Liquid pump control system

A technology of control system and liquid phase pump, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problems of emergency stop without overpressure alarm, liquid leakage detection fault judgment, single communication method, etc. To achieve the effect of convenient operation, sensitive control, high flow accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

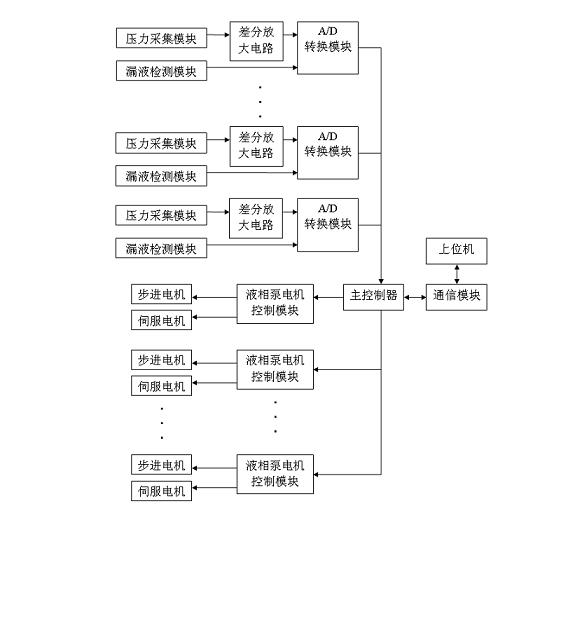

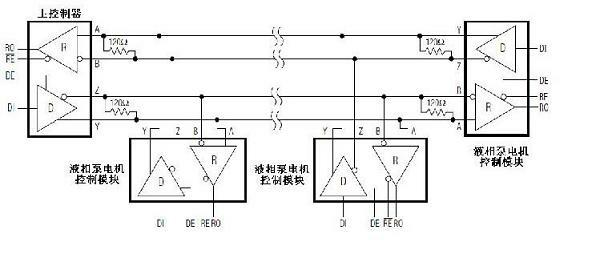

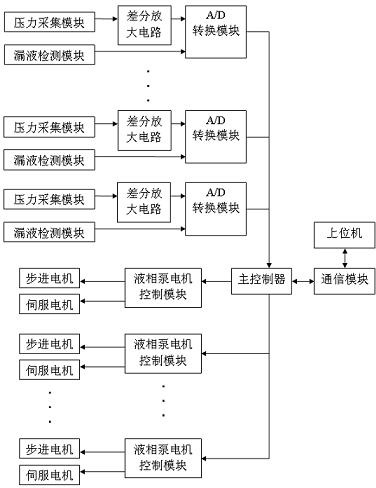

[0018] Such as figure 1 , 2 Shown, a kind of liquid-phase pump control system is characterized in that it comprises a plurality of pressure acquisition modules, a plurality of leakage detection modules, a plurality of A / D conversion modules, a main controller (using a micro single-chip microcomputer, the model can be CPU: C8051F120), a plurality of liquid phase pump motor control modules (the model can be 57BYG350DL) and communication modules, the pressure acquisition modules and leakage detection modules described above are respectively used as the pressure and leakage signal input terminals of the liquid phase pump control system to collect corresponding The pressure and leakage signal of the liquid phase pump, the signal output terminals of each pressure acquisition module and the leakage detection module are connected with the corresponding signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com