Continuous explosive manufacturing, filling and packing production line of thermoplastic seismic explosive column

A packaging production line and seismic source charge technology, which is applied to ammunition, ammunition storage, weapon accessories, etc., can solve the problems of excessive labor, complex charging and packaging procedures, and increased production costs, so as to reduce operators and realize continuous automation. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

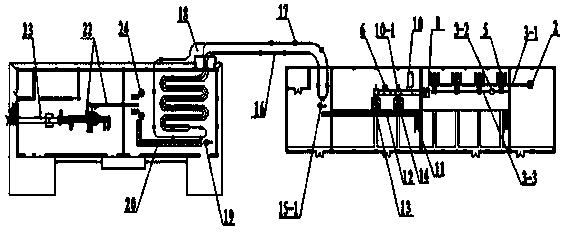

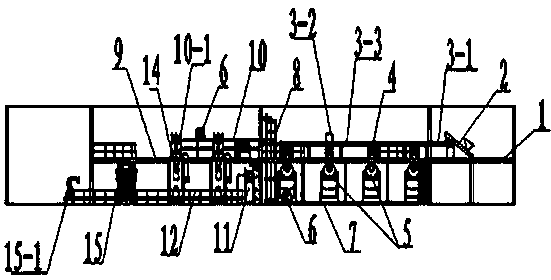

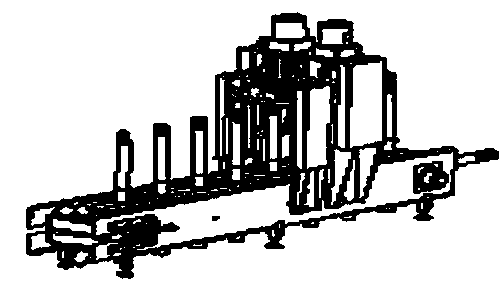

[0013] The present invention consists of A platform 1, B platform 9, feeding mechanism, material plasticizing and transshipment mechanism, charging and capping mechanism, powder column transfer and cooling mechanism, seismic source powder column automatic heat sealing and connecting sleeve assembly machine 24, and automatic packaging machine 22 and finished product belt conveyor 23, the feeding mechanism is composed of lifting screw conveyor 2, screw conveyor 3-1, conveying hopper 3-2, light rail 3-3 and quantitative feeding machine 4, lifting screw conveyor 2, screw conveyor Machine 3-1, light rail 3-3 and quantitative feeding machine 4 are respectively installed on platform A 1, the outlet of lifting screw conveyor 2 is connected with the inlet of screw conveyor 3-1, and screw conveyor 3-1 The outlet of the feeder and the inlet of the quantitative feeder 4

[0014] In the same way, the conveying hopper 3-2 is installed on the light rail 3-3 through rollers, and an explosion-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com