Fuse melt processing apparatus

A technology of processing equipment and fuses, which is applied in the manufacture of fuses, etc., can solve the problems of low processing efficiency and high processing cost, achieve the effect of improving melt processing efficiency and processing quality, and realizing continuous automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

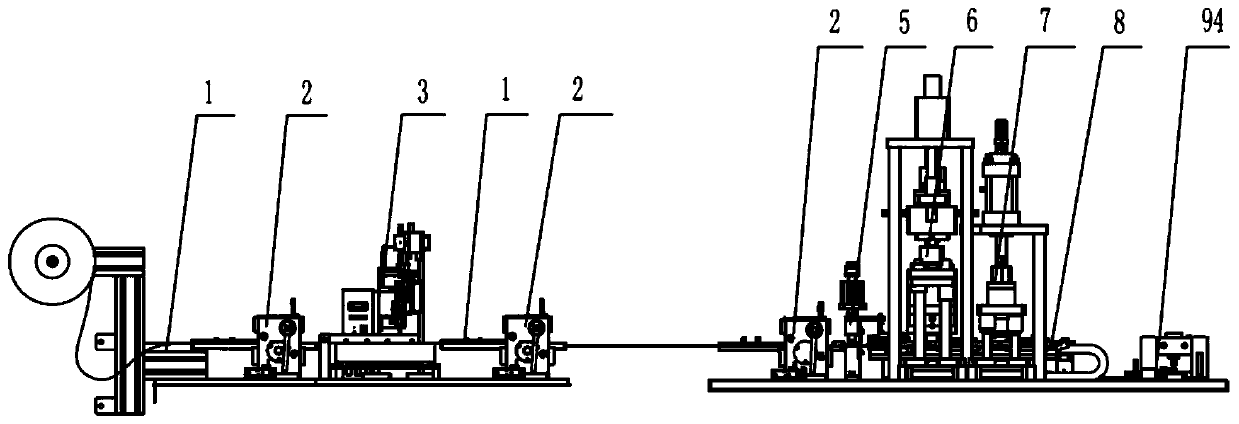

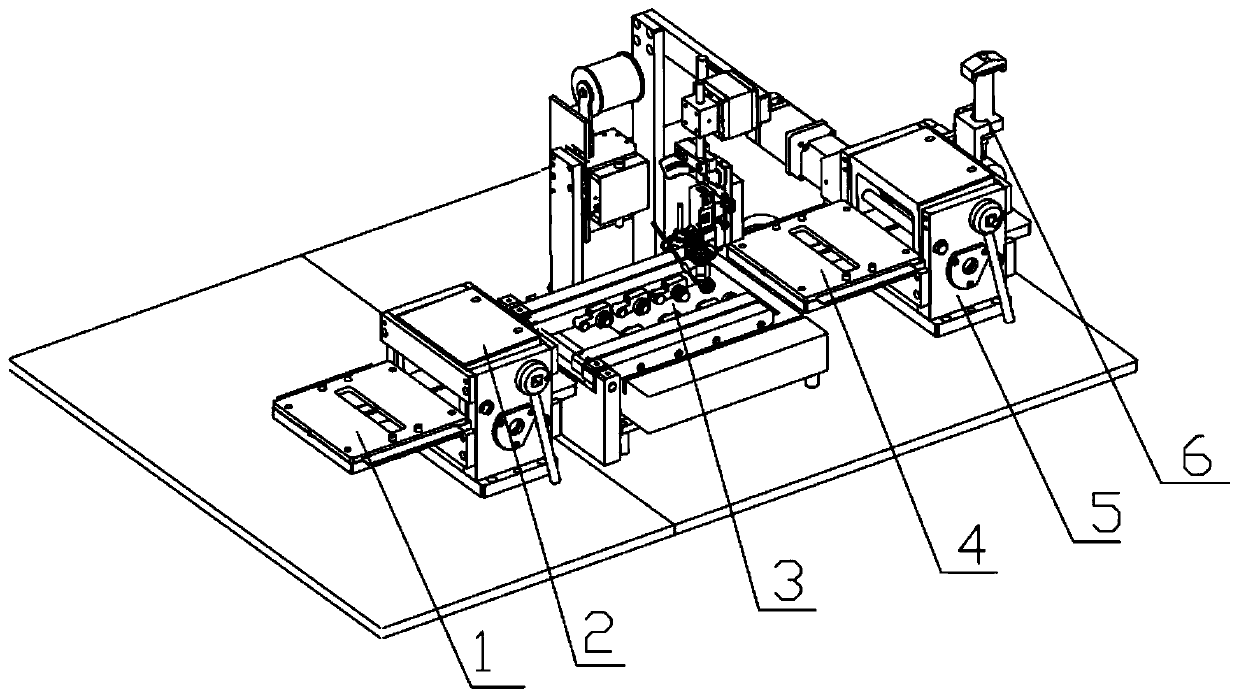

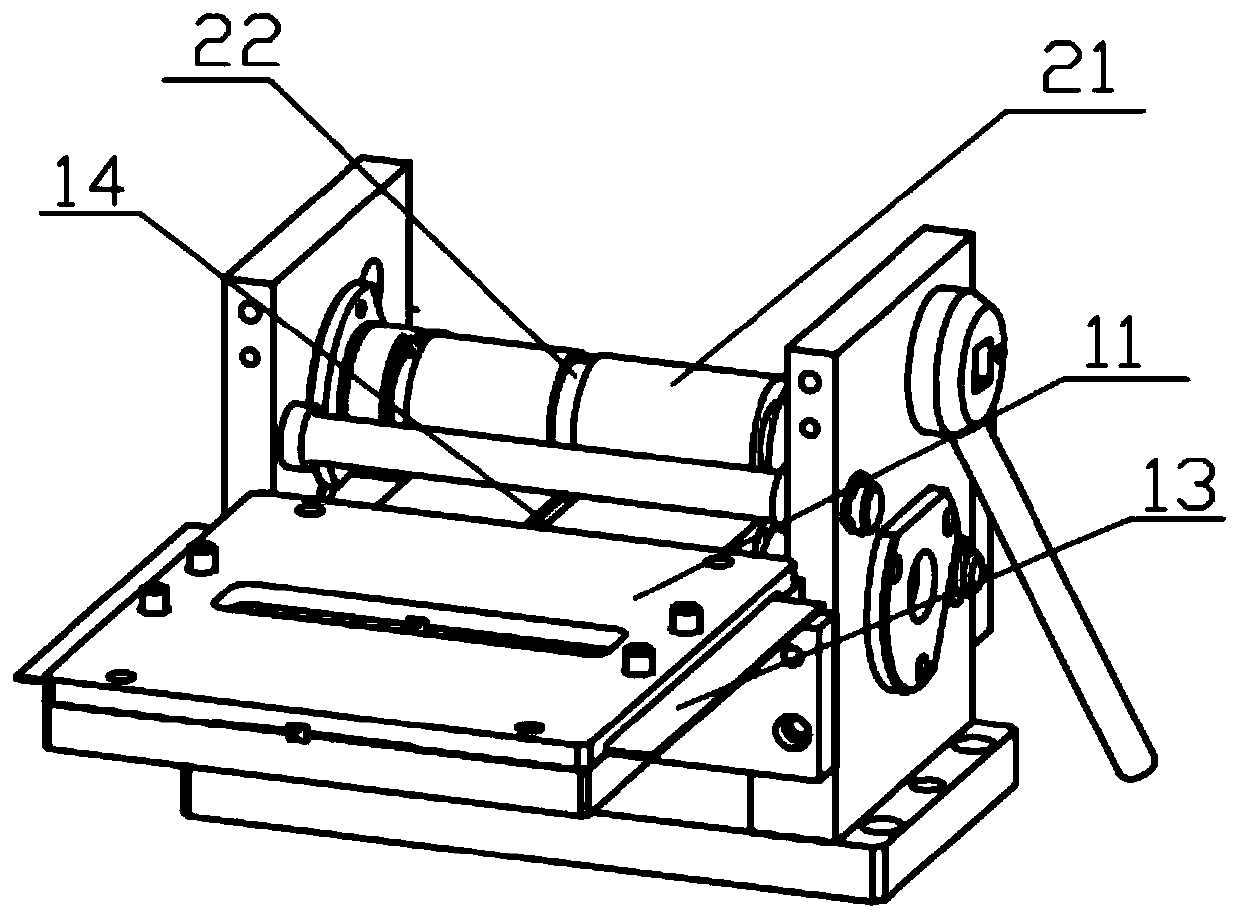

[0032] With regard to the above technical solutions, preferred embodiments are given and described in detail in conjunction with the drawings. see Figure 1 to Figure 13 ,

[0033] The melt processing equipment of the present invention sequentially includes a trough device 1, a feeding device 2, a tin lining device 3, a grooving device 1, a feeding device 2, a cleaning device 4, a feeding device 2, a cutter device 5, and a forming device from front to back. 6. The punching device 7 and the transfer device 8, wherein.

[0034] The function of the grooving device is to press out the groove to be tinned on the initial flat melt along the length of the melt; the function of the feeding device is to provide feeding power for the automatic operation of the melt; the function of the tinning device is to press the groove The molten solder is coated in the melt groove after the tinning; the cleaning device is used to clean the rosin and other substances on the melt after tin enamel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com