accounts for 0.005‰ of the total mass of vinyl-terminated polyether and heptamethyltrisiloxane), stirred at 80°C for 30min; then added dropwise at 80°C Add 600g of heptamethylhydrogentrisiloxane for 2 hours. After dropping, keep warm for 2 hours; remove unreacted reaction materials at 60°C and -0.08MPa for 1 hour, and recover porous Al by filtration. 2 o 3 The Pt (0) catalyst of material support obtains 1540g polyether modified trisiloxane wetting agent product, and product is light yellow liquid, and viscosity is 20cSt, and surface tension is 20.8mN / m (gained polyether modified trisiloxane The alkane wetting agent product is prepared with a mass fraction of ...

Embodiment 2

[0043] Add 7kg of vinyl-terminated polyether (the number of repeating units m of propoxy group is 0, the number of repeating units of ethoxy group is 15, and the other end is hydrogen) and porous Al in a glass reactor with a volume of 20L. 2 o 3 Material-supported Pt(0) catalyst (the mass of Pt element accounts for 0.020‰ of the total mass of vinyl-terminated polyether and heptamethyltrisiloxane), stirred at 90°C for 30min; then added dropwise at 90°C 3.5kg of heptamethylhydrogentrisiloxane, the time of dropping is 2h, after dropping, keep warm for 2h; remove the unreacted reaction raw materials at 90℃, -0.08MPa for 1h, filter and recover porous Al 2 o 3 The Pt (0) catalyst of material load, obtains 10.1kg polyether modified trisiloxane wetting agent product, and product is light yellow liquid, and viscosity is 50cSt, and surface tension is 20.5mN / m (gained polyether modified trisiloxane The oxane wetting agent product is prepared into an aqueous solution with a mass fractio...

Embodiment 3

[0045] In a reactor with a diversion barrel with a volume of 1500L, add 750kg of vinyl-terminated polyether (the number of repeating units m of propoxy group is 3, the number of repeating units n of ethoxy group is 7, and the other end is hydrogen ) and porous SiO 2 Material-supported Pt(0) catalyst (the mass of Pt element accounts for 0.015‰ of the total mass of vinyl-terminated polyether and heptamethyltrisiloxane), stirred at 100°C for 40min; then added dropwise at 100°C 300kg of heptamethylhydrogentrisiloxane, the time for dropping is 2h, after dropping, keep warm for 2h; remove the unreacted reaction raw materials at 90°C and -0.09MPa for 1h, cool down to 40°C, filter and recover porous SiO 2 The Pt (0) catalyst of material load obtains 980kg polyether modified trisiloxane wetting agent product, and product is light yellow liquid, and viscosity is 500cSt, and surface tension is 21mN / m (gained polyether modified trisiloxane The wetting agent product is prepared with an aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com