Aldol condensation catalyst, preparation method and method for preparing methyl methacrylate by using aldol condensation catalyst

An aldol condensation and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of poor catalyst strength, high wear, and insufficient industrialization demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

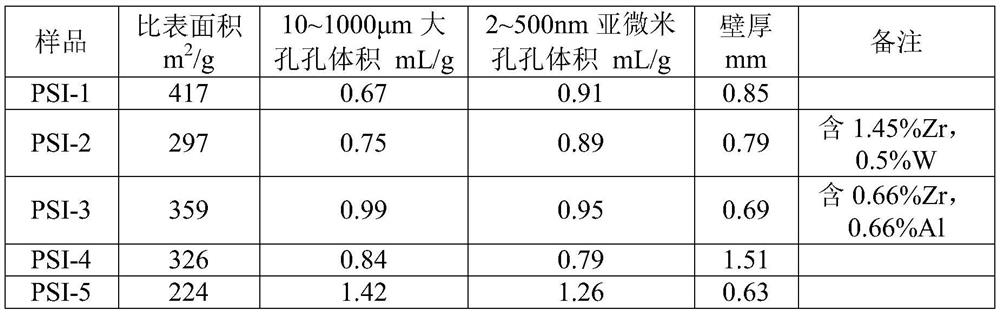

[0071] Take 6.82g of zirconium nitrate, 1.16g of bismuth nitrate, 2.78g of aluminum nitrate, 5g of concentrated nitric acid dissolved in 90g of deionized water, add 100g of foamed silica PSI-1, impregnate for 12h, dry at 90°C for 3h, then dry at 120°C 2h, and calcined at 450°C for 3h to prepare a modified foamed silica carrier.

[0072] Dissolve 2.93g of cesium nitrate and 0.646g of potassium nitrate in 45g of deionized water, add 50g of the above-mentioned modified silica carrier, soak for 12h, then dry at 90°C for 3h, and then dry at 120°C for 2h to obtain catalyst precursor A. Catalyst precursor A in 100mL / min N containing 13% water vapor 2 , the temperature was raised to 500°C at 2°C / min, and after being treated for 5 hours, it was taken out and cooled down to room temperature to obtain catalyst precursor B. The catalyst precursor B was soaked in 100 g of a mixture of methanol and methyl propionate (methanol accounted for 40%) for 20 h, and dried at 110° C. for 2 h after ...

Embodiment 2

[0077] Take 2.36g of zirconium nitrate, 0.29g of ammonium metavanadate, 0.24g of antimony acetate and dissolve them in 90g of deionized water, add 100g of foamed silica PSI-1, soak for 12h, dry at 90°C for 3h, then dry at 110°C for 10h , Calcined at 600°C for 1h to obtain a modified foamed silica carrier.

[0078] Dissolve 3.22g of cesium hydroxide and 0.19g of sodium hydroxide in 45g of deionized water, add 50g of the above-mentioned modified carrier, soak for 12h, then dry at 90°C for 3h, and then dry at 110°C for 10h to obtain catalyst precursor A. Catalyst precursor A in 200mL / min N containing 5% water vapor 2 , the temperature was raised to 600°C at 2°C / min, and the catalyst precursor B was obtained after being treated for 1 hour and then taken out and lowered to room temperature. The catalyst precursor B was soaked in 100 g of methanol and methyl propionate mixture (methanol accounted for 10%) for 15 h, and dried at 100° C. for 2 h after removing the liquid to prepare t...

Embodiment 3

[0083] Take 100g of foamed silica PSI-2 and place it at 300°C for 4 hours to calcinate to obtain a modified foamed silica carrier.

[0084] Dissolve 5.05g of cesium hydroxide in 45g of deionized water, add 50g of the above-mentioned modified carrier, impregnate for 12h, then dry at 90°C for 3h, and then dry at 120°C for 2h to obtain catalyst precursor A. Catalyst precursor A in 200mL / min N containing 6% water vapor 2 , the temperature was raised to 550°C at 2°C / min, and the catalyst precursor B was obtained after being treated for 3 hours and then taken out and lowered to room temperature. The catalyst precursor B was soaked in 100 g of methanol and methyl propionate mixture (methanol accounted for 20%) for 30 h, and dried at 100° C. for 2 h after removing the liquid to prepare the catalyst.

[0085] The measured free Cs content of the catalyst is 0.09%, and the BET specific surface area is 209m2 / g, the average pore diameter is 11.35nm.

[0086] The catalyst was tested for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com