Patents

Literature

124results about How to "Reduce the chance of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-emitting diode and manufacturing method thereof

PendingCN107681032AUndamagedIncrease current spreadingSolid-state devicesSemiconductor devicesElectrical conductorProtection layer

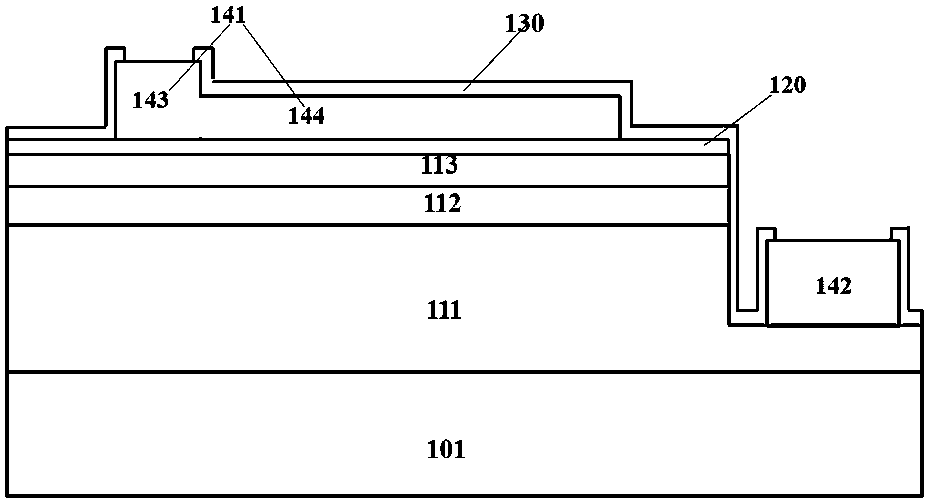

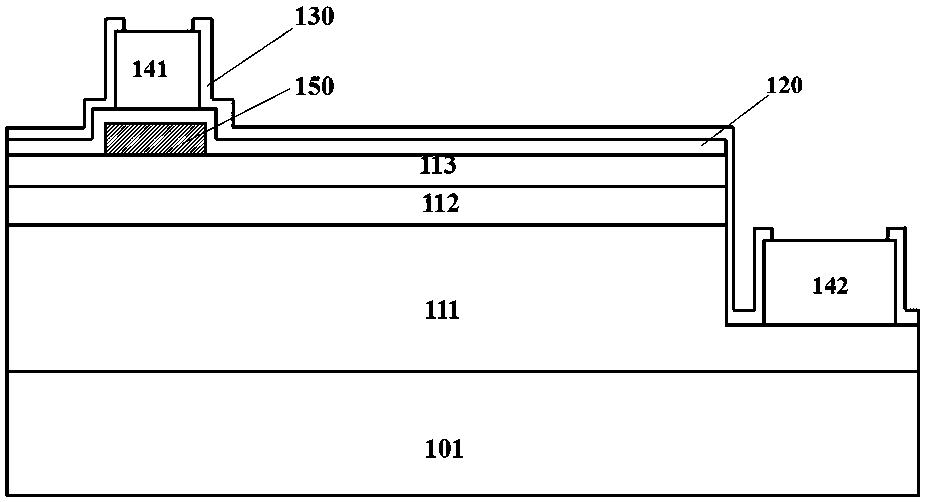

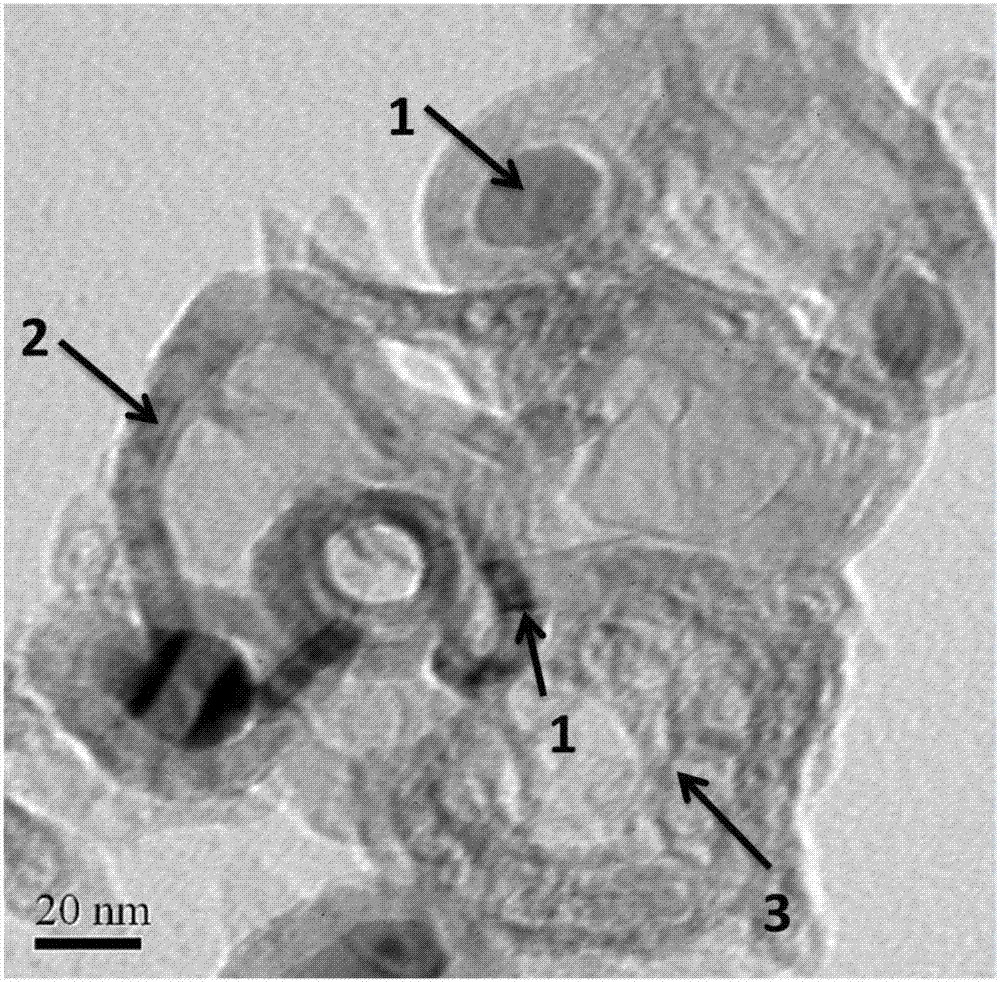

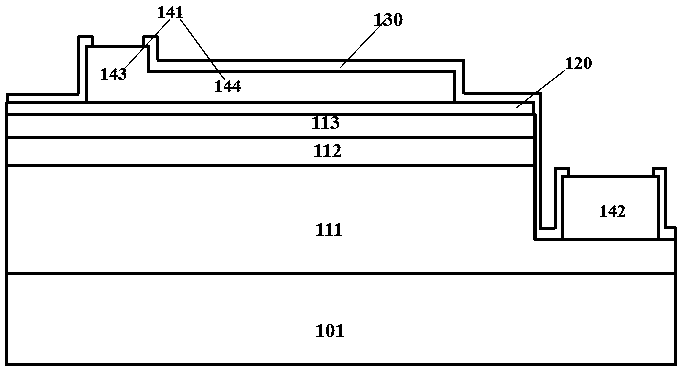

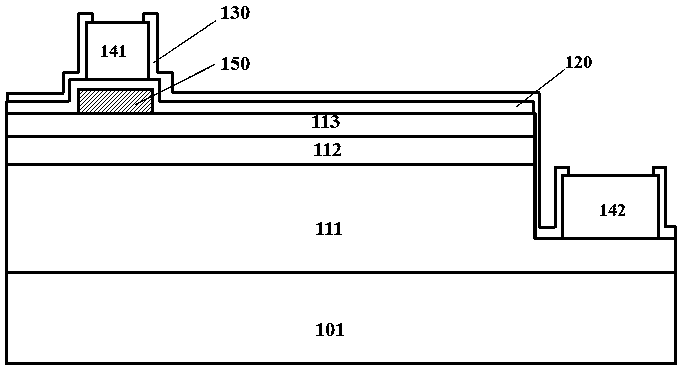

The invention discloses a light-emitting diode and a manufacturing method thereof. The light-emitting diode comprises a light-emitting epitaxial layer, a transparent conductive layer, a protection layer and a first electrode, wherein the light-emitting epitaxial layer sequentially comprises a first semiconductor layer, a light-emitting layer and a second semiconductor layer from top to bottom; a first electrode area is arranged on the upper surface of the light-emitting epitaxial layer; the first electrode area comprises a bonding pad area and an expansion area; the transparent conductive layer is formed on the surface of the first semiconductor layer of the light-emitting epitaxial layer, a first opening is formed in the bonding pad area, and the surface, in the bonding pad area, of the first semiconductor layer is exposed; the protection layer is formed on the surface of the transparent conductive layer, a second opening and a third opening are formed in the bonding pad area and theexpansion area of the first electrode area separately, and the surface, in the bonding pad area, of the first semiconductor layer and the surface, in the expansion area, of the transparent conductivelayer are exposed; and the first electrode is formed on the protection layer, and is in direct contact with the first semiconductor layer of the bonding pad area through the first opening and the second opening.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

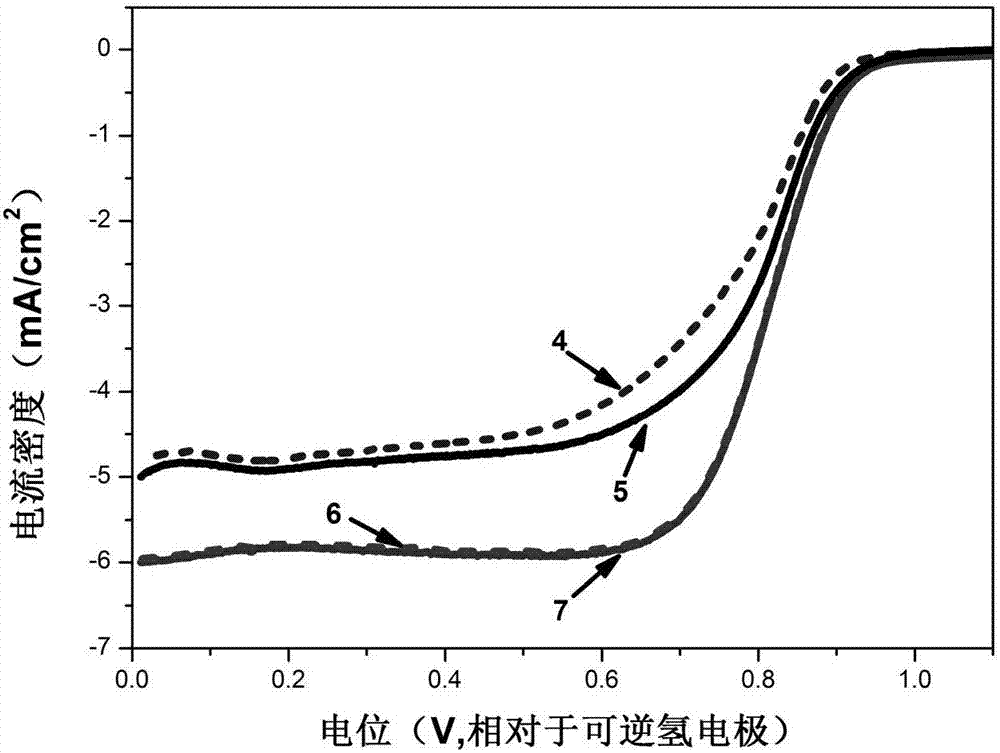

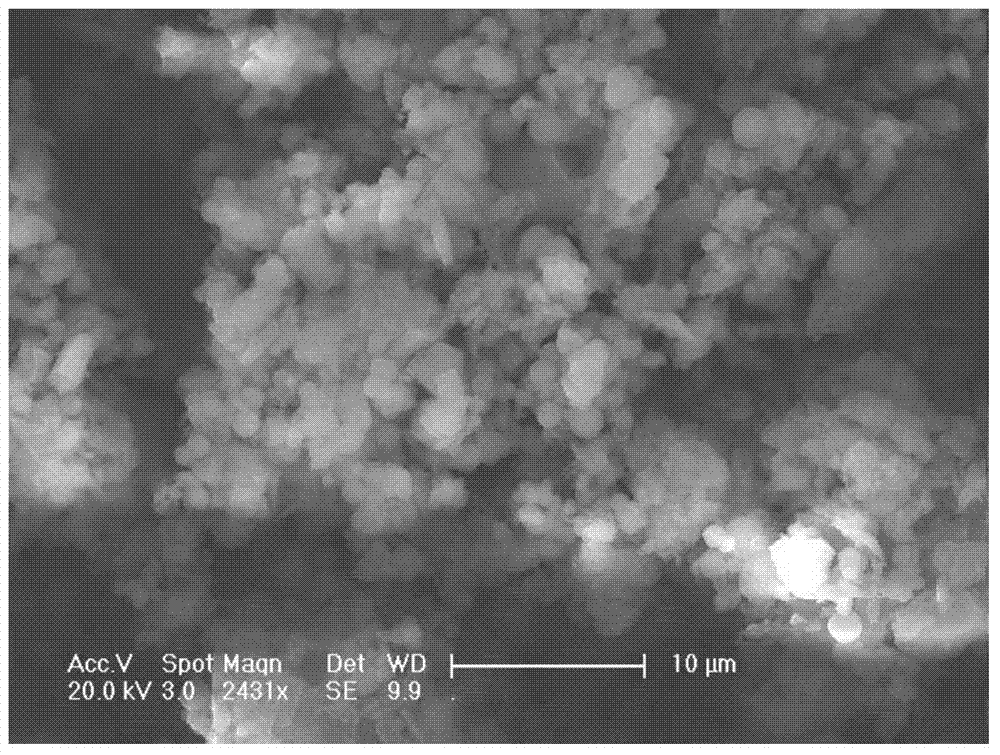

Preparation method for Fe-N-C oxygen reduction catalyst

InactiveCN107069048AReduces the chance of corrosion or oxidationHinder reunionCell electrodesChemistryComposite structure

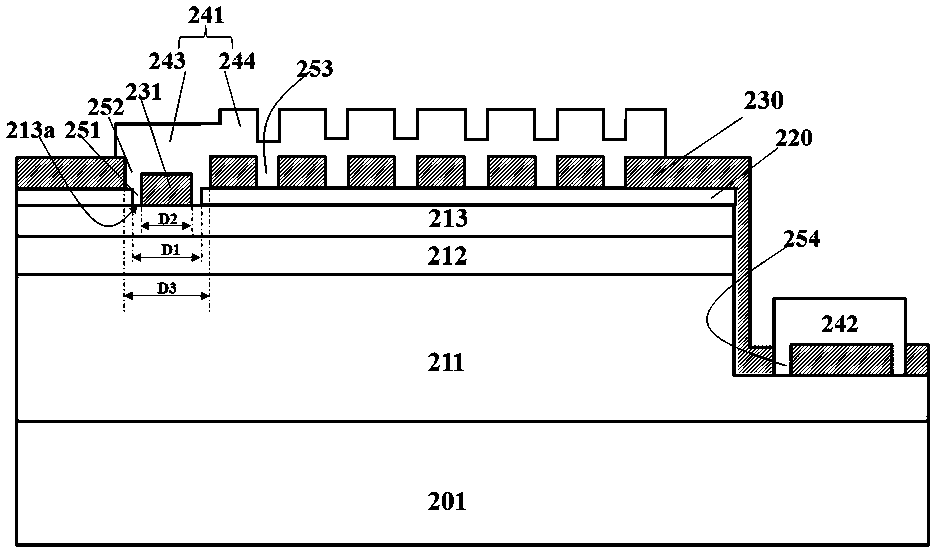

The invention provides a preparation method for a Fe-N-C oxygen reduction (ORR) catalyst with a special structure. In a Fe-N-C composite structure, C is used as an ORR catalytic base material which mainly exists in the form of graphitized nanosheets and nanotubes; N is doped into a graphite C network framework to replace a part of C so as to strengthen the catalytic capability of the base active center; and Fe-based nanoparticles are wrapped in the C nanotubes and nanosheets to maintain the catalytic activity of the graphite C. The Fe-N-C catalyst obtained in the invention not only has high ORR catalytic activity buts also shows extremely high stability; and the adopted preparation method is simple, the equipment requirement is low, the product performance is good, and commercial popularization and application can be realized favorably.

Owner:CENT SOUTH UNIV

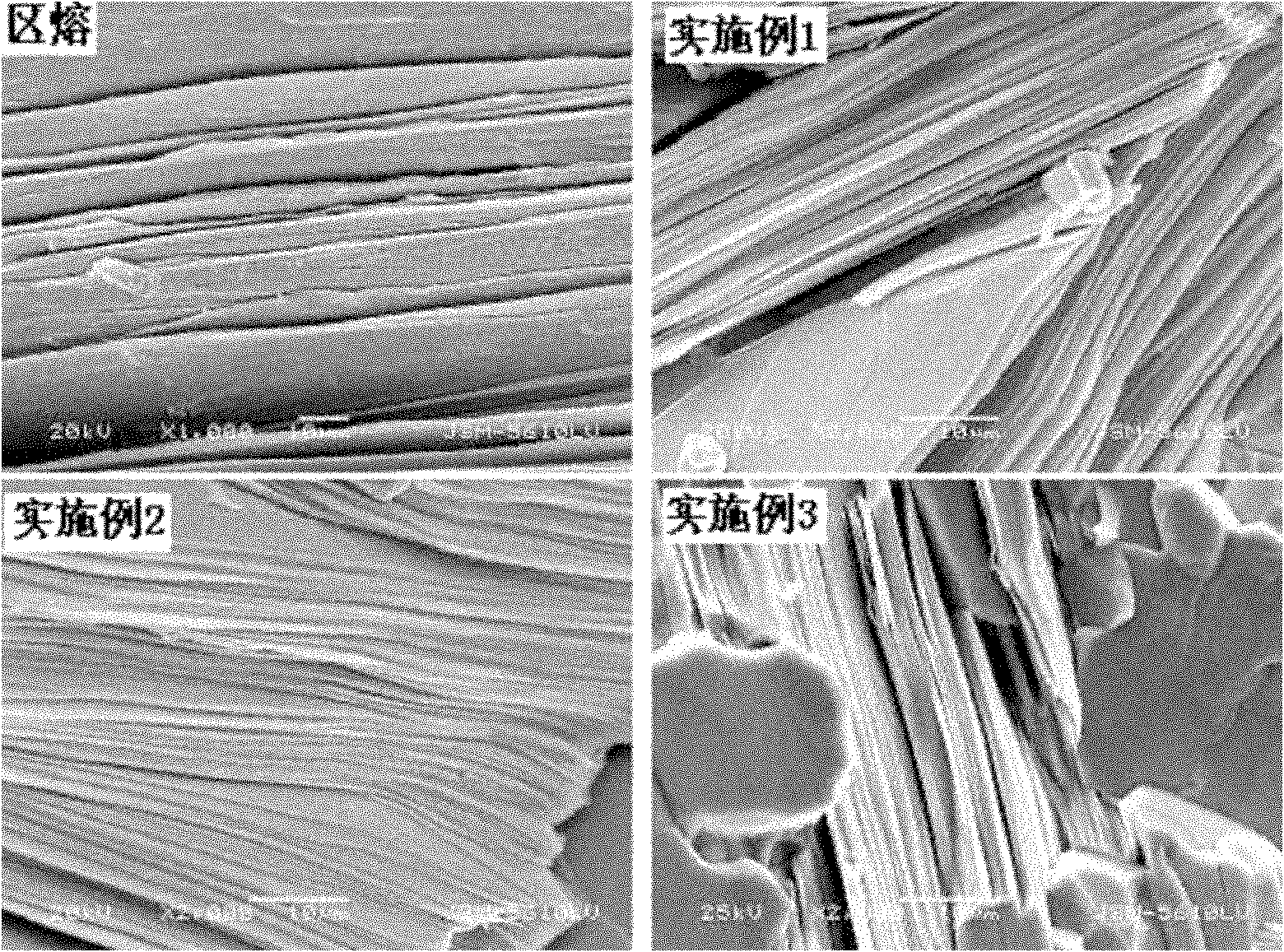

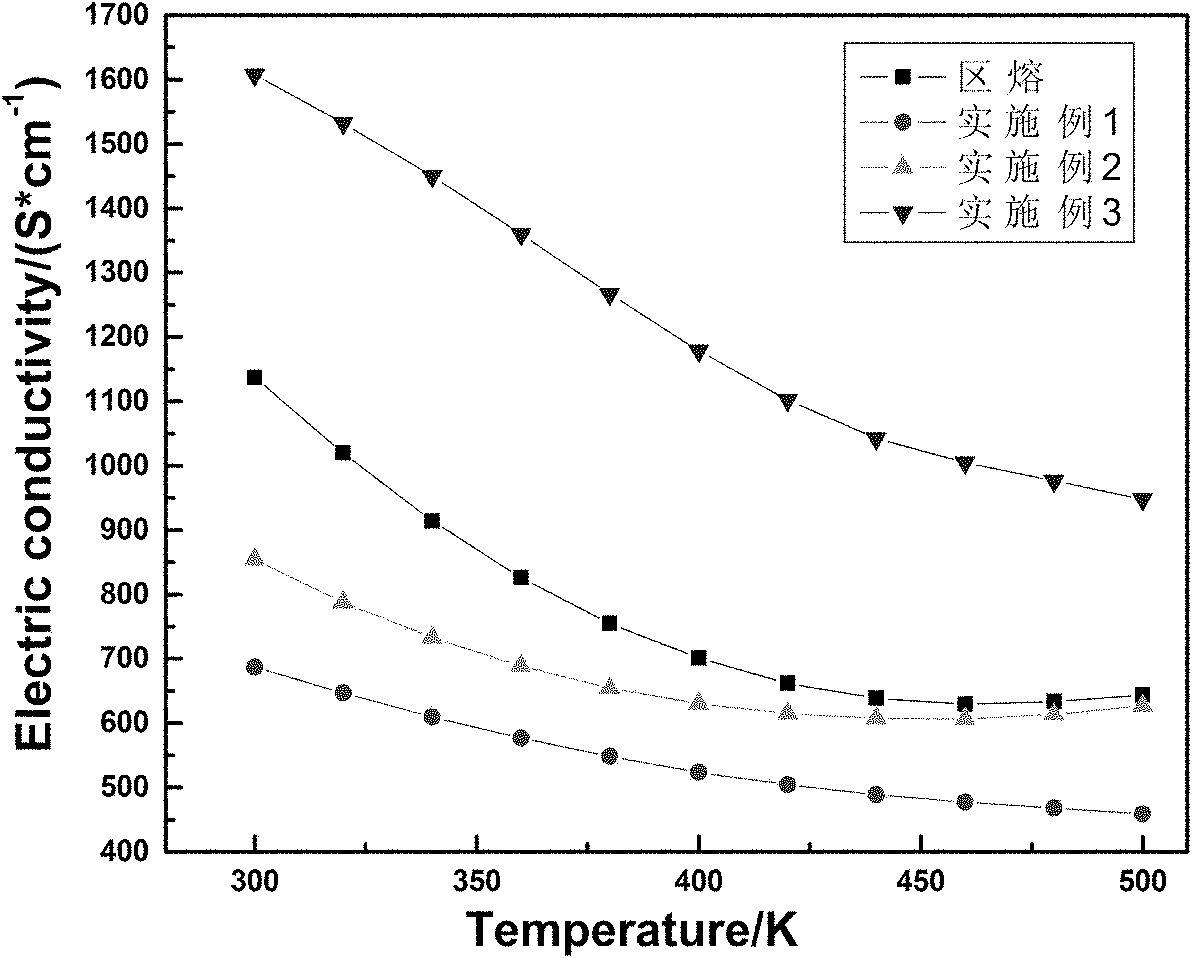

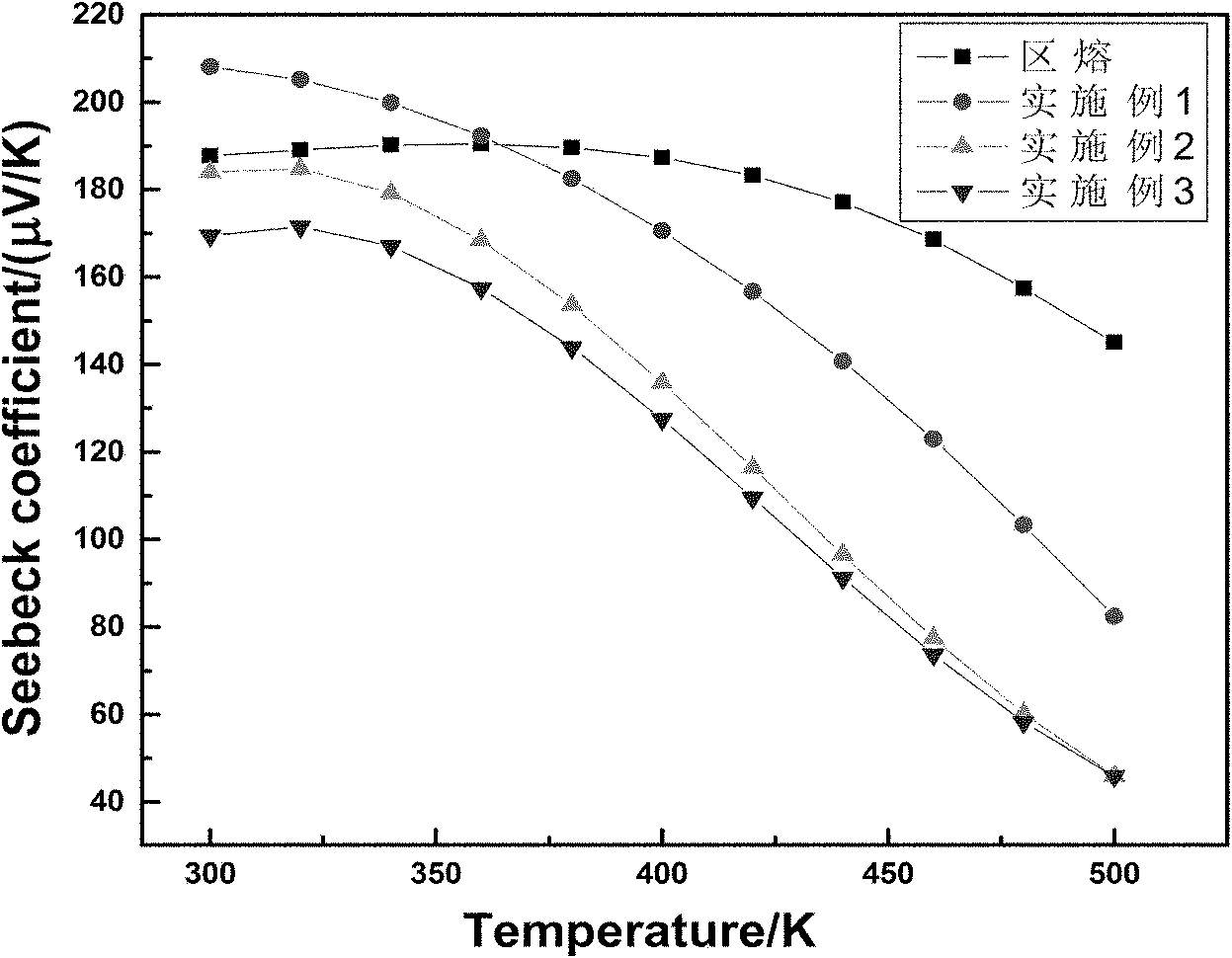

Method for preparing bismuth telluride-based thermoelectric material

InactiveCN101985776AReduce the chance of oxidationImprove thermoelectric performancePolycrystalline material growthBy zone-melting liquidsBreaking strengthBismuth telluride

The invention relates to a method for preparing a thermoelectric material, in particular to a method for preparing a bismuth telluride-based thermoelectric material. The method is characterized by comprising the following steps of: 1) preparing bismuth telluride-based thermoelectric material ingots by a zone-melting method; and 2) directly loading the prepared bismuth telluride-based thermoelectric material ingots into an extrusion die, putting the bismuth telluride-based thermoelectric material ingots and the extrusion die together into a hot extrusion furnace and performing hot extrusion in vacuum or under the protection of inert gas to obtain the bismuth telluride-based thermoelectric material, wherein the hot extrusion conditions are that: the hot extrusion temperature is between 250 and 550 DEG C, the heating rate is 10 DEG C / min, the heat preservation time is 1 to 3 hours, the extrusion ratio is 9:1-3:1, the extrusion angle is 30 to 60 degrees and the extrusion speed is 1mm / min. The method saves cost and can shorten the production period; and the bismuth telluride-based thermoelectric material prepared by the method has the characteristics of high breaking strength and compression strength.

Owner:WUHAN UNIV OF TECH +1

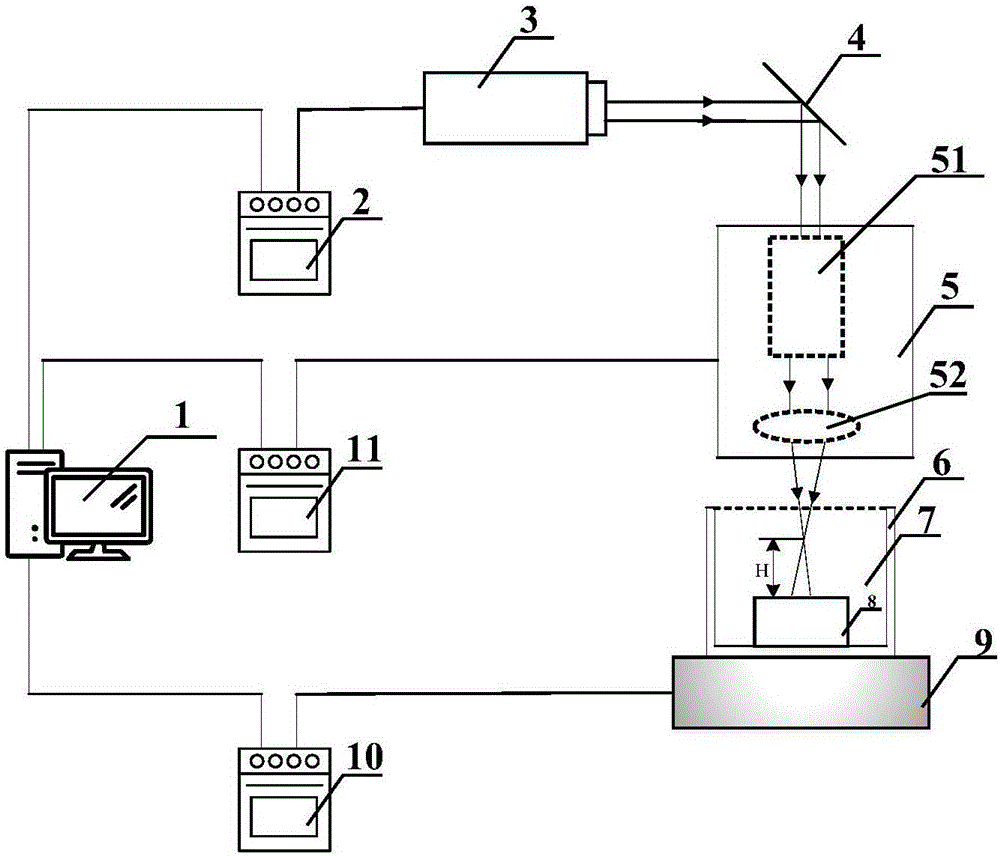

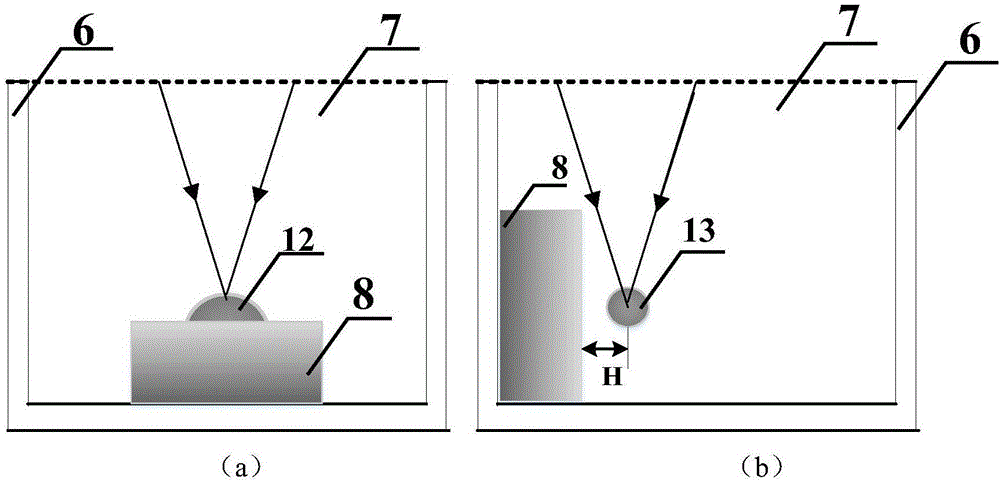

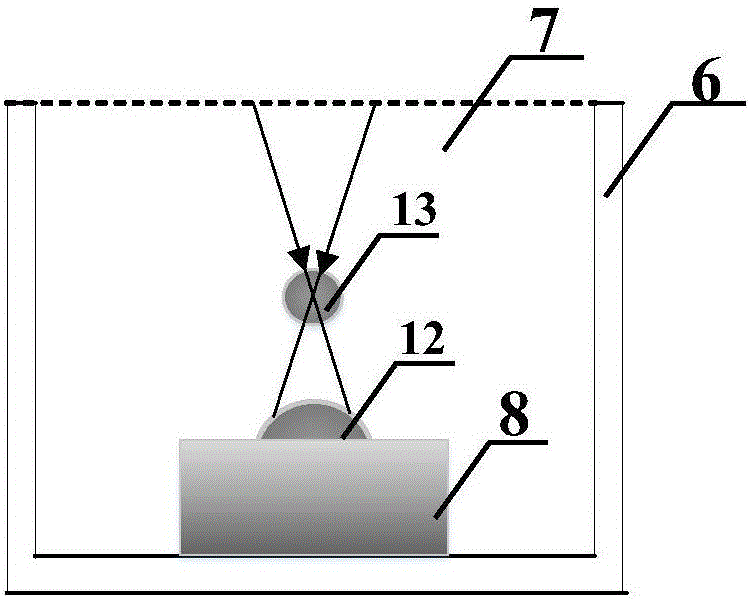

Method and device using laser to induce double cavitations

ActiveCN106271063AComposite processing effect is goodIncrease the strength of the actionLaser beam welding apparatusShock waveLiquid medium

The invention discloses a method and a device using laser to induce double cavitations. The method and the device using the laser to induce the double cavitations have the advantages that when liquid medium is radiated by a laser beam, the cavitations are simultaneously produced on the laser focusing part and the surface of to-be-processed material, so that the cavitation inducing strong shock wave in the liquid medium and the strong shock wave produced by the cavitation inducing at the surface of the to-be-processed material are overlapped, repeated, or simultaneously acted on the surface of the to-be-processed material; the surface intensity of the material is improved; the impact pressure is high, the oxidizing degree of material is low, and the like; the application prospect is wide.

Owner:JIANGSU UNIV

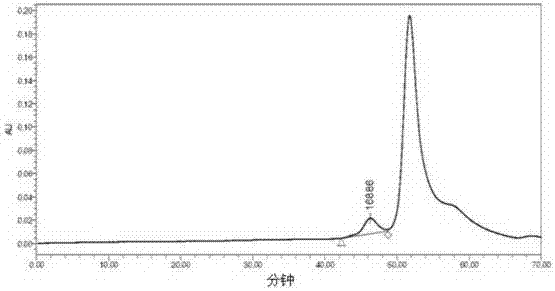

Mercapto polyaniline and preparation method thereof

The invention provides mercapto polyaniline and a preparation method thereof, and belongs to the field of polyaniline preparation methods. The problem that a mercapto group is oxidized by an oxidant in the process of a conventional preparation method for the mercapto polyaniline is solved. The method comprises the following steps of dissolving mercapto aniline monomers into an organic solvent to obtain a first mixed solution; dissolving the oxidant into an aqueous solution of an inorganic acid to obtain a second mixed solution; mixing the first and second mixed solutions, and polymerizing the mercapto aniline monomers on a water-organic solvent interface to obtain a reaction product; washing, alcohol-washing and drying the reaction product to obtain the mercapto polyaniline. According to the mercapto polyaniline and the preparation method thereof, the mercapto group in the polyaniline obtained by the method can be prevented from being oxidized by the oxidant and oxygen in air in a preparation process, and experimental results show that the mercapto polyaniline has a number average molecular weight of 12,671 to 18,306 daltons and a weight average molecular weight of 17,112 to 20,303 daltons.

Owner:中科应化(长春)科技有限公司

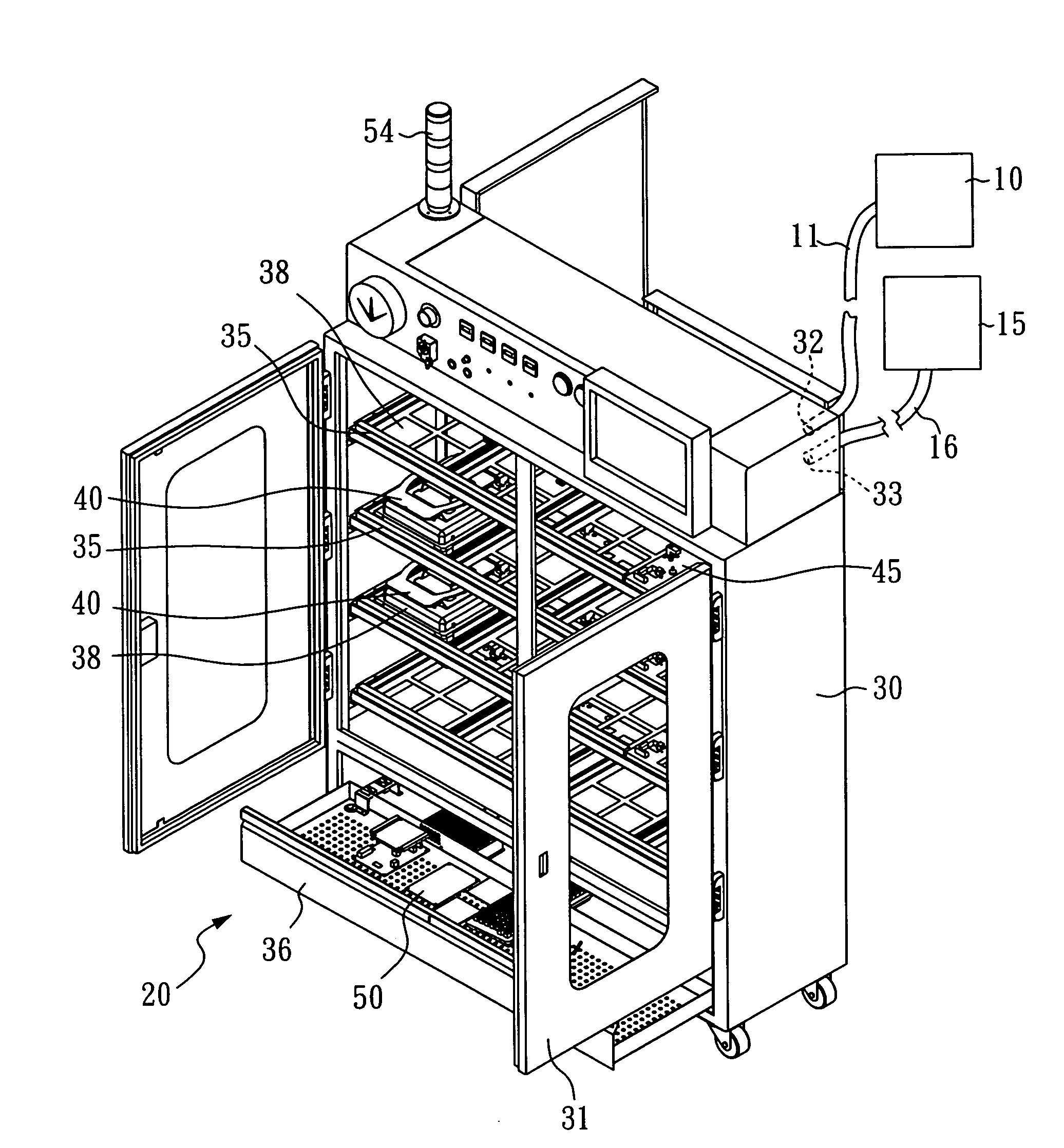

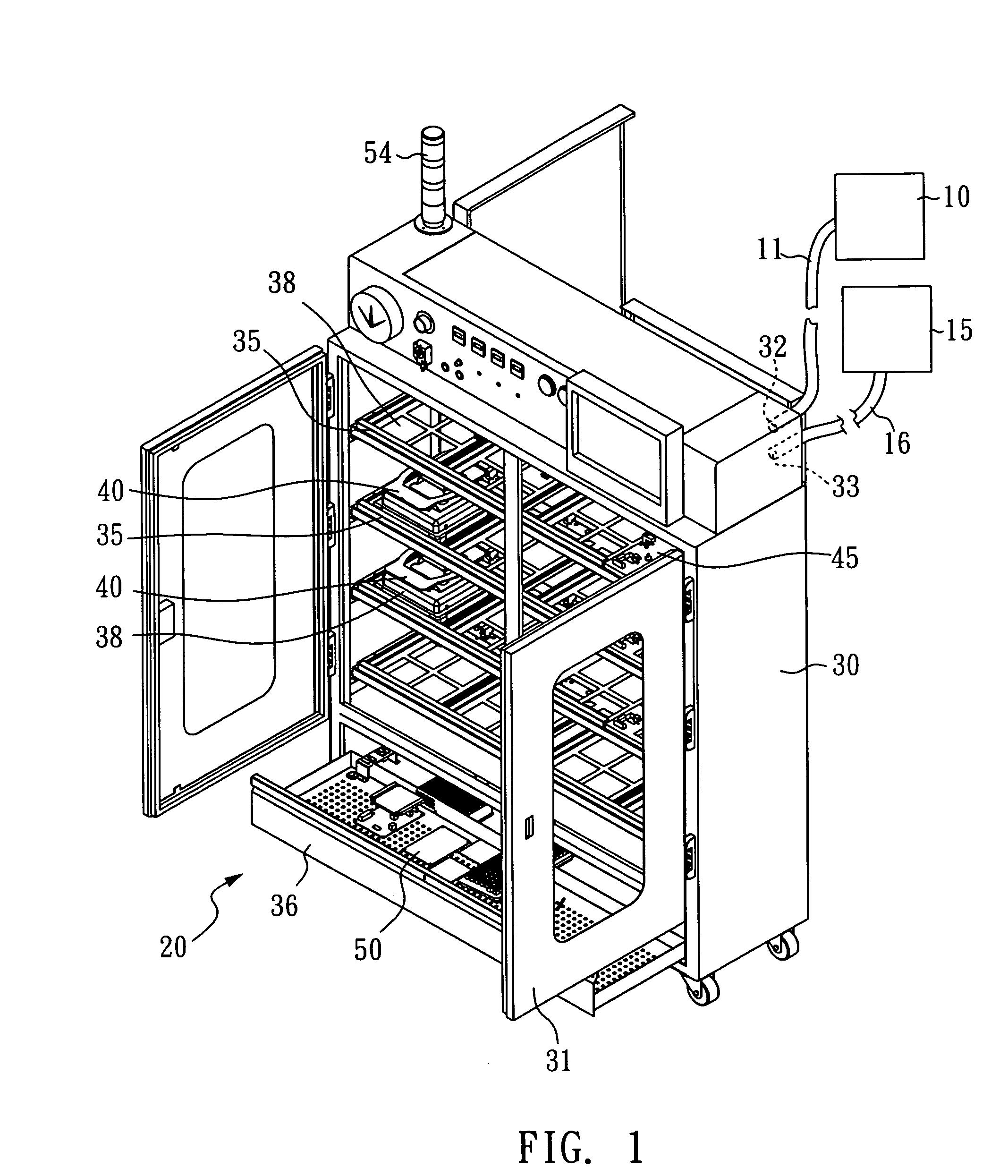

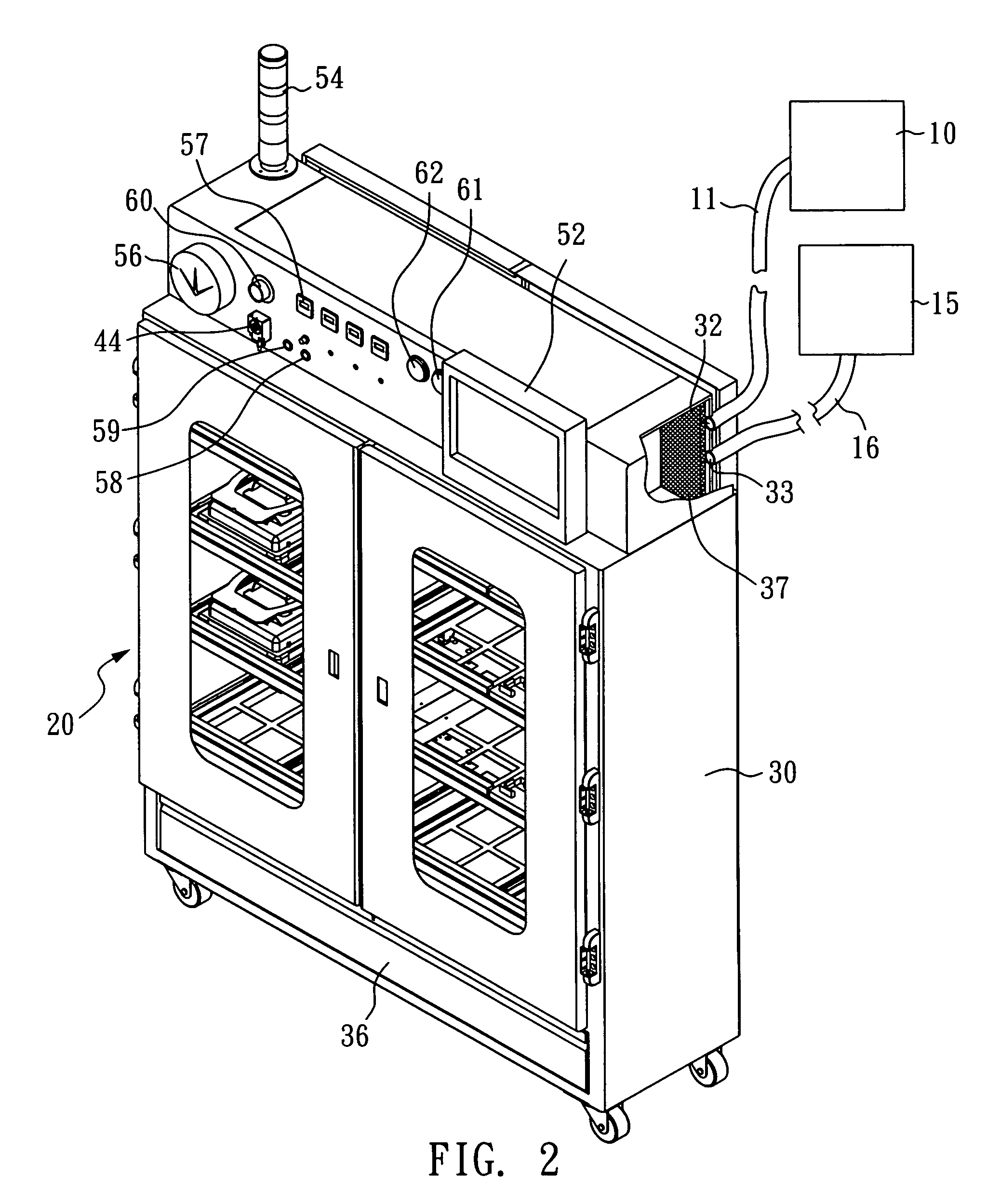

Nitrogen cabinet with ID management and gas charging means

InactiveUS20070251116A1Reduce the chance of oxidationEffective controlSemiconductor/solid-state device manufacturingDrying chambers/containersNitrogenIdentification device

A nitrogen cabinet is disclosed to include at least one cabinet body having a door and a nitrogen inlet connected to a nitrogen supplier, multiple shelves mounted inside the cabinet body and defining multiple storage spaces, multiple containers mounted in storage spaces, each container having at least one gas charging port and an identification device, and multiple gas-charging units mounted inside the cabinet body and respectively connected to the nitrogen inlet for charging the containers with nitrogen. Thus, the nitrogen cabinet combines the functions of storage, charging, management, identification, and tracing of the containers, thereby lowering the chance of oxidation or contamination of storage items in the containers and effectively controlling real-time inventory data to improve product yield rate.

Owner:FORTREND TAIWAN SCI

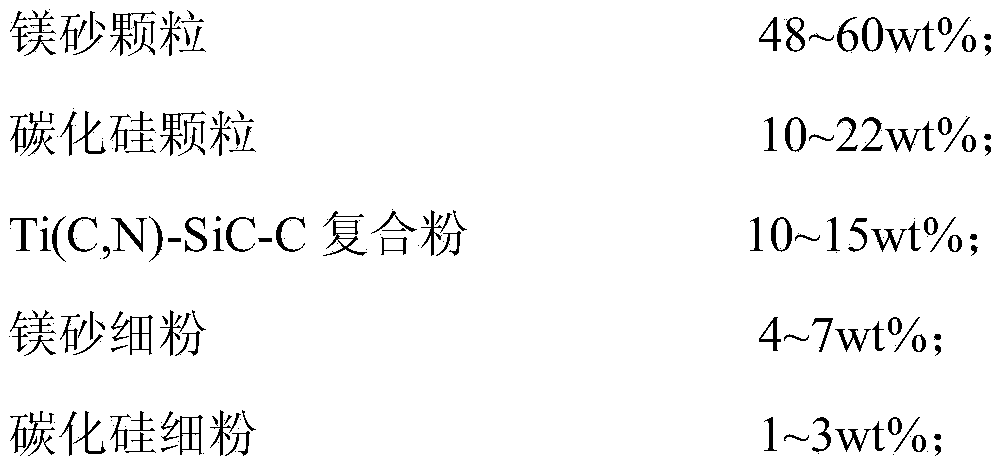

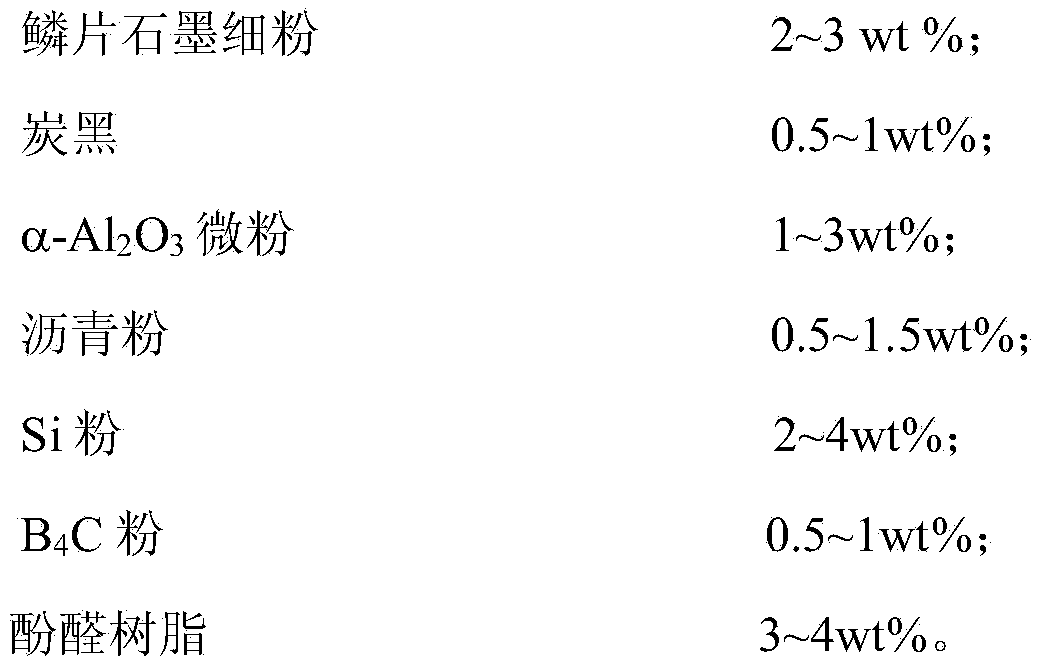

Smelting separation furnace lining material and preparation method thereof

InactiveCN104003738AGood antioxidant propertiesGood thermal shock stabilityTemperature resistanceCarbon black

The invention relates to a smelting separation furnace lining material and a preparation method thereof. According to the technical scheme, the preparation method of the smelting separation furnace lining material comprises the following steps: mixing 48-60wt% of magnesite particles and 10-22wt% of silicon carbide particles, adding 3-4wt% of phenolic resin, mixing, then adding mixed powder, mixing, moulding, and then drying for 24 hours at the temperature of 180-220 DEG C, so that the melting separation furnace lining material is obtained; the mixed powder is obtained by mixing 10-15wt% of Ti(C,N)-SiC-C composite powder, 4-7wt% of magnesite fine powder, 1-3wt% of silicon carbide fine powder, 2-3wt% of crystalline flake graphite fine powder, 0.5-1wt% of carbon black, 1-3wt% of alpha-Al2O3 micro powder, 0.5-1.5wt% of asphalt powder, 2-4wt% of Si powder and 0.5-1wt% of B4C powder. The smelting separation furnace lining material has the characteristics of high temperature resistance, washing resistance, strong FeO and TiO2 corrosion resistance, good oxidation resistance and excellent thermal shock performance.

Owner:WUHAN UNIV OF SCI & TECH

A light emitting diode and a manufacturing method thereof

ActiveCN109844968AImprove adhesionReduce risk of sheddingSemiconductor devicesElectrical conductorProtection layer

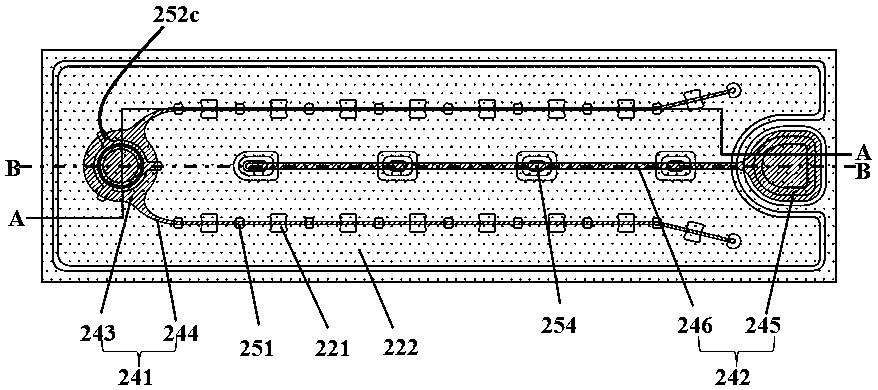

The invention discloses a light emitting diode and a manufacturing method thereof. In some embodiments, the light emitting diode comprises: a light emitting epitaxial layer which comprises a first semiconductor layer, a light emitting layer and a second semiconductor layer in order from top to bottom, and the upper surface of which is provided with a first electrode zone including a welding pad zone and an extension zone; an insulating layer formed on the extension zone of the first semiconductor layer; a transparent conductive layer formed on the surface of the first semiconductor layer and covering the insulating layer; a protective layer formed on the surface of the transparent conductive layer, forming a first opening in the extension zone, exposing a part of the surface of the transparent conductive layer of the extension zone; a first electrode formed on the protective layer, and including a pad portion and an extension portion, wherein the extension portion is electrically connected to the transparent conductive layer of the extension zone through the first opening.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

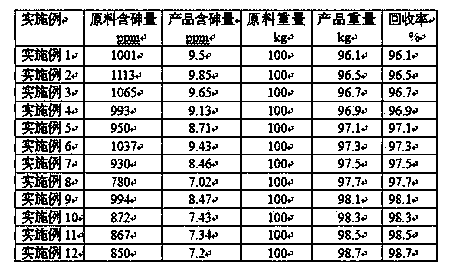

Arsenic removal method used in pyrometallurgucal process for antimony

The invention discloses an arsenic removal method used in a pyrometallurgucal process for antimony. The method comprises the following steps: heating crude antimony containing arsenic and a composite smelting agent to a molten state; smelting the above-mentioned molten raw materials to complete slagging and arsenic removal reactions; and finally, carrying out slag-antimony separation and repeating the previous steps several times to prepare a product; wherein the composite smelting agent comprises, by weight, 70 to 80 parts of anhydrous sodium carbonate, 10 to 15 parts of sodium nitrate, 0.5 to 5 parts of quartz sand and 1 to 3 parts of borax. With the composite smelting agent and a smelting method provided by the invention, 1000 ppm of arsenic in industrial No. 2 antimony is reduced to less than 10 ppm, the recovery rate of antimony is maintained to be more than 96%, and quality requirements of semiconductor thermoelectric materials and war industries on the raw material--antimony are completely met.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Industrial preparation method of high-yield cinnamaldehyde

InactiveCN102718638AReduce the chance of oxidationLess side effectsOrganic compound preparationCarbonyl compound preparationDistillationBenzaldehyde

The invention provides an industrial preparation method of high-yield cinnamaldehyde. The method includes the following steps of: A, adding a solid catalyst and a water solution of polyethylene glycol 400 to a reaction vessel, then adding benzaldehyde; B, adding dropwisely 30 % to 50% by mass of an acetaldehyde water solution slowly with stirring, after the dropwisely adding, controlling the temperature from 25 DEG C to 30 DEG C for a reaction for 3 to 5 hours; C, performing washing after the completion of the reaction, and allowing the mixture to stand for delamination; and D, performing distillation after separating out an oil layer to obtain the cinnamaldehyde. The method in the invention is advantaged in operational simplicity, easiness in obtaining raw materials and in preparation of the catalyst, simple recovery, environmental friendliness, continuous operation, fast forward reaction speed compared with common processes, low probability of a side reaction, reduced unit energy consumption of a product as well as stable quality, high yield, and high purity of the produced cinnamaldehyde.

Owner:湖北远成赛创科技有限公司

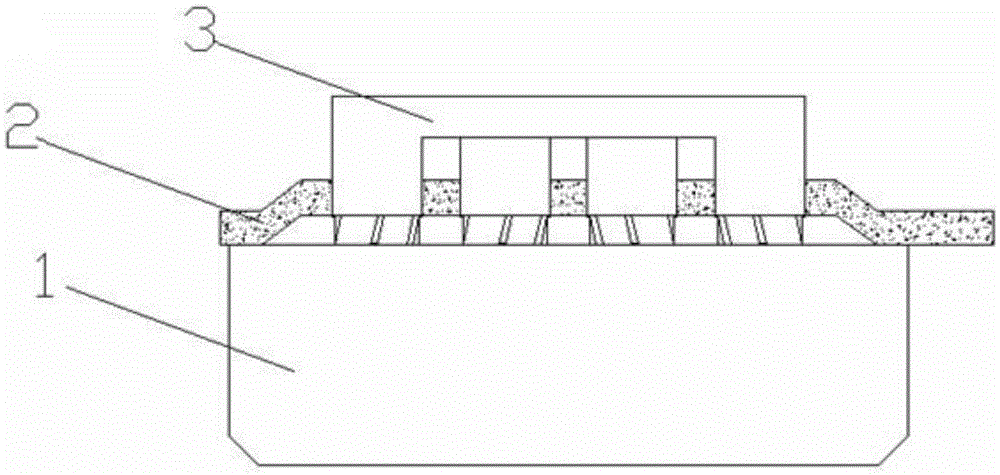

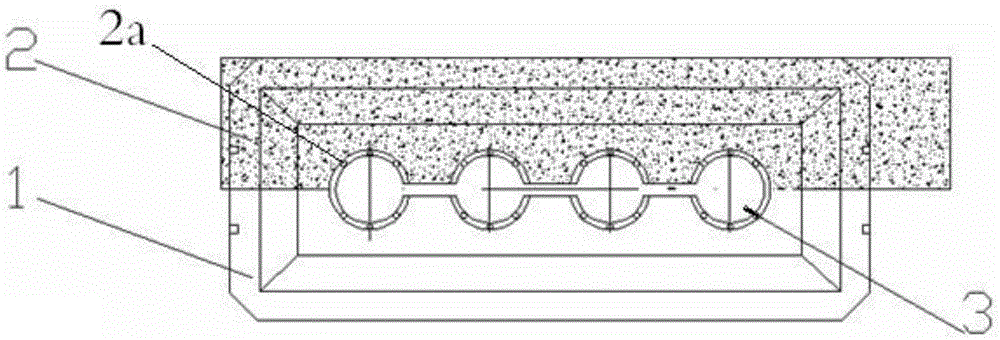

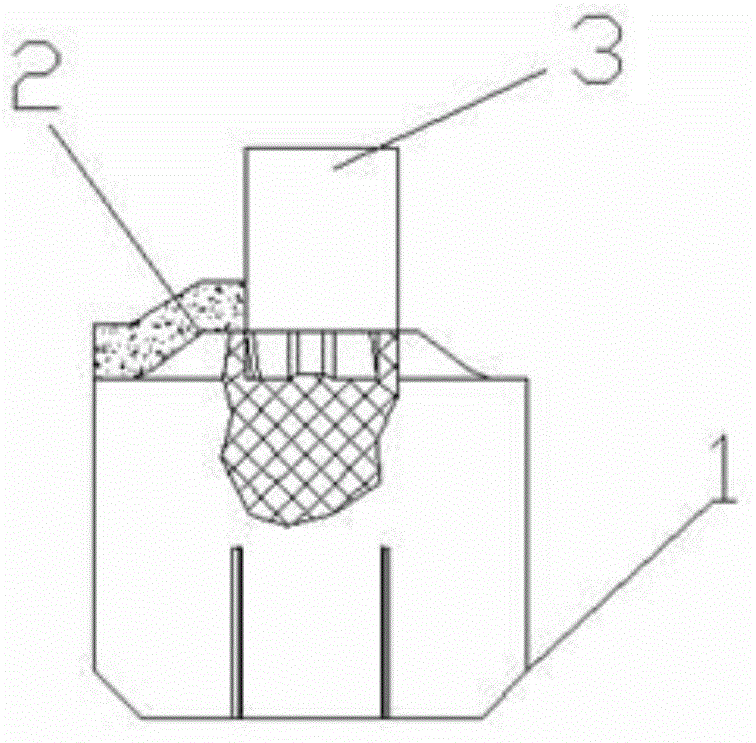

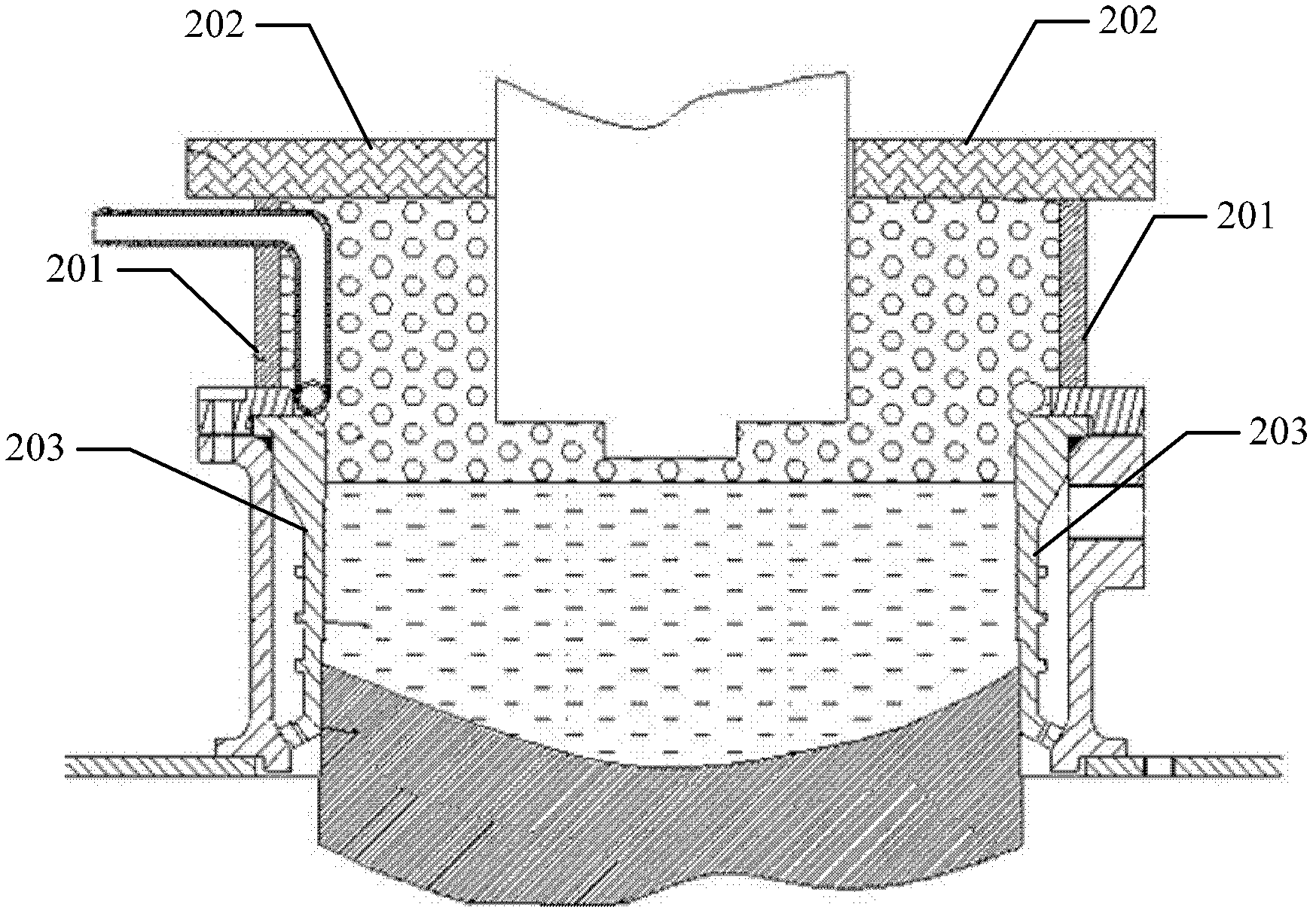

Preparing method and using method of aluminum electrolytic anode covering device

The invention provides a preparing method and a using method of an aluminum electrolytic anode covering device. The preparing method comprises the steps of agitating and leaching dross generated in aluminum electrolysis remelting aluminum ingot production or aluminum alloy smelting process with water to obtain slurry, then washing leached residues obtained by pressing and leaching the slurry through three sections of reversed flow to obtain cleaned residues and then pressing the cleaned residues into the anode covering device. The anode covering device (2) comprises at least four semicircular through holes (2a) where anode steel claws are arranged. The using method is that two anode covering devices are symmetrically arranged on the upper surface of an anode carbon block and then are arranged into an electrolytic cell together, the gaps between anodes and the gaps between the anode steel claws and the anode covering devices are coated and sealed by aluminum ash cleaned residues, the spaces formed between middle joints and hearths are filled with and sealed by covering material shell blocks of the electrolytic cell and aluminum ash cleaned residues. By means of the preparing method and the using method, the problems that aluminum electrolytic anode covering is complex in operation and large in labor intensity of workers are solved, and recycling of waste aluminum ash is achieved.

Owner:YUNNAN RUNXIN ALUMINUM +1

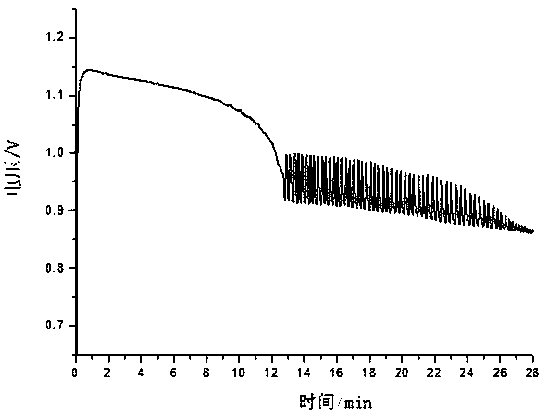

Method for authenticating truth or falsity of polyurethane water-borne wood paint on the basis of nonlinear fingerprint graph

ActiveCN109556932AGuaranteed demulsification effectPromote stratificationPreparing sample for investigationMaterial analysis by electric/magnetic meansEmulsionReduced properties

The invention belongs to the technical field of water-borne wood paint authentication, and particularly relates to a method for authenticating the truth or falsity of polyurethane water-borne wood paint on the basis of a nonlinear fingerprint graph. A water-borne wood paint sample is subjected to preliminary treatment to quicken the layering of sample emulsion, so that an organic phase and an inorganic phase are fully separated, and an emulsion breaking effect on samples is guaranteed; the method is convenient for subsequent detection; if acrylic acid water-borne wood paint is doped in the polyurethane water-borne wood paint, during detection, acrylic acid emulsion subjected to acidolysis in sulfuric acid solution generates acrylic acid with reducing properties; and the above products aremixed in a B-Z vibration system consisting of H+, BrO3, Mn2+ and acrylic acid, a sample to be authenticated and a standard sample are compared according to the extraction characteristic parameters ofthe nonlinear fingerprint graph, and the variety as well as the truth or falsity of the sample to be authenticated can be authenticated according to an integral similarity. In addition, the method hasthe advantages of being good in reproducibility, short in operation time, economic and the like, and is suitable to be widely prompted and applied in authentication fields of the polyurethane water-borne wood paint.

Owner:HANDAN COLLEGE

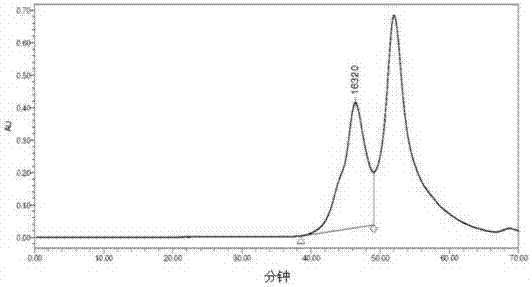

Production technology of green tea extract with high EGCG content

InactiveCN107721967AReduce the chance of oxidationReduce consumptionOrganic chemistryDigestionProduction cycle

The invention provides a production technology of a green tea extract with a high EGCG content. In the production technology of the invention, the green tea extract is prepared by methods of digestion, adsorption, concentration, extraction, concentration drying, crystallization, drying and pulverization. The production technology of the green tea extract with the high EGCG content is simple and convenient, has high separation efficiency and short production cycle, and is low in cost and is suitable for large-scale and industrial production of the green tea extract with the high EGCG content.

Owner:浙江天草生物科技股份有限公司

Process for preparing aluminium alloy damping cylinder

This invention relates to the aluminum alloy damping canister production for motorcycle absorber, which uses aluminum silicon alloy containing more then 6% silicon and continious furnace, and polybasic new type alternative deteropate disposal, and it uses conduct to continiously inbreathe gas N2 into the continious furnace liquid outlet; the advantage of this invention is that the surface air hole occur rate is low, corrosion resistant capability is strong, and it produces fewer waste residue.

Owner:陈月丹

Surface metallization process of dielectric ceramic filter

ActiveCN112779494AImprove work performanceReduce the chance of oxidationVacuum evaporation coatingSputtering coatingOrganic solventConductive coating

The invention belongs to the field of nonmetal surface metallization, and particularly relates to a surface metallization process of a dielectric ceramic filter. The surface metallization process comprises the following steps of ultrasonically cleaning the dielectric ceramic filter by using an organic solvent; carrying out high-temperature baking and heat preservation; then charging into a furnace, vacuumizing, heating and preserving heat; introducing argon into the furnace, and starting a Hall ion source to carry out sputtering cleaning on the surface of the dielectric ceramic filter; stopping introducing argon, and injecting metal ions into the surface of the dielectric ceramic filter by adopting a high-energy pulse ion injection method and a metal target; adopting a magnetron sputtering method, introducing argon and reducing gas, adoptinng a metal target, and depositing a metal layer on the surface of the metal layer subjected to ion implantation; and continuously introducing argon, and taking out the dielectric ceramic filter from the furnace after the dielectric ceramic filter is cooled. By means of the process, the film-substrate binding force between the ceramic substrate and a surface metal conductive coating can be effectively improved, and the dielectric ceramic filter obtained after metallization treatment has good electrical performance.

Owner:SOUTHWESTERN INST OF PHYSICS

Extraction method for panax notoginseng saponins

The invention provides an extraction method for panax notoginseng saponins. The extraction method comprises the following steps: enzymolysis treatment, aqueous extraction, macroporous resin adsorption, activated carbon adsorption and cation exchange resin adsorption, wherein citric acid is added for anti-oxidization in the step of aqueous extraction, so that the quality and yield of the product can be increased. The method adopts water as a solvent for digesting pseudo-ginseng and is beneficial to the reduction of residual organic solvent in the product.

Owner:四川奇格曼药业有限公司

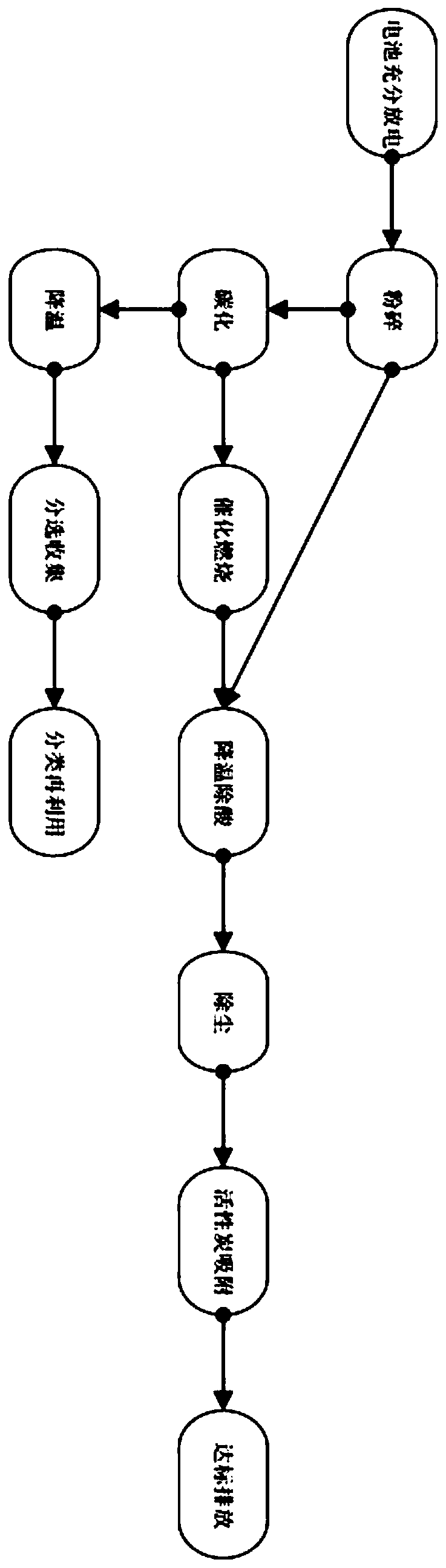

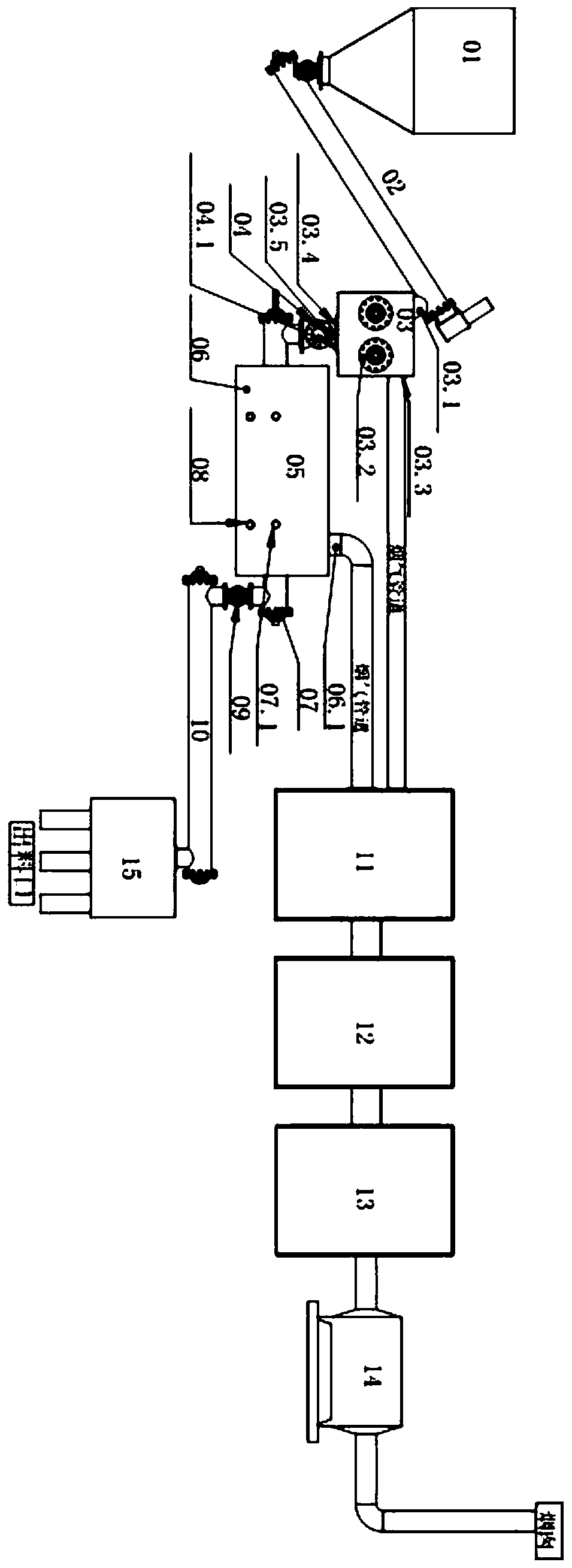

Continuous carbonization and pyrolysis treatment method of waste lithium battery

PendingCN111271711ARealize continuous automationImprove processing efficiencyIncinerator apparatusCentral heating systemThermodynamicsProcess engineering

The invention provides a continuous carbonization and pyrolysis treatment method of a waste lithium battery. The method adopts the following treatment flow of step 1, preheating, specifically, preheating a carbonization device to a working temperature; step 2, pretreating, specifically, discharging and crushing the lithium battery, wherein firstly, the lithium battery is put into a temporary storage tank after being subjected to full discharge and enters a crusher through a closed conveying device, and after crushing, mixed materials enter the carbonization device; step 3, performing a carbonization and pyrolysis treatment process and a gas combustion process; step 5, performing a tail gas treatment process; and step 6, sorting solid materials discharged from the carbonization device. According to the treatment method of the waste lithium battery, isolation between a carbonization chamber and gas combustion in the carbonization process is realized, the mixed materials obtained after the waste lithium battery is crushed are heated through the indirect heat transfer mode between gas combustion as well as an auxiliary heating device and the carbonization chamber, oxygen is completelyisolated in the carbonization chamber, and oxidation of metal in the carbonization chamber is effectively avoided through the control by means of the pressure difference and a one-way valve, so that the utilization value of the final product is improved.

Owner:上海智迭科技有限公司

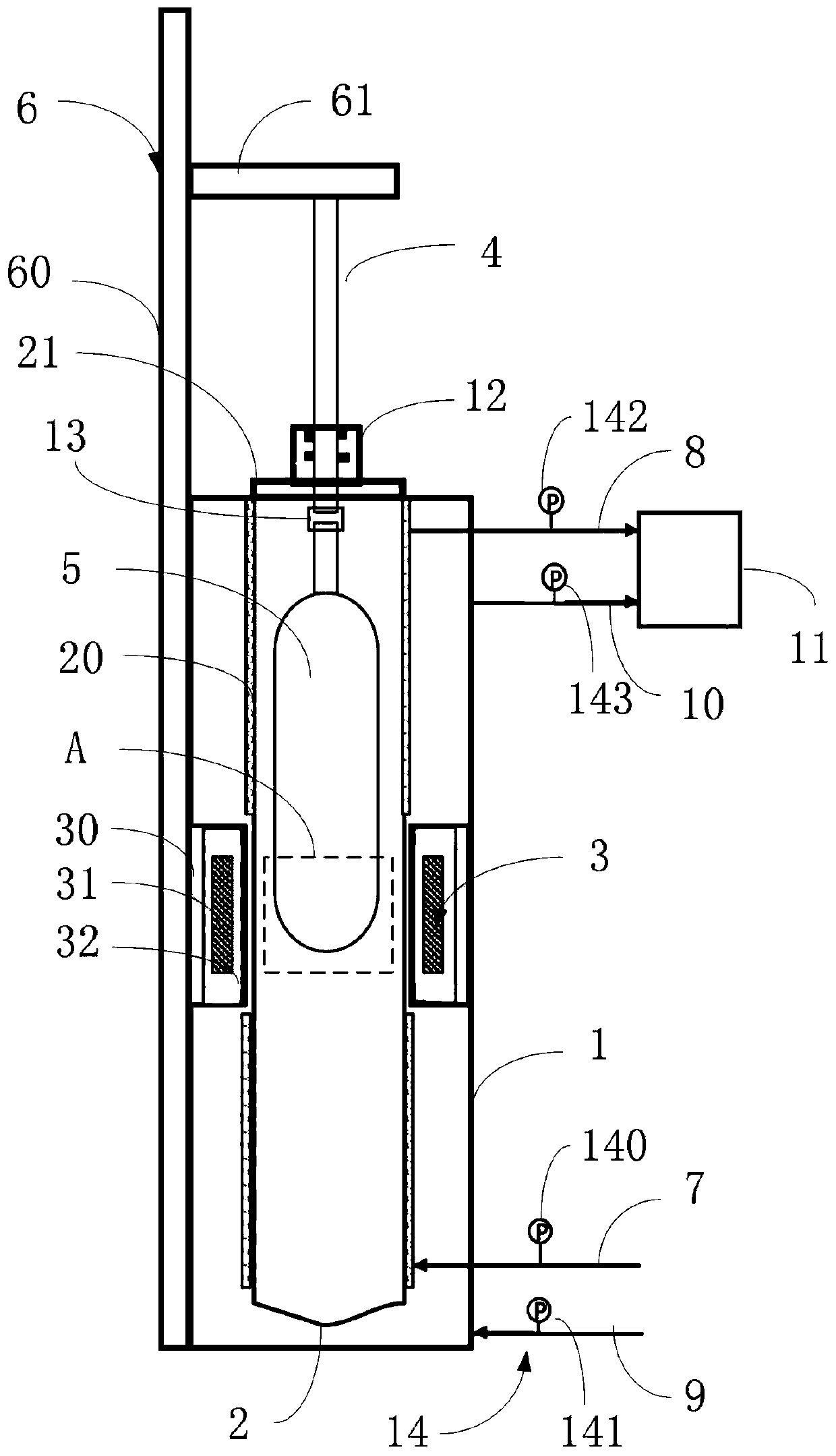

Sintering device and sintering method for optical fiber preform loose body

InactiveCN111423106AReduce defectsRemove completelyGlass making apparatusGlass productionExhaust pipeCore (optical fiber)

The invention relates to a sintering device and method for an optical fiber preform loose body. The sintering device comprises a sintering box body, a furnace core pipe, a heating assembly, a guide rod, a rod feeding mechanism, a first pipe set and a second pipe set. The furnace core pipe and the heating assembly are assembled in the sintering box body, and the heating assembly forms a heating area; the guide rod extends into the furnace core pipe and is used for being connected with a preform loose body; the rod feeding mechanism is connected with the guide rod and is used for driving the guide rod to move, so that the preform loose body is heated in the heating area; the first pipe set penetrates through the sintering box body and the wall surface of the furnace core pipe, is communicated with the inner cavity of the furnace core pipe and comprises a first gas inlet pipe and a first gas outlet pipe; the second pipe set penetrates through the wall surface of the sintering box body, iscommunicated with the inner cavity of the sintering box body and comprises a second air inlet pipe and a second air outlet pipe. The invention integrates dehydroxylation, vitrification sintering anddeuterization, can effectively eliminate gas residues in the optical fiber preform, reduces the use amount of He, and eliminates structural defects from the manufacturing source of the optical fiber preform, thereby reducing the hydrogen sensitivity of the optical fiber.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

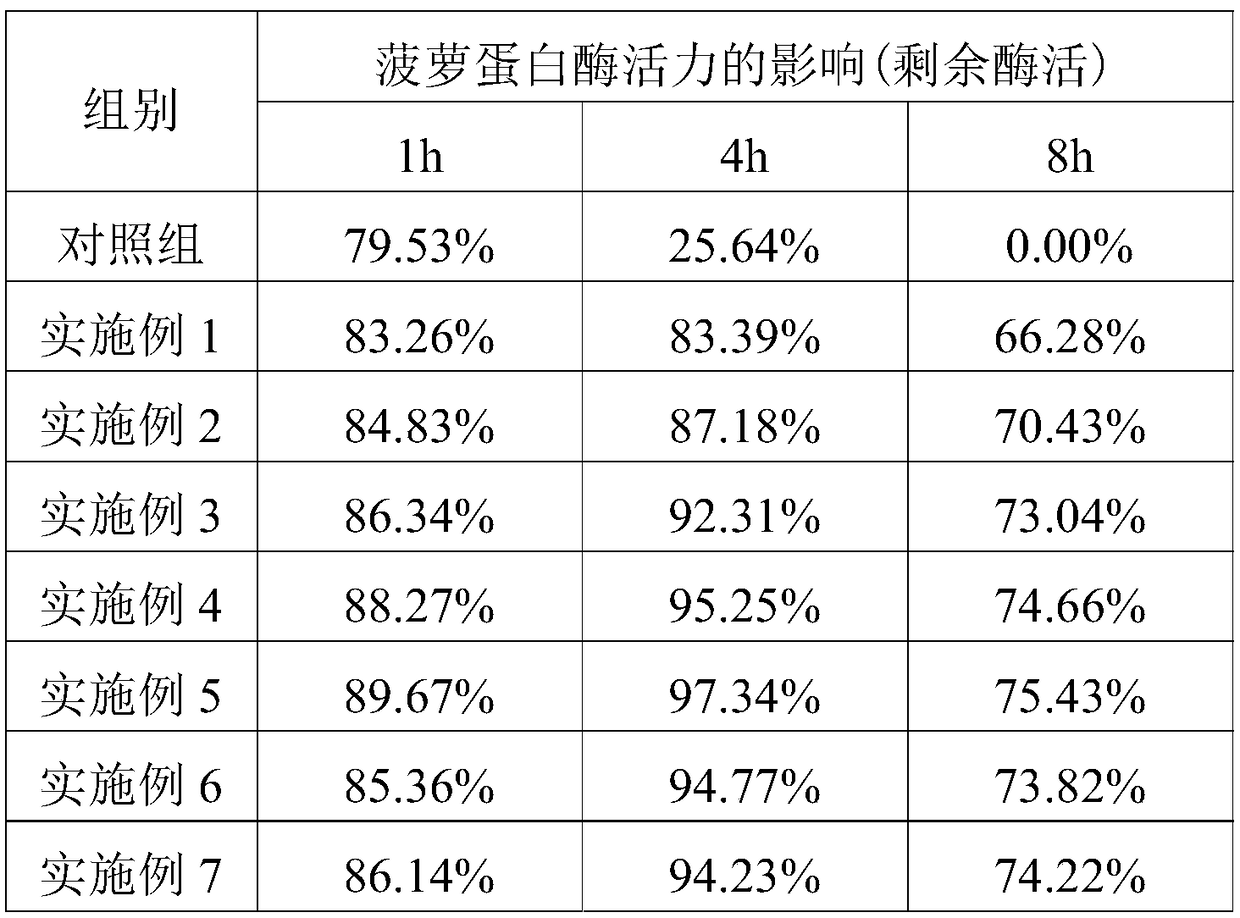

Bromelain stabilizer and preparation method and application thereof

ActiveCN108977428AExtended half-lifePrevent free sulfhydryl oxidationEnzyme stabilisationPeptidasesHalf-lifePreservative

The invention discloses a bromelain stabilizer and a preparation method and application thereof, and relates to the technical field of biology. The bromelain stabilizer is prepared from the followingcomponents in parts by weight: 0.015 to 0.13 part of reductant, 0.002 to 0.07 part of metal ion chelating agent, 0.01 to 0.09 part of organic carboxylate, 0.05 to 0.15 part of preservative, and 0.001to 0.02 part of vitamin. The bromelain stabilizer has the advantages that the effect of protecting enzyme activity is obvious, the loss of enzyme activity is reduced, the half-life period of enzyme isshortened, the usage amount is small, the cost is low, and the like. The preparation method has the advantages that the operation is simple, and the preparation method is suitable for industrializedproduction; the bromelain stabilizer can be directly added inr the process of storage of enzyme solid powder or production of liquid enzyme, and the application range is broad.

Owner:CHONGQING JOYWIN NATURAL PROD

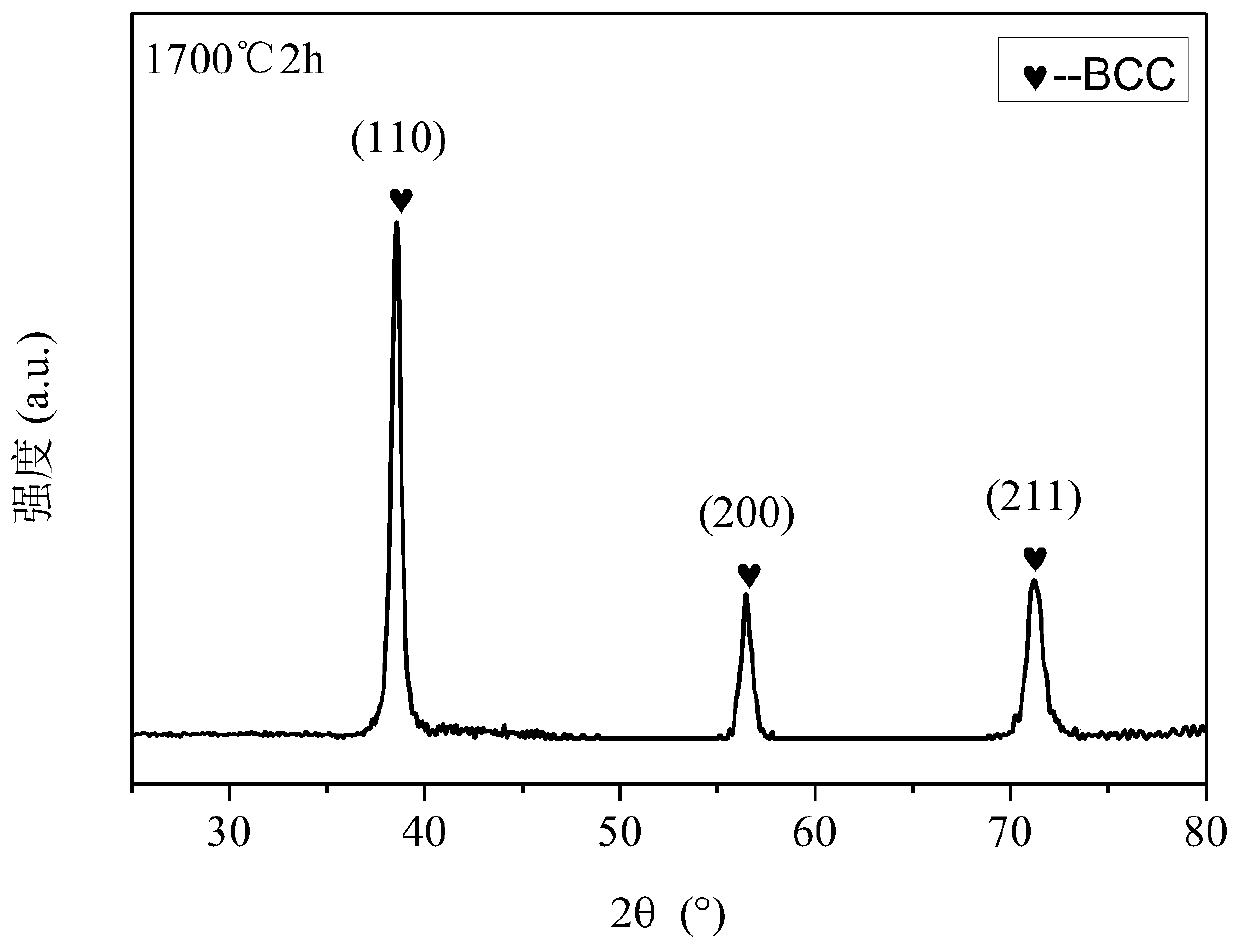

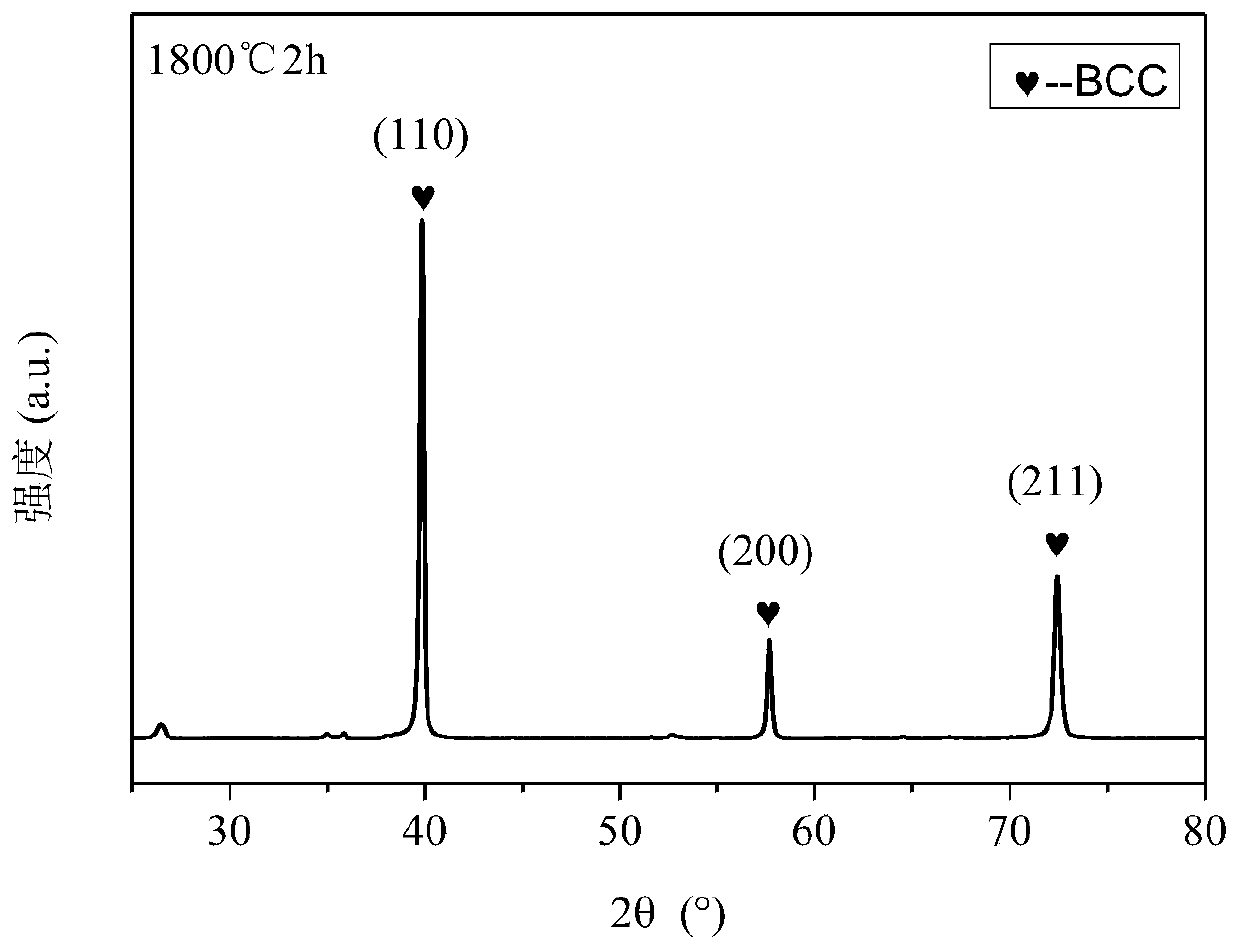

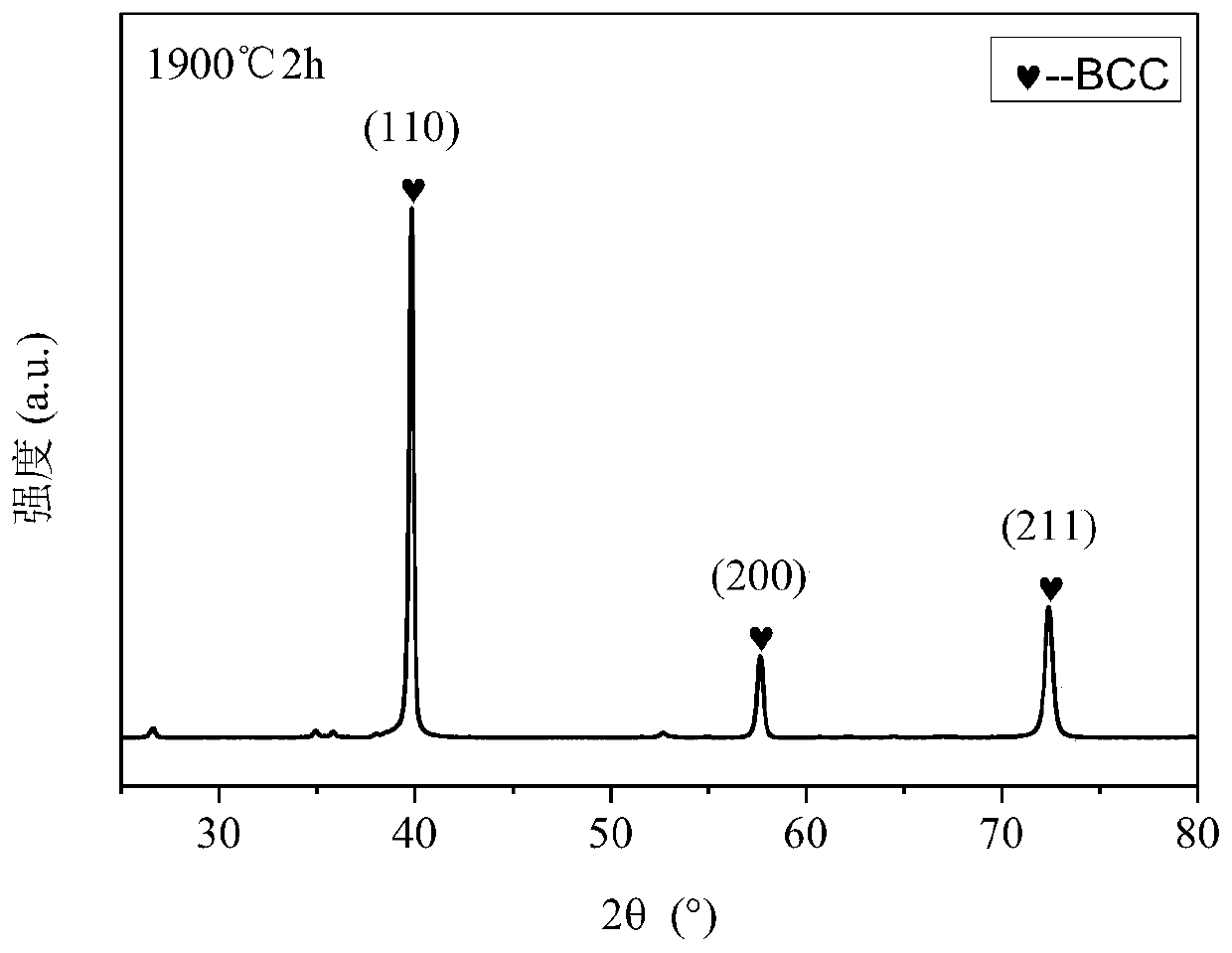

Preparation method of VNbMoTaW high-entropy alloy

ActiveCN111411249ASimple preparation processReduce the chance of oxidationHigh entropy alloysMelting Point Temperature

The invention discloses a preparation method of a VNbMoTaW high-entropy alloy. The preparation method of the VNbMoTaW high-entropy alloy comprises the following steps that simple substance powder of W, Mo, V, Nb and Ta are mixed by adopting a mechanical alloying method firstly, ball milling is carried out without adding a ball milling medium to obtain single-phase or double-phase single-body centripetal cubic structure VNbMoTaW high-entropy alloy powder, then hot-pressing sintering is adopted, the pressure ranges from 30 MPa to 50 MPa, the heating rate ranges from 5 DEG C / min to 15 DEG C / min,the heat preservation temperature ranges from 1700 DEG C to 1900 DEG C, and the VNbMoTaW high-entropy alloy block with the single-phase single-body centripetal cubic structure and the density larger than 99.5% is obtained. The preparation method of the VNbMoTaW high-entropy alloy is simple in process, a block material with good performance can be obtained without being heated to the melting pointtemperature, the processing temperature is effectively reduced, the preparation cost is lower, and a very high industrial application value is achieved.

Owner:NAT UNIV OF DEFENSE TECH

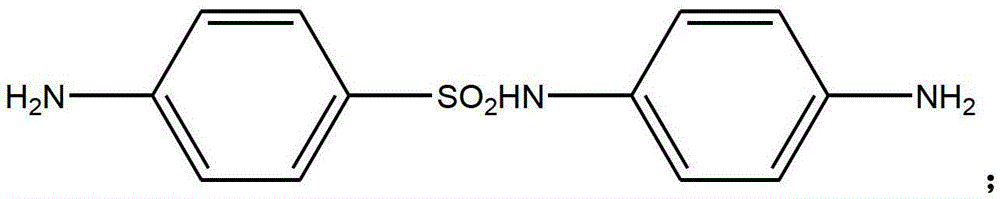

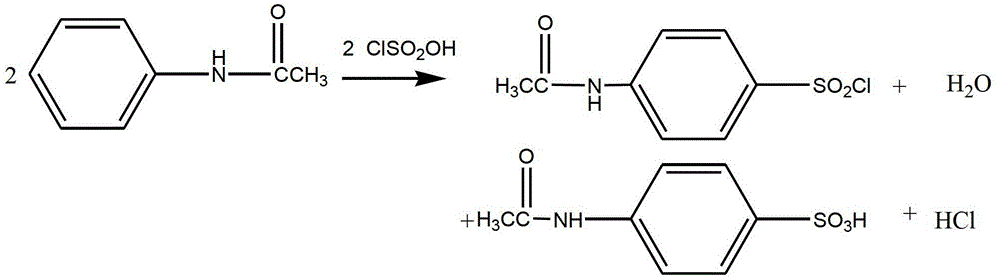

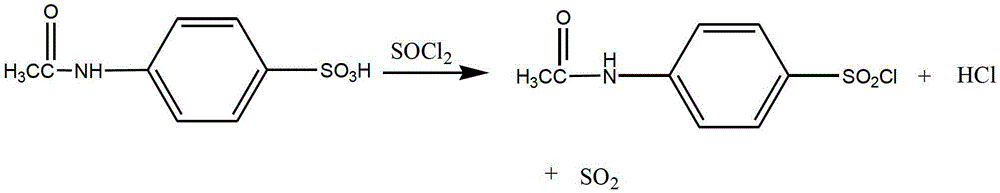

Preparation method of 4,4'-diaminobenzenesulphonamide

InactiveCN103145593AAvoid excessive oxidationHigh puritySulfonic acid amide preparationCell separationHydrolysis

The invention discloses a preparation method of 4,4'-diaminobenzenesulphonamide. The method comprises the following steps of: based on acetanilide, chlorosulfonic acid, thionyl chloride, water, liquid caustic soda, p-phenylenediamine and the like as raw materials, implementing chlorosulfonation, ice separation, condensation, hydrolysis, neutralization, filter pressing and other processes to obtain the target product 4,4'-diaminobenzenesulphonamide. 4,4'-diaminobenzenesulphonamide prepared by the method disclosed by the invention is good in stability, quite stable, high in yield, and low in production cost.

Owner:河北永泰柯瑞特化工有限公司

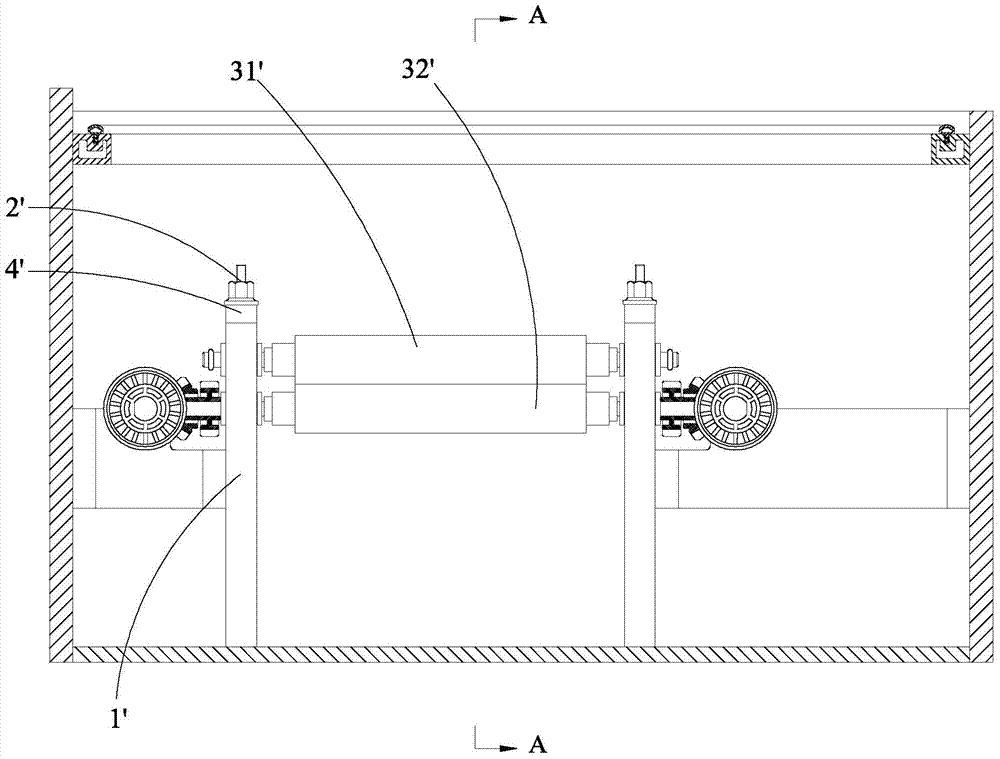

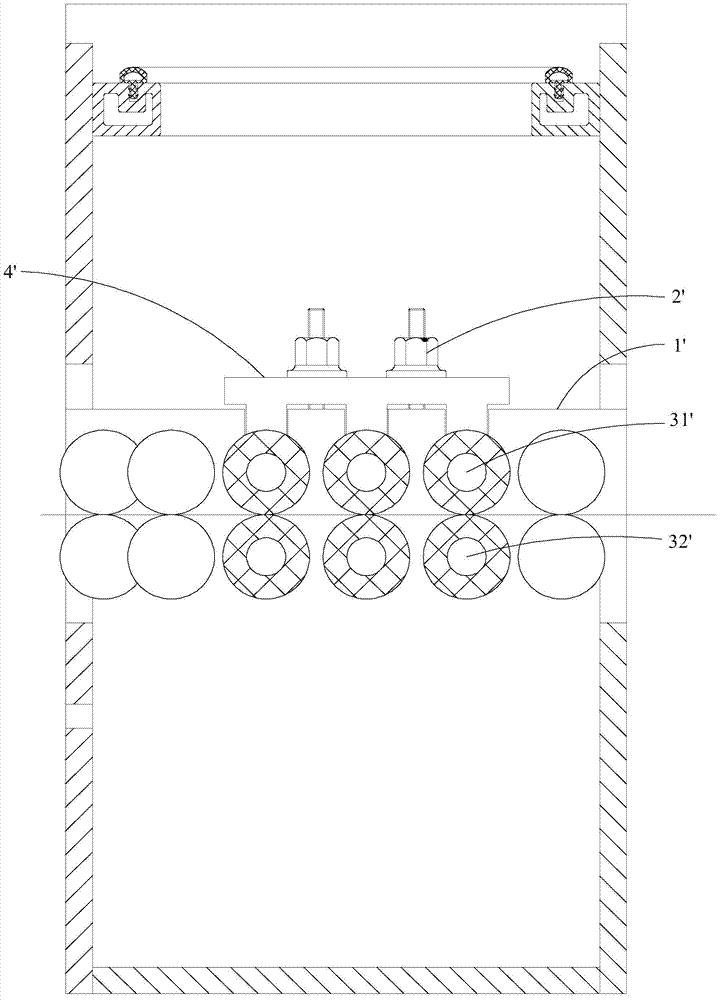

Water suction windlass device

ActiveCN104754872AImprove the phenomenon of the posterior bandImprove the phenomenonConductive pattern polishing/cleaningEngineeringExtrusion

The invention relates to the technical field of water washing equipment for circuit boards and discloses a water suction windlass device used for extruding, sucking and etching liquid on the circuit board. The water suction windlass device comprises an isolation groove, a stand firmly arranged in the isolation groove, a water suction windlass group arranged on the stand and used for extruding and sucking the liquid on the circuit board, and a transmission device arranged on the stand and used for driving the water suction windlass group to rotate axially, and moreover, the stand is provided with a water press windlass for extruding the water suction windlass group, an angle is formed between the water press windlass and the water suction windlass group, and spiral water extrusion threads are formed in the outer wall of the water press windlass. According to the water suction windlass device, the water press windlass with water extrusion threads is arranged at the oblique upper side of the water suction windlass group, the water suction windlass group is extruded through the water press windlass, the liquid sucked by the water suction windlass group is extruded towards the two ends through the water extrusion threads, the post-liquid taking phenomenon is reduced, the energy saving and emission reduction demands are satisfied, the circuit board surface oxidization chance is reduced, and the circuit board quality is improved.

Owner:UNIVERSAL P C B EQUIP SHENZHEN

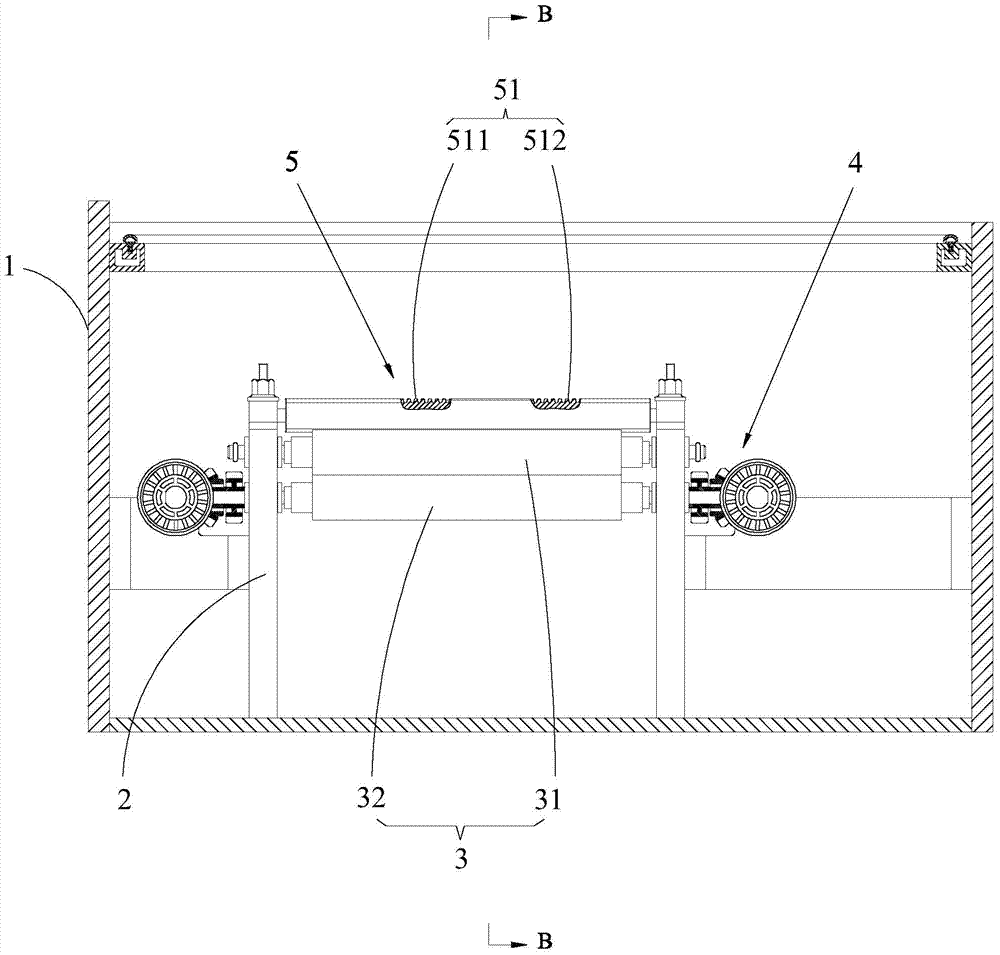

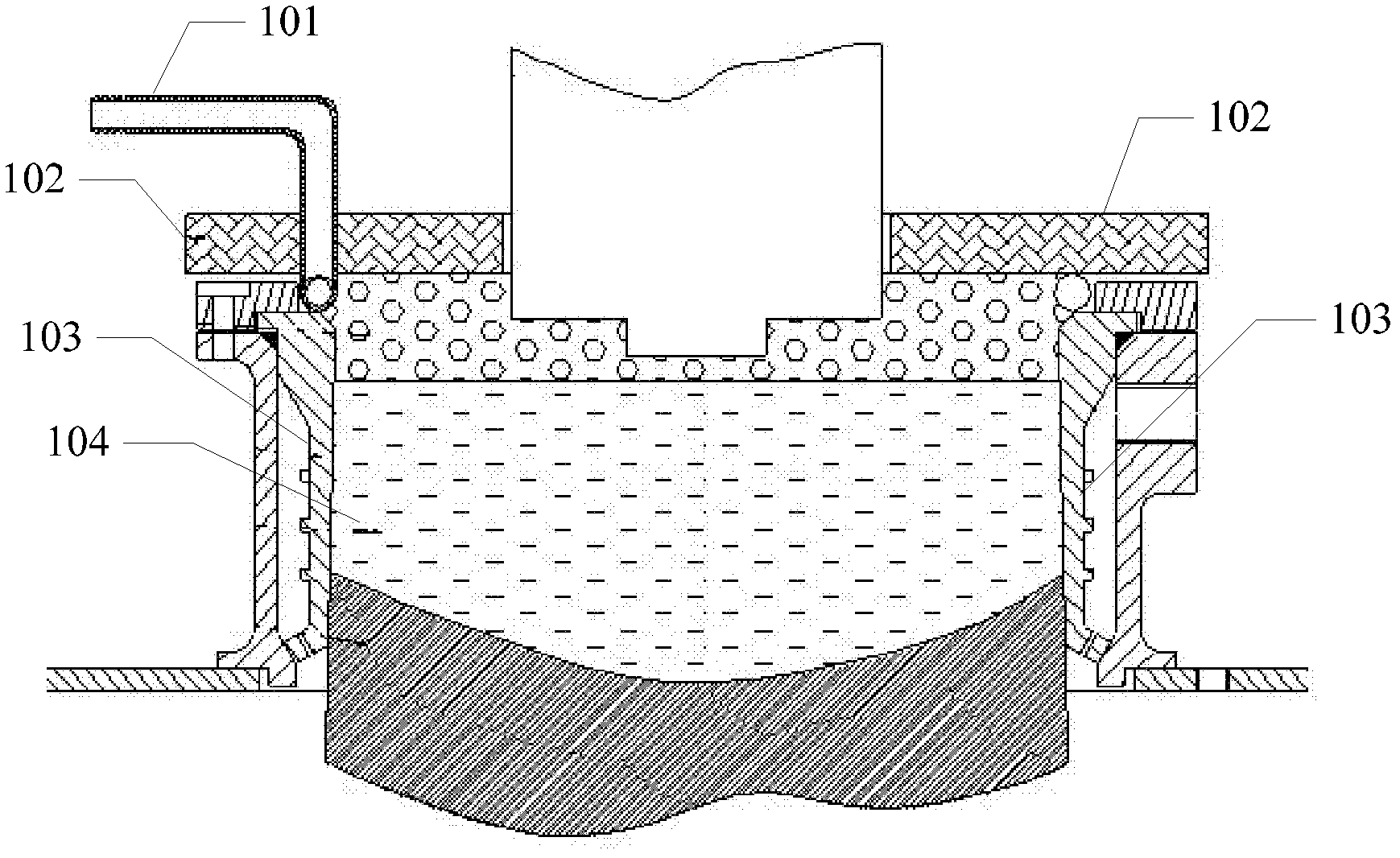

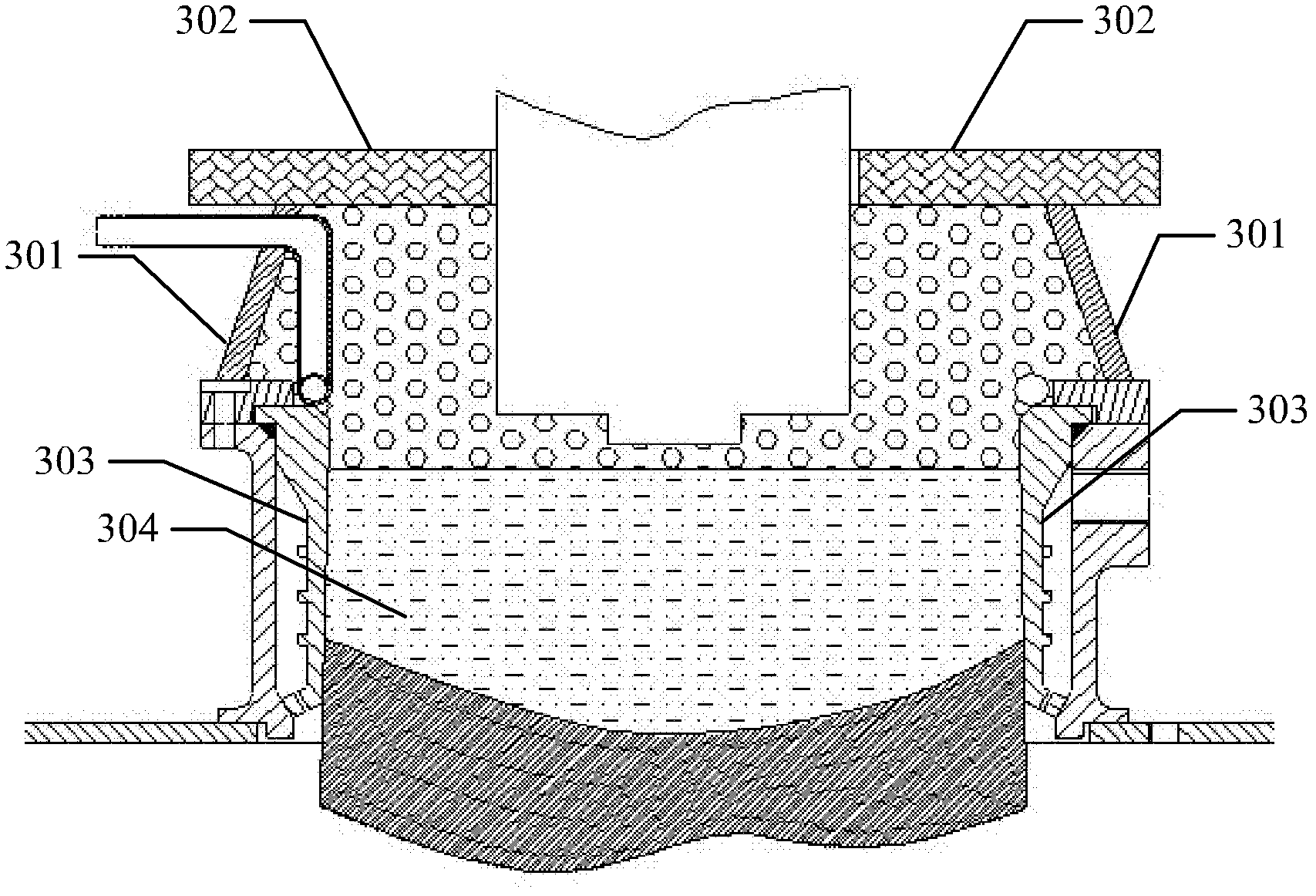

A melt protection device and method

The embodiment of the present invention discloses a melt protection device and method for protecting the melt. The device according to the embodiment of the present invention includes: an inert gas protection ring, an inert gas protection cover, and a crystallizer, and the inert gas protection ring is placed between the lower surface of the inert gas protection cover and the upper edge of the crystallizer, and the gap between the two is increased. distance, the inert gas protective cover is placed on the upper edge of the inert gas protective ring to cover the upper edge of the inert gas protective ring, and the crystallizer is placed under the lower edge of the inert gas protective ring for Holds alloy melt.

Owner:SOUTHWEST ALUMINUM GRP

Preparation method of water-resistant and anti-oxidative protein-based adhesive

InactiveCN108641675AImprove antioxidant capacityPromote hydrolysisNon-macromolecular adhesive additivesProtein adhesivesAntioxidant proteinCarboxylic acid

The invention relates to a preparation method of a water-resistant and anti-oxidative protein-based adhesive and belongs to the technical field of wood adhesive preparation. The preparation method comprises steps as follows: firstly, metallothionein is extracted from the liver of a meat rabbit and mixed with isolated soybean protein for modification, and pre-modified isolated soybean protein is obtained; pine sawdust is taken as a raw material and firstly subjected to ethanol wet milling pretreatment, the pretreated pine sawdust and an organic carboxylic acid solution are blended and subjectedto high-temperature and high-pressure cooking, modified pine sawdust is obtained, finally, the modified pine sawdust is subjected to blending reaction with the pre-modified isolated soybean protein,tourmaline powder and other auxiliary materials, and the water-resistant and anti-oxidative protein-based adhesive is obtained. The prepared water-resistant and anti-oxidative protein-based adhesive is high in adhesion strength, good in water resistance and high in oxidation resistance, is not prone to cracking and falling and has broad application prospect.

Owner:陈毅忠

Preparation method of silicon-free calcium and iron-containing alloy

The invention provides a preparation method of silicon-free calcium and iron-containing alloy. In the method, the alloy is smelted by adopting a metal remelting process. The preparation method comprises the following steps: putting a raw material in a closed smelting furnace for smelting, and casting the smelted raw material in a closed casting chamber; and respectively putting comburents to the smelting furnace and the casting chamber when smelting and casting are carried out, so that the oxygen contents in gases in the smelting furnace and the casting chamber are less than 6% or 5% of gas volume, thereby not supporting combustion and inhibiting the combustion and oxidization of calcium, wherein a fire retardant and / or noble gas are / is injected to the smelting furnace according to the requirement so as to assist inhibiting the combustion and oxidization of calcium, and the noble gas is injected by vacuum for carrying out sealed package or coating a paraffin protection film on the silicon-free calcium and iron-containing alloy so as to prevent the pulverization of alloy. By using the preparation method of the silicon-free calcium and iron-containing alloy, the burning loss and oxidation of calcium are effectively reduced, and the content of calcium in calcium-iron alloy is improved. The preparation method is used for steel-smelting deoxidization and desulfuration.

Owner:谢应凯 +1

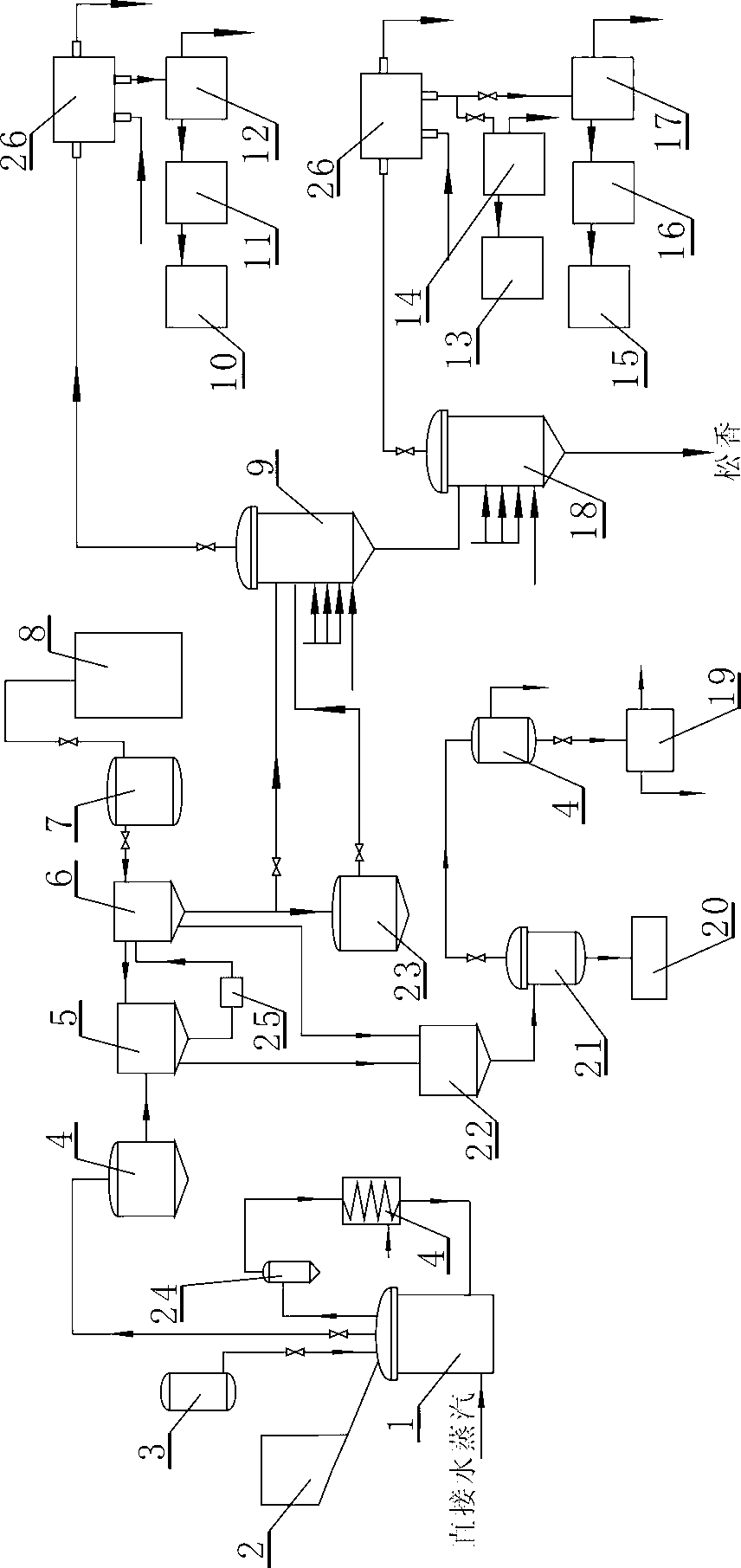

Gum rosin processing unit adopting vacuum filtration method

InactiveCN103059733AFast clarificationReduce chance of oxidationNatural resin purificationRosinChemistry

The invention discloses a gum rosin processing unit adopting a vacuum filtration method, and the gum rosin processing unit comprises a dissolving device, a clarification plant and a distilling device, wherein the dissolving device comprises a dissolving kettle, a hopper and a grease feed tank; the dissolving kettle is connected with a direct water vapor source; the clarification plant comprises a vacuum filtering device and a negative pressure device matched with the vacuum filtering device; the negative pressure device comprises a vacuum cylinder and a low-position water-jet vacuum unit; the distilling device comprises a distilling kettle and a fraction purifying device; a grease liquid outlet of the dissolving kettle is technically connected with an inlet of the vacuum filtering device; a pure grease liquid outlet of the vacuum filtering device is technically connected with the inlet of the distilling kettle; and a distillation outlet of the distilling kettle is technically connected with the fraction purifying device. By replacing the traditional natural sedimentation clarification method by a vacuum filtration method, the gum rosin processing unit disclosed by the invention increases the clarification speed, reduces the time of the grease liquid in a high-temperature environment, increases good quality rate, reduces the amount of intermediate-layer grease liquid, and increases the yield of the product. The method mentioned in the invention is suitable for production of gum rosin adopting an intermittent or continuous vapor method.

Owner:KUNMING GEMING COMMERCE & TRADE CO LTD

Cadmium tellude preparation method

ActiveCN103274372AReduce harmReduce the chance of oxidationBinary selenium/tellurium compoundsGraphiteQuartz

The invention provides a cadmium tellude preparation method, which comprises steps of primary synthesis and secondary synthesis. The primary synthesis comprises the steps: putting tellurium and cadmium which are arranged in a staggered and up-and-down manner into a first graphite boat in a layered manner, putting the first graphite boat in a first quartz tube, and then placing the first quartz tube in a first synthesis furnace; filling first protective gas to discharge air in the first quartz tube; conducting three-section temperature increment, filling the first protective gas into the first section, and filling a first reducing gas into the second and the third section; filling the first reducing gas after the completion of synthesis reaction, and cooling down to an room temperature; and obtaining a first synthetic product. The secondary synthesis comprises the steps: putting the first synthetic product into a second graphite boat after being crushed, placing the second graphite boat into a second quartz tube, and placing the quartz tube into a second synthesis furnace; filling a second protective gas to discharge air in the second quartz tube; conducting two-section temperature increment, filling the second protective gas into the first section, and filling a second reducing gas into the second section; and after the completion of synthesis reaction, stopping heating, filling the second reducing gas, cooling down to the room temperature, so as to obtain a second synthetic product. Due to adoption of the method provided by the invention, the raw materials can be prevented from oxidation and being in contact with poisonous substances.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

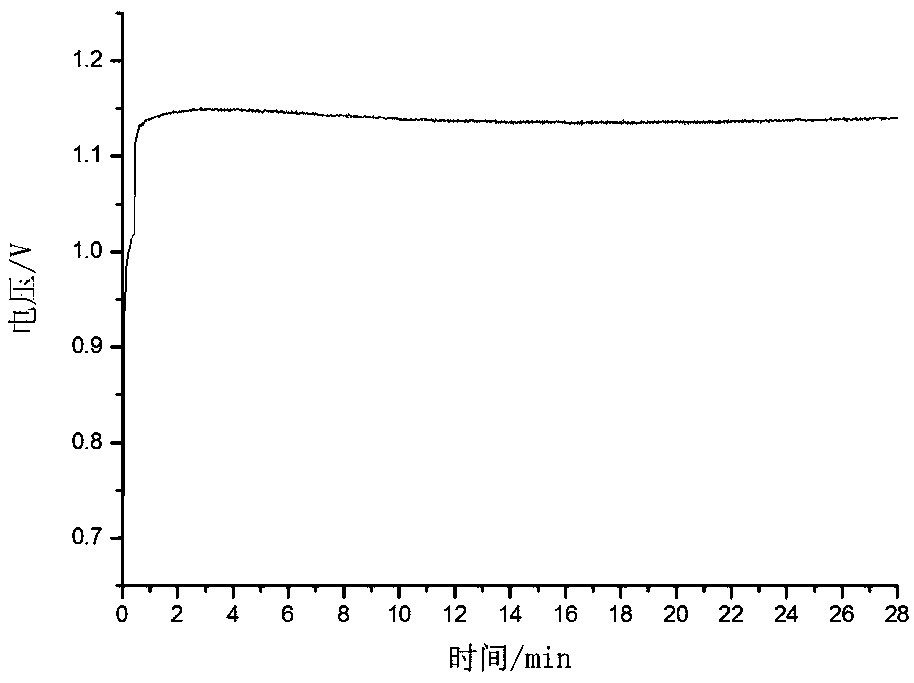

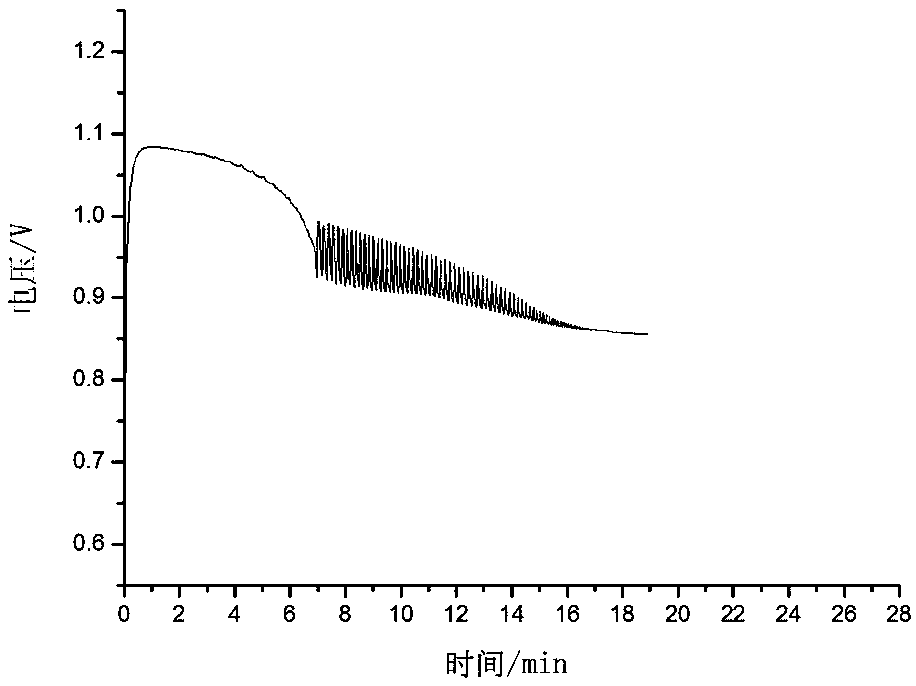

PH-regulated p-type and n-type conversion thermoelectric material and preparation method

PendingCN109841724AGood dispersionImprove conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsType conversion

The invention discloses a pH-regulated p-type and n-type conversion thermoelectric material and a preparation method thereof. The method improves the n-type stability of a polyethyleneimine / carbon nanotube thermoelectric material by polyethyleneimine doping and pH regulation, a pH-regulated p / n conversion polyethyleneimine / carbon nanotube thermoelectric material is provided, and also, a new polyethyleneimine / carbon nanotube thermoelectric material preparation method with simple and convenient operation, good film formation, high conductivity and p / n regulation is provided.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of dendrobe extract at normal temperature

InactiveCN106362001AReduce the chance of oxidationReduce pollutionPlant ingredientsNanoparticlePlasma generator

The invention relates to a preparation method of a dendrobe extract at normal temperature. The method comprises the following steps: drying dendrobe, pulverizing, and adding into an infrared plasma surface modification device, wherein the device comprises a closed vacuumizable shell, an ultrasonic tank arranged in the shell, and an infrared transmitter and a plasma generator which are arranged on the ultrasonic tank; adding water into the ultrasonic tank, and adding Dendrobium officinale polysaccharide nanoparticles; and starting the ultrasonic device, infrared transmitter and plasma generator to perform extraction at normal temperature under the vacuum degree of 10-25 mmHg, and filtering to obtain the dendrobe extract. The method provided by the invention has the characteristics of low energy consumption, high cleanliness, environment friendliness and high yield.

Owner:JIANGSU CHUNSHENTANG PHARMA

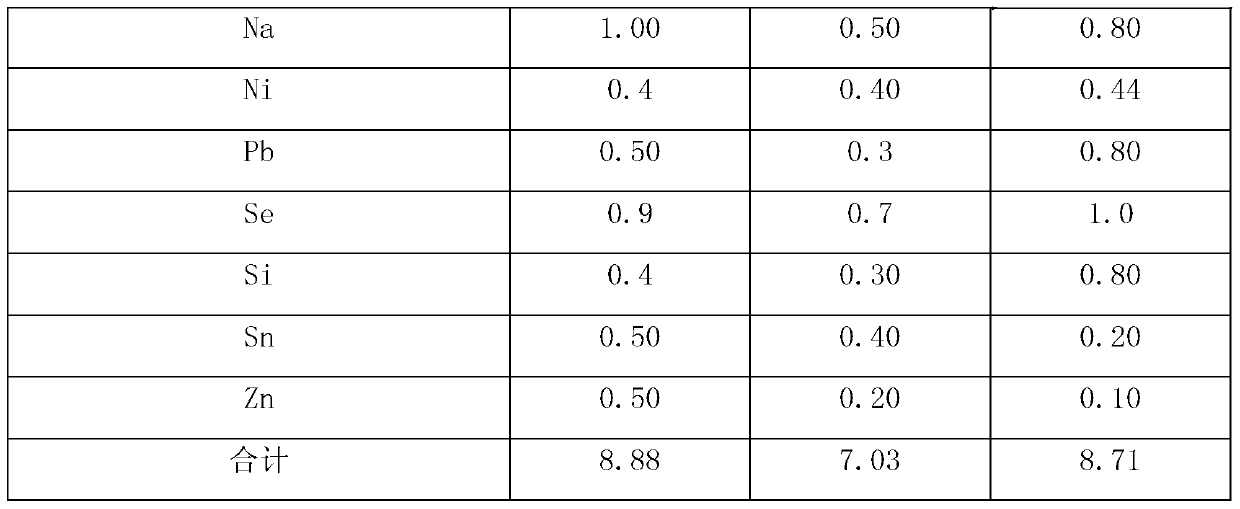

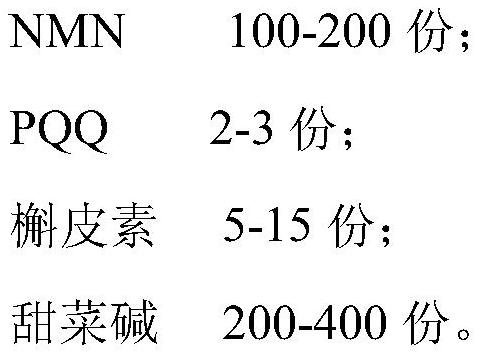

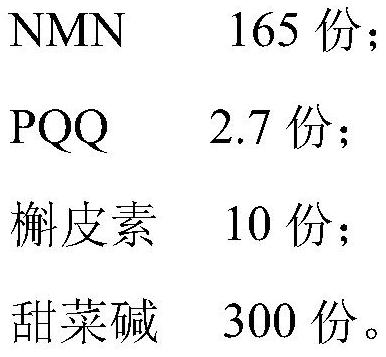

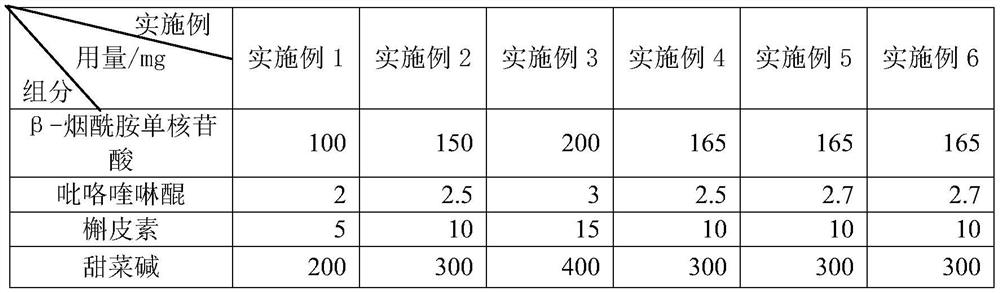

Compound anti-aging composition, compound anti-aging tablet and preparation method and application of compound anti-aging composition and compound anti-aging tablet

InactiveCN113170889AEffective regulation of osmotic pressureReduce stress responseFood freezingFood dryingBetaineMagnesium stearate

The invention relates to the technical field of healthy food, and particularly discloses a compound anti-aging composition, a compound anti-aging tablet and a preparation method and application of the compound anti-aging composition and the compound anti-aging tablet. The compound anti-aging compositio is prepared from 100 to 200 parts of NMN, 2 to 3 parts of PQQ, 5 to 15 parts of quercetin, 200 to 400 parts of betaine and 300 to 400 parts of auxiliary materials, wherein the auxiliary materials comprise one or more of stevioside, calcium phosphate, magnesium stearate and silicon dioxide. According to the compound anti-aging compositio disclosed by the invention, the betaine is matched with the PQQ and the NMN, so that the cell osmotic pressure can be effectively regulated, the intestinal tract is protected, the stress reaction of the compound anti-aging compositio is reduced, and fat metabolism and protein synthesis of a human body are promoted; the effects of promoting energy metabolism of human cells and accelerating metabolism are also achieved while the immunity of the organism is enhanced; and the betaine can effectively reduce the probability that NMN, PQQ and quercetin are oxidized, so that the anti-oxidation, anti-inflammation and anti-aging effects of quercetin, PQQ and NMN on human cells after the quercetin, PQQ and NMN are compounded are further stimulated.

Owner:张祁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com