Automatic strip-inserting process of heat-insulting bridge cut-off aluminum window and door profiles

A technology of aluminum alloy doors and windows, thermal insulation and broken bridges, applied in the direction of windows/doors, building components, buildings, etc., can solve the problems of high import price, can not meet the requirements of use, can not achieve comprehensive and continuous automation of threading, and improve production. Efficiency, the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

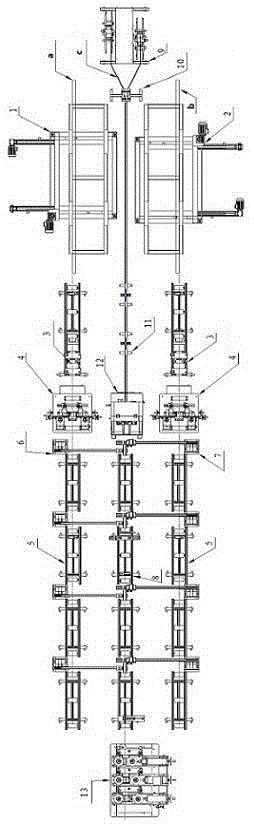

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing of description and specific embodiment:

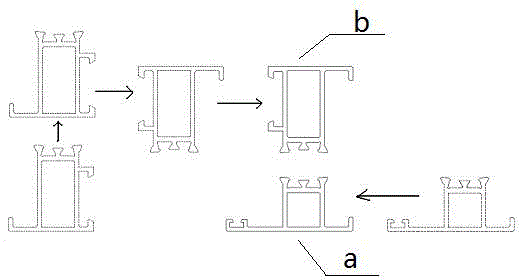

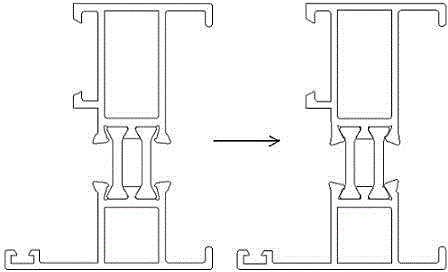

[0025] This embodiment takes the PX5501 outer frame broken bridge heat-insulating aluminum profile as an example.

[0026] The automatic strip-threading process of aluminum alloy door and window profiles for heat-insulating broken bridges includes the following steps:

[0027] (1) Automatic feeding process: the upper profile material frame machine 2 and the lower profile material frame machine 1 respectively automatically send the upper profile a and the lower profile b into the film laminating machine 3;

[0028] (2) Film sticking and gear cutting process: the film sticking machine 3 automatically sticks the film and cuts the film on the aluminum profile, and the profile after the film sticking automatically enters the gear cutting machine 4 for gear cutting;

[0029] (3) Manipulator transmission process: the profiles after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com