Automatic feeding device for soft magnetic grinding machine and implementation method for automatic feeding device

An automatic feeding and grinding machine technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of factory recruitment troubles, affecting factory production rate, time-consuming and other problems, and achieves convenient adjustment and operation. Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

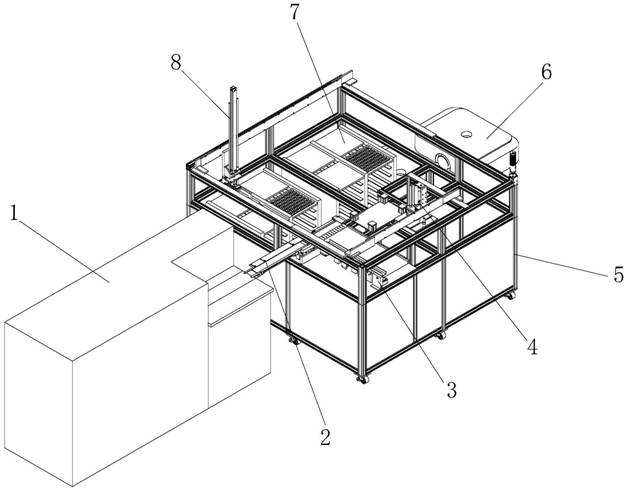

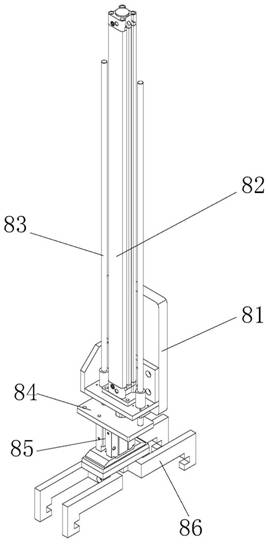

[0040] see Figure 1-9 , the present invention provides the following technical solutions: an automatic feeding device for a soft magnetic grinder, comprising a grinder body 1, an equipment frame 5 is provided on one side of the feed end of the grinder body 1, a transfer platform 53 is provided on the equipment frame 5, and the equipment frame 5 A material trolley 7 is placed inside, and a suction mechanism 4 and a grasping mechanism 8 are respectively provided on the equipment frame 5. A grinding mechanism 3 is provided on the side of the equipment frame 5 close to the grinder body 1, and the end of the grinder mechanism 3 is connected to the grinder body. 1 are connected by a conveying mechanism 2.

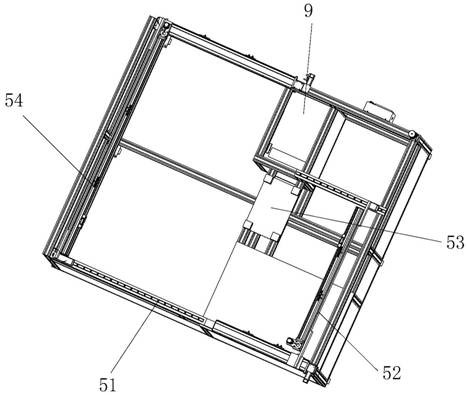

[0041] Specifically, the equipment frame 5 includes a support 51 on which a first single-axis robot 52 for driving the suction mechanism 4 and a second single-axis robot 54 for driving the grasping mechanism 8 are arranged.

[0042] By adopting the above technical solution, the...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that: specifically, a cleaning mechanism 9 is also provided on the equipment frame 5, and the cleaning mechanism 9 includes a cleaning platform 91, wherein the cleaning platform 91 is installed on the bracket 51, and the cleaning mechanism 91 is installed above the cleaning platform 91. A roller brush 93 is provided, one end of the roller brush 93 is connected to the bracket 51 through the guide rail 92 , and the other end of the roller brush 93 is connected to the bracket 51 through the cleaning cylinder 94 .

[0057] By adopting the above technical scheme, when all the products on the setter plate are taken away, the second single-axis robot 54 drives the grasping mechanism 8 to grab the setter plate onto the cleaning table 91, and the cleaning cylinder 94 drives the roller brush 93 to move , to clean the setter plate, after the cleaning is completed, the second single-axis robot 54 drives the grasping mechanis...

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that specifically, the two sides of the installation frame 31 close to the end of the driven shaft 35 are respectively provided with adjusting cylinders 34, the driven shaft 35 is connected to the output end of the adjusting cylinder 34, and the baffle plate 32 It is connected with the installation frame 31 through the bolt 33 .

[0060] By adopting the above technical solution, the tightness of the abrasive belt 39 can be adjusted easily by adjusting the setting of the cylinder 34 , and the bolt 33 facilitates the disassembly of the baffle plate 32 , so that the quick replacement of the abrasive belt 39 can be realized.

[0061] Further, a method for realizing an automatic feeding device for a soft magnetic grinder according to the present invention includes the following steps:

[0062] (1) The AGV trolley 6 drives the material cart 7 with the product to the designated position, and the second single-axis robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com