Oxide scale recovery device for hot stamping die

A technology of hot stamping die and recycling device, applied in the field of sheet metal hot stamping, can solve the problems of unfavorable full automation, reduce production efficiency, increase production cost, etc., and achieve the effect of eliminating potential safety hazards, improving work efficiency and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

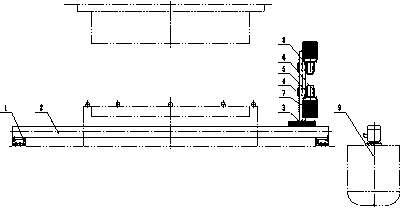

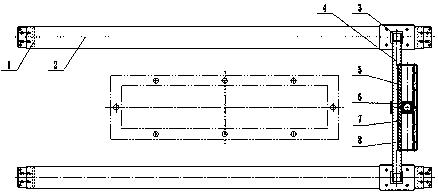

[0009] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: a scale recovery device for hot stamping dies, including a drive base 1, a linear drive mechanism 2, a powerful vacuum cleaner 9, etc., and a linear drive base 1 is set The driving mechanism 2 is characterized in that a vertical beam 3 is arranged on the linear driving mechanism 2, a crossbeam 4 is arranged on the vertical beam 3, a handle joint 6 is arranged on the crossbeam 4, a suction bucket 5 is arranged on the bucket handle joint 6, and a suction bucket The brush body 7 is set on the 5 and has a strong air port 8.

[0010] Adjust the upper / lower beam 4 to a suitable height, and adjust the bucket handle contact body 6 to a suitable position, so as to avoid contact between the brush body 7 and the mold body during the movement.

[0011] After the mold is opened, the strong air outlet 8 is ventilated, the powerful vacuum cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com