Speed-adjustable turning equipment for flange surfaces with same bore

A flange surface and turning technology, which is applied in metal processing equipment, metal processing machinery parts, feeding devices, etc., can solve the problems of small transmission distance of planetary gear, affect the quality and accuracy of flange surface, and long processing time, etc. Accuracy and stability, reasonable structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below by means of embodiments in conjunction with the accompanying drawings.

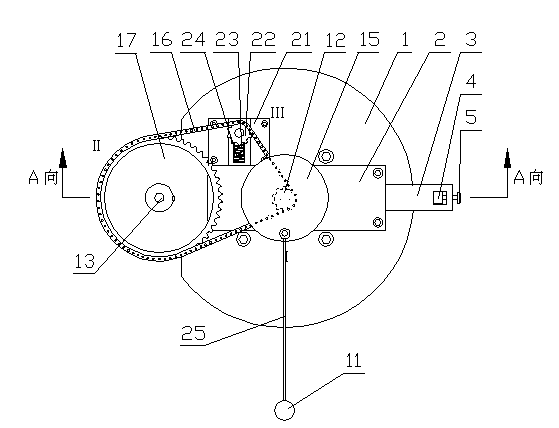

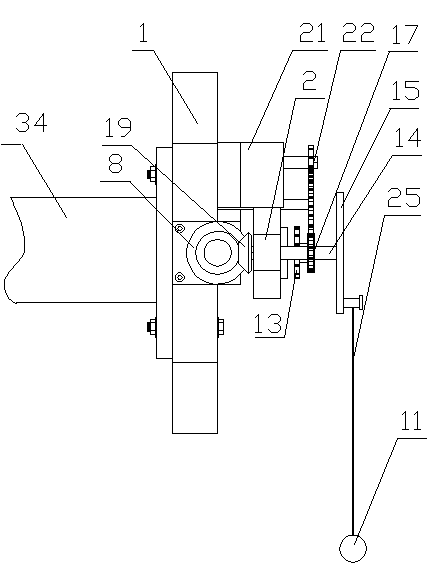

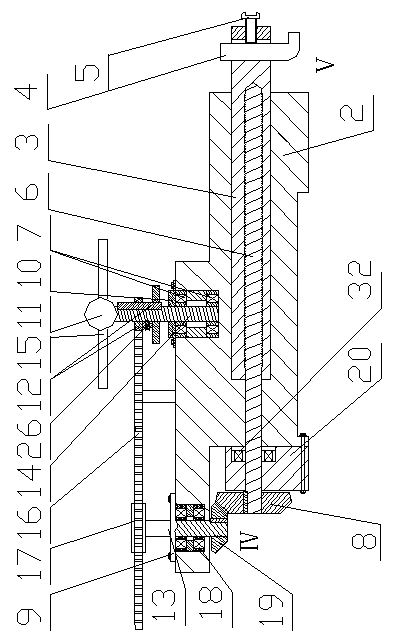

[0020] see Figure 1~3 , the embodiment of the turning equipment with adjustable speed and same boring flange surface includes a rotating base plate 1, a machine base 2, a counterweight assembly I, a chain transmission mechanism II, an adjusting sprocket assembly III, a gear transmission mechanism IV, a screw transmission mechanism V, The turning tool 4, the rotating floor 1 are fixed on the boring bar 34 by bolts, the base 2 is welded and fixed on the rotating base 1, the chain transmission mechanism II, the gear transmission mechanism IV and the screw transmission mechanism V are all installed on the base 2, The counterweight assembly I is connected to the chain transmission mechanism II, the chain transmission mechanism II is connected to the gear transmission mechanism IV, the gear transmission mechanism IV is connected to the screw transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com