straw crushing box

A technology for crushing boxes and straws, which is applied to devices for catching or killing insects, agricultural machinery and implements, and agriculture. It can solve problems such as the impact of straw planting and production, and achieve smooth operation, simple structure, and uniform and thorough decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

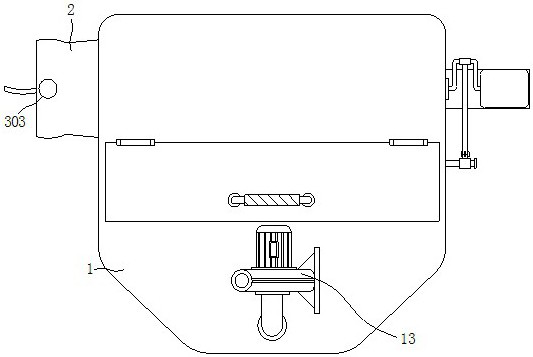

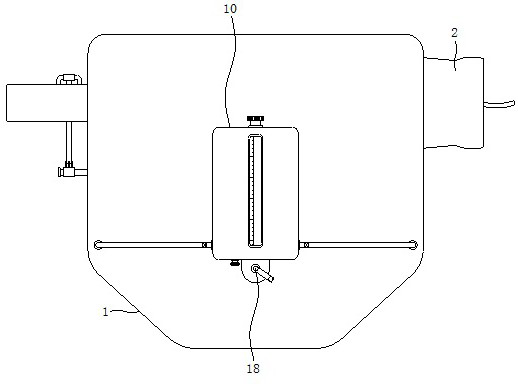

[0029] see Figure 1-6 , the present invention provides a technical solution: a straw crushing box, comprising a box body 1, a feeding shell 2 is fixedly installed on one side of the outer wall of the box body 1 and communicated with its interior, and a feeding mechanism is arranged inside the feeding shell 2 3. A rotating rod 4 is rotatably installed on the inner wall of one side of the box body 1, a pulverizing blade 11 is fixedly installed on the outer wall of the rotating rod 4, a cutting mechanism 8 is arranged on the rotating rod 4, and a support block is fixedly installed on the other side of the box body 1 , the front side of the support block is fixedly installed with the casing, the inner wall of one side of the casing is fixedly installed with the motor 5, the output shaft of the motor 5 passes through the casing through the coupling and is fixedly connected with the crank rod 6, and the crank rod 6 is provided with There is a screening mechanism 7, one end of the r...

Embodiment 2

[0034] see Figure 1-6 , on the basis of Embodiment 1, the feeding mechanism 3 includes a rotating rod 301, a material shifting arm 302 and a motor 303, the inner rotation of the feeding shell 2 is equipped with a rotating rod 301, and the outer wall of the rotating rod 301 is fixedly equipped with a rotating rod The motor 303 is fixedly installed on the front side of the arm 302 and the feeding shell 2 , the output shaft of the motor 303 passes through the feeding shell 2 through a coupling and is fixedly connected with the rotating rod 301 . When in use, control the start of the motor 303, the motor 303 drives the rotation of the rotating rod 301 and the shifting arm 302, and the shifting arm 302 moves the neatly arranged wheat straw horizontally into the feeding shell 2 and sends it into the box 1 , so as to realize the feeding of wheat straw.

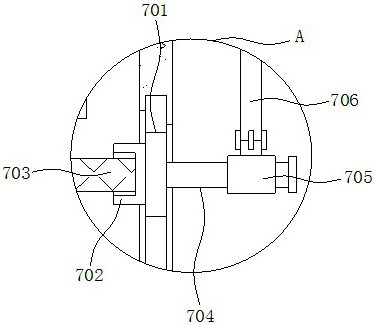

[0035] Further, the screening mechanism 7 includes a slider 701, a clamping block 702, a screen 703, a moving rod 704, a movable ...

Embodiment 3

[0040] see Figure 7 , on the basis of the above-mentioned embodiment, the circular array of the shifting arm 302 is uniformly arranged on the outside of the rotating rod 301, and the shifting arm 302 is an arc-shaped plate body;

[0041] Coaxial with the rotating rod 301, a material shifting plate 304 is also provided, and the material shifting plate 304 is divided into two groups of oppositely arranged, each group of material shifting plates 304 includes several veneers, and the veneers are arranged along the axis of the rotating rod 301, each group The veneers are twisted in a spiral trend;

[0042] The veneer helical directions of the two sets of shifting plates 304 are opposite;

[0043] The outer diameter of the shifting arm 302 corresponds to the inner diameter of the feed shell 2 where it is located. The outer diameter of the shifting arm 302 is slightly smaller than the inner diameter of the feed shell 2 where it is located. The outer diameter of the shifting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com