Automatic feeding mechanism of E-type magnetic material vision inspection device

A visual inspection device and automatic feeding technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of unstable spacing, irregular arrangement, and difficult adjustment of feeding speed of E-type magnetic materials, so as to achieve stable spacing, The effect of neat feeding and stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

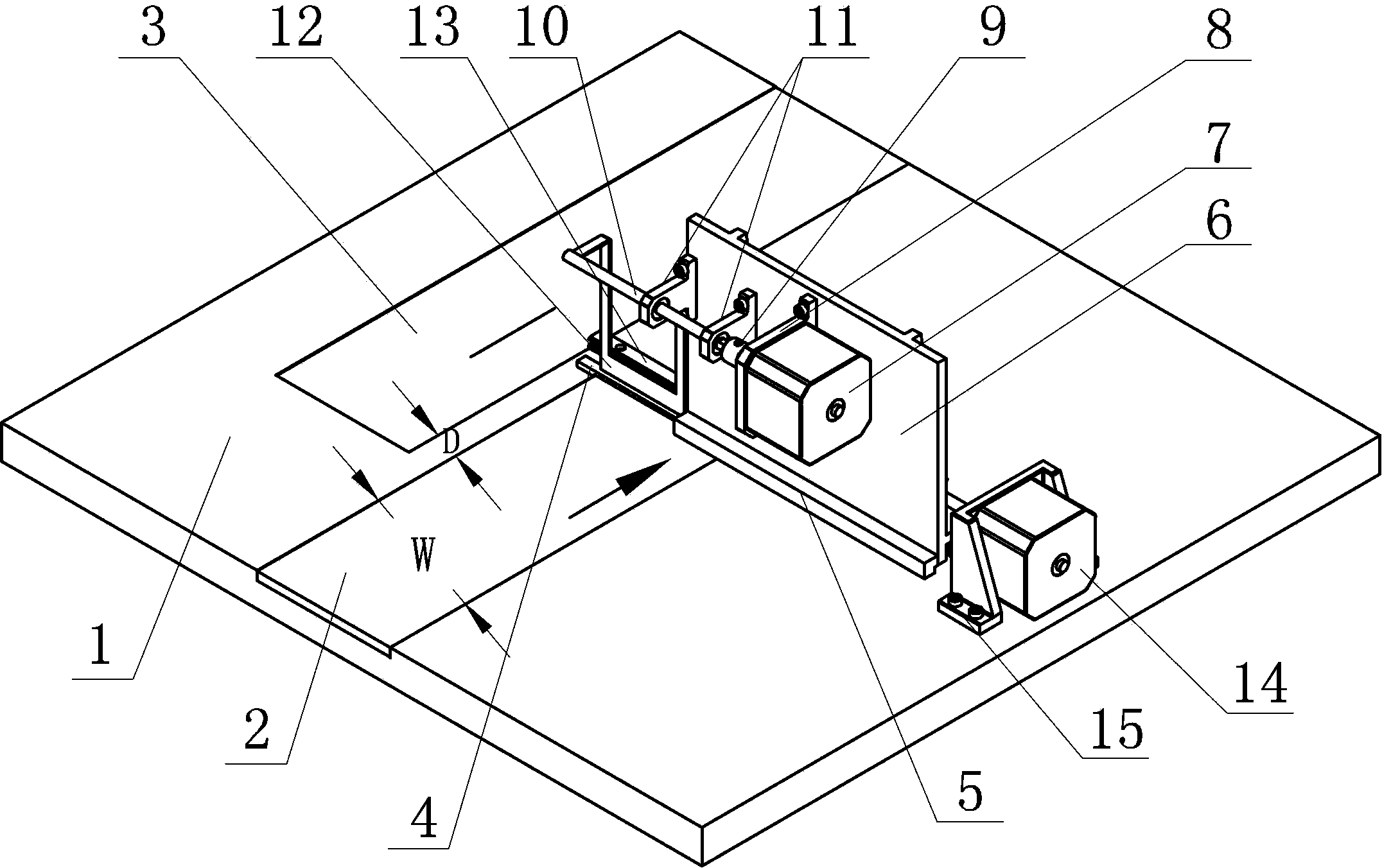

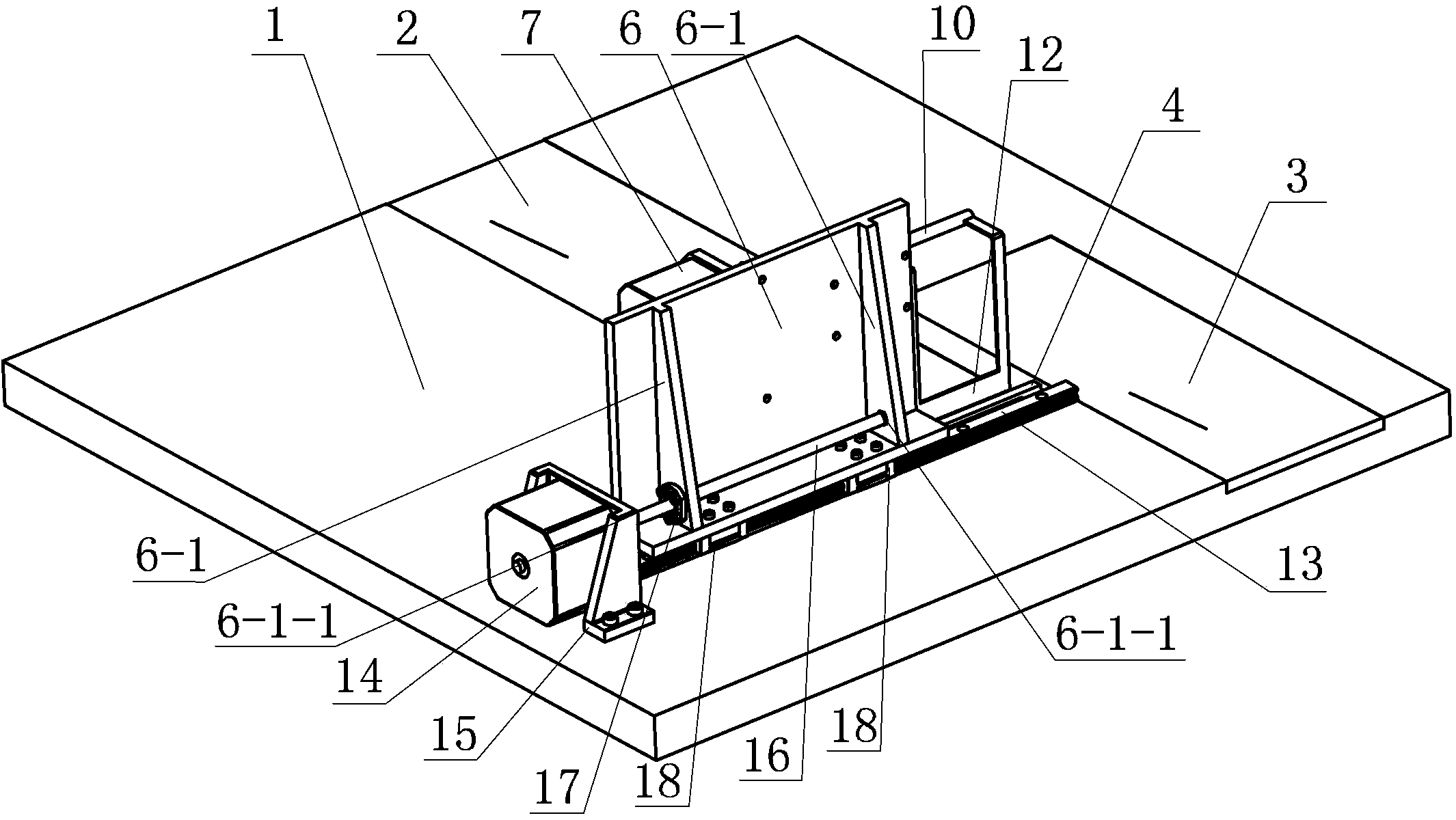

[0012] Specific implementation manner one: such as Figure 1~2 As shown, the automatic feeding mechanism for the E-shaped magnetic material visual inspection device of this embodiment includes a first conveyor belt 2, a second conveyor belt 3, a waiting baffle 4, a push rod 5, a translational support 6, a first Motor 7, first motor support 8, rotating shaft 10, rotatable baffle 12, linear guide 13, second motor 14, second motor bracket 15, screw 16, nut 17, at least one rotating shaft support frame 11 and two Two sliders 18, the second motor 14 is a stepping motor, the first conveyor belt 2 and the second conveyor belt 3 are arranged in parallel and staggered on the working table 1, and the waiting baffle 4 is fixed across the end of the first conveyor belt 2 On the work surface 1, the linear guide 13 is fixed on the work surface 1 and is arranged adjacent to and parallel to the baffle 4, two sliding blocks 18 are installed on the linear guide 13 in turn, and the lower end surf...

specific Embodiment approach 2

[0014] Specific implementation manner two: such as Figure 1~2 As shown, the width W of the first conveyor belt 2 and the second conveyor belt 3 in this embodiment are both 80 mm. This design can meet the loading requirements of all types of E-type magnetic materials within the detection range. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation manner three: such as Figure 1~2 As shown, in this embodiment, the distance D between the first conveyor belt 2 and the second conveyor belt 3 is 5 mm. Such a design can reduce the stroke of the translational support 6. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com