Patents

Literature

33results about How to "Realize continuous automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

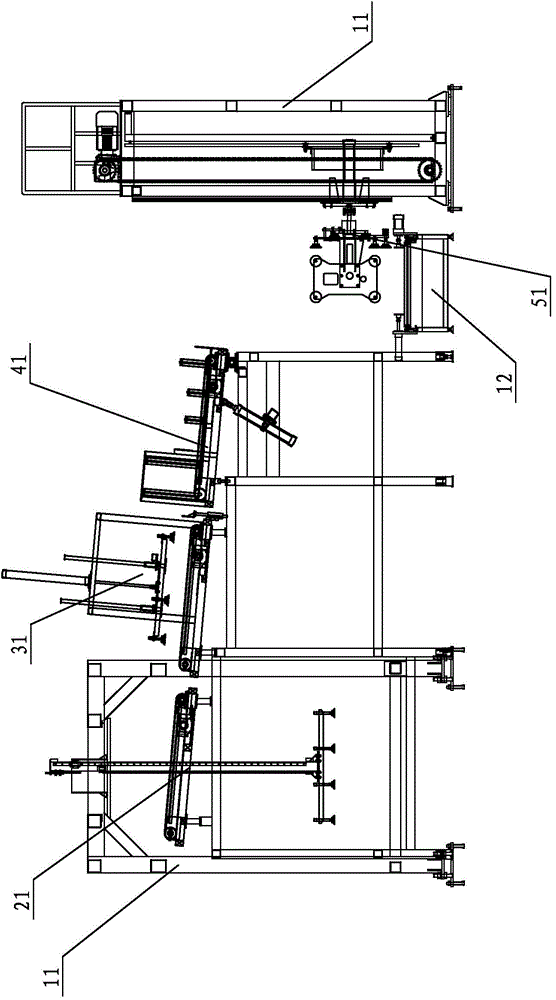

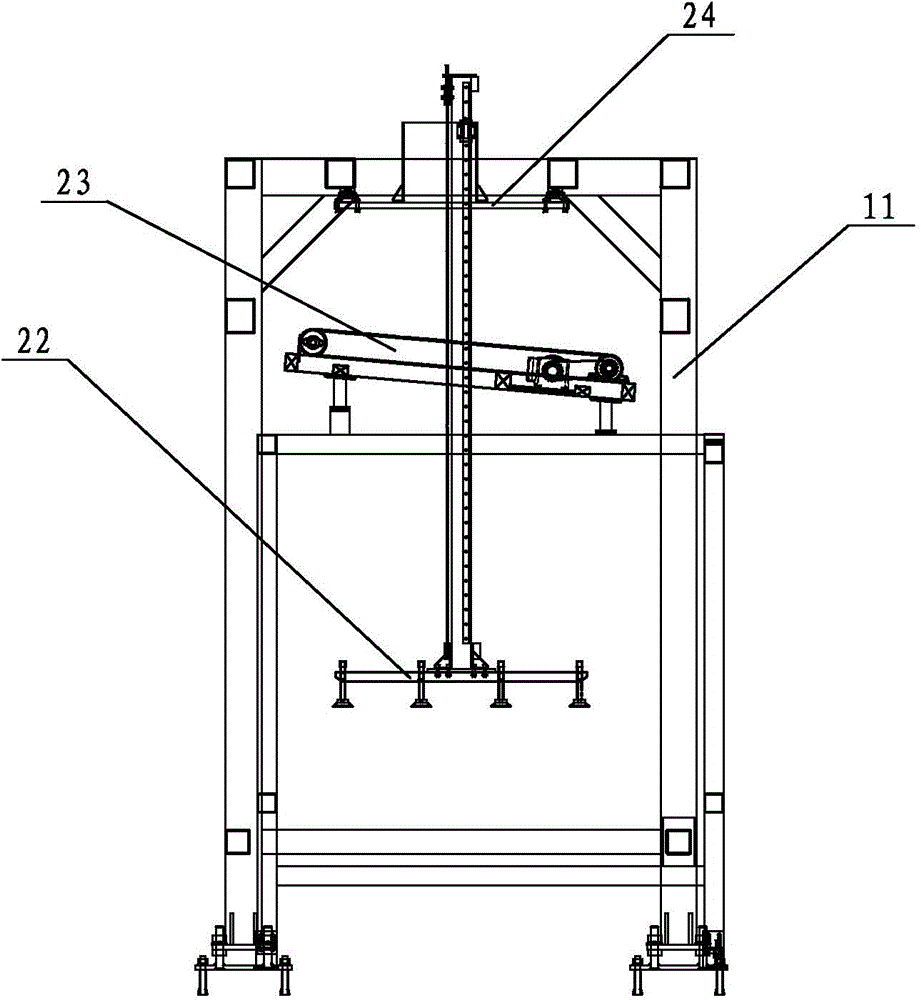

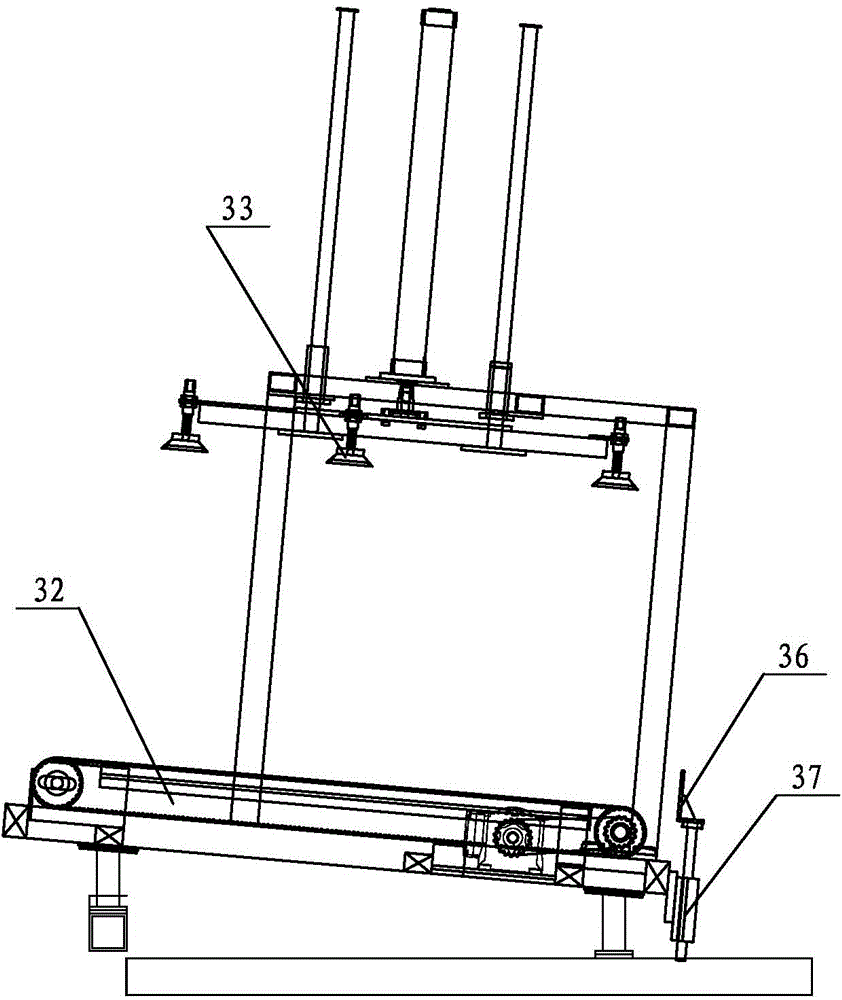

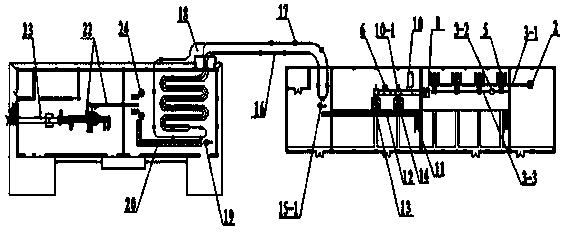

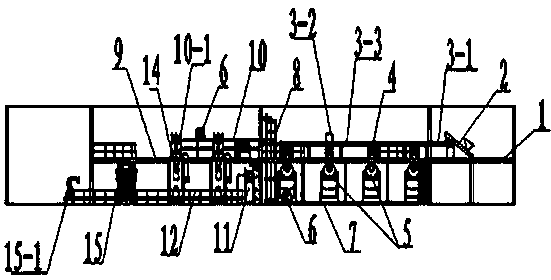

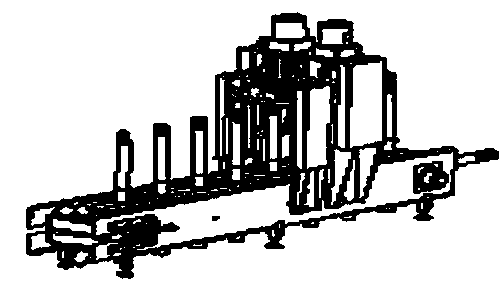

Automatic box covering machine

ActiveCN104787365ARealize continuous automationReduce labor costsIndividual articlesProduction lineCarton

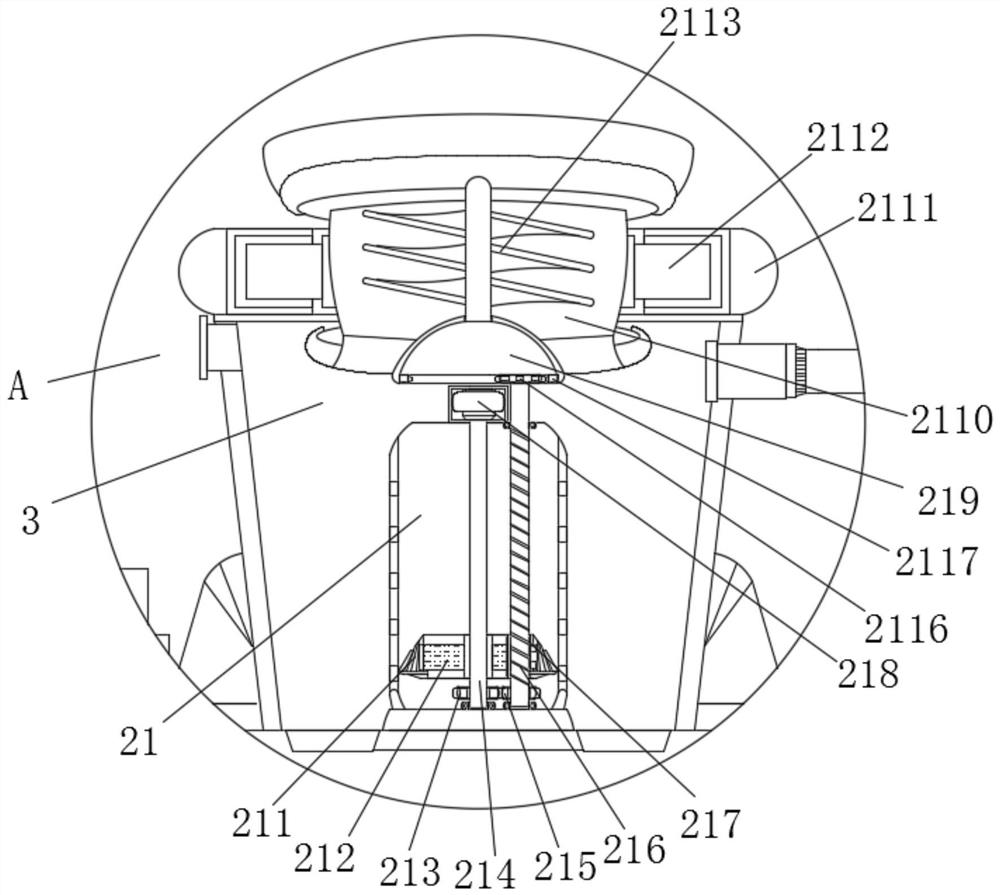

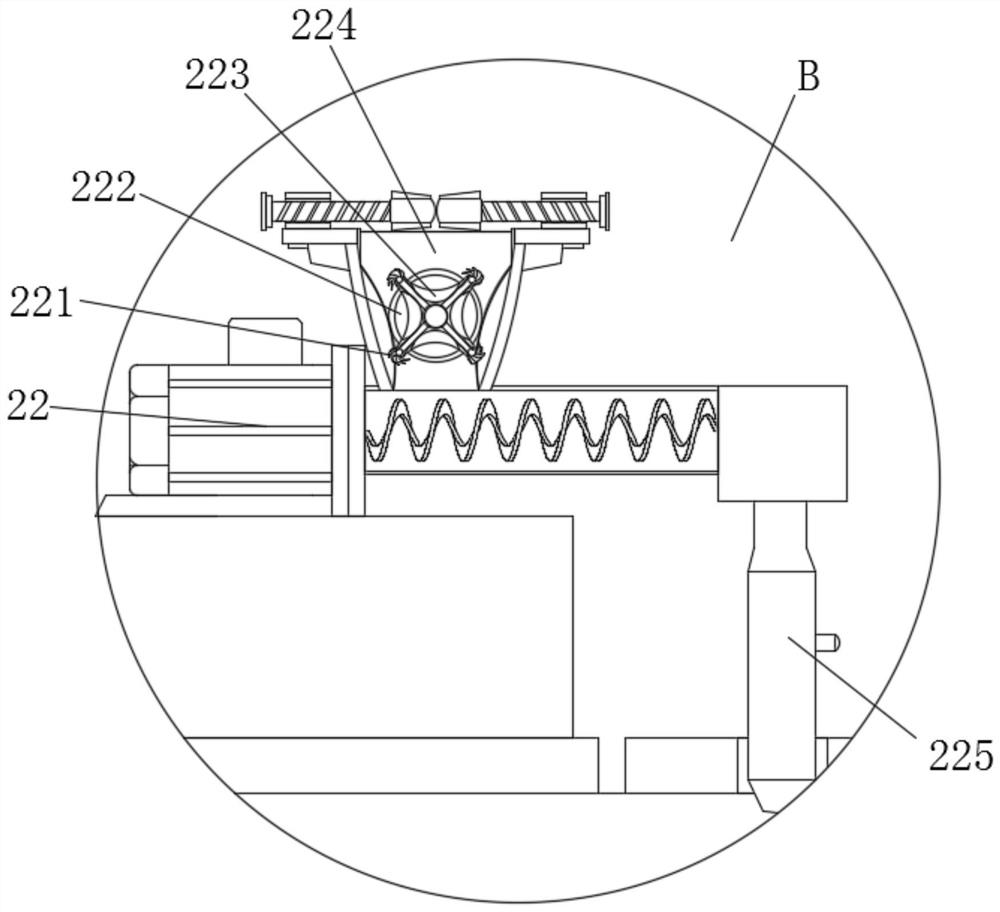

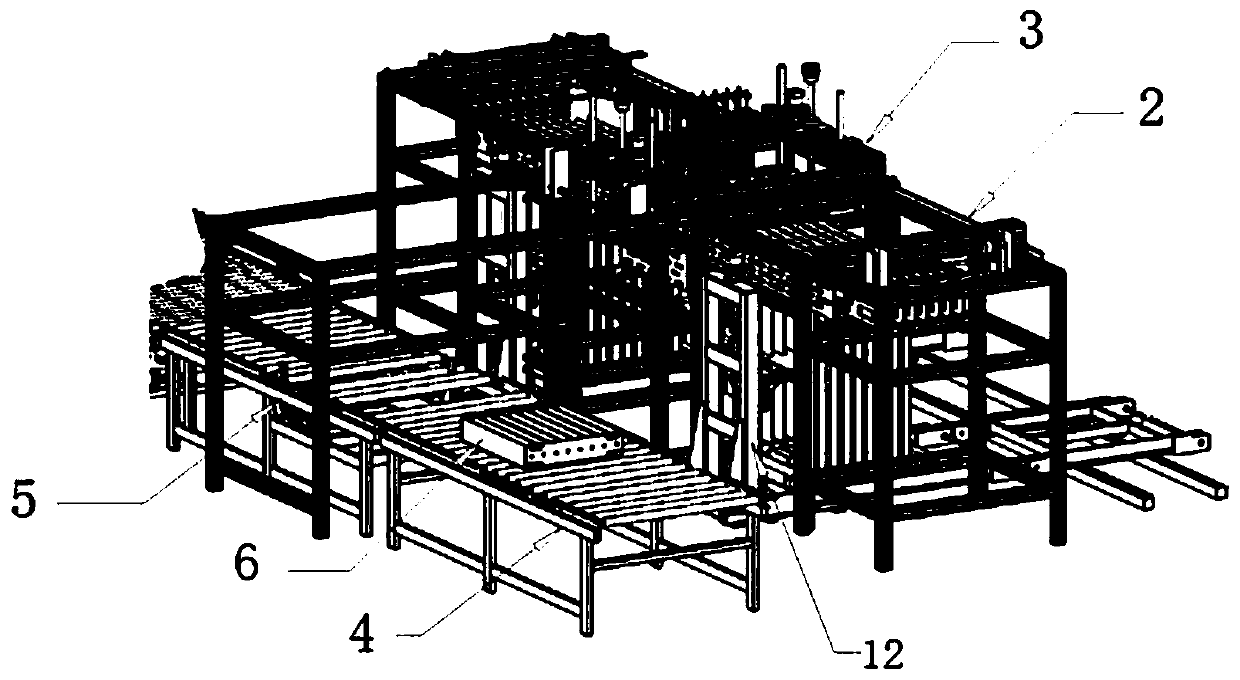

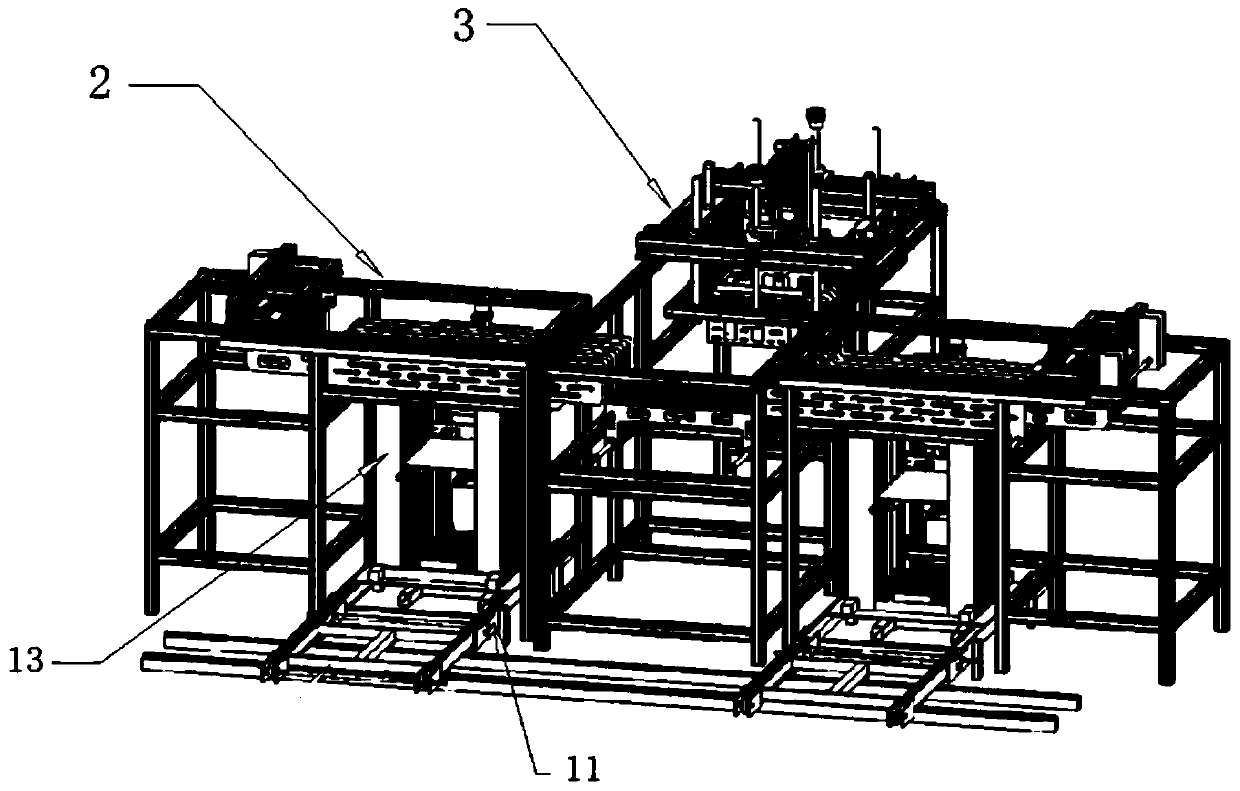

The invention discloses an automatic box covering machine. The machine comprises a bracket, and a flat paper box grabbing unit, a paper box spreading unit, a paper box pushing unit and a box covering unit arranged on the bracket in sequence, wherein a product main production line penetrates through the paper box pushing unit and the box covering unit; and a conveying line 1, a conveying line 2 and a conveying line 3 are all conveying lines operated independently. The machine realizes the continuous automation operation of the process from the flat paper box grabbing to the three-dimensional paper box covering through the combined application of the four units of the flat paper box grabbing unit, the paper box spreading unit, the paper box pushing unit and the box covering unit, so that the labor cost is largely reduced, and the production efficiency is improved.

Owner:SUZHOU YEE FUNG ELECTRIC EQUIP

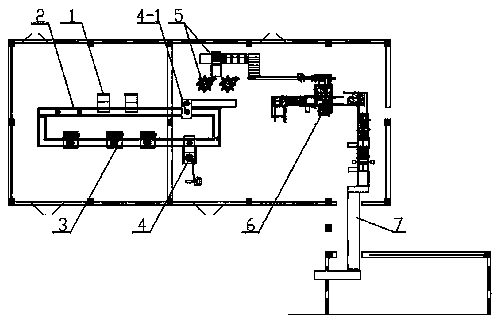

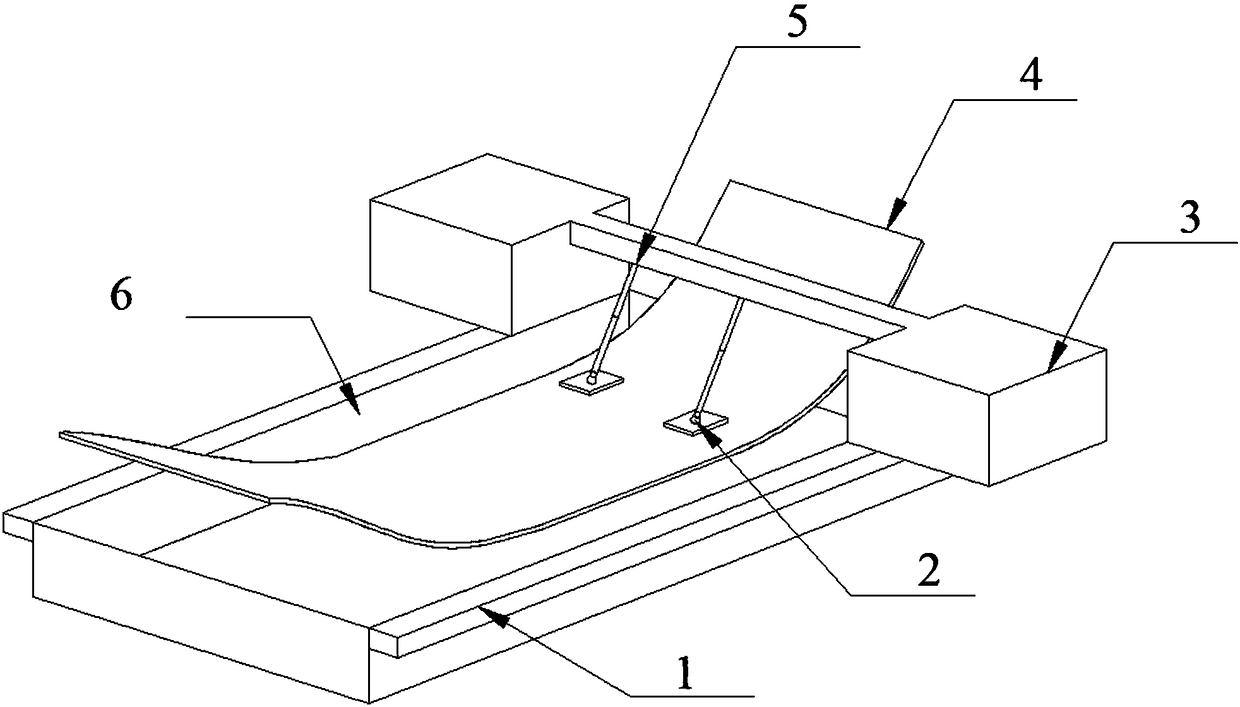

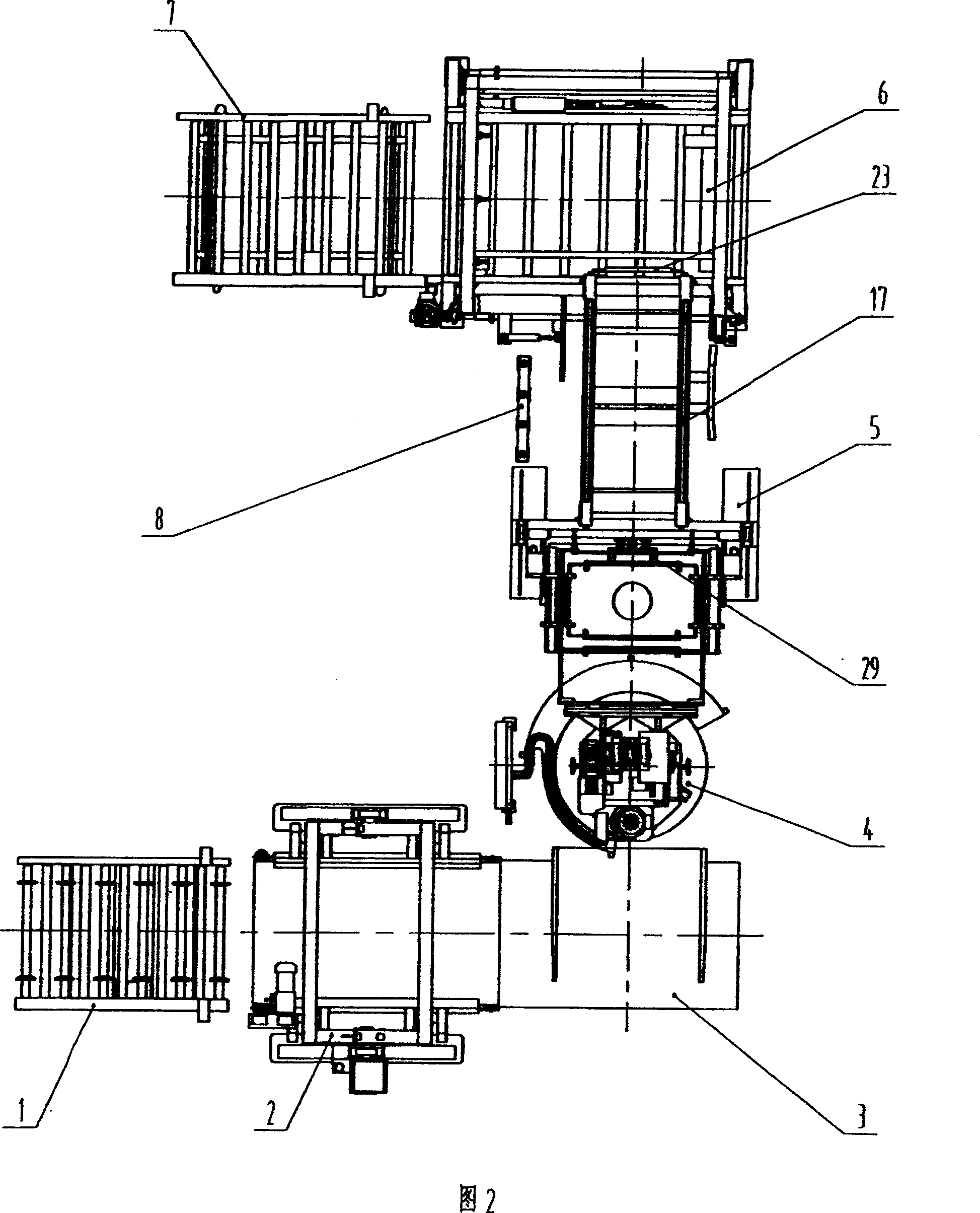

Automatic charge packaging production line for seismic explosive columns of emulsion explosive

InactiveCN103360187ARealize continuous automationExplosive working-up apparatusProduction lineExplosive Agents

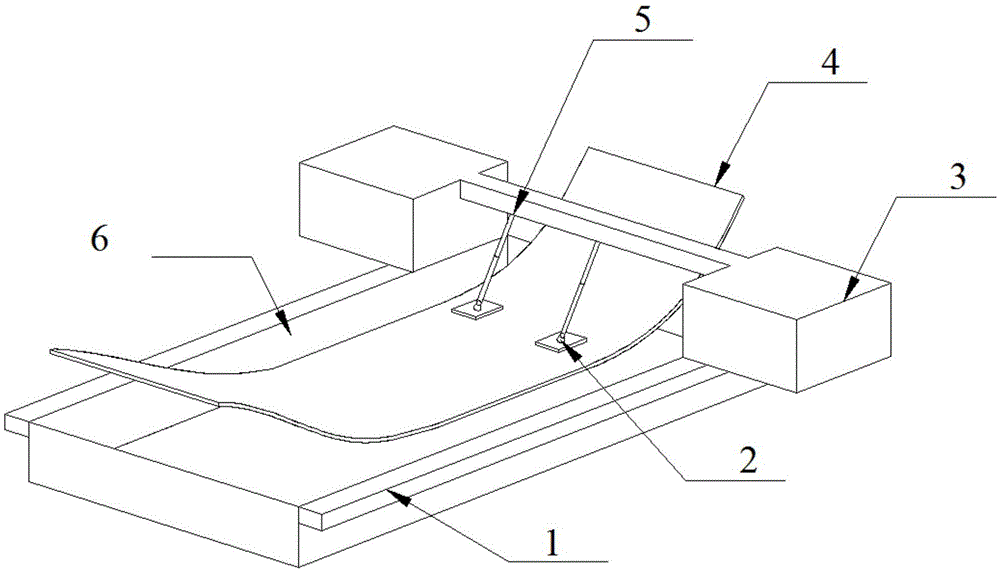

The invention discloses an automatic charge packaging production line for seismic explosive columns of emulsion explosive. The automatic charge packaging production line is composed of an automatic casing machine (1) of seismic explosive columns, a speed chain conveying line (2), an automatic charging machine (3), a seismic explosive column gland device (4), a grabbing mechanism (4-1), an automatic thermal sealing and connecting sleeve assembling machine (5) of seismic explosive columns, an automatic packaging unit (6) and a finished product belt conveyor (7). The automatic charge packaging production line disclosed by the invention has the advantages of improving the preparing, charging and packaging efficiency of the seismic explosive columns and mine blasting explosive columns, realizing automation and serialization and decreasing operators.

Owner:HUBEI KAILONG CHEM GRP

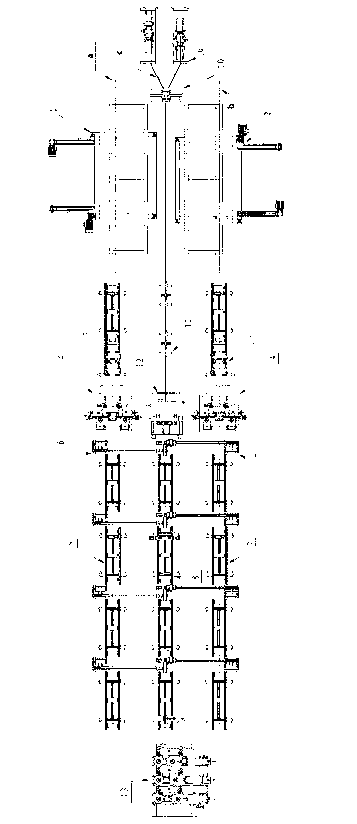

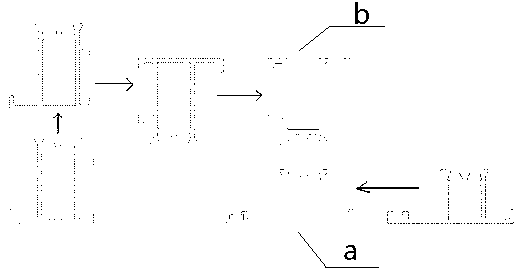

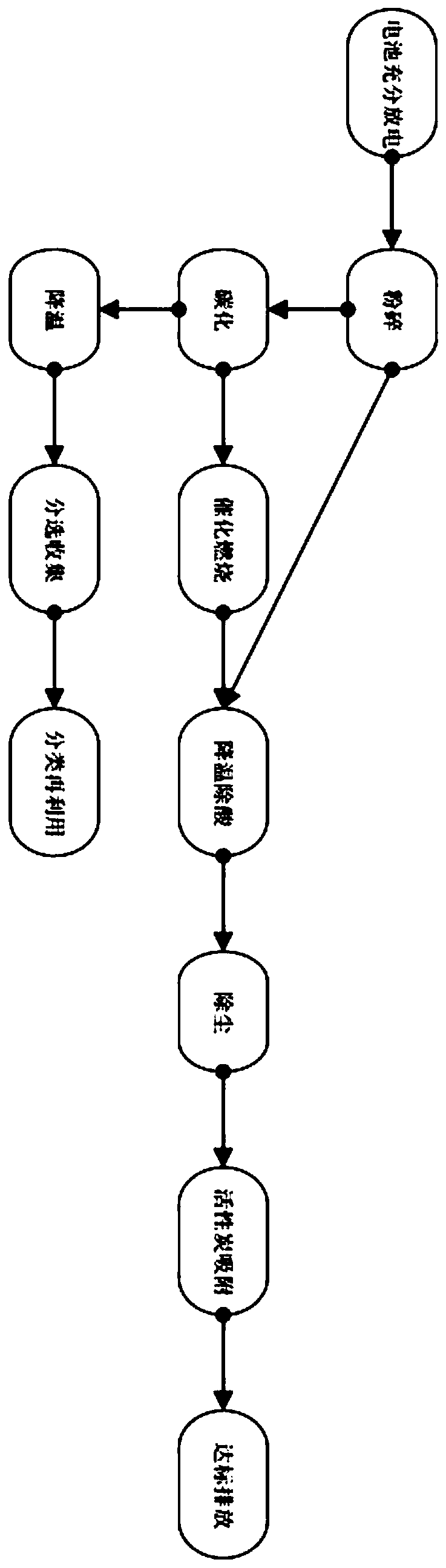

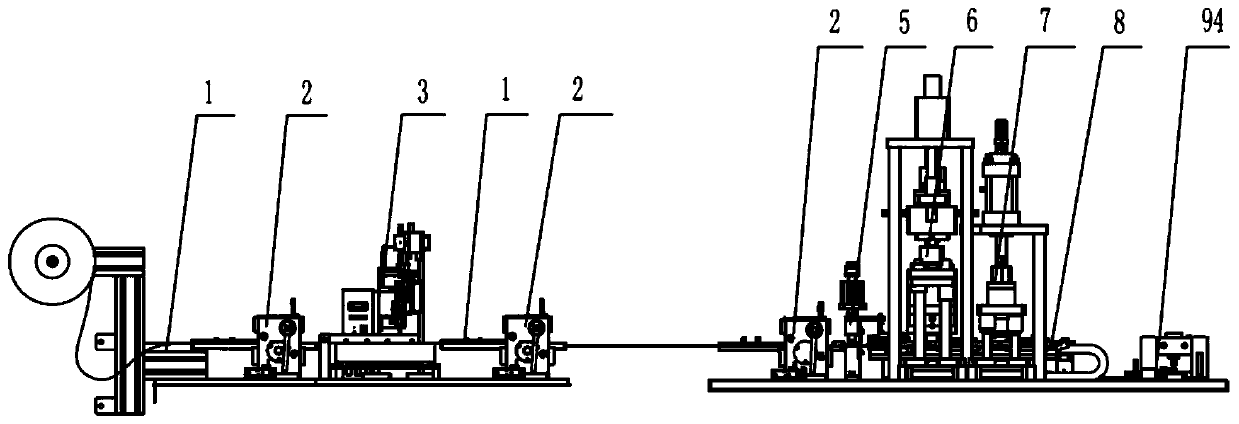

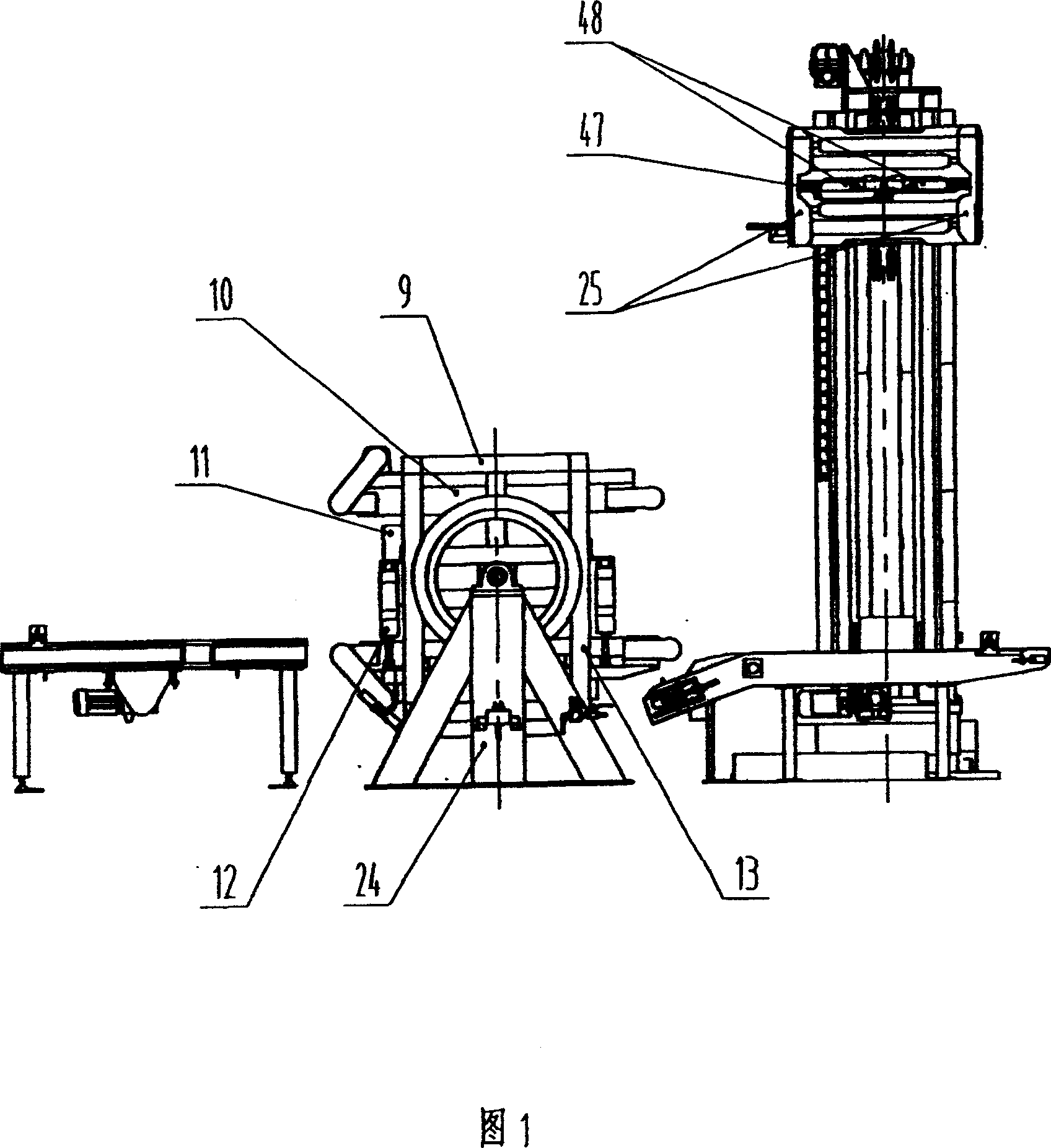

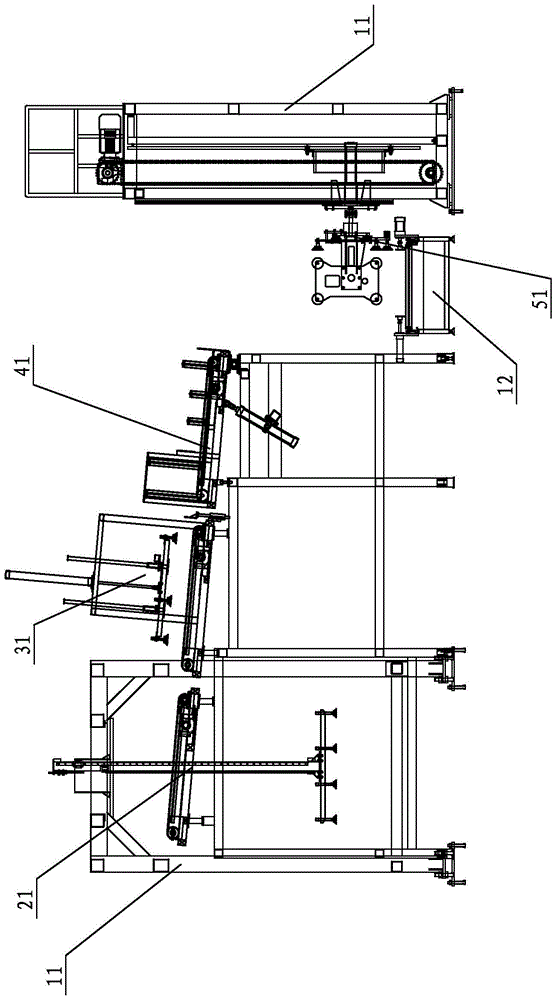

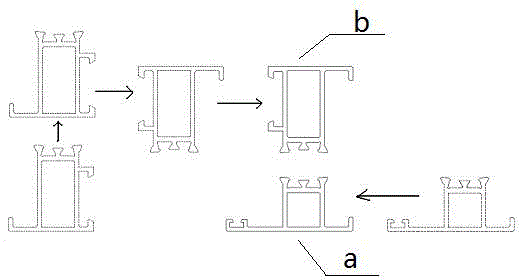

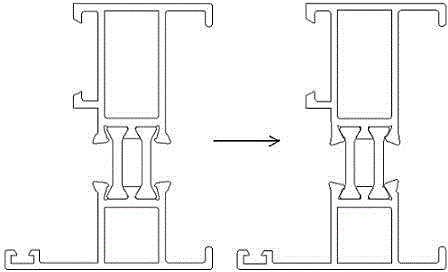

Automatic strip-inserting process of heat-insulting bridge cut-off aluminum window and door profiles

Disclosed is an automatic strip-inserting process of heat-insulting bridge cut-off aluminum window and door profiles. The automatic strip-inserting process includes the steps: (1), an automatic feeding process: automatically feeding aluminum profiles placed in a feed frame into a feeding frame of a laminator automatically; (2), a laminating-and-tooth punching linkage process: automatically laminating and delaminating the aluminum profiles by the laminator driven by a tooth punching machine which is used for punching teeth and roughening rabbets for inserting strips of the aluminum profiles; (3), a manipulator delivery process: transversely moving and turning to deliver upper profiles and lower profiles which are punched with teeth into a fixed conveyer to be subjected to strip inserting process by a manipulator; (4), a continuous automatic strip-inserting process: placing the strips in trays in a strip feeding rack, completing strip inserting, strip length determining and strip cutting automatically by the strip feeding rack, the strip cutting detecting platform and an automatic strip-inserting machine in a linkage manner; and (5), a rolling depression process: flattening strip-inserted upper profiles and lower profiles and then conveying the same into a roller press to be rolled and finally discharged. The automatic strip-inserting process has the advantages of realizing completely continuous automation of production of the heat-insulting bridge cut-off aluminum window and door profiles.

Owner:SHANGHAI ZENITH ENG EQUIP

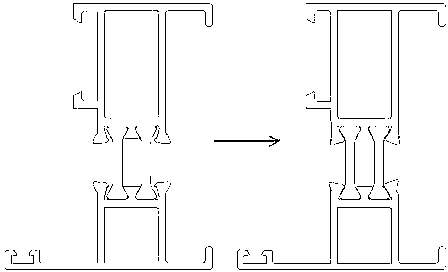

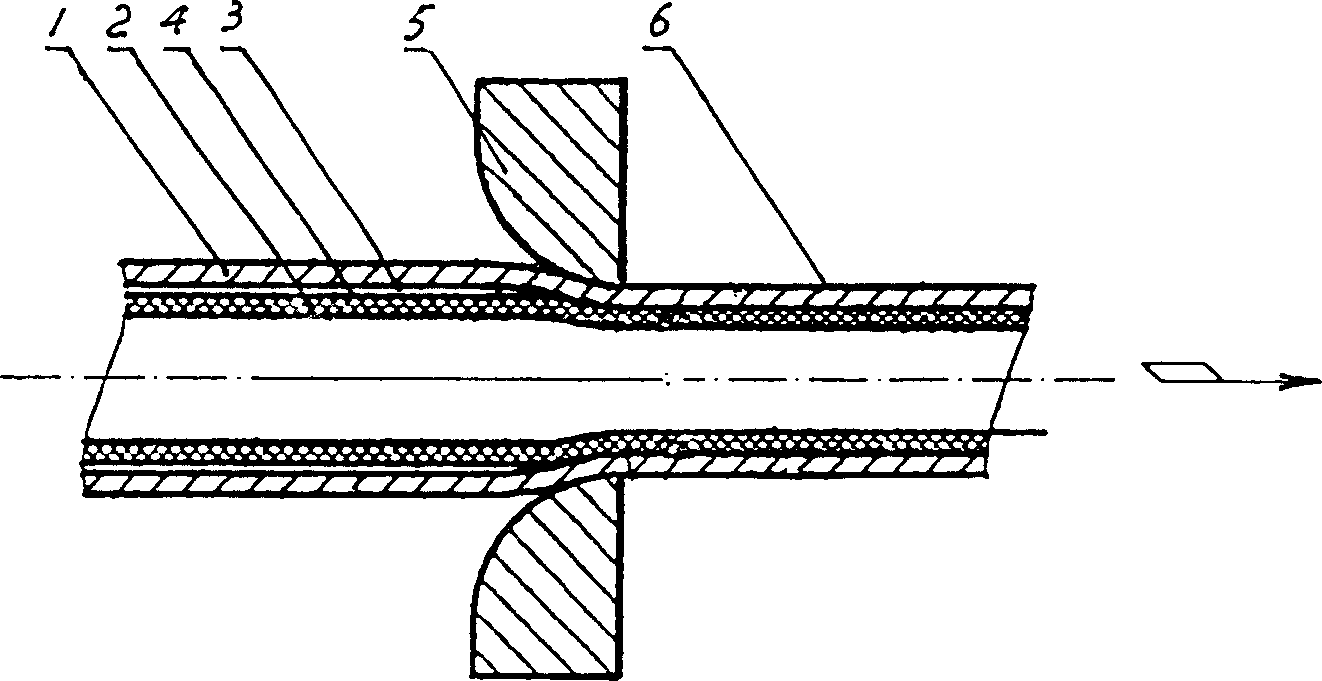

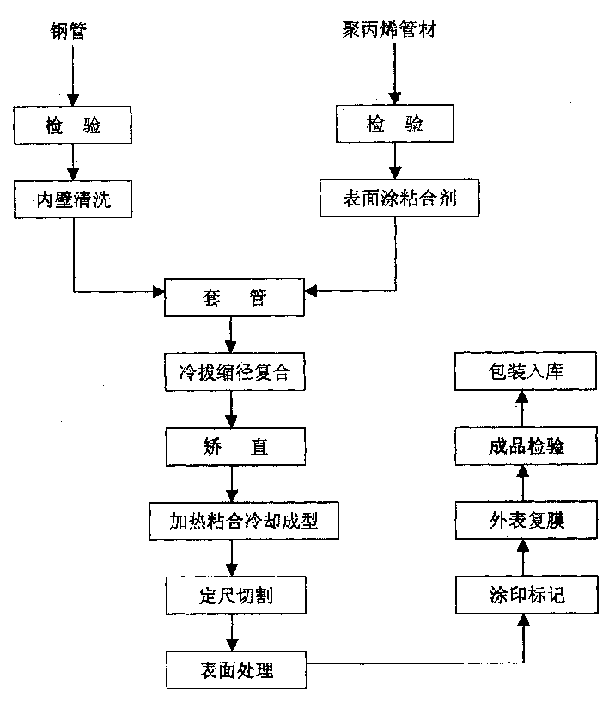

Method for manufacturing lining plastic composite carbon steel pipe

The invention discloses a manufacturing method for plastic lining compound carbon steel pipe. The character is: the outer surface of the plastic pipe is painted with a layer thin and even bond which is solid in normal temperature; the plastic pipe is inserted into the external steep pipe whose inner wall is cleaned; the pipes are put into drawing machine to reduce the diameter of the external steep pipe, eliminate the gap, discharges the air, makes the two pipes attached tightly. The compound pipe is put into the heater before the interference elastic deformation force of the plastic pipe disappears, makes the bond melted to the best state and the two pipes are bonded together; then they are cooled to normal temperature and bonds the two pipes tightly; the merits are: the process is simple, the cost is low, and the quality is excellent, and it has no contamination to environment.

Owner:成都帝拓管业科技开发有限公司

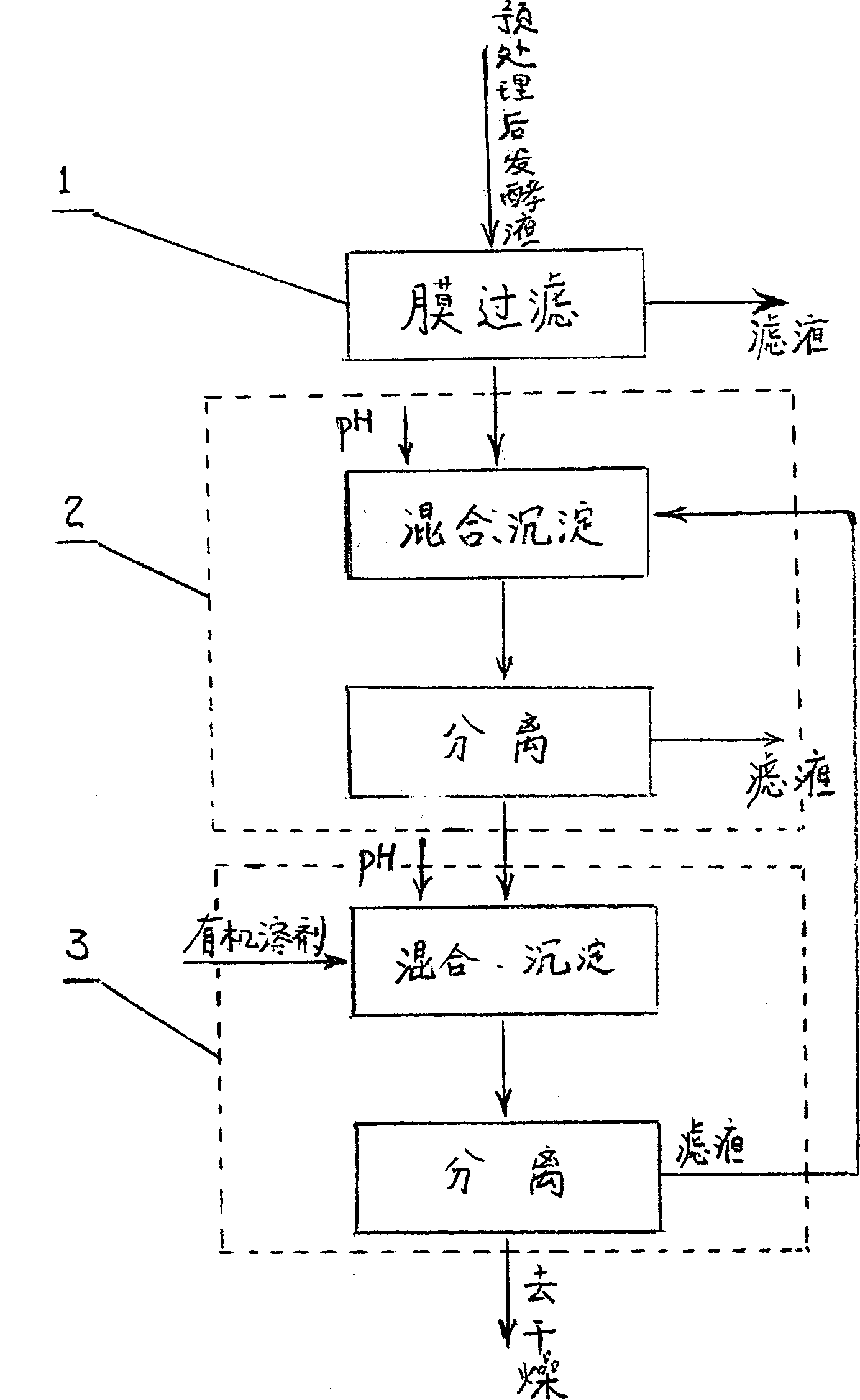

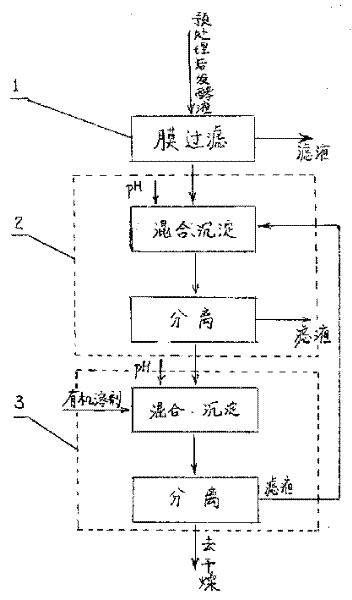

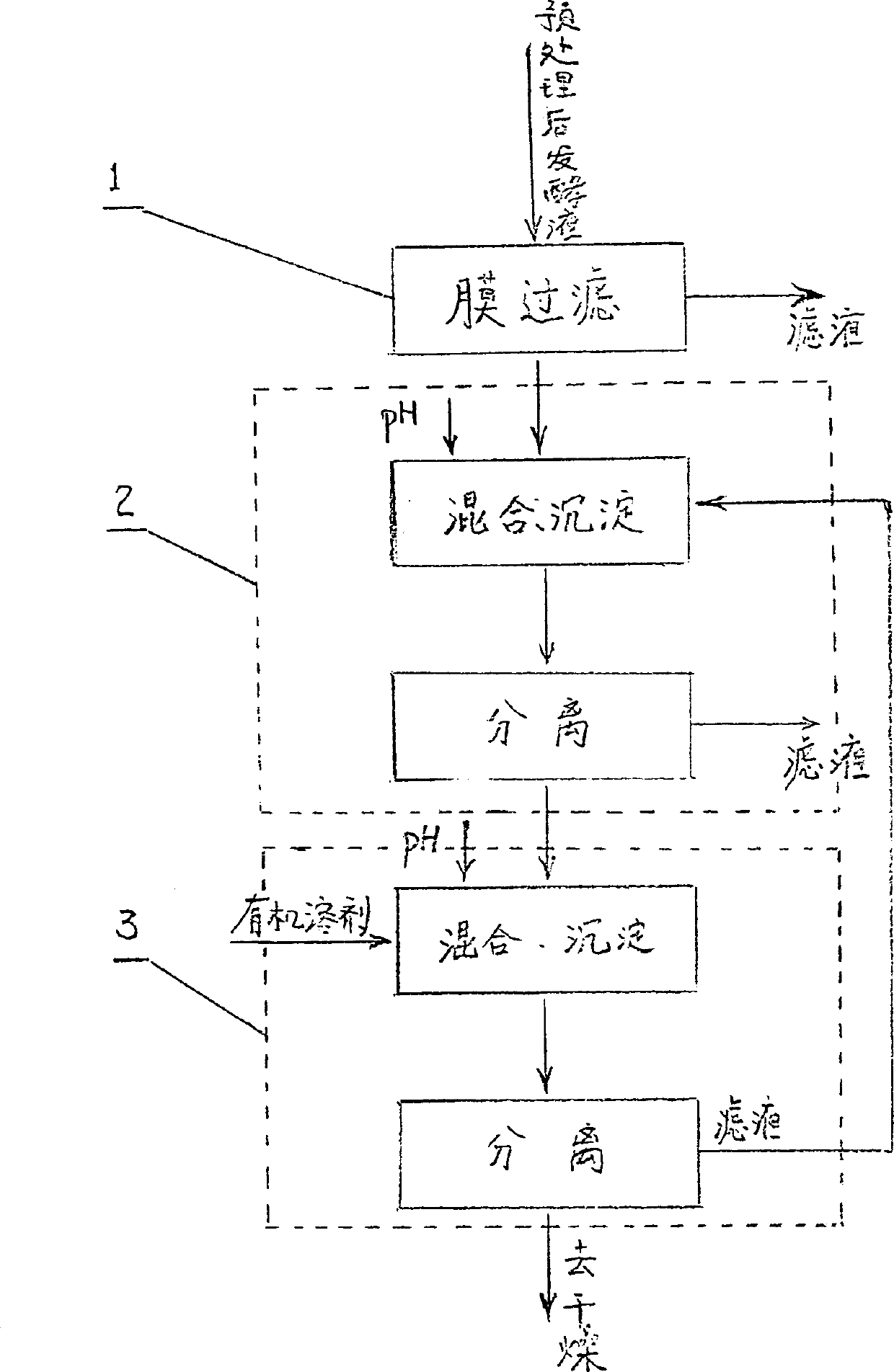

Engineering method for separating and extracting xanthan gum

The engineering method for separating and extracting xanthan gum is characterized by that the processes of charging materials, mixing, precipitation, separation and regulation of pH value can be continuously uniformly implemented in a closed mechanical equipment. Said ivnention can maximally prevent the organic solvent from producing volatillization in the course of production, under the normal production condition does not produce explosive gas, and can ensure safe production. As compared with ethyl alcohol precipitation method its alcohol consumption can be reduced by 80%, if after extraction vacuum drying process is adopted the ethyl alcohol consumption can be reduced by 95%. Its product quality is high and stable.

Owner:张孝宽

Continuous carbonization and pyrolysis treatment method of waste lithium battery

PendingCN111271711ARealize continuous automationImprove processing efficiencyIncinerator apparatusCentral heating systemThermodynamicsProcess engineering

The invention provides a continuous carbonization and pyrolysis treatment method of a waste lithium battery. The method adopts the following treatment flow of step 1, preheating, specifically, preheating a carbonization device to a working temperature; step 2, pretreating, specifically, discharging and crushing the lithium battery, wherein firstly, the lithium battery is put into a temporary storage tank after being subjected to full discharge and enters a crusher through a closed conveying device, and after crushing, mixed materials enter the carbonization device; step 3, performing a carbonization and pyrolysis treatment process and a gas combustion process; step 5, performing a tail gas treatment process; and step 6, sorting solid materials discharged from the carbonization device. According to the treatment method of the waste lithium battery, isolation between a carbonization chamber and gas combustion in the carbonization process is realized, the mixed materials obtained after the waste lithium battery is crushed are heated through the indirect heat transfer mode between gas combustion as well as an auxiliary heating device and the carbonization chamber, oxygen is completelyisolated in the carbonization chamber, and oxidation of metal in the carbonization chamber is effectively avoided through the control by means of the pressure difference and a one-way valve, so that the utilization value of the final product is improved.

Owner:上海智迭科技有限公司

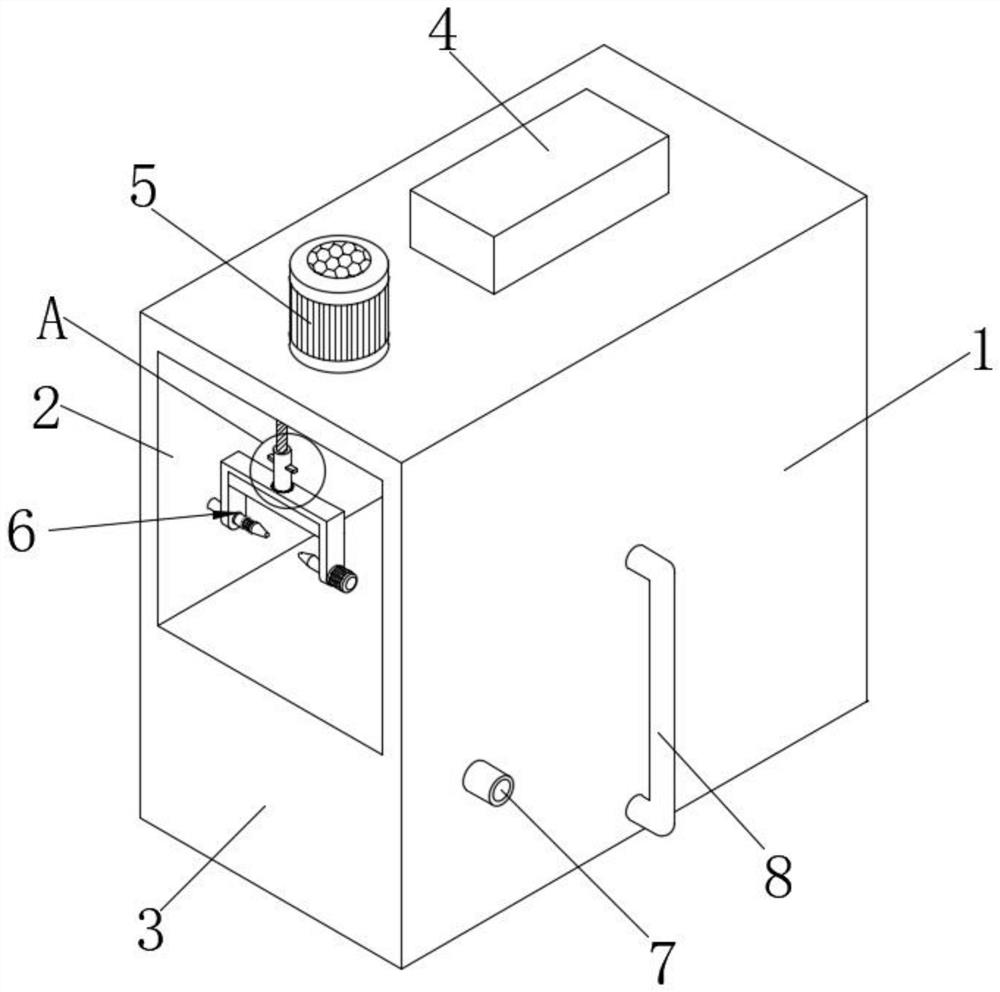

Putty smearing apparatus for building construction

InactiveCN109653476ARealize continuous automationApply evenlyBuilding constructionsPuttyWaste management

The invention discloses a putty smearing apparatus for building construction, which relates to the field of building construction devices. The putty smearing apparatus for the building construction comprises a slide rail, wherein a base is slidably arranged on the slide rail; a front support, a rear support and a charging barrel are fixedly arranged on the base; a crawler apparatus is vertically arranged on the front support; the crawler apparatus is parallel to a wall; a scraper plate is fixedly arranged on the crawler apparatus; the scraper plate is obliquely arranged on the crawler apparatus; the charging barrel is provided with a charging port, a pressurizing air pump and a discharging pipe; the discharging pipe is connected to the bottom of the side surface of the charging barrel; thedischarging pipe is arranged on the rear support by virtue of a fixing part;, and the output end of the discharging pipe is disposed above the crawler device and disposed above an inclined high position of the scraper plate. By adopting the technical scheme disclosed by the invention, the continuous automatic operation for smearing the wall putty can be realized, the operation efficiency is high,the putty is uniformity in smearing, and no obvious smearing operation boundary is produced.

Owner:广东腾越建筑工程有限公司

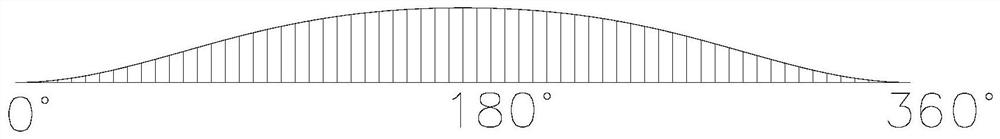

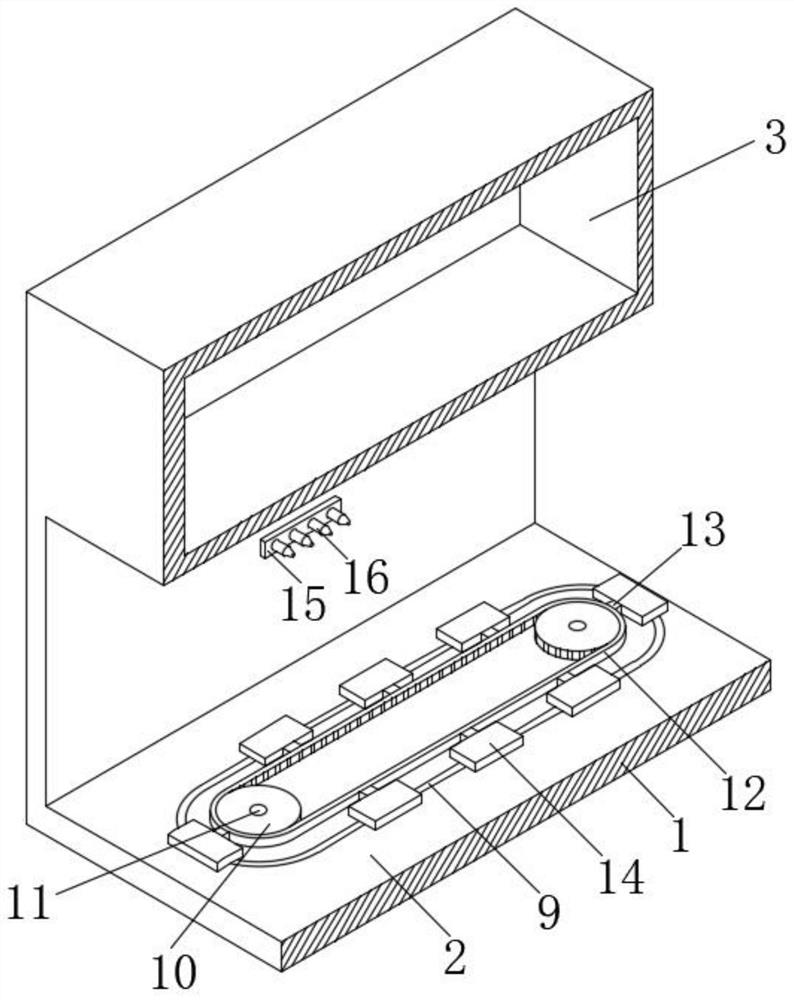

Spring testing system and method

ActiveCN106353081APrecise positioningRealize continuous automationMachine part testingConveyorsEngineeringAutomation

The invention relates to a spring testing system and method and belongs to the technical field of spring testing. The system comprises a conveying device, wherein end positioning devices, direction recognizing devices, testing devices, a color code printing device and an outlet control device are sequentially arranged on the conveying device in the conveying direction, the conveying device, the end positioning devices, the direction recognizing devices, the testing devices, the color code printing device and the outlet control device are all electrically connected with the control device. The system and the method have the advantages that continuous automation of spring production and testing can be realized, the positioning and direction recognizing are accurate, the test result is accurate, and springs can be automatically sorted and marked according to the testing result.

Owner:济南凯镭迪精密仪器有限公司

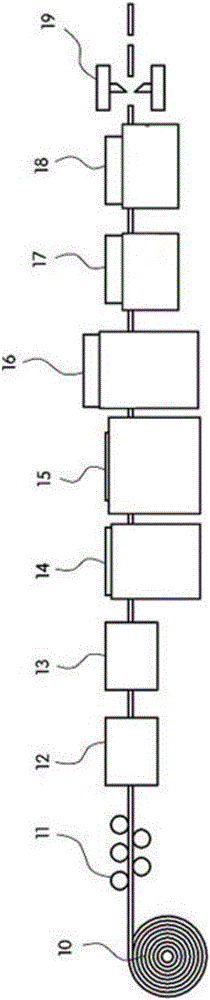

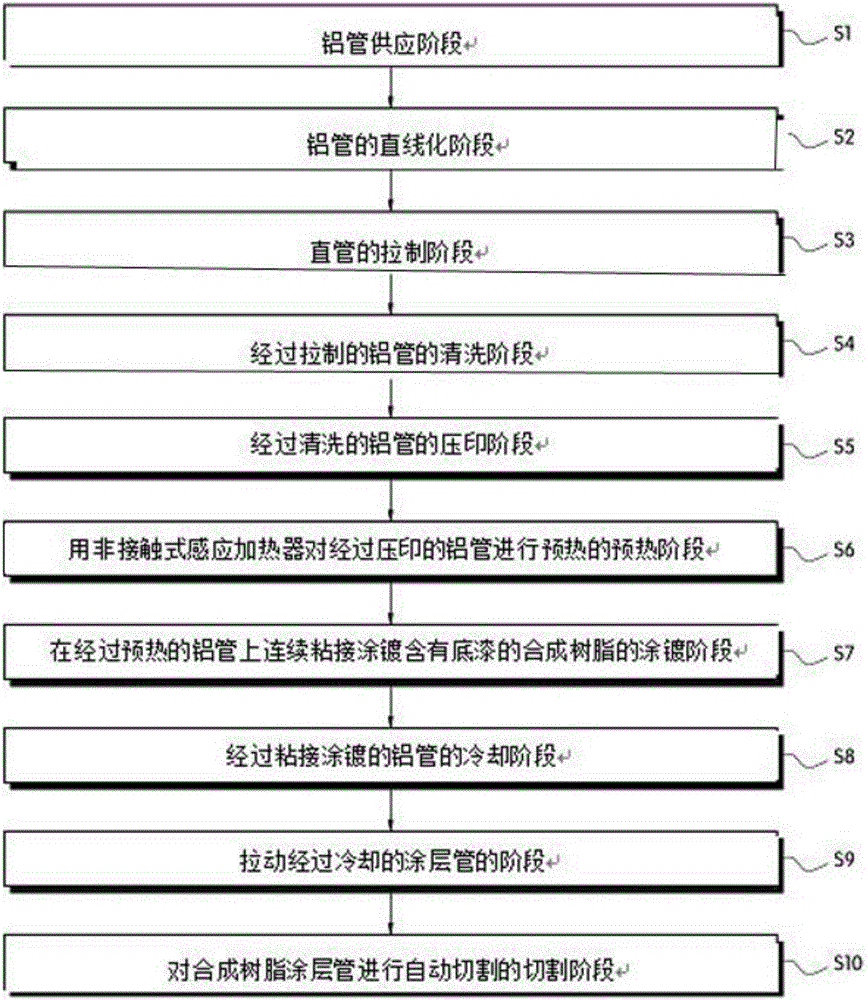

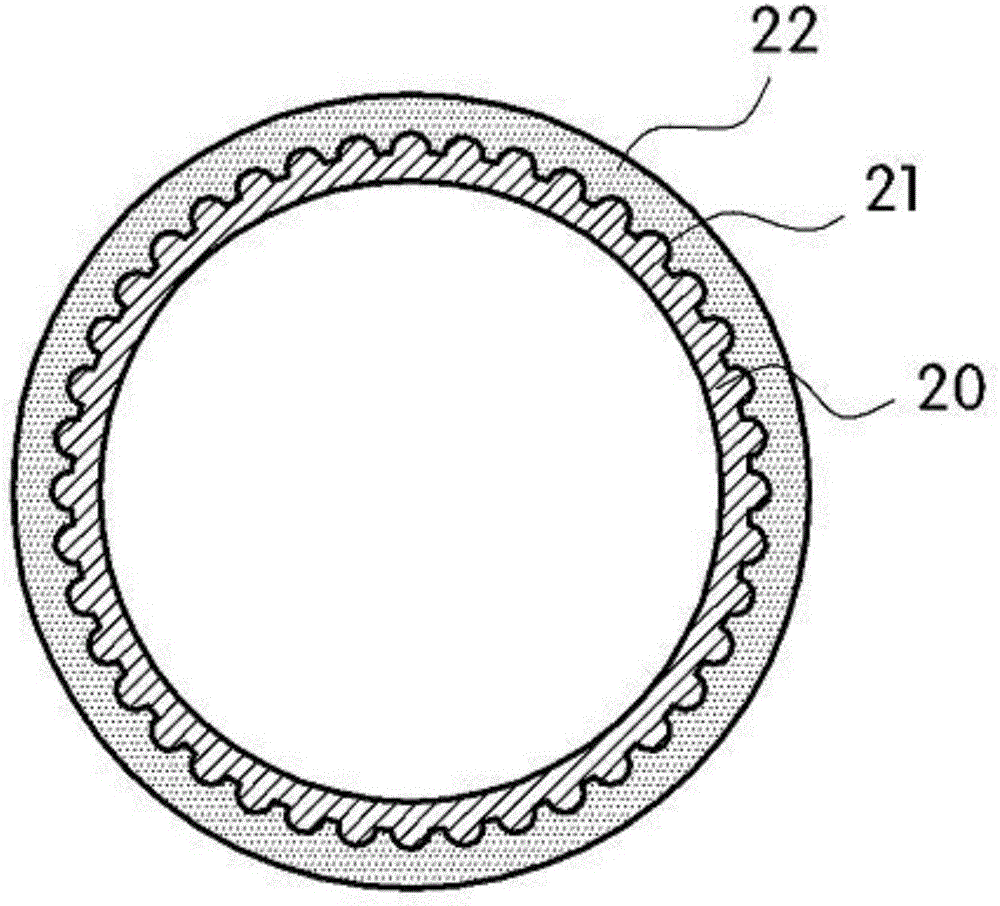

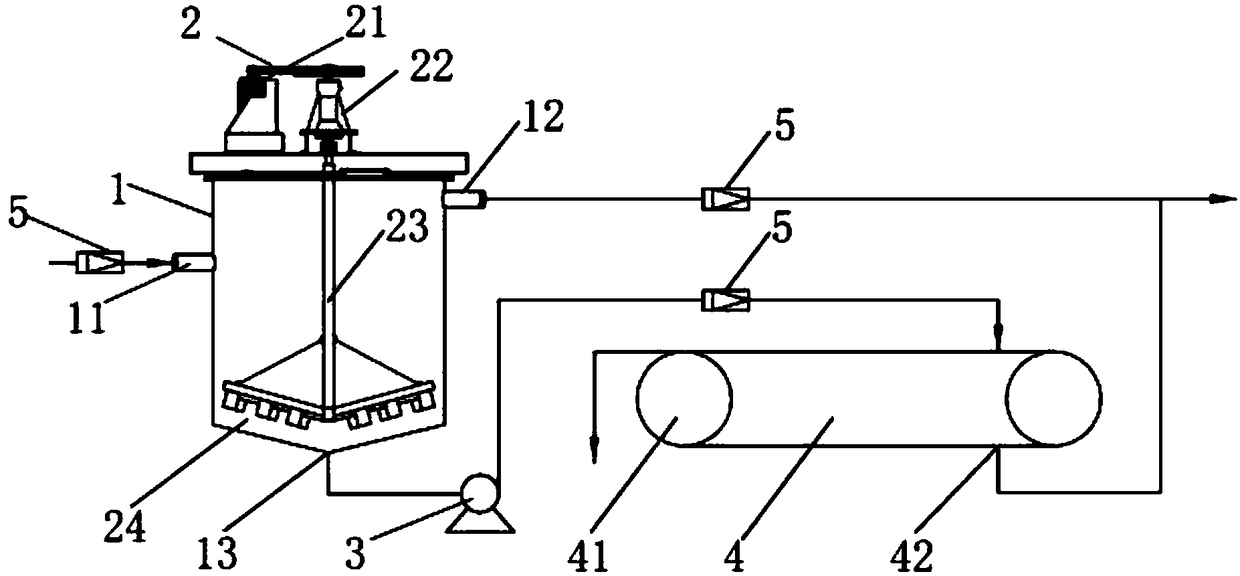

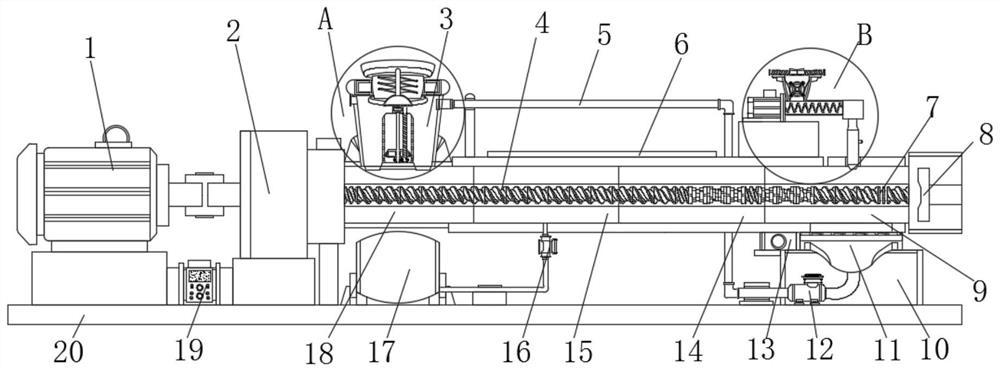

Manufacturing method and production line for resin-coated aluminum pipe

ActiveCN106077128AImprove adhesionRealize continuous automationProduction lineHigh volume manufacturing

The invention discloses a manufacturing method for a resin-coated aluminum pipe. The manufacturing method for the resin-coated aluminum pipe comprises (S1) the stage of aluminum pipe supply, (S2) the stage of linearization of an aluminum pipe, (S3) the stage of drawing of the straight pipe, (S4) the stage of cleaning of the drawn aluminum pipe, (S5) the stage of imprinting of the cleaned aluminum pipe, (S6) the preheating stage of preheating the imprinted aluminum pipe through a non-contact induction heater, (S7) the coating and plating stage of continuously coating and plating the preheated aluminum pipe with synthetic resin containing primer in a glued mode, (S8) the stage of cooling the aluminum pipe subjected to glued coating and plating, (S9) the stage of pulling the cooled coated pipe, and (S10) the cutting stage of automatically cutting the pipe coated with the synthetic resin. According to the manufacturing method for the resin-coated aluminum pipe, all the procedures including the raw aluminum pipe supply stage, the imprinting stage, the glued coating stage and the automatic cutting stage are continuous and automatic, mass production can be achieved through automation, the productbility is improved, and the product quality can also be improved.

Owner:深圳弘国林科技有限公司

Device and method for solid-liquid separation in continuous production of rare-earth carbonate

PendingCN109276947AImprove equipment utilizationRealize unattendedFiltration circuitsMother liquorCarbonic acid

The invention discloses a device for solid-liquid separation in continuous production of rare-earth carbonate. The device comprises a solid-liquid separation tank, a rake type stirrer, a concentratedslurry extraction pump, a vacuum filter and flowmeters; a slurry inlet and a mother liquor outlet are formed in the side wall of the solid-liquid separation tank, and a concentrated slurry outlet is formed in the bottom of the solid-liquid separation tank; the slurry inlet and the mother liquor outlet are both provided with one flowmeter, the concentrated slurry outlet is connected with the vacuumfilter, and a pipeline between the concentrated slurry outlet and the vacuum filter is provided with the concentrated slurry extraction pump and one flowmeter; the bottom of the solid-liquid separation tank is an inverted conical bottom or slope-shaped bottom, and the concentrated slurry outlet is formed in the top end of the conical bottom or the slope-shaped bottom; the rake type stirrer comprises a variable frequency motor, an actuator, a transmission shaft and stirring blades; and the vacuum filter is provided with a rare-earth carbonate outlet and the mother liquor outlet. The inventionfurther discloses a solid-liquid separation method in continuous production of the rare-earth carbonate. According to the invention, continuous automation of a whole process of precipitation and solid-liquid separation can be realized.

Owner:CHINA NORTHERN RARE EARTH (GROUP) HIGH TECH CO LTD

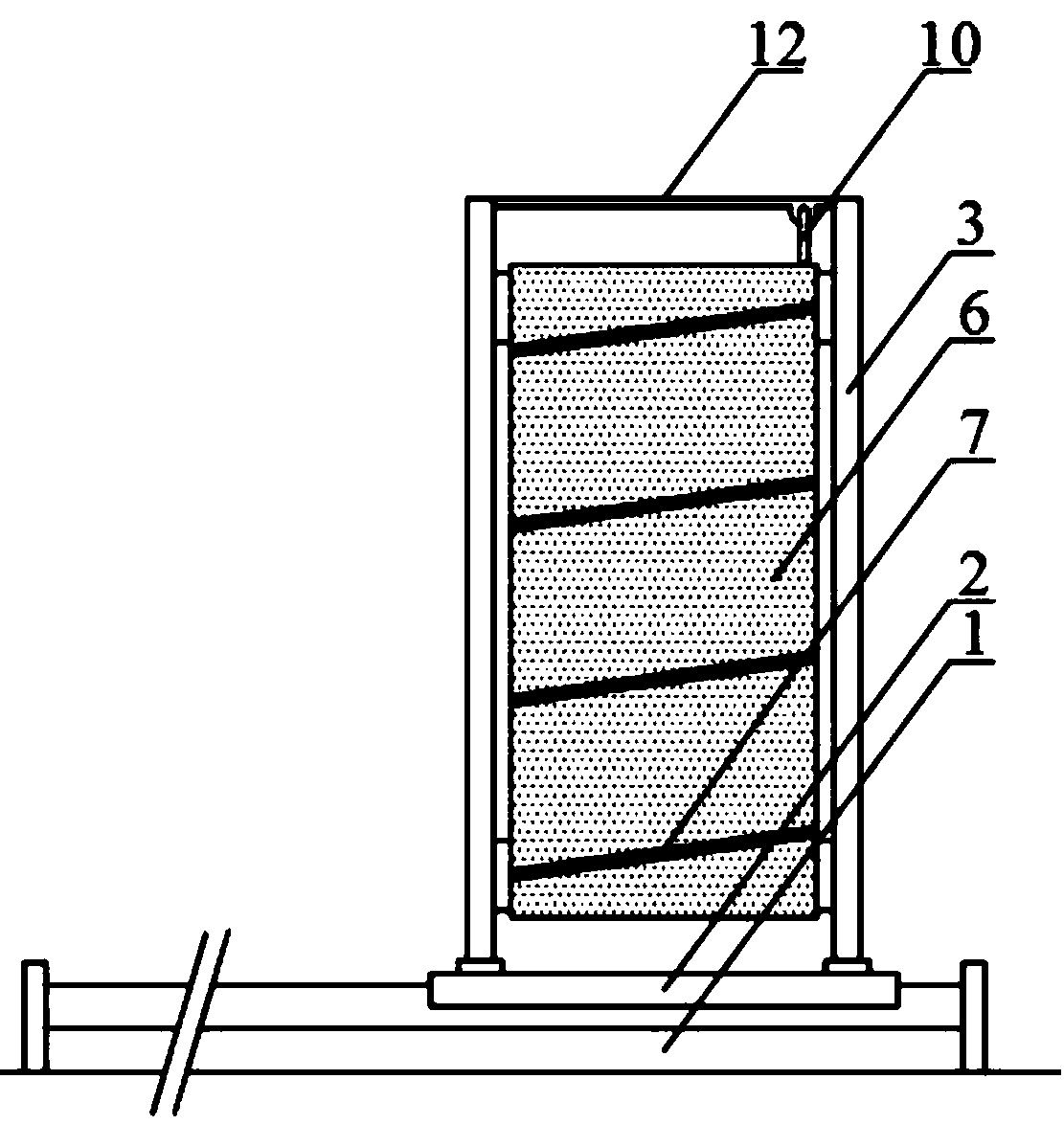

Bearing tank for vertical continuous crystallization

InactiveCN107345259AAdjustable quantityRealize continuous automationSugar crystallisationSteam pressureUltimate tensile strength

The invention discloses a vertical continuous crystallization carrying tank, comprising a circular carrying base, the upper surface of the circular carrying base is fixedly connected to the circular carrying tank, and a continuous crystallization mechanism is arranged in the circular carrying tank, A supporting and moving mechanism is provided on the lower surface of the circular bearing base. The beneficial effect of the present invention is that the device adopts a vertical stacking installation of a plurality of connected crystallization chambers 6, which can continuously realize the complete continuous automation of the crystallization process. The crystallization tank is reduced by 14%, the energy consumption is reduced, the operation difficulty and labor factor of the crystallization process are reduced, the product quality is guaranteed, the labor intensity is reduced, the work efficiency is obviously improved, the work is smooth, the structure is compact, the occupation area is small, the energy consumption is low, and the crystallization chamber can be adjusted. The number of devices that are easy to move.

Owner:鲍孟波

Device and method for continuously preparing small-particle reclaimed rubber with low Mooney rebound

The invention discloses a device and method for continuously preparing small-particle reclaimed rubber with low Mooney rebound. The device comprises a base, wherein a motor is arranged on one side of the top of the base, a mounting base is arranged on the other side of the top of the base, a reduction gearbox and a double-screw extrusion mechanism are arranged at the output end of the motor, the input end of the reduction gearbox is connected with the double-screw extrusion mechanism, and a first extrusion conveying section, a compression refining section, a shearing refining section and a steady flow cooling conveying section are arranged in the double-screw extrusion mechanism. According to the invention, continuous automation of reclaimed rubber refining production is realized, the whole operation process is realized in a closed environment, and environmental protection and labor saving are realized. Supercritical carbon dioxide fluid is added in the compression refining section, so that the Mooney viscosity of desulfurized rubber powder is greatly reduced, and a damaged cross-linked network is homogenized; and in addition, the torque of an extruder is reduced, and the equipment manufacturing difficulty and the use energy consumption are greatly reduced.

Owner:宿迁绿金人橡塑机械有限公司

Continuous production method of modified nitro-amine compound explosive

InactiveCN1208290CIncrease temperatureImprove the crushing finenessExplosive working-up apparatusCycloneSulfate

Owner:YUNNAN YUXI CHEM ENG

Low-temperature heat insulation box heat insulation cotton filling device of liquefied natural gas ship liquid cargo maintenance system

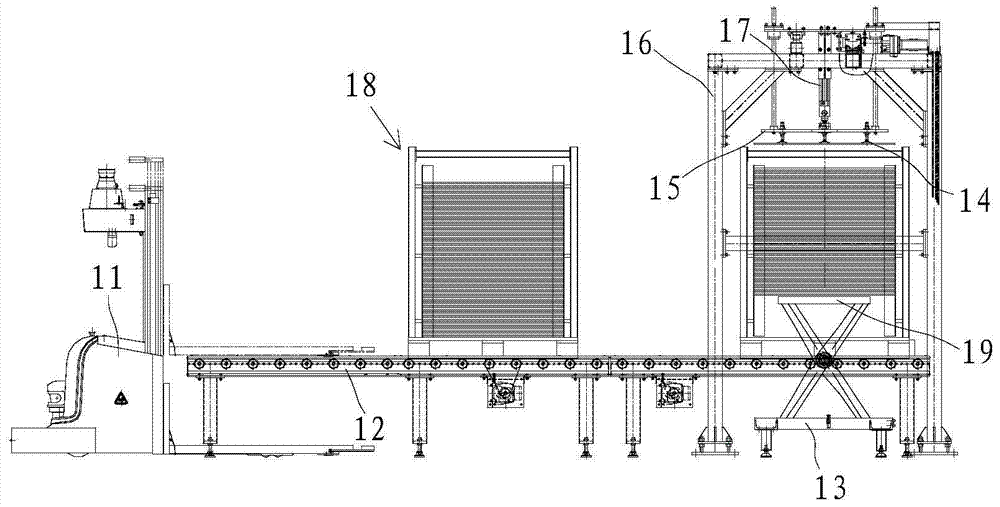

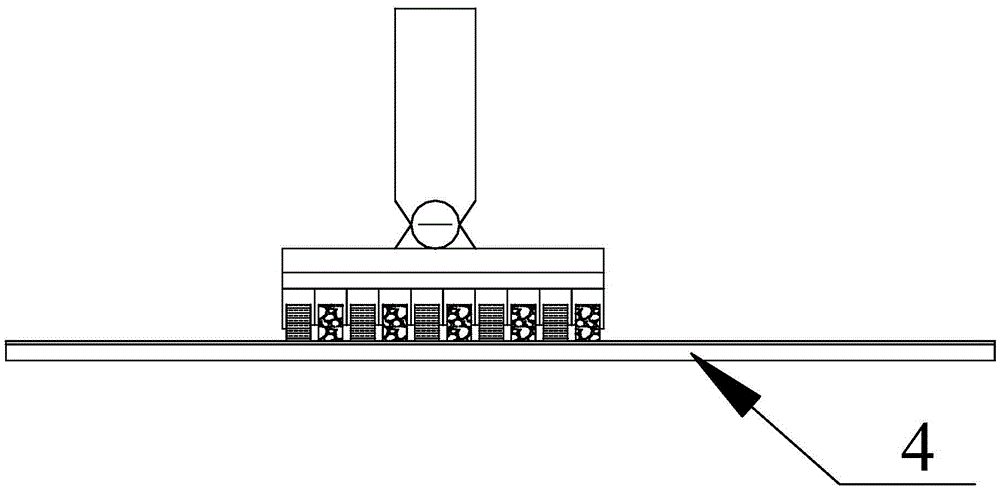

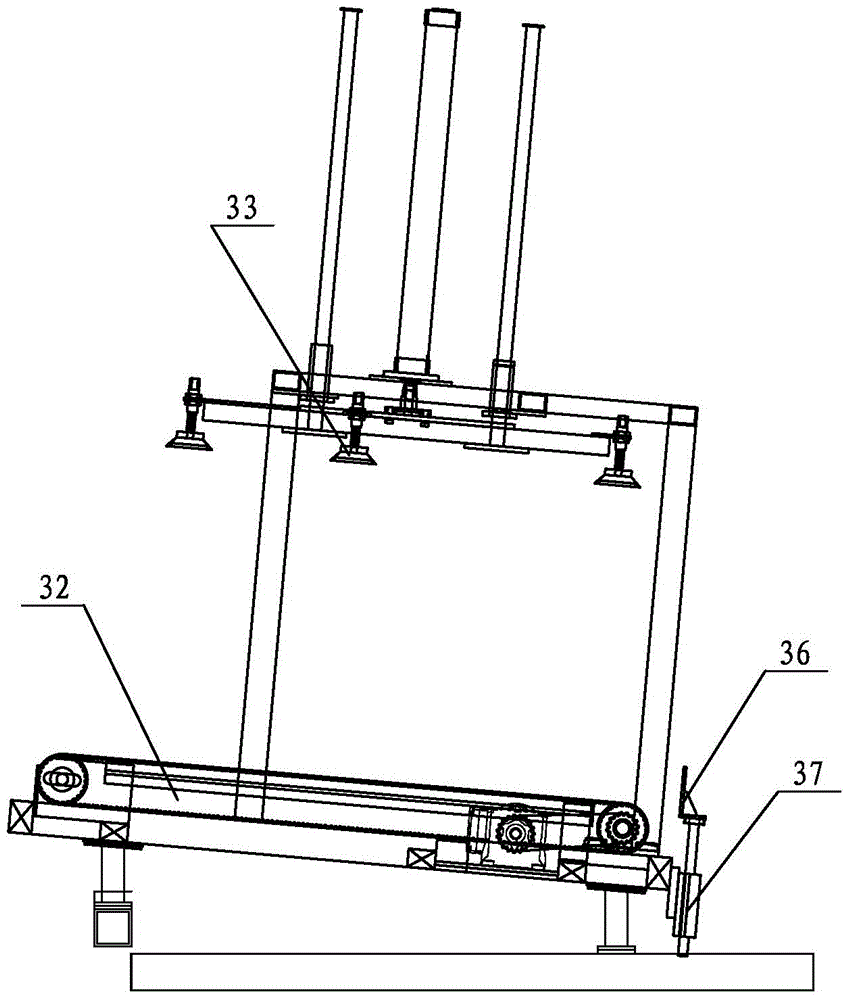

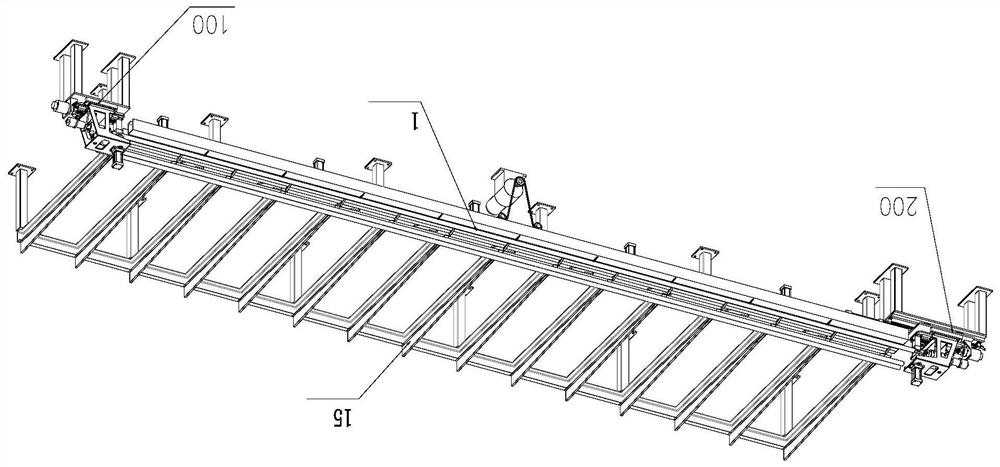

PendingCN110293505ARealize continuous automationReduce manual interventionMetal-working hand toolsControl systemEngineering

The invention relates to a low-temperature heat insulation box heat insulation cotton filling device of a liquefied natural gas ship liquid cargo maintenance system. The device comprises a heat insulation cotton feeding conveying part, a heat insulation cotton horizontal layering pushing part positioned above the heat insulation cotton feeding conveying part, a heat insulation cotton transverse moving filling part, an insulation box feeding roller way, an insulation box filling roller way and the like, wherein the insulation box feeding roller way and the insulation box filling roller way aremutually supported and used for conveying insulation boxes to be filled with heat insulation cotton. Compared with the prior art, after being matched with a control system, the full automatic and high-efficiency batch filling of the heat insulation cotton of the low-temperature heat insulation boxes of the liquefied natural gas ship liquid cargo maintenance system with different specifications canbe flexibly achieved, the dependence on manpower in the operation process can be completely avoided, and the high quality and consistency of the filling effect can be achieved and guaranteed.

Owner:SHANGHAI JIAO TONG UNIV +1

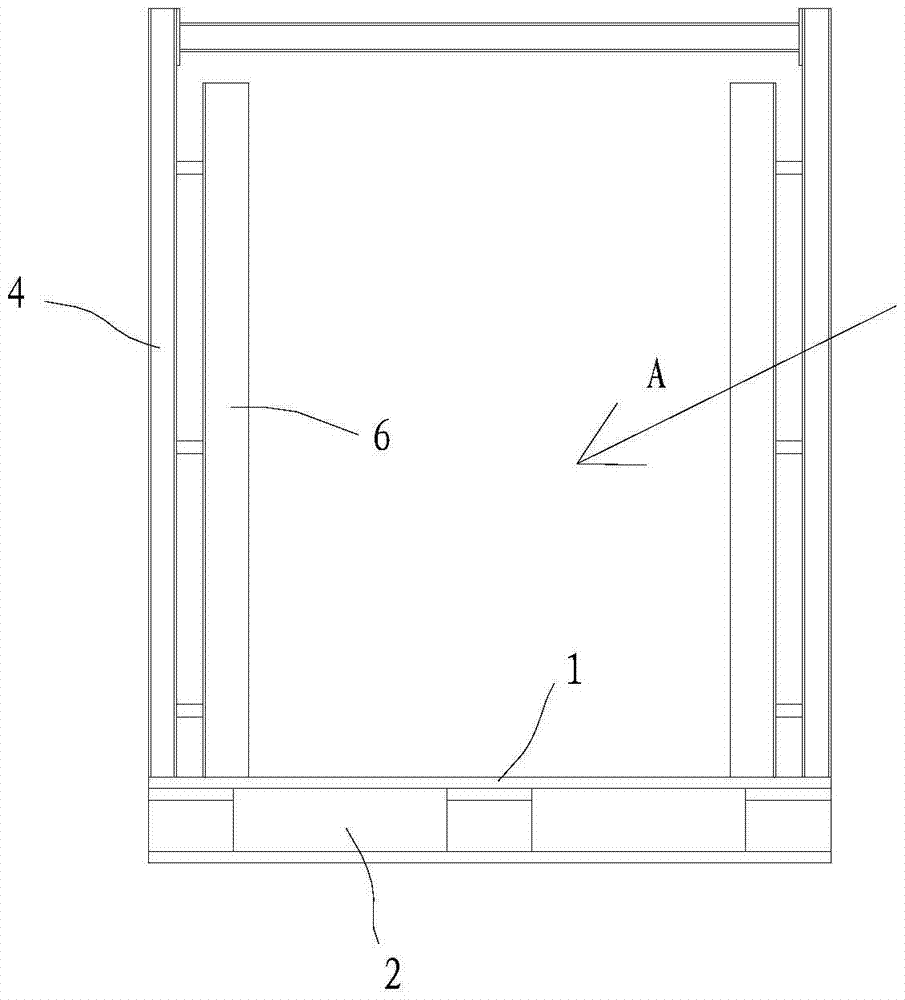

A method for loading and unloading box blanks

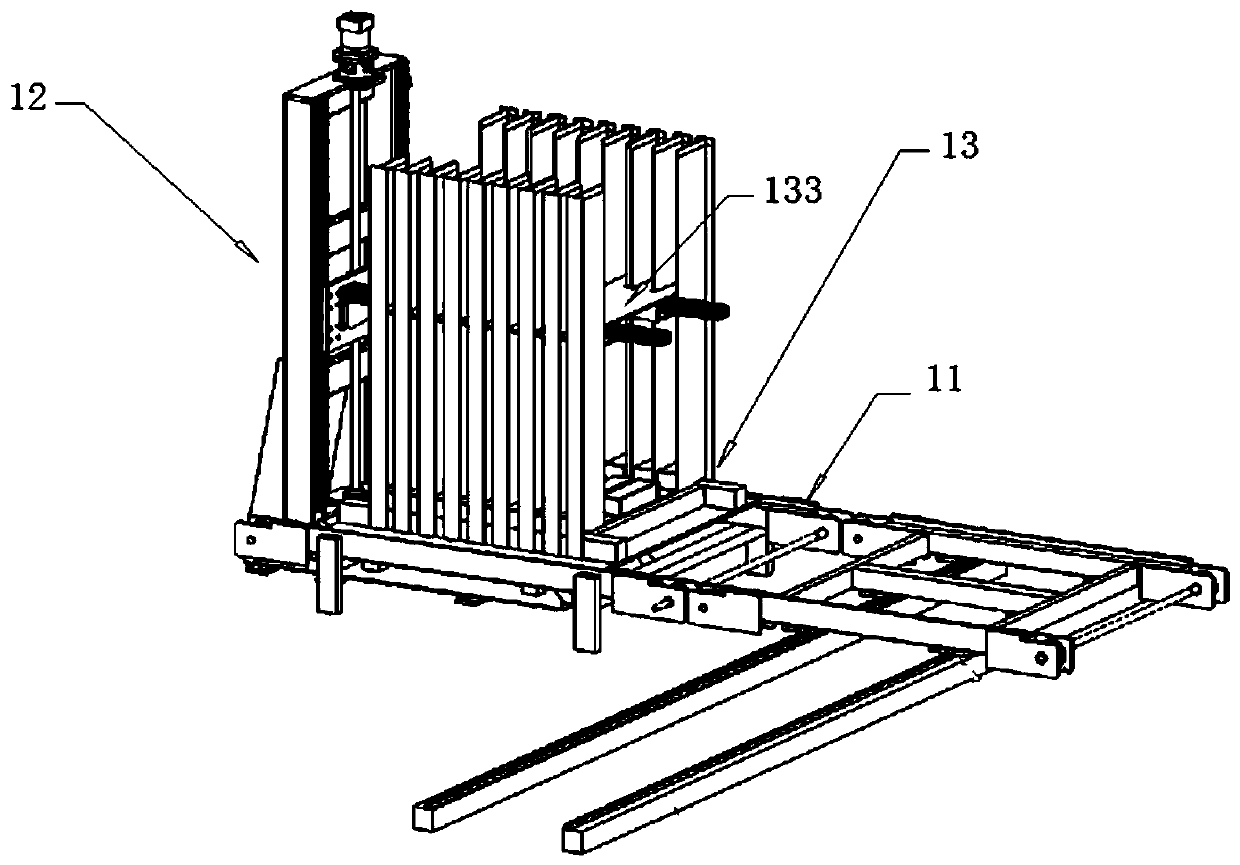

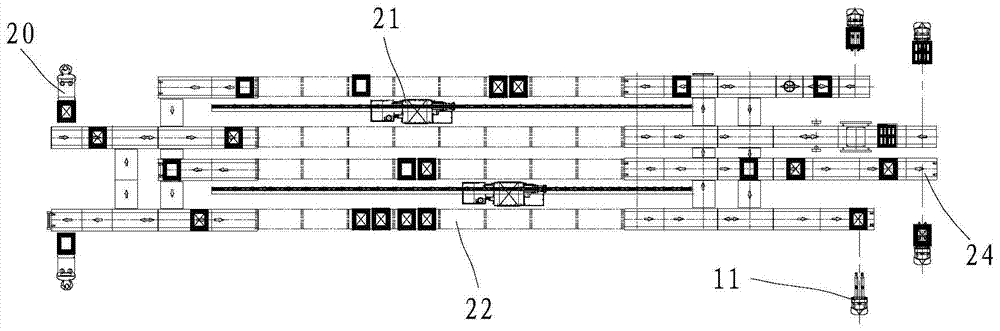

ActiveCN105438543BRealize continuous automationReduce labor intensityPackagingEngineeringUltimate tensile strength

The invention discloses an ex-warehouse and storage operating method of box blanks. The ex-warehouse and storage operating method comprises the steps of step 1, the box blanks are put into a box blank fixing device one by one; step 2, a forklift sends the box blank fixing device carrying the box blanks to feeding channel openings of the warehouse zone, and a stocker moves the box blank fixing device carrying the box blanks to goods shelves; step 3, during ex-warehouse, the box blank fixing device carrying the box blanks is sent to a roller conveyer sequentially through the stocker and the forklift; and step 4, the roller conveyer is paused when the box blank fixing device moves to the tail end of the roller conveyer, a jacking device jacks up the clearance among the box blanks sequentially through the roller conveyer and a yield hole in a bottom tray, and at the same time, a box blank grabbing device grabs the box blanks one by one and moves the box blanks to corresponding using stations. According to the ex-warehouse and storage operating method of the box blanks disclosed by the invention, the ex-warehouse and storage of the box blanks and the process of transporting the box blanks to assigned stations for use can be fully automated, the labor intensity of workers is reduced, and the efficiency is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

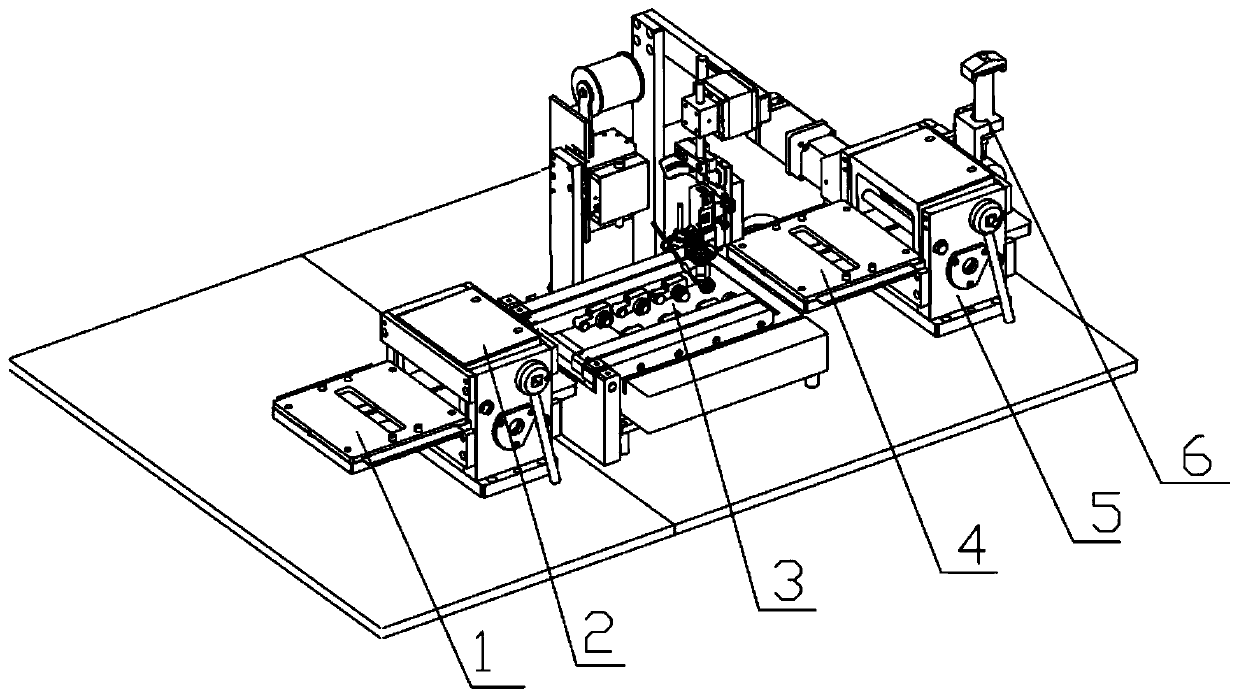

Fuse melt processing apparatus

PendingCN110706982ARealize continuous automationImprove melt processing efficiency and processing qualityFuse device manufactureMoulding deviceTransfer mechanism

A fuse melt processing apparatus comprises a feeding device, a tinning device, a pulling device, a cutter device, a forming device, a punching device and a transferring device which are arranged in sequence, the feeding device comprises a groove pressing device for pressing a groove in the melt and a transmission device for providing power for movement of the melt; the tinning device is used for coating molten soldering tin in the melt groove; the cutter device is used for cutting off the tin-coated melt; the cut melt can be bent and formed by the forming device and then punched by the punching device; the transferring device comprises a transferring mechanism with three sets of clamps and an air suction device, and the three sets of clamps can clamp the melt at the cutter device, the meltat the forming device and the melt at the punching device respectively and correspondingly move the melts to the next procedure; and the air suction device sucks the melt transferred from the punching device tightly and sends the melt to the next procedure. And compared with the traditional melt processing mode, the melt processing efficiency and the processing quality are improved.

Owner:XIAN ZHONGRONG ELECTRIC CO LTD

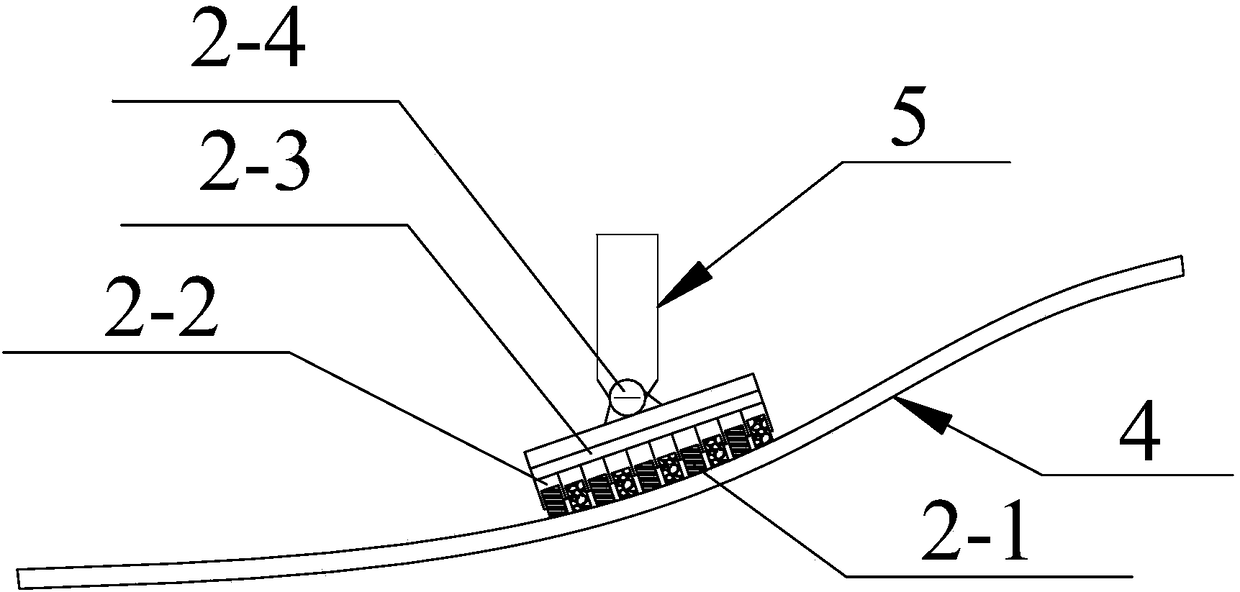

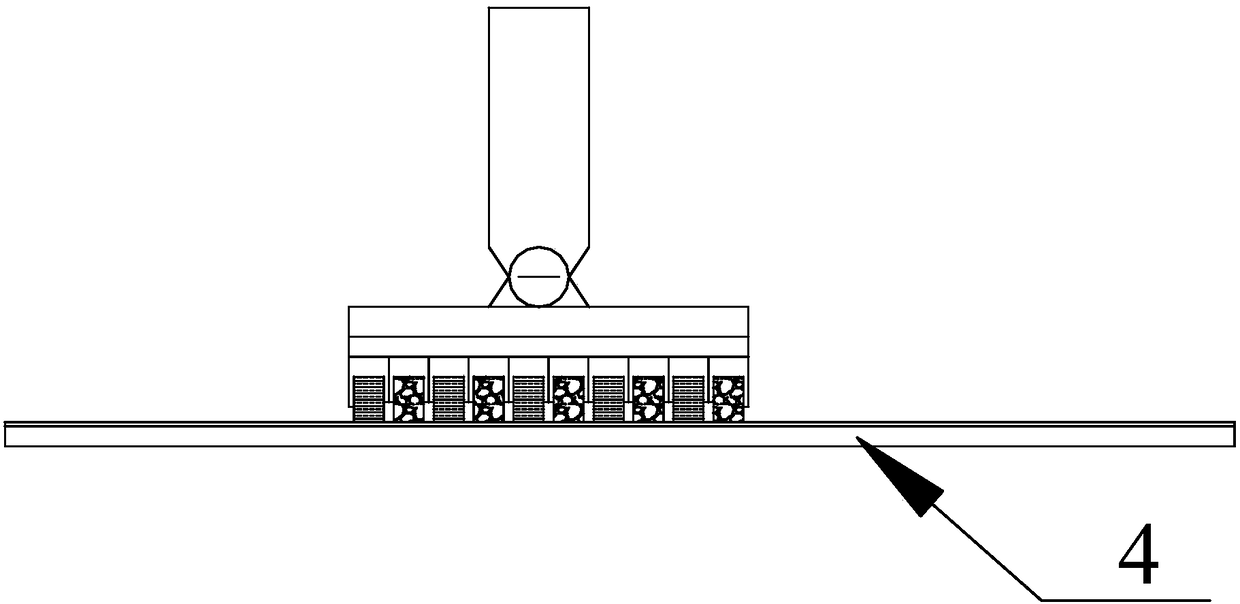

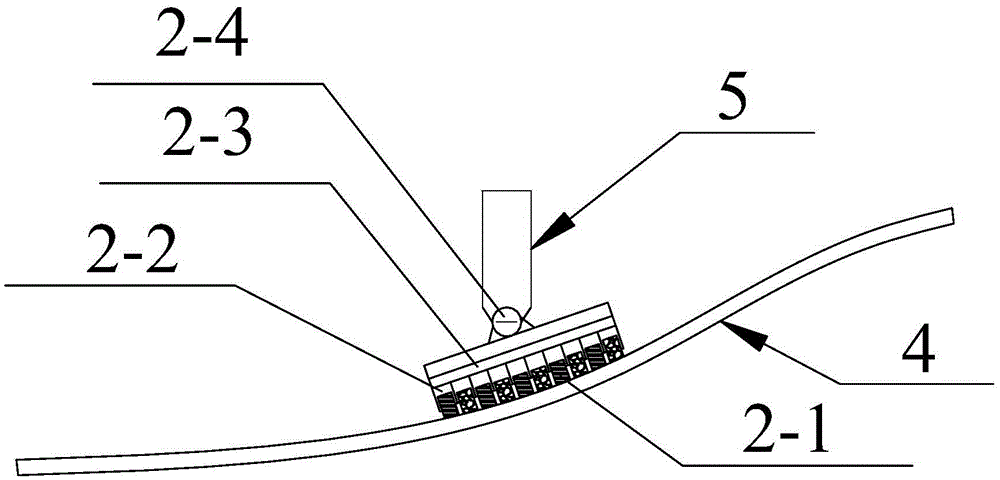

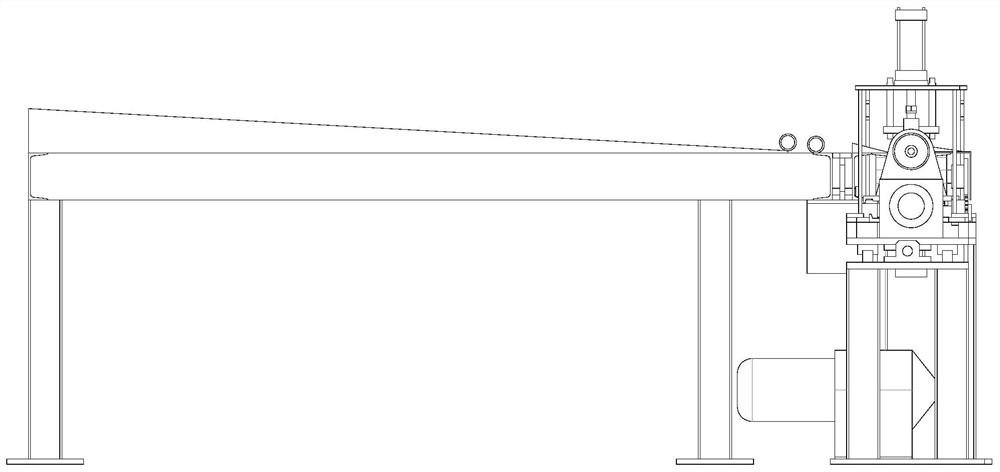

A curved surface self-coupling automatic flaw detector for explosive welding and its application

ActiveCN105548361BImprove accuracy and reliabilityGuaranteed coupling effectAnalysing solids using sonic/ultrasonic/infrasonic wavesCouplingEngineering

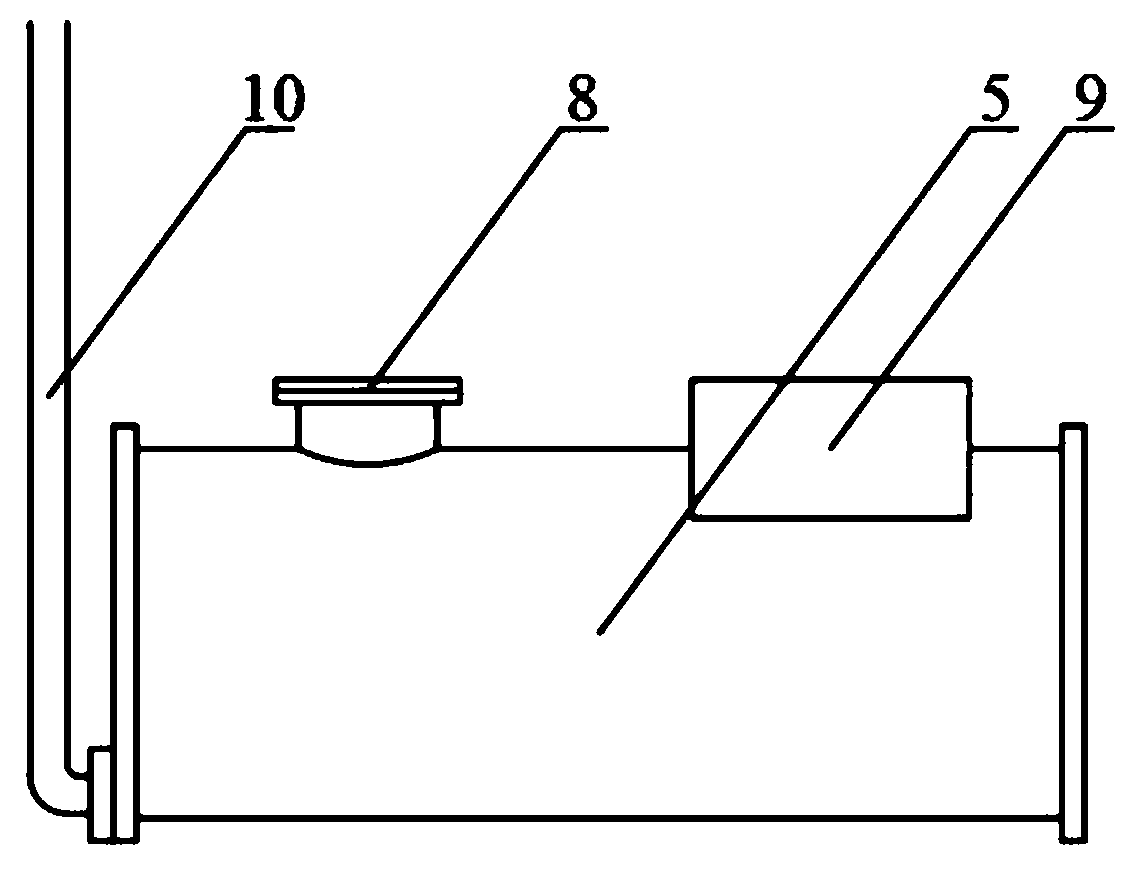

The invention discloses a curved-surface self-coupling automatic flaw detector for explosive welding. The curved-surface self-coupling automatic flaw detector is provided with a flaw detection pool, a coupling probe and analyzers. Sliding rails are arranged at the two sides of the flaw detection pool, the analyzers slide on the sliding rails, and the bottom of a rotary rod is connected with the coupling probe. The coupling probe is provided with a plurality of independent probe telescopic air cylinders, a sub-probe is arranged in each probe telescopic air cylinder, and a clearance exists between every two adjacent probe telescopic air cylinders. A water injector is arranged on the upper portions of the probe telescopic air cylinders, and the clearance between every two adjacent probe telescopic air cylinders is communicated with the water injector. The curved-surface self-coupling automatic flaw detector has the advantages that the height of the small probes can be automatically adjusted through the probe of the self-coupling flaw detector according to the curved surface, coupling on the whole curved surface is guaranteed, a rotary joint of the probe can rotate by any angle to guarantee the proper flaw detection angle, the precise reliability of an ultrasonic nondestructive inspection explosive welding composite plate is greatly improved through the automatic flaw detector, and production efficiency is improved.

Owner:HUBEI JINLAN SPECIAL METAL MATERIAL

Curved-surface self-coupling automatic flaw detector for explosive welding and application thereof

ActiveCN105548361AImprove accuracy and reliabilityGuaranteed coupling effectAnalysing solids using sonic/ultrasonic/infrasonic wavesCouplingEngineering

The invention discloses a curved-surface self-coupling automatic flaw detector for explosive welding. The curved-surface self-coupling automatic flaw detector is provided with a flaw detection pool, a coupling probe and analyzers. Sliding rails are arranged at the two sides of the flaw detection pool, the analyzers slide on the sliding rails, and the bottom of a rotary rod is connected with the coupling probe. The coupling probe is provided with a plurality of independent probe telescopic air cylinders, a sub-probe is arranged in each probe telescopic air cylinder, and a clearance exists between every two adjacent probe telescopic air cylinders. A water injector is arranged on the upper portions of the probe telescopic air cylinders, and the clearance between every two adjacent probe telescopic air cylinders is communicated with the water injector. The curved-surface self-coupling automatic flaw detector has the advantages that the height of the small probes can be automatically adjusted through the probe of the self-coupling flaw detector according to the curved surface, coupling on the whole curved surface is guaranteed, a rotary joint of the probe can rotate by any angle to guarantee the proper flaw detection angle, the precise reliability of an ultrasonic nondestructive inspection explosive welding composite plate is greatly improved through the automatic flaw detector, and production efficiency is improved.

Owner:HUBEI JINLAN SPECIAL METAL MATERIAL

System for opening package of paper case

An unpacking system for the carton containing goods, especially the cigarette carton is composed of carton conveyer, carton turning over unit, goods conveyer, empty carton clamping unit for removing it away, and empty carton folding-stacking unit for reusing them. Its advantage are no damage to carton and reducing stacking space.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE +1

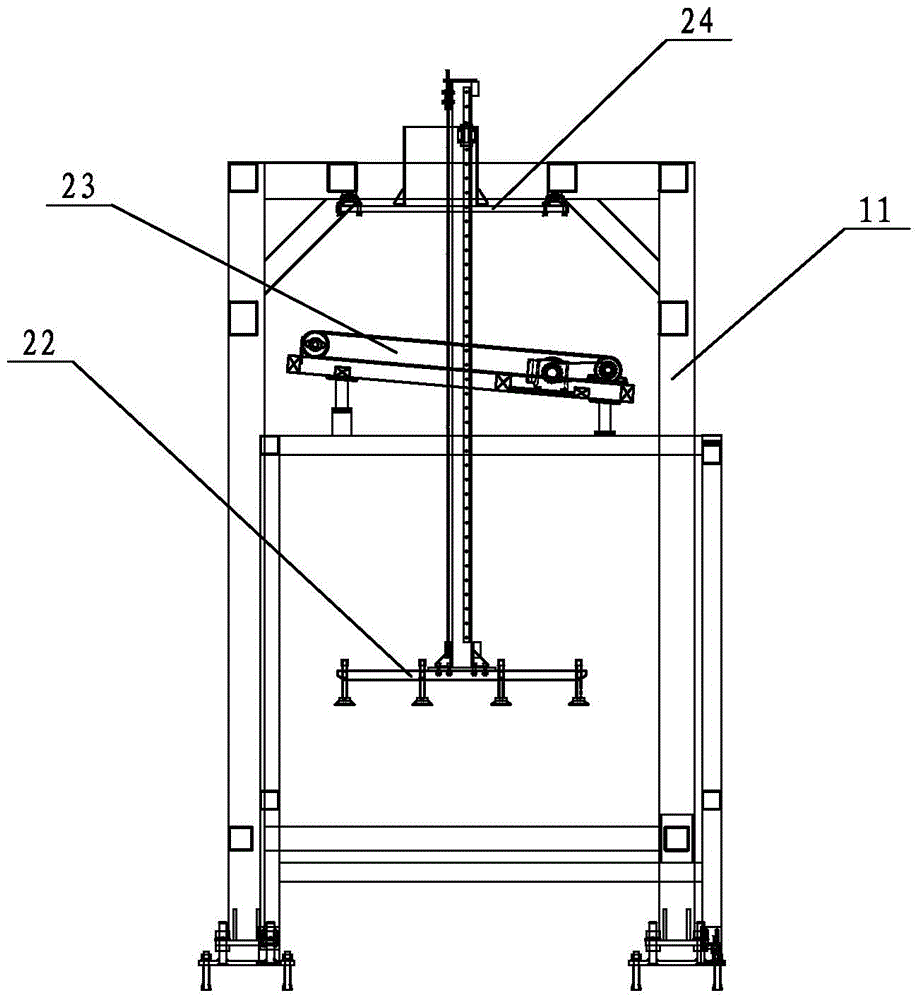

An automatic boxing machine

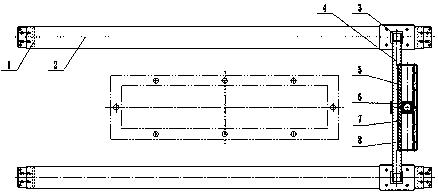

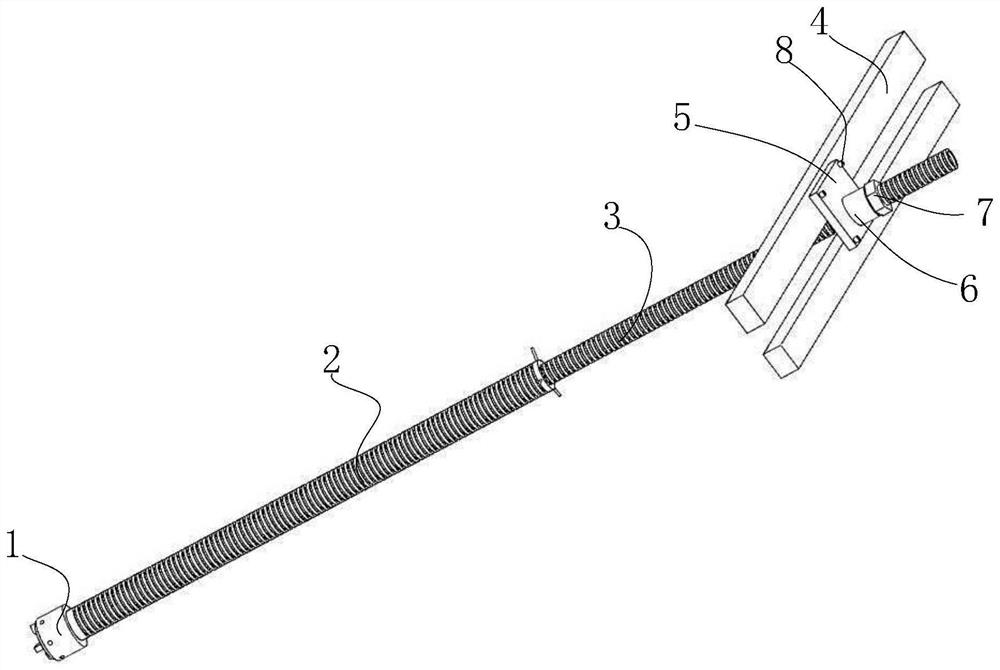

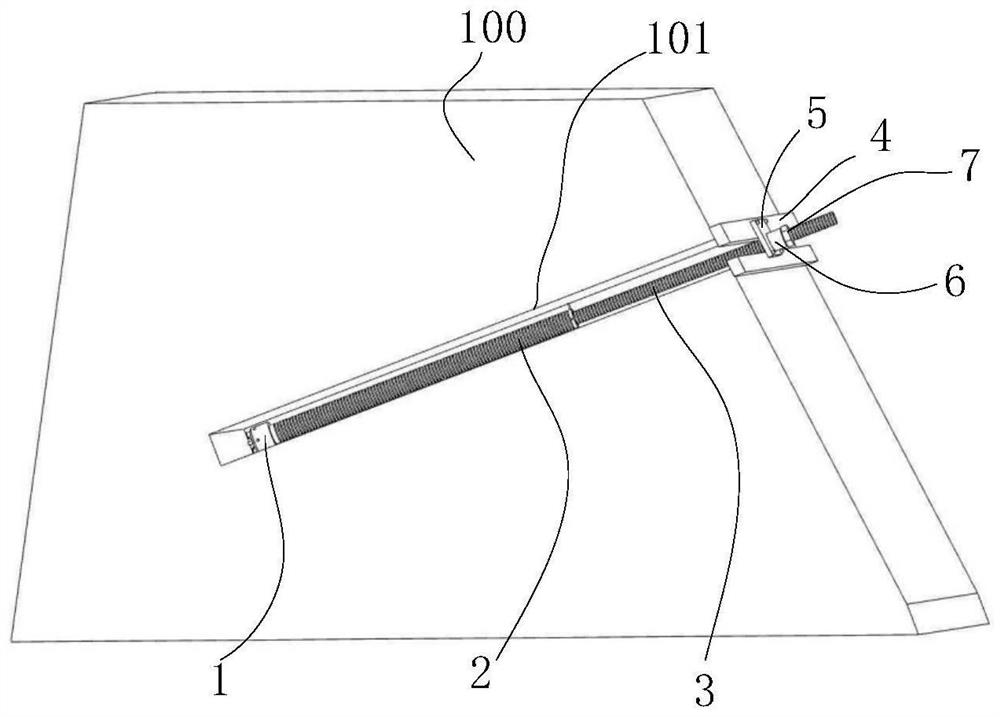

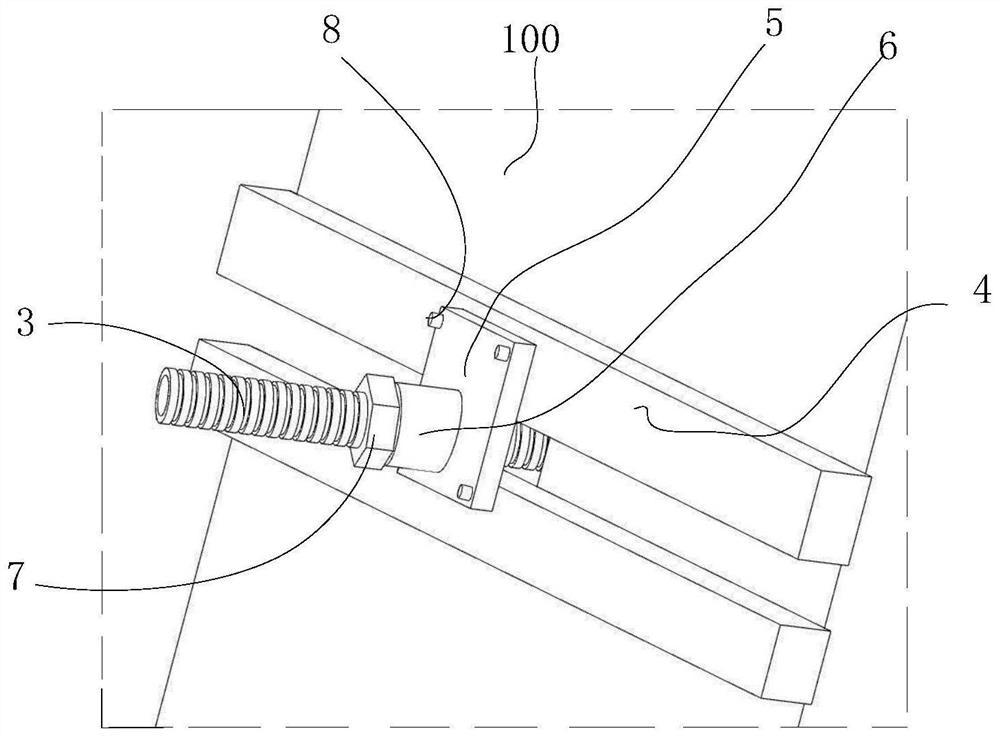

ActiveCN104787365BRealize continuous automationReduce labor costsIndividual articlesProduction lineCarton

The invention discloses an automatic box covering machine. The machine comprises a bracket, and a flat paper box grabbing unit, a paper box spreading unit, a paper box pushing unit and a box covering unit arranged on the bracket in sequence, wherein a product main production line penetrates through the paper box pushing unit and the box covering unit; and a conveying line 1, a conveying line 2 and a conveying line 3 are all conveying lines operated independently. The machine realizes the continuous automation operation of the process from the flat paper box grabbing to the three-dimensional paper box covering through the combined application of the four units of the flat paper box grabbing unit, the paper box spreading unit, the paper box pushing unit and the box covering unit, so that the labor cost is largely reduced, and the production efficiency is improved.

Owner:SUZHOU YEE FUNG ELECTRIC EQUIP

A spring testing system and method

ActiveCN106353081BPrecise positioningRealize continuous automationMachine part testingConveyorsElectricityEngineering

Owner:济南凯镭迪精密仪器有限公司

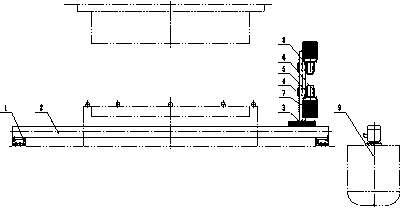

Double-end saddle type welding groove machining production line

PendingCN112296704ARealize continuous automationImprove processing qualityWork clamping meansFeeding apparatusProduction lineReciprocating motion

The invention discloses a double-end saddle type welding groove machining production line which comprises a material channel, a fixed saddle beveling machine and a movable saddle beveling machine. Thefixed saddle beveling machine and the movable saddle beveling machine are arranged at the two ends of the material channel correspondingly, and the height of the central axis of the fixed saddle beveling machine and the height of the central axis of the movable saddle beveling machine are equal to the height of the central line of the material channel. The fixed saddle beveling machine is fixed to the ground, the movable saddle beveling machine is fixed to a movable base, the movable base is fixed to a guide rail, the movable base is synchronously connected to a servo motor through a lead screw assembly, and the servo motor drives the lead screw assembly to move, so that the movable base does front-and-back reciprocating motion on the guide rail. The production line is simple in structural design, capable of automatically machining double-end saddle grooves, good in machining quality, high in efficiency, adjustable in parameter, wide in machining range and high in mechanization degree.

Owner:住重福惠动力机械有限公司

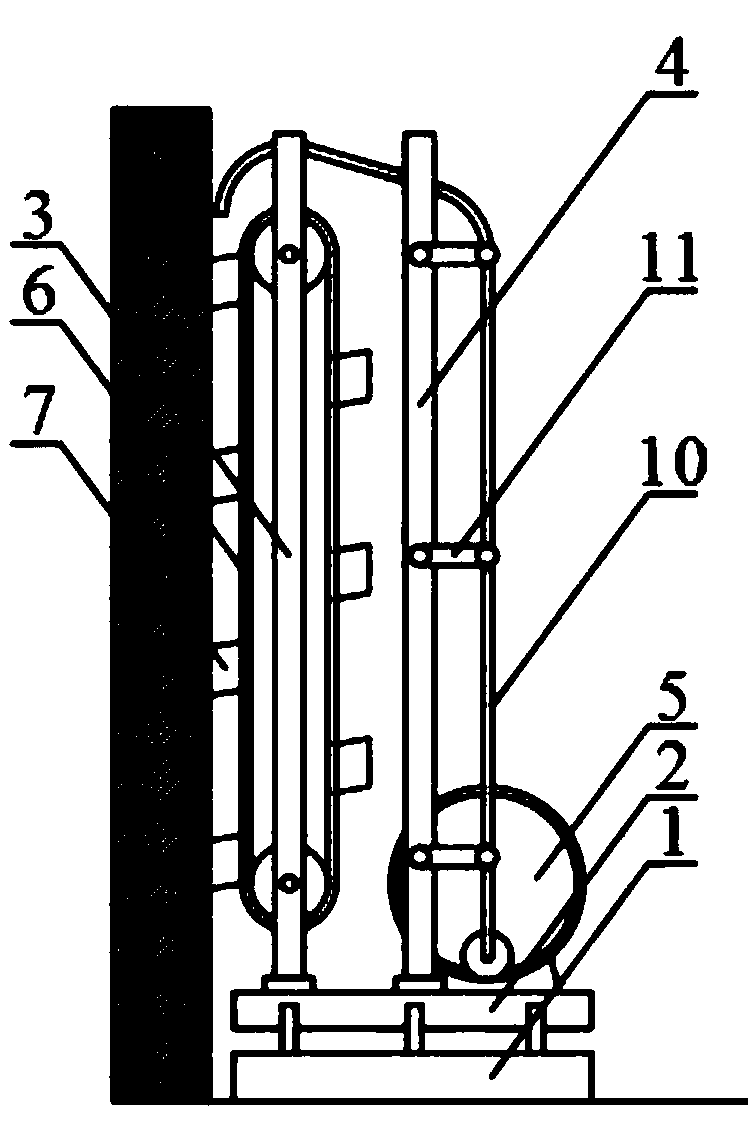

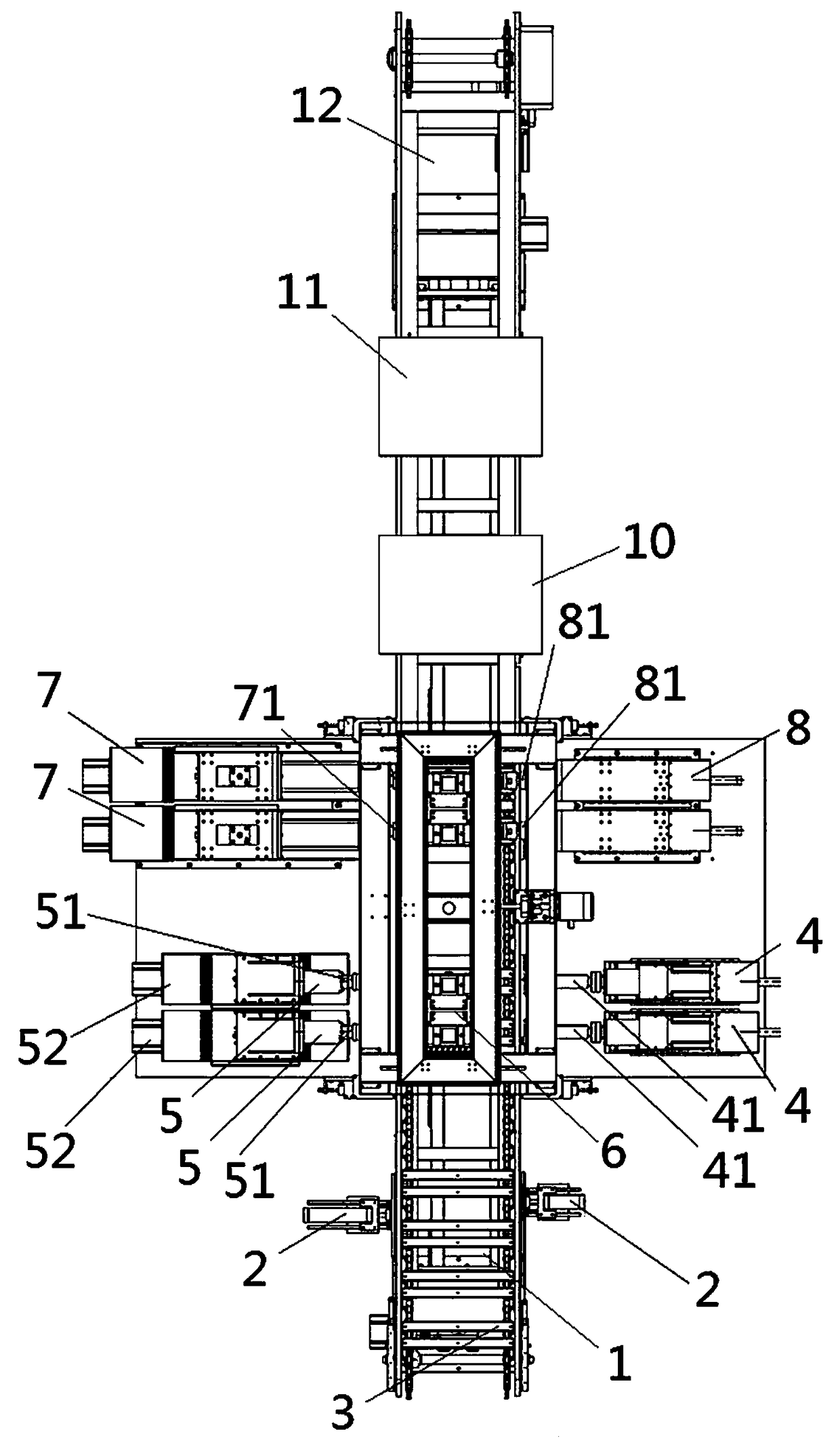

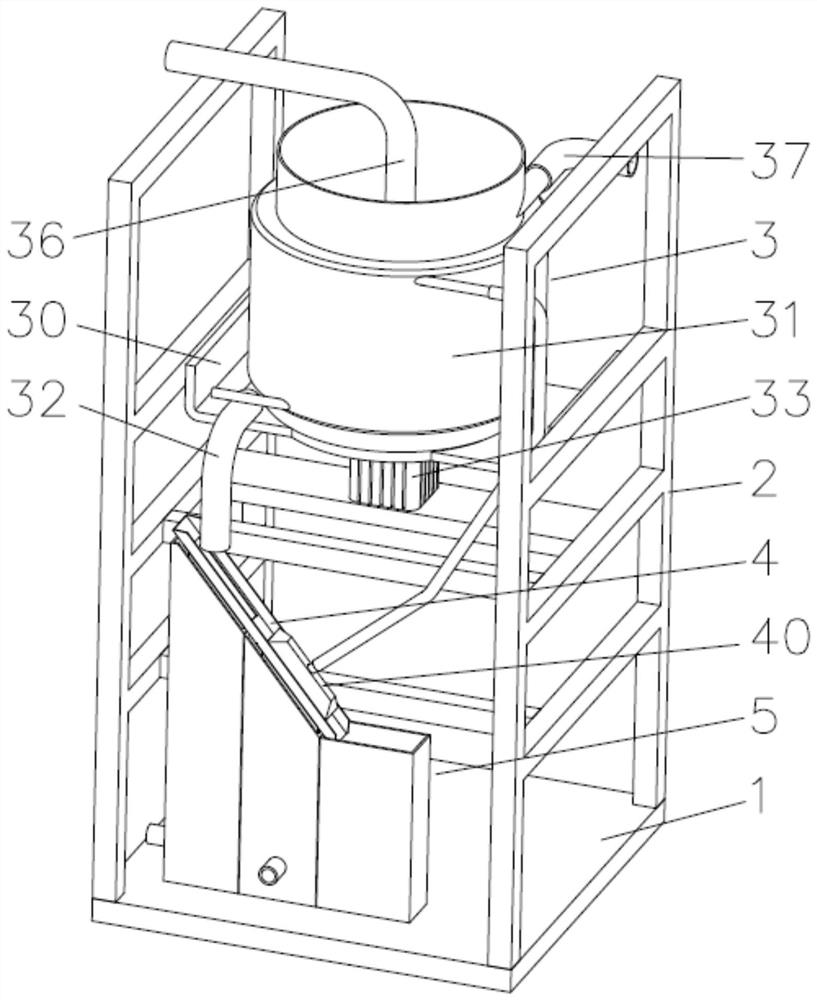

A kind of automatic system and method for lysine production and crystallization extraction

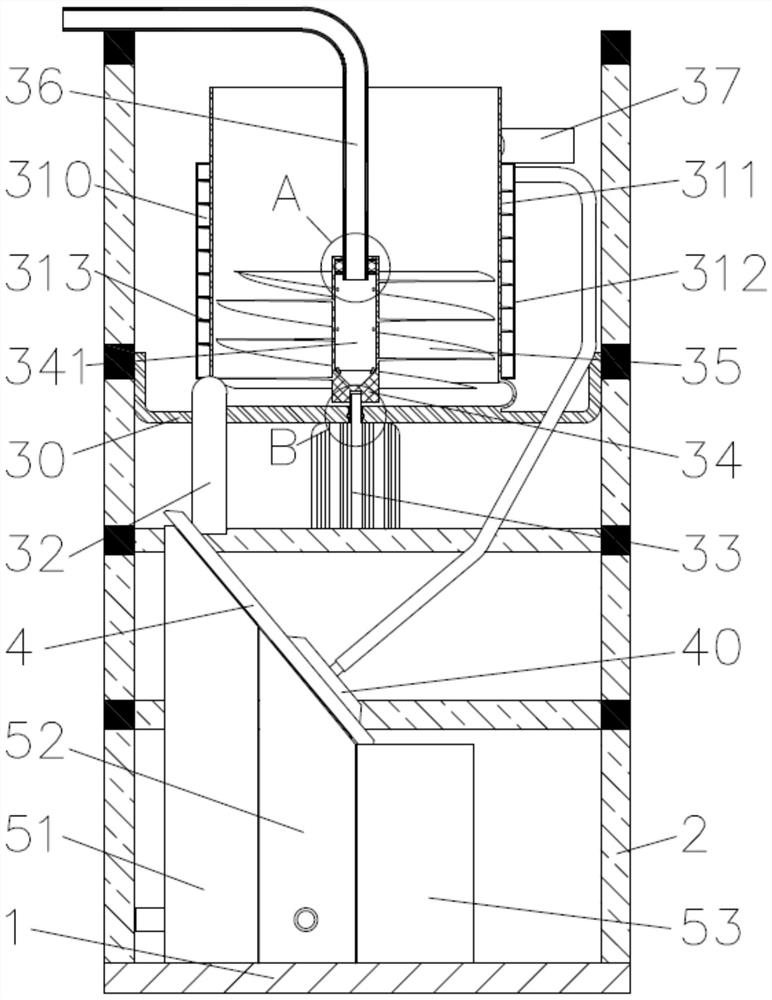

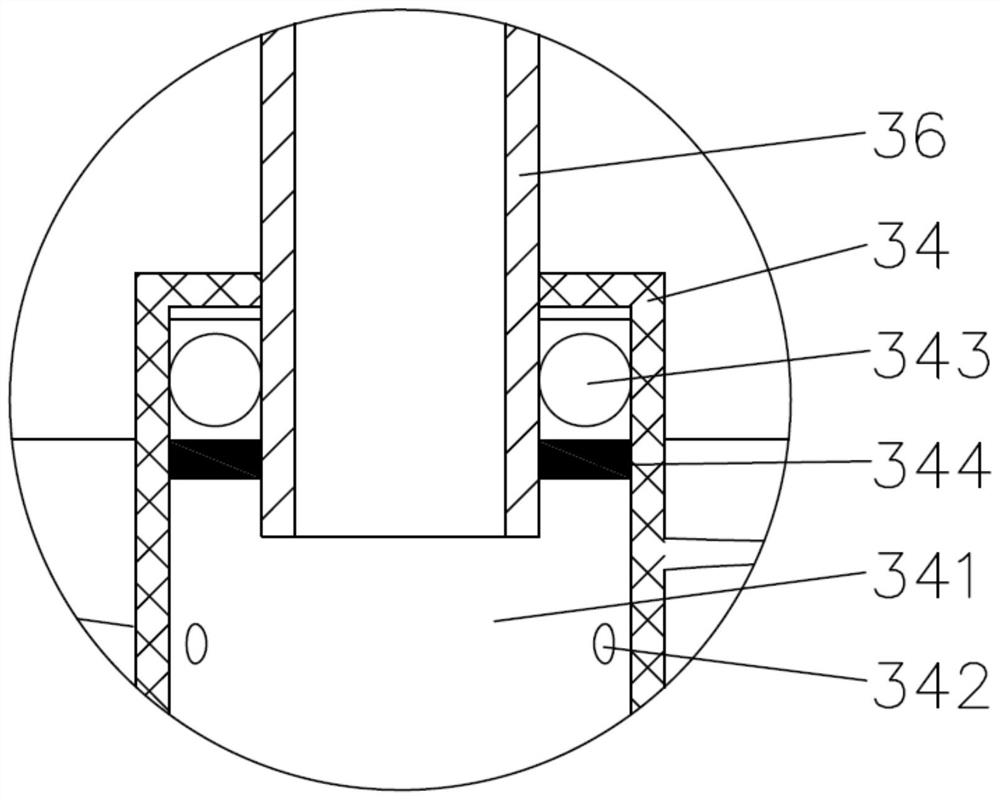

ActiveCN113173861BRealize continuous automationGuaranteed validityOrganic compound preparationChemical industryRotational axisThermal insulation

The invention provides an automatic system and method for lysine production and crystallization extraction, the system includes a base (1), a support (2), a cooling and separation assembly (3), a feed tank (4) and a liquid collector assembly (5); wherein, the cooling separation assembly (3) includes a cooling separation tank (31), a discharge pipe (32), a drive motor (33), a rotating shaft (34), a separation blade (35) and a feed pipe (36 ), the cooling separation tank (31) is a double-layer structure, including a cooling inner wall (311) and an insulating outer wall (312), and a cooling cavity (310) and a cooling cavity are formed between the cooling inner wall (311) and the insulating outer wall (312). A spiral deflector (313) is arranged inside the (310), and a cavity (341) and a through hole (342) are arranged on the rotating shaft (34). The system can effectively control the cooling temperature to ensure the cooling effect and efficiency; at the same time, the system separates synchronously during the cooling process, which improves the separation efficiency, reduces production costs, and saves manpower and material resources.

Owner:长春市吉达自动化系统有限公司

Engineering method for separating and extracting xanthic gum

InactiveCN1176108CRealize continuous automationPromote safe productionOrganic solventMechanical equipment

The engineering method for separating and extracting xanthan gum is characterized by that the processes of charging materials, mixing, precipitation, separation and regulation of pH value can be continuously uniformly implemented in a closed mechanical equipment. Said ivnention can maximally prevent the organic solvent from producing volatillization in the course of production, under the normal production condition does not produce explosive gas, and can ensure safe production. As compared with ethyl alcohol precipitation method its alcohol consumption can be reduced by 80%, if after extraction vacuum drying process is adopted the ethyl alcohol consumption can be reduced by 95%. Its product quality is high and stable.

Owner:张孝宽

Automatic strip-inserting process of heat-insulting bridge cut-off aluminum window and door profiles

Owner:SHANGHAI ZENITH ENG EQUIP

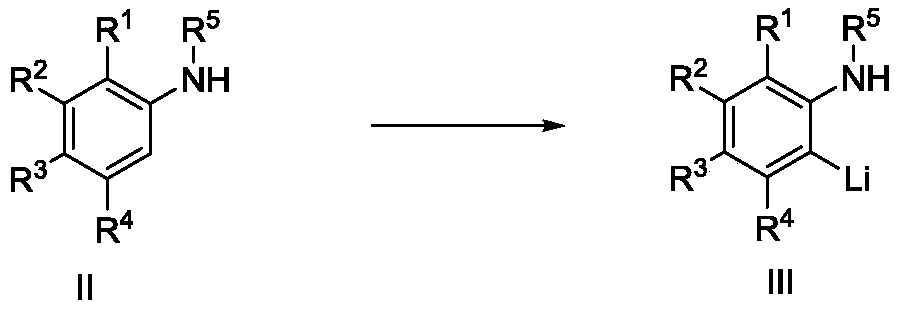

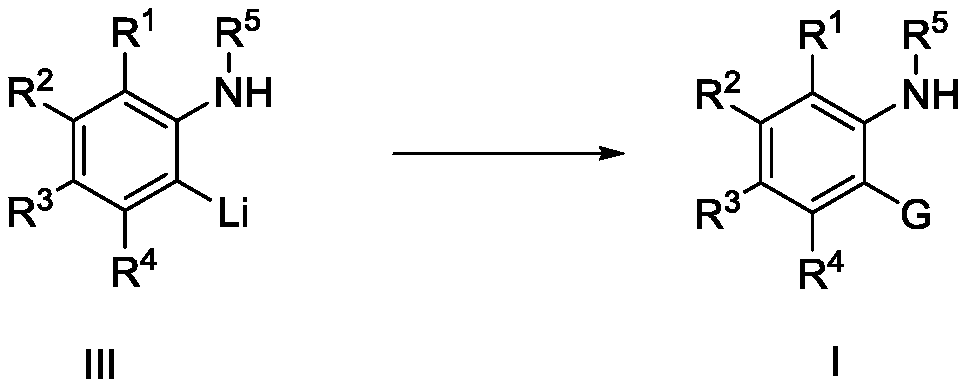

Preparation method of arylamine o-substituted compound

PendingCN110396108AReduce online trafficRealize continuous automationLithium organic compoundsCarbamic acid derivatives preparationOrganic solventRoom temperature

The invention discloses a preparation method of an arylamine o-substituted compound as shown in a formula I in the specification. The preparation method provided by the invention comprises the following steps: (1) in a continuous flow reactor, carrying out lithiation reaction on a material 1 and an alkyl lithium reagent to obtain a solution containing a metal lithium compound as shown in a formulaIII, which is described in the specification, wherein the material 1 is a mixed solution of an arylamine compound as shown in a formula II, which is described in the specification and an organic solvent; and (2) carrying out a coupling reaction on the material 2 and the solution containing the metal lithium compound represented by the formula III in the step (1) in a continuous flow reactor to obtain the arylamine o-substituted compound represented by the formula I. With the method, the lithiation reaction on the aromatic ring can be realized at room temperature to prepare corresponding products such as bromo-, boric acid, aldehyde, carboxylic acid and the like; the method has the advantages of short reaction time, reduction of the on-line amounts of inflammable materials and high reaction activity intermediates, and improvement of the safety.

Owner:LIANHE CHEM TECH +1

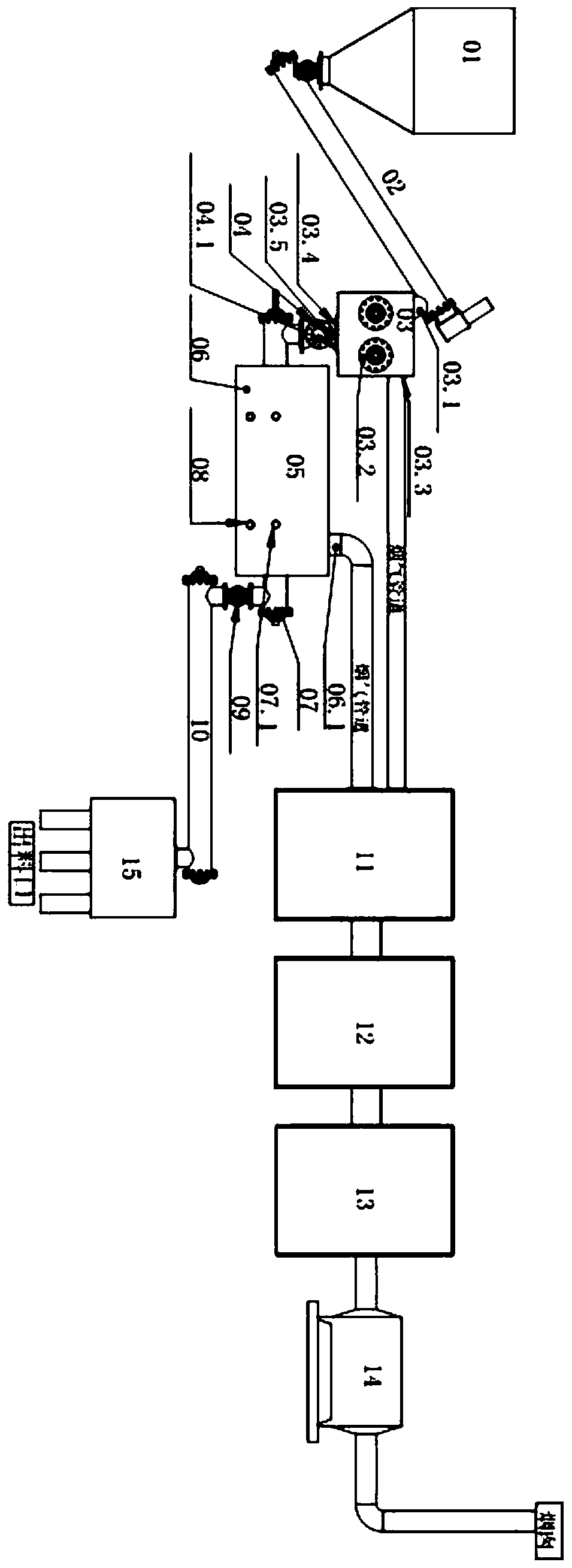

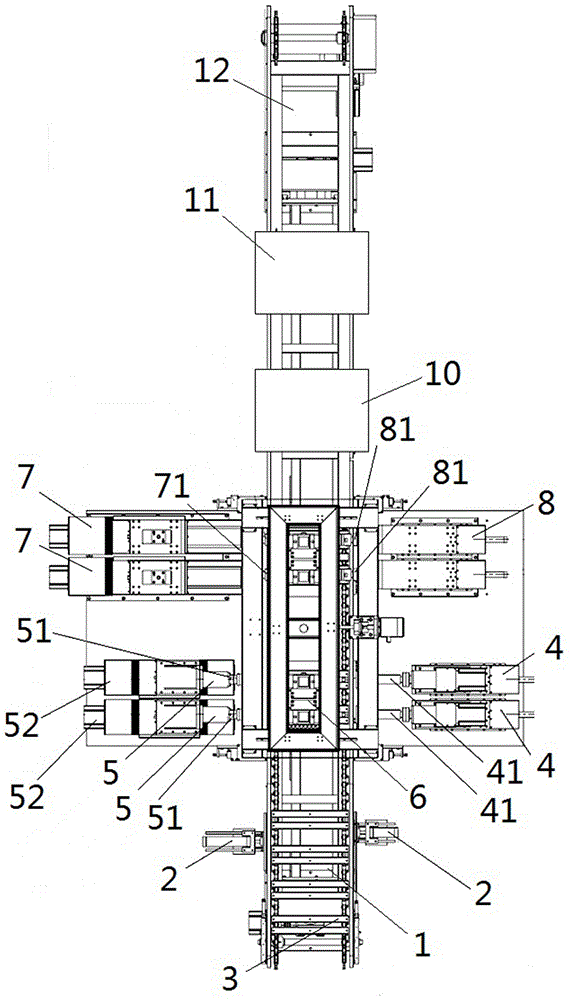

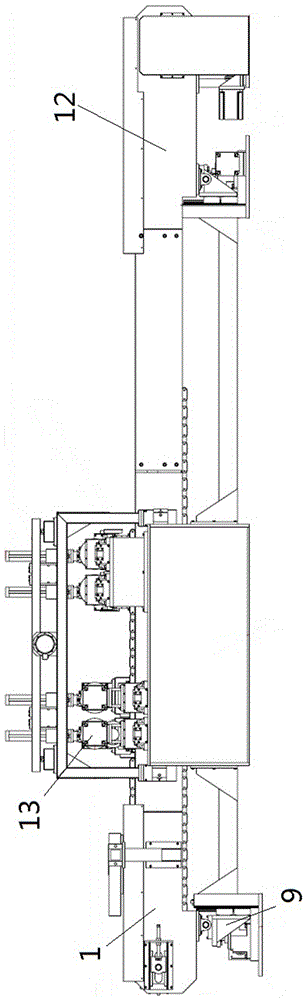

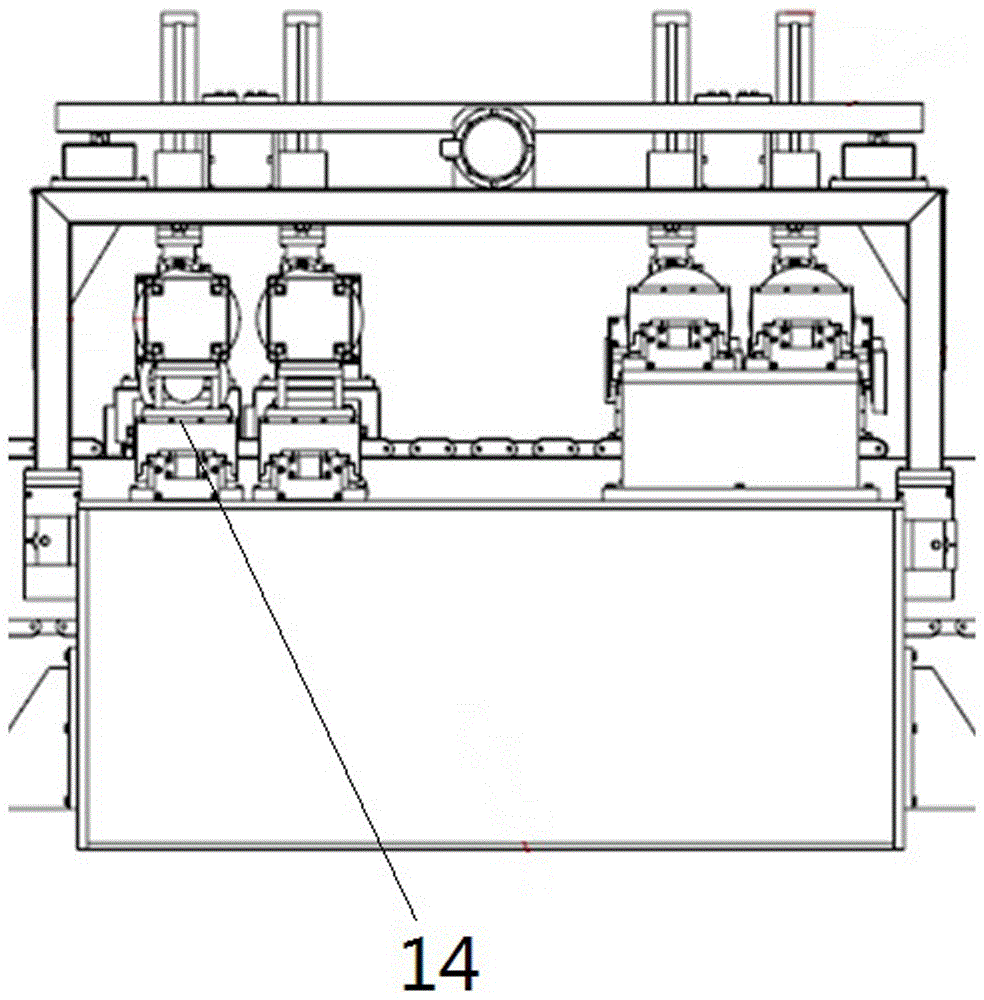

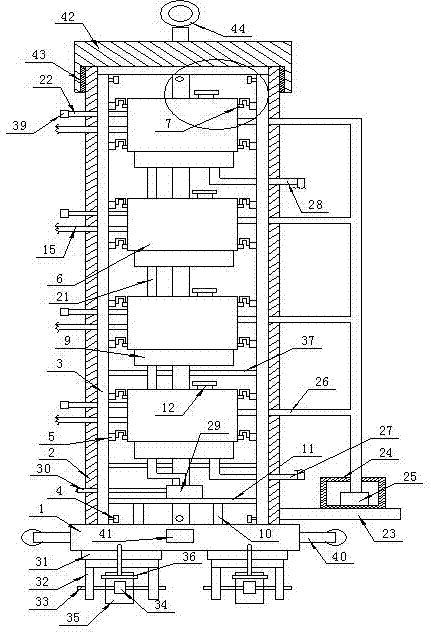

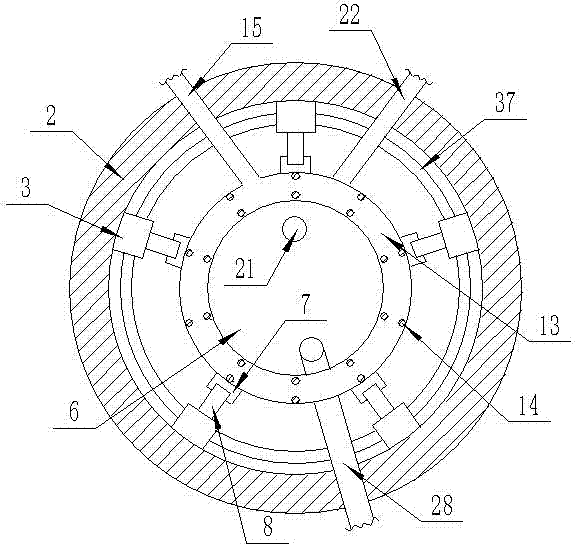

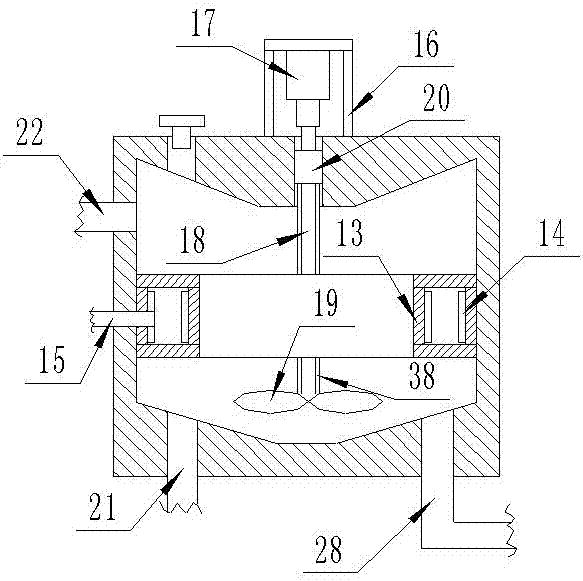

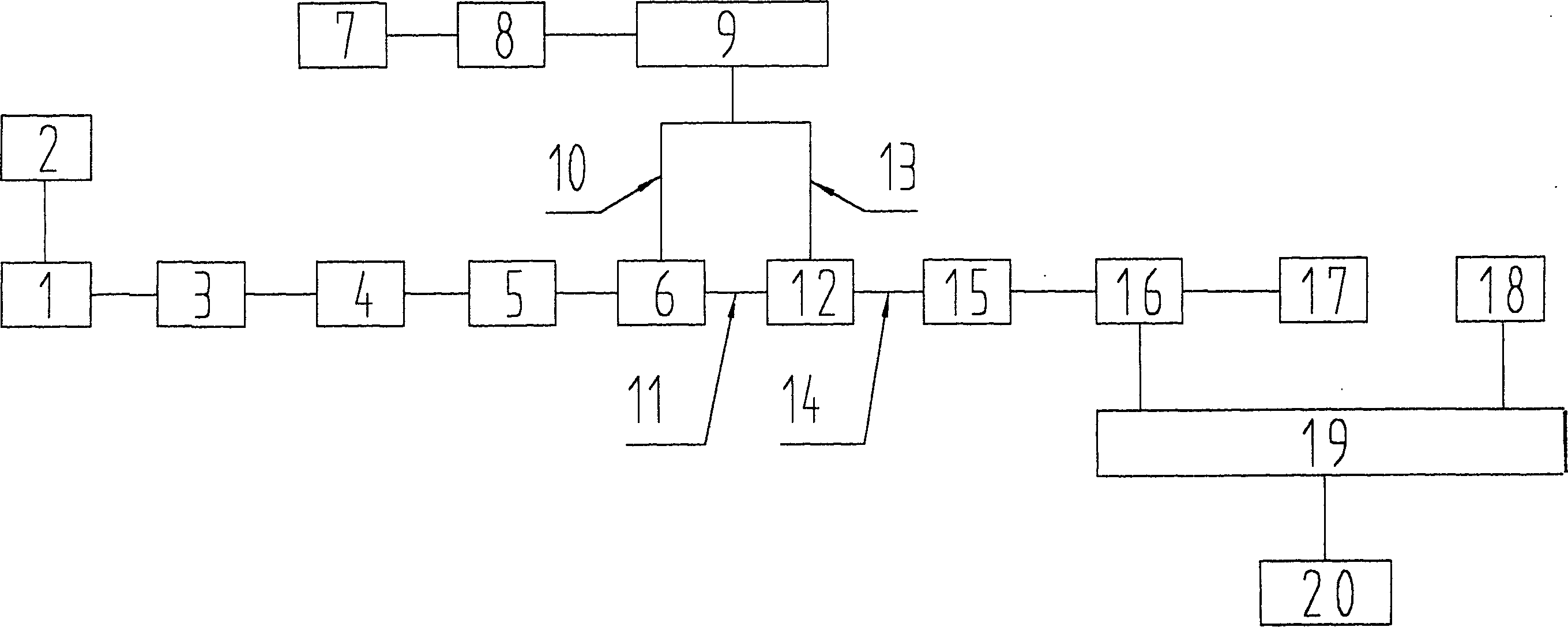

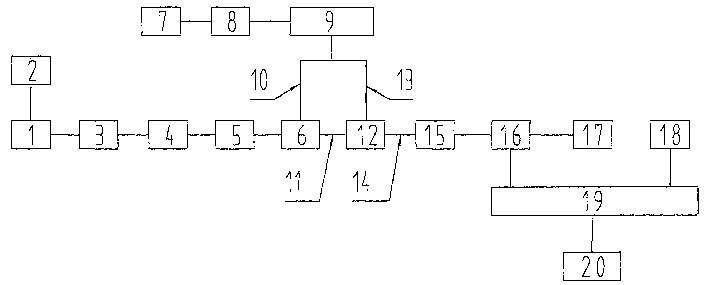

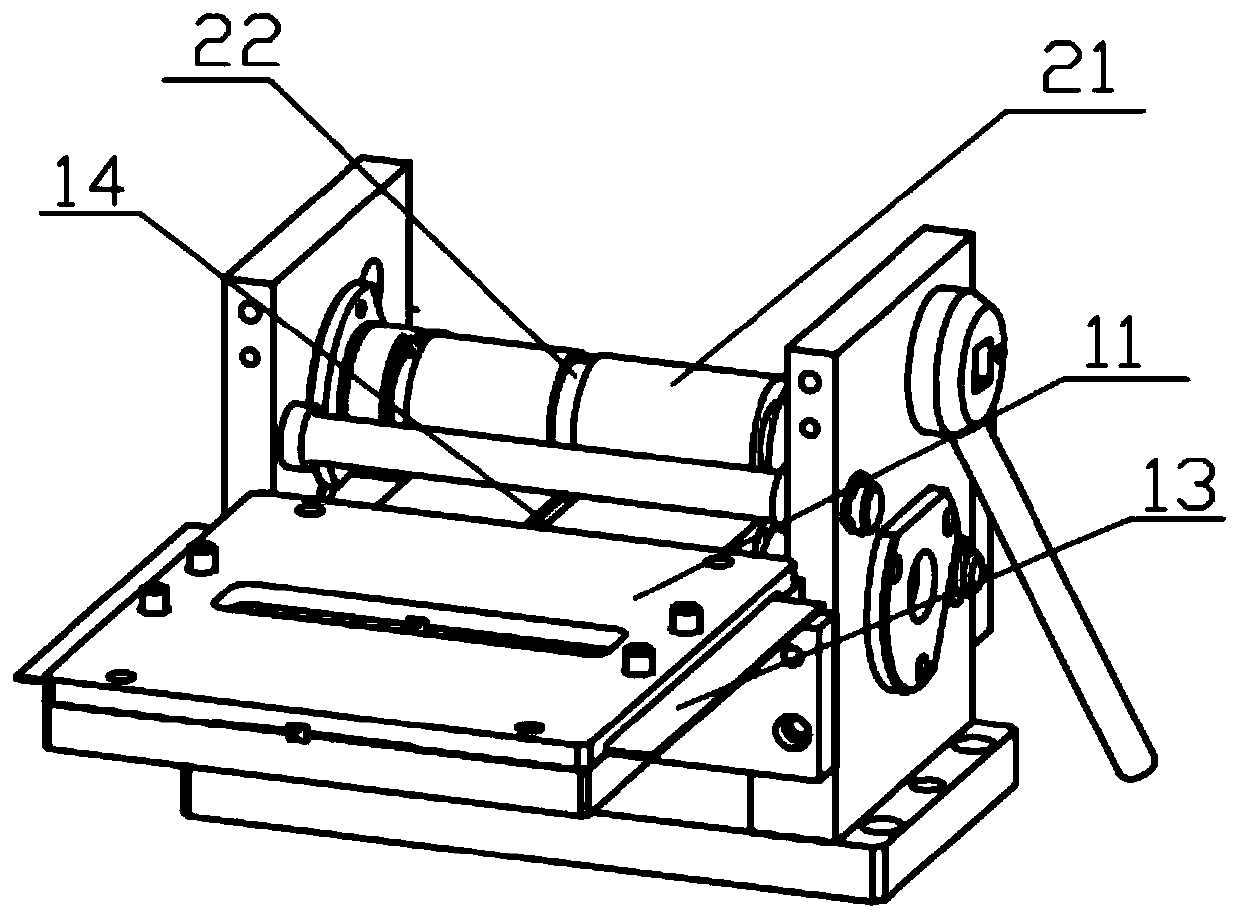

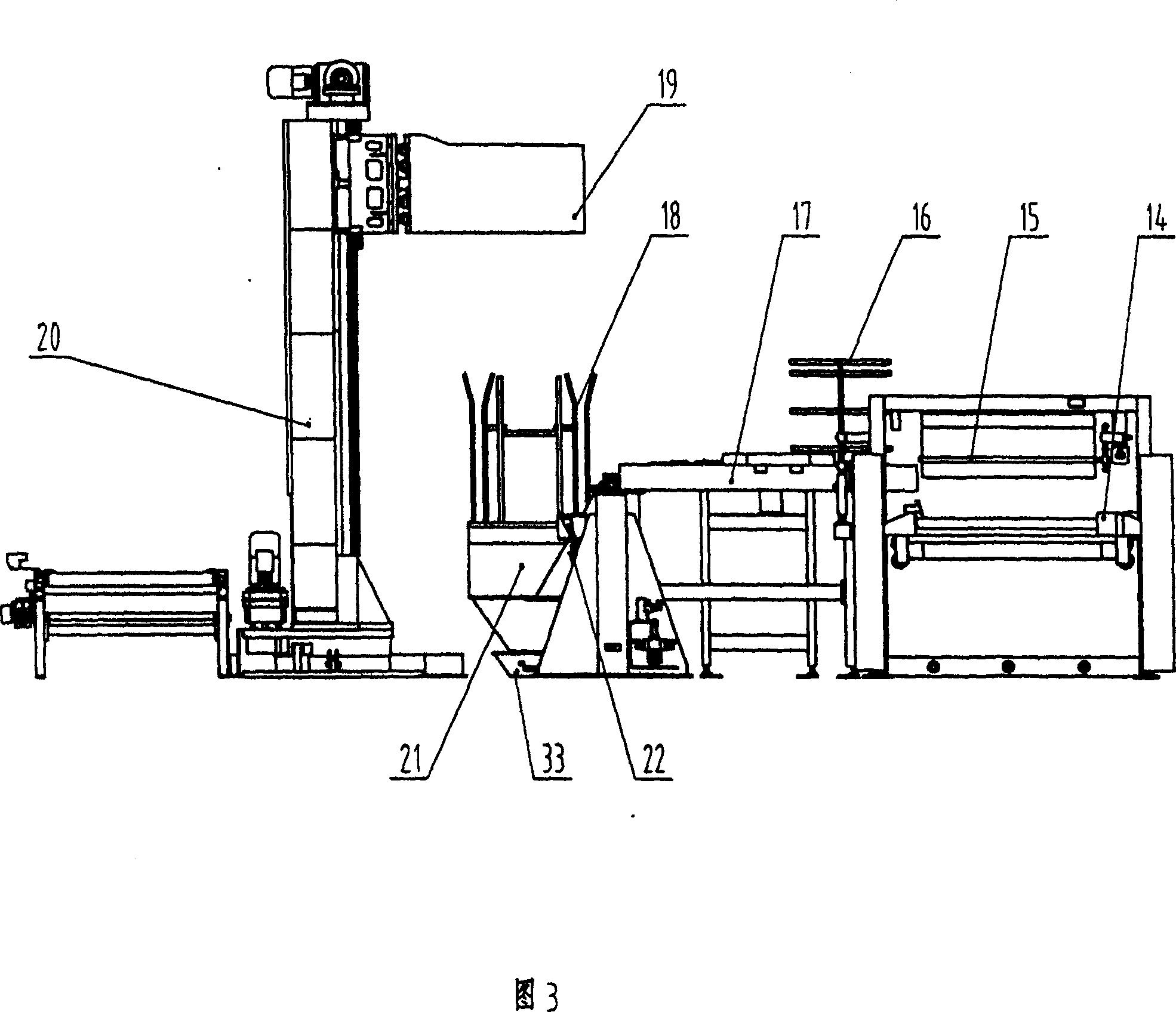

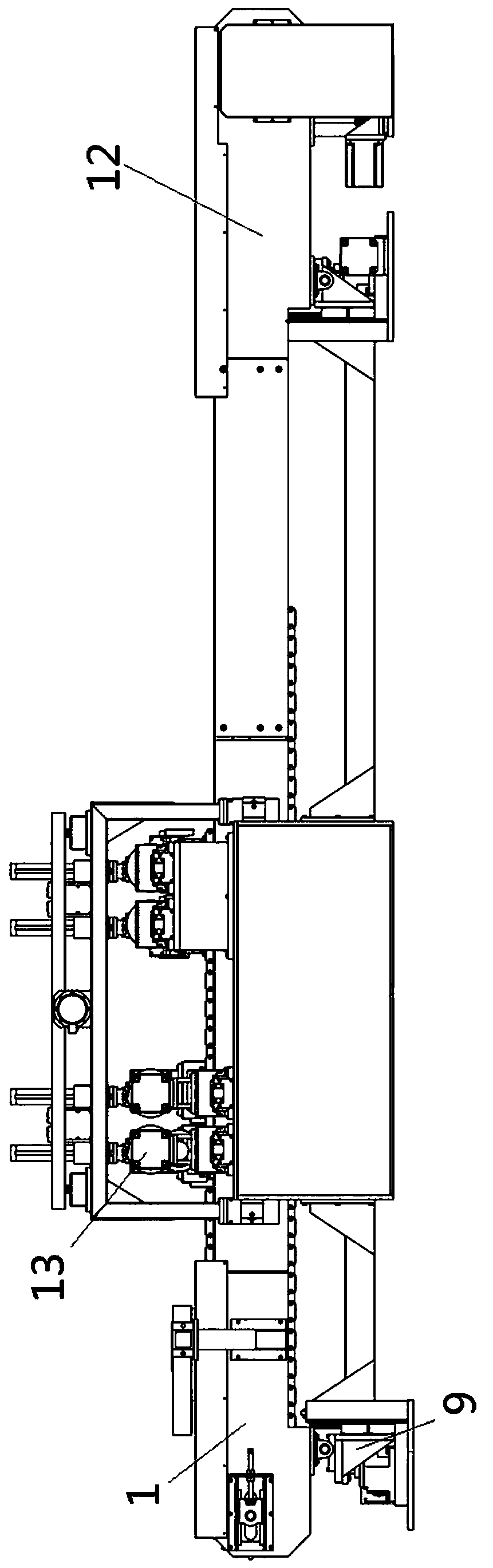

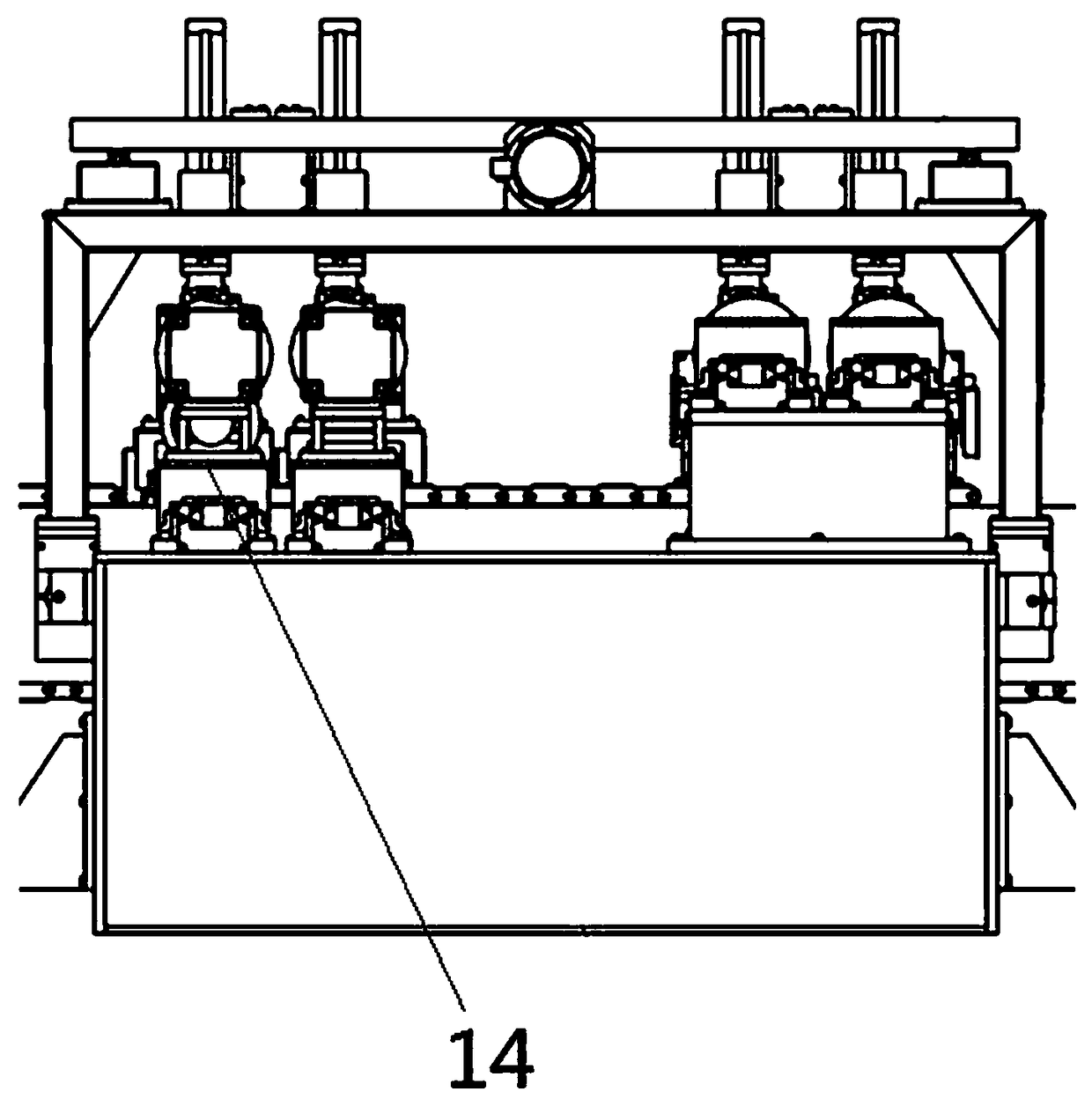

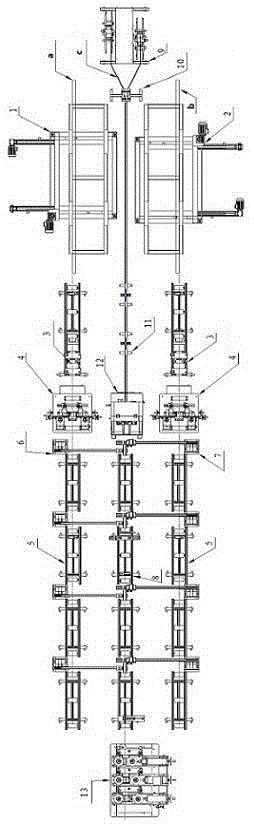

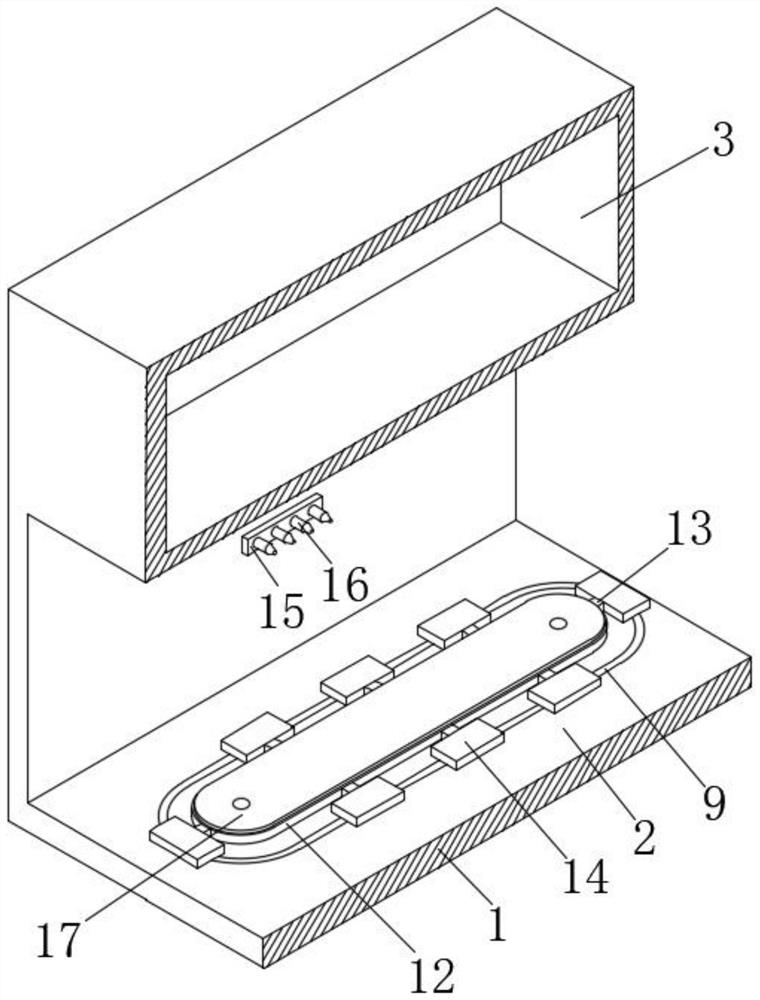

Continuous explosive manufacturing, filling and packing production line of thermoplastic seismic explosive column

ActiveCN102853725BRealize continuous automationAmmunition storageTransfer mechanismMaterials science

The invention provides a continuous explosive manufacturing, filling and packing production line of a thermoplastic seismic explosive column. The continuous explosive manufacturing, filling and packing production line of the thermoplastic seismic explosive column is composed of an A platform (1), a B platform (9), a feeding mechanism, a material plasticizing and transferring mechanism, an explosive filling cover-pressing mechanism, an explosive column transferring and cooling mechanism, a seismic explosive column automatic heat-sealing and connecting sleeve assembly machine (24), an automatic packing machine (22) and a finished product belt conveyor (23). The continuous explosive manufacturing, filling and packing production line of the thermoplastic seismic explosive column has the advantages of improving explosive manufacturing, filling and packing efficiency of the thermoplastic seismic explosive column and a mine blasting explosive column, achieving automation and continuity, and reducing operators.

Owner:HUBEI KAILONG CHEM GRP

Spraying equipment for intelligent water meter processing and treatment method thereof

InactiveCN112844928ARealize automatic deliveryHeight adjustablePretreated surfacesLiquid spraying apparatusSmart waterDrive shaft

The invention discloses spraying equipment for intelligent water meter processing. The spraying equipment comprises a machine body, a spraying channel located at the upper end of the machine body and a paint storage cavity located at the lower end of the machine body, wherein the spraying channel transversely penetrates through the machine body, two gears are symmetrically arranged in the middle of the top wall of the spraying channel, transmission shafts are fixedly connected to the inner sides of the two gears in an inserted mode, the two gears are fixed on the top wall of the spraying channel through the transmission shafts, one of the transmission shafts extends to the outer side of the machine body to be fixedly connected with a first motor fixedly arranged on the top wall of the machine body, the outer sides of the two gears are in meshing connection with a toothed belt, an annular guide rail is arranged on the top wall, on the outer sides of the two gears, of the spraying channel, and a plurality of connecting blocks arranged at intervals are fixed to the outer side surface of the toothed belt. According to the spraying equipment for intelligent water meter processing and the treatment method thereof, in the spraying process of an intelligent water meter, continuous and automatic spraying can be achieved, the spraying efficiency is improved, the spraying uniformity can further be improved, and meanwhile quick drying is facilitated after spraying is completed.

Owner:王文

Oxide scale recovery device for hot stamping die

InactiveCN111085475AImplement automated removal functionsWith automatic cleaning functionDirt cleaningCleaning using toolsHot stampingStamping

The invention provides an oxide scale recovery device for a hot stamping die. The device is mainly composed of a linear driving mechanism, a base, a cross beam, a vertical beam, a suction bucket, a bucket handle connector, a brush body and the like. The linear driving mechanism is arranged on the base. The device is characterized in that the vertical beam is arranged on the linear driving mechanism, the cross beam is arranged on the vertical beam, the bucket handle connector is arranged on the cross beam, the suction bucket is arranged on the bucket handle connector, and the brush body is arranged on the suction bucket and provided with a strong air opening. The recovery device is provided with upper and lower oxide scale removal devices, has the function of automatically cleaning the upper and lower die surfaces of the hot stamping die, and can remove oxide scale attached to the upper and lower die surfaces through strong blowing of the strong air opening and mechanical sweeping of the brush body, and the oxide scale is sucked into a container through a strong vacuum cleaner. The device achieves the oxide scale automatic removal function, does not need manual operation, eliminatessafety hidden hazards during manual operation, also achieves continuous automatic stamping, greatly improves the working efficiency and reduces the production cost.

Owner:北京机科国创轻量化科学研究院有限公司烟台分公司 +1

Prefabricated pre-stressed anchor rod construction structure

ActiveCN114197465AImprove construction efficiencyRealize continuous automationClimate change adaptationBulkheads/pilesDrill bitRock bolt

The invention discloses a prefabricated prestressed anchor rod construction structure. The prefabricated pre-stressed anchor rod construction structure comprises a drill bit, a hollow primary anchor pipe and a hollow secondary anchor pipe, during use, the hollow mother anchor pipe can be fixed through mechanical equipment and driven to rotate, hole digging is conducted through a drill bit at the end of the hollow mother anchor pipe, after the hollow mother anchor pipe enters a hole, the hollow child anchor pipe is fixed through the mechanical equipment and pulled outwards, and the hollow mother anchor pipe is driven to rotate. The telescopic column of the hollow secondary anchor pipe is inserted into the second through hole of the hollow primary anchor pipe, axial fixation of the hollow secondary anchor pipe and the hollow primary anchor pipe is achieved, then the hollow secondary anchor pipe can be driven by mechanical equipment to rotate, hole digging continues to be conducted inwards, manual connection of the anchor pipes is not needed in the working process, construction efficiency is improved, interruption in the process is not needed, and construction efficiency is improved. And continuous automatic operation is realized.

Owner:GUANGDONG YUANTIAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com