Patents

Literature

52 results about "Bucket Handle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Movement of the ribs during respiration such that with inhalation the lateral aspect of the rib moves cephalad resulting in an increase of transverse diameter of the thorax. This type of rib motion is predominantly found in lower ribs, increasing from the upper to the lower ribs.

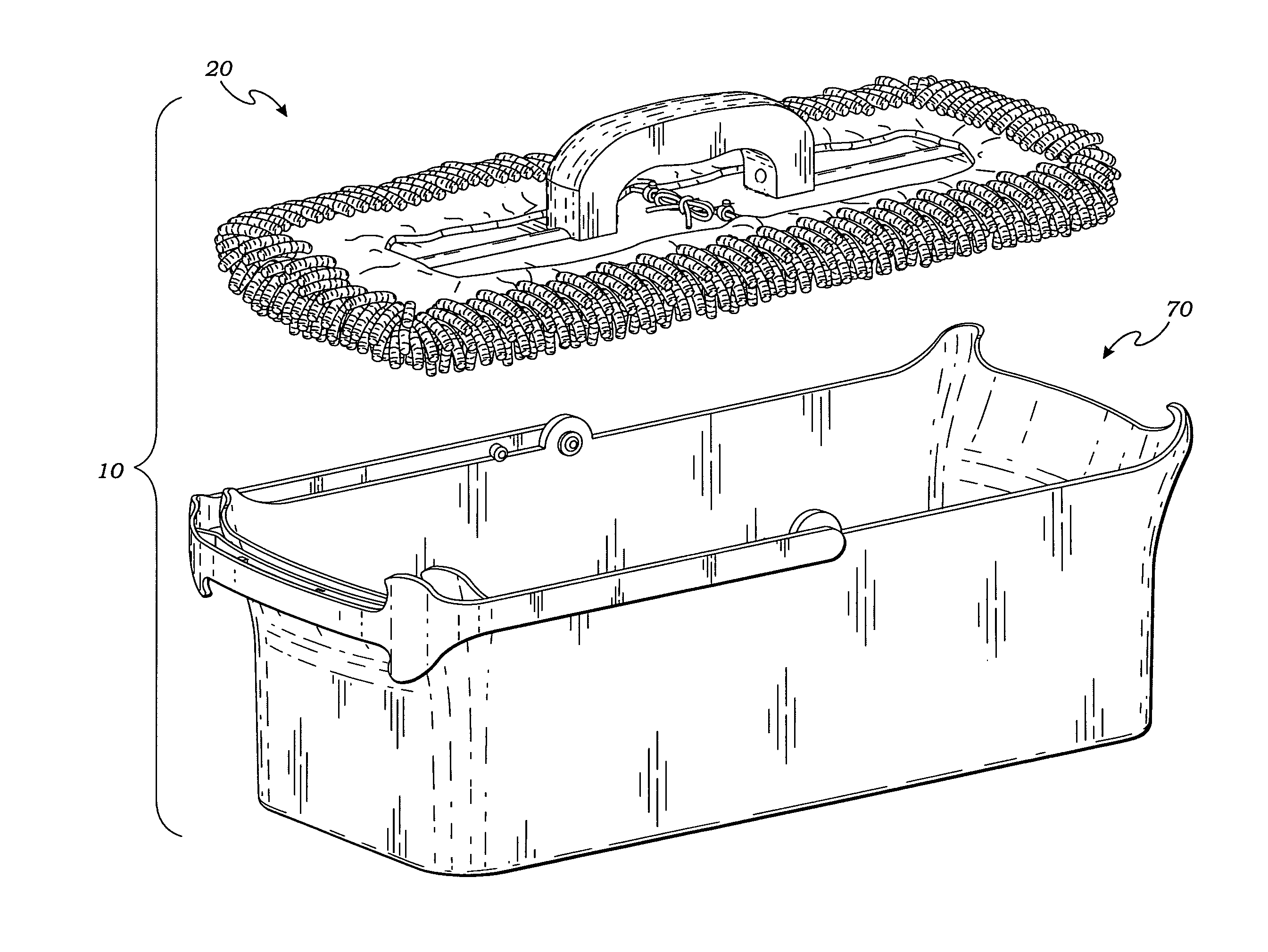

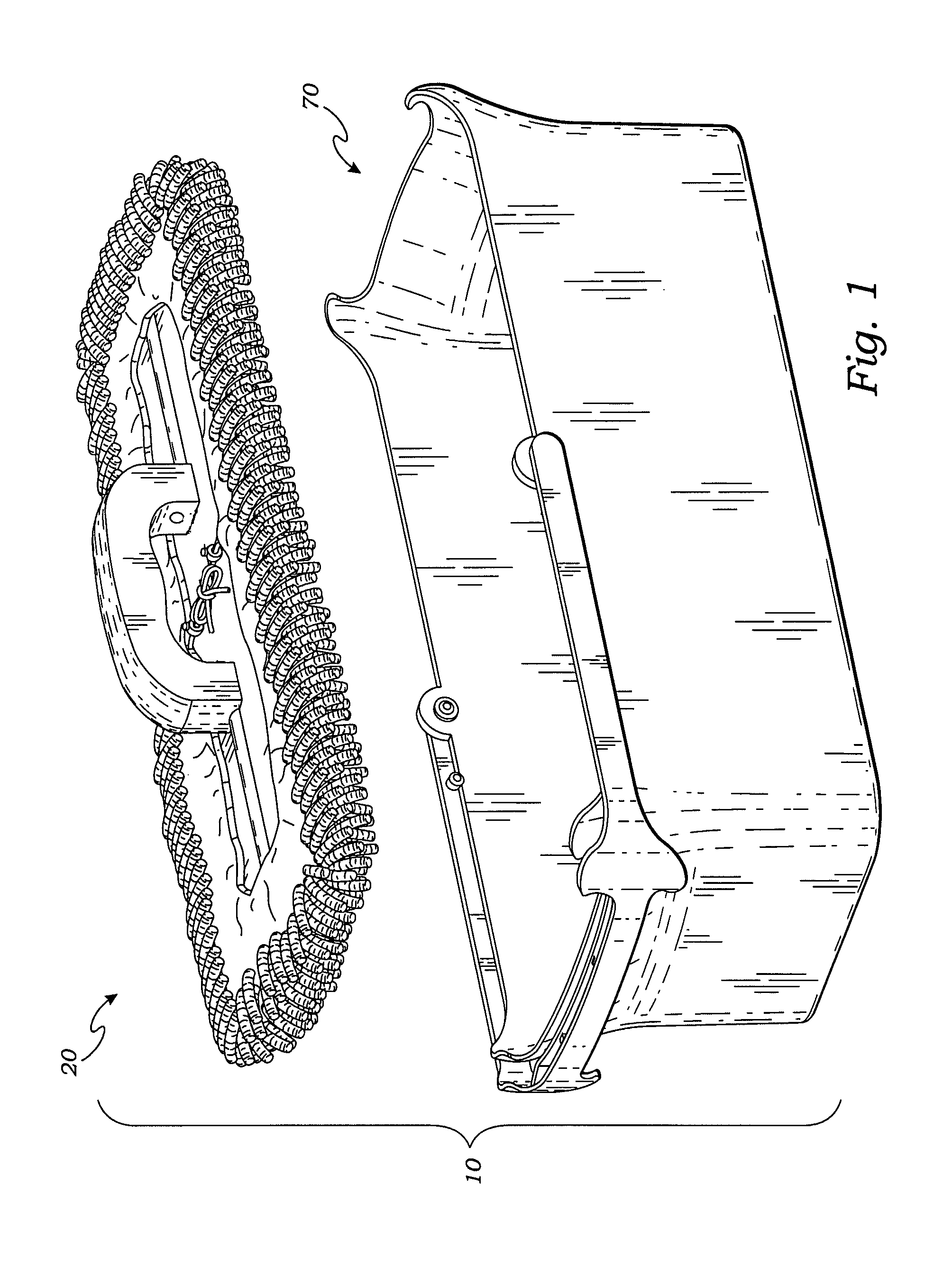

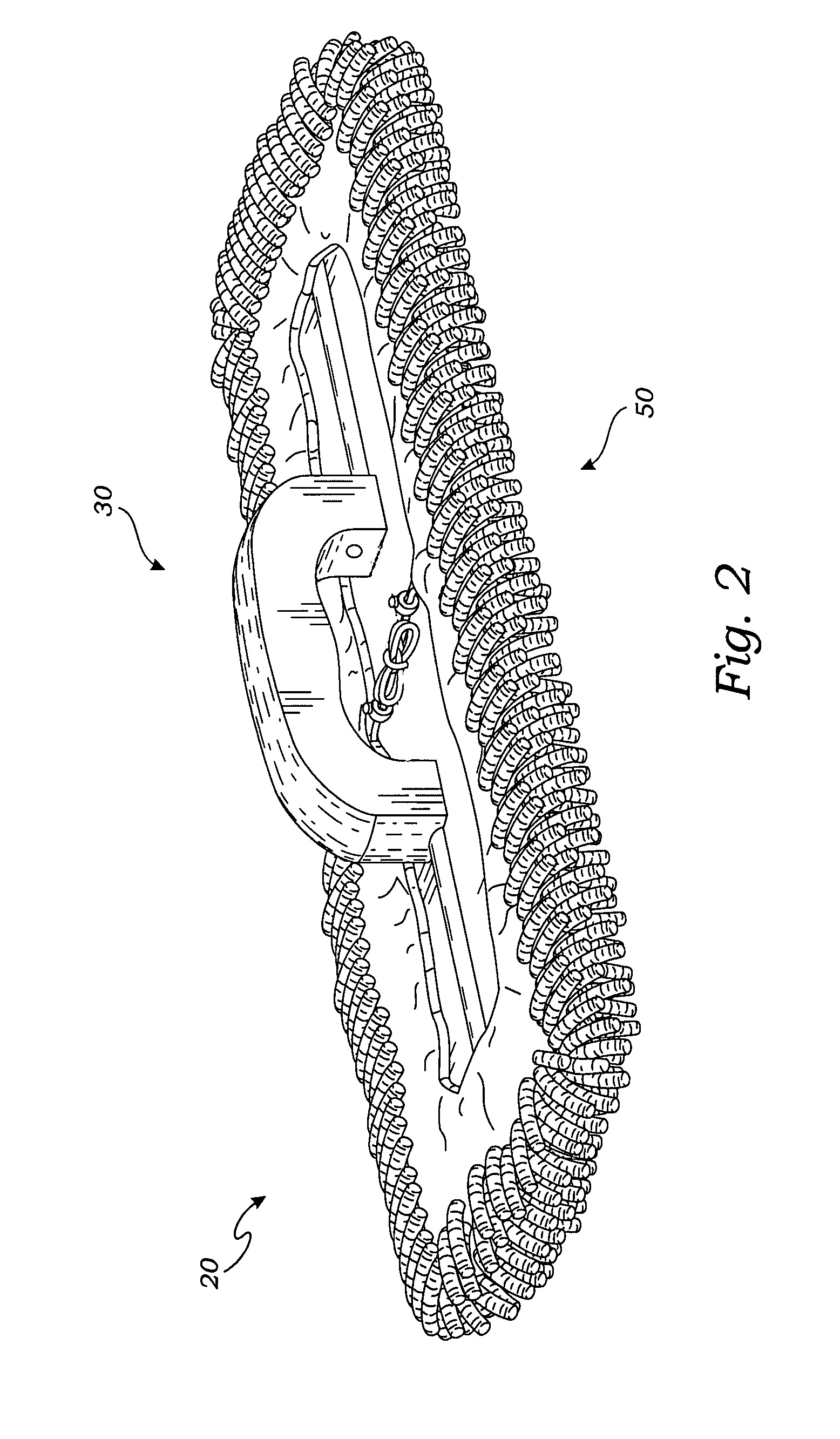

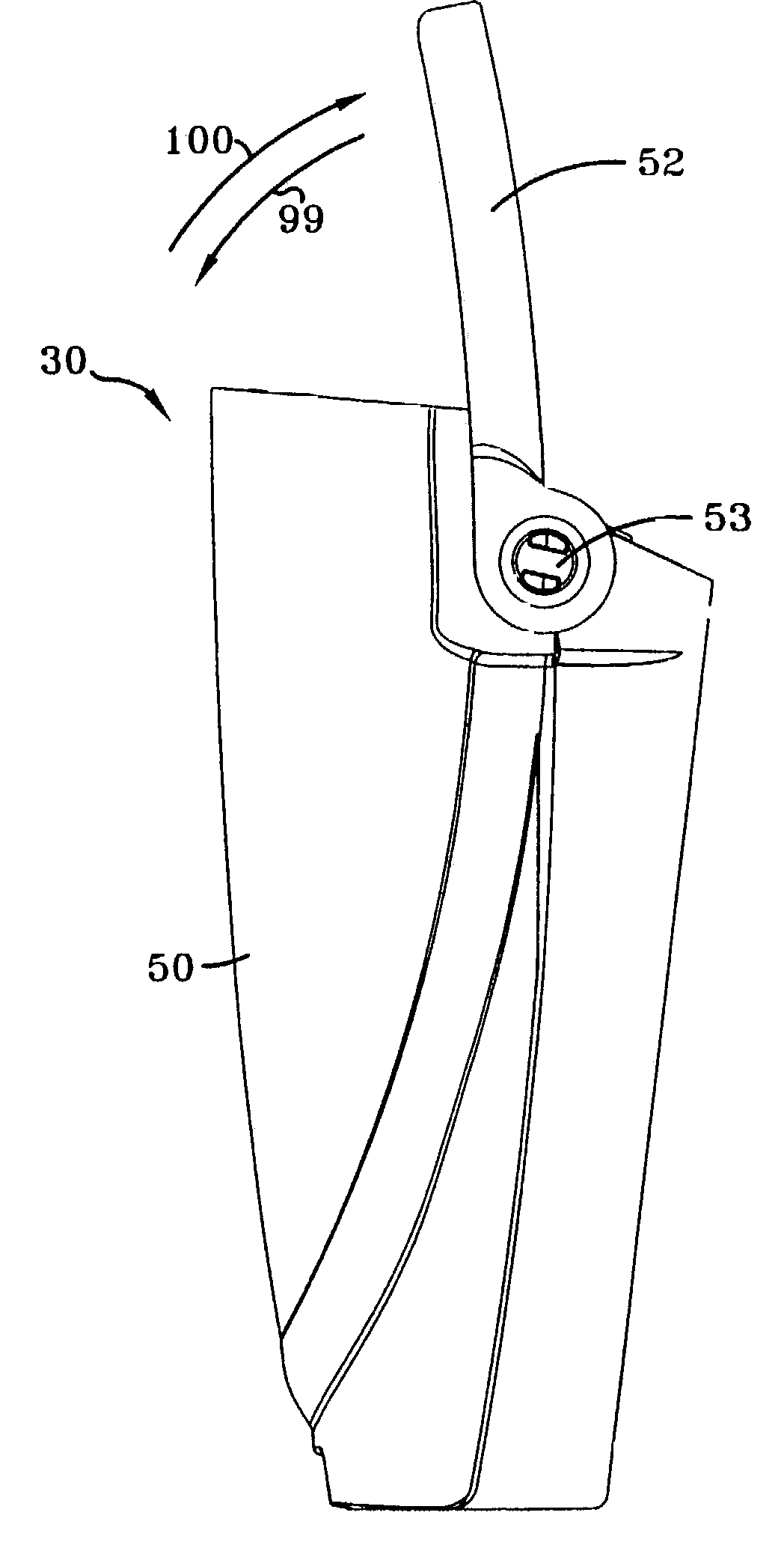

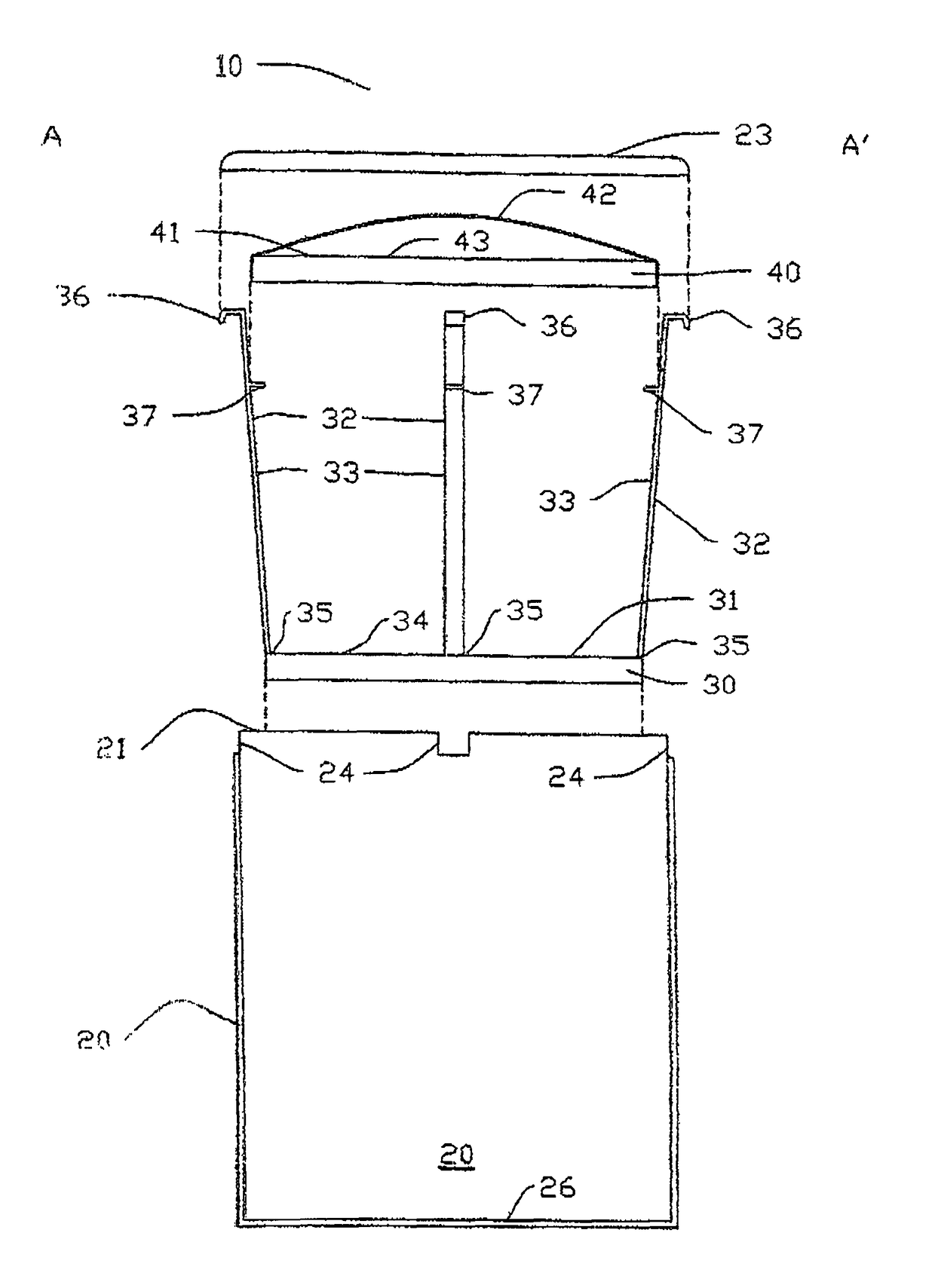

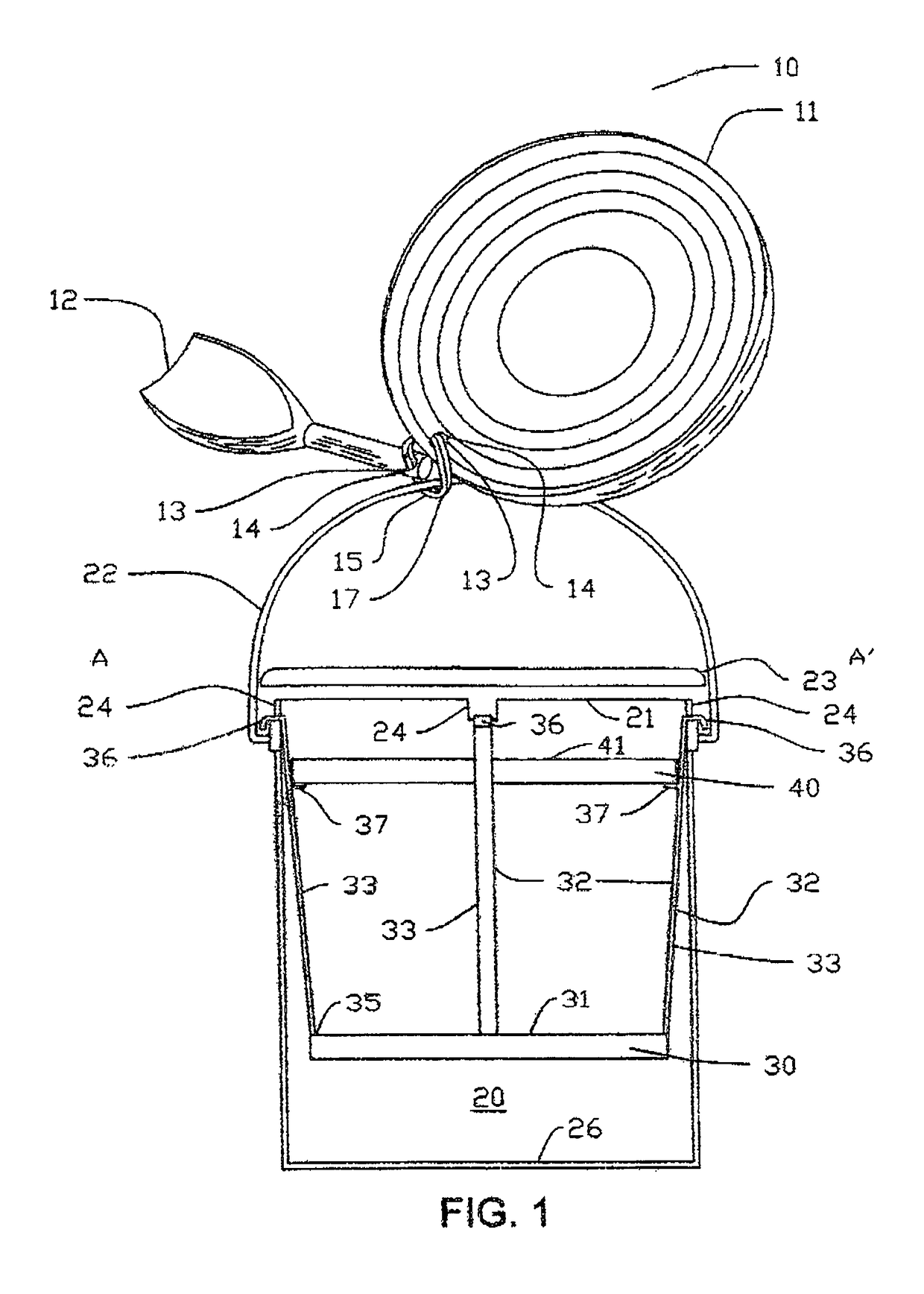

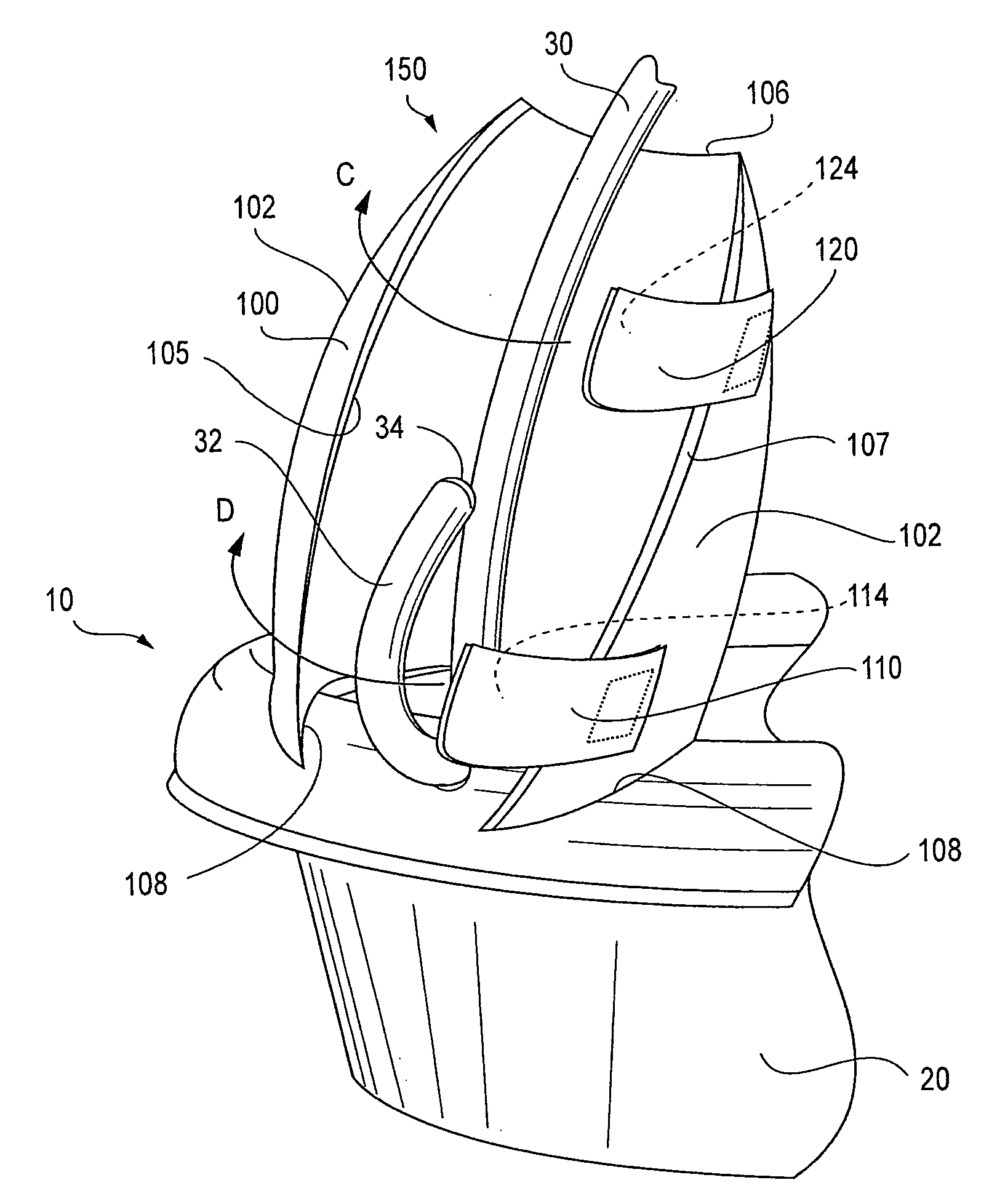

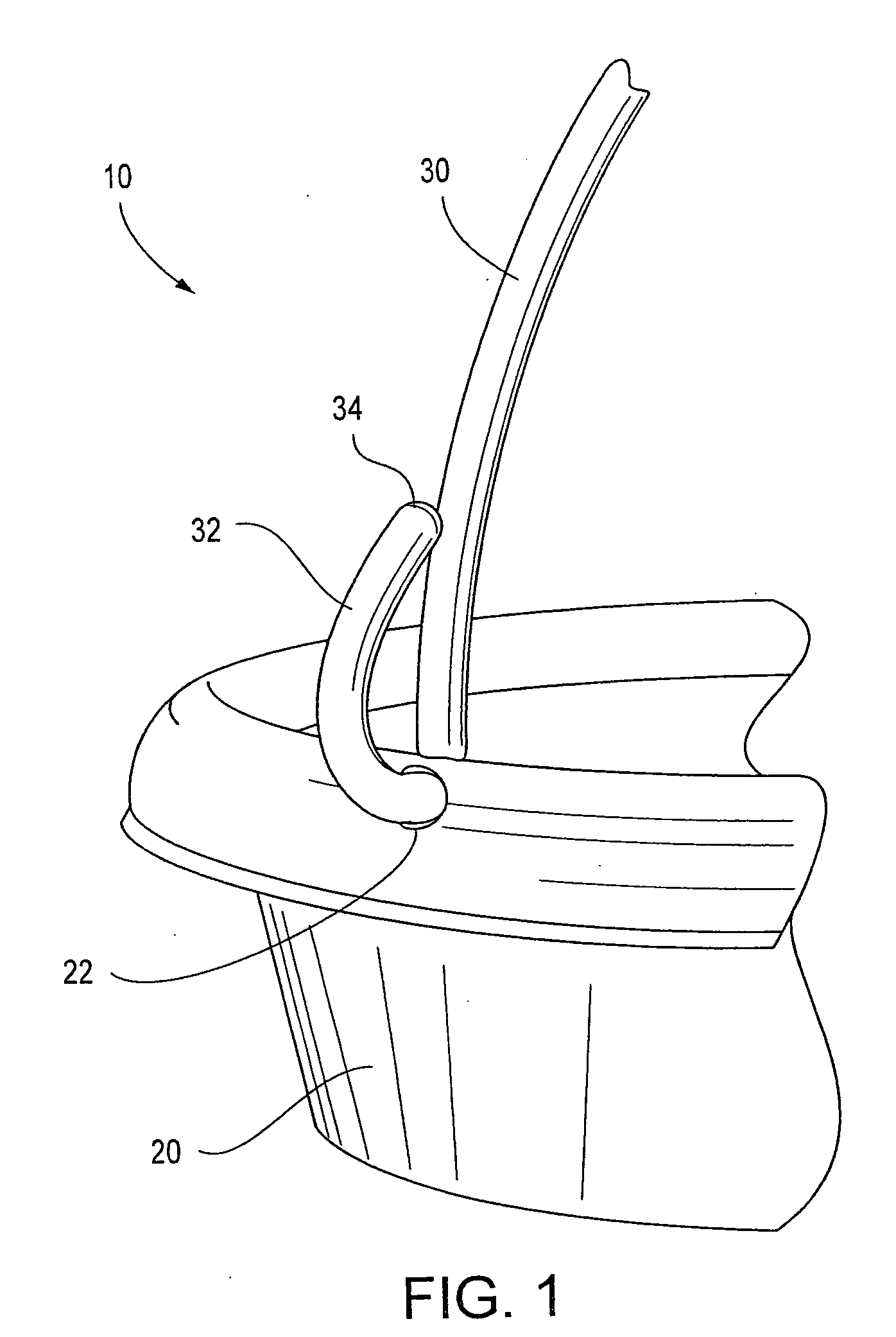

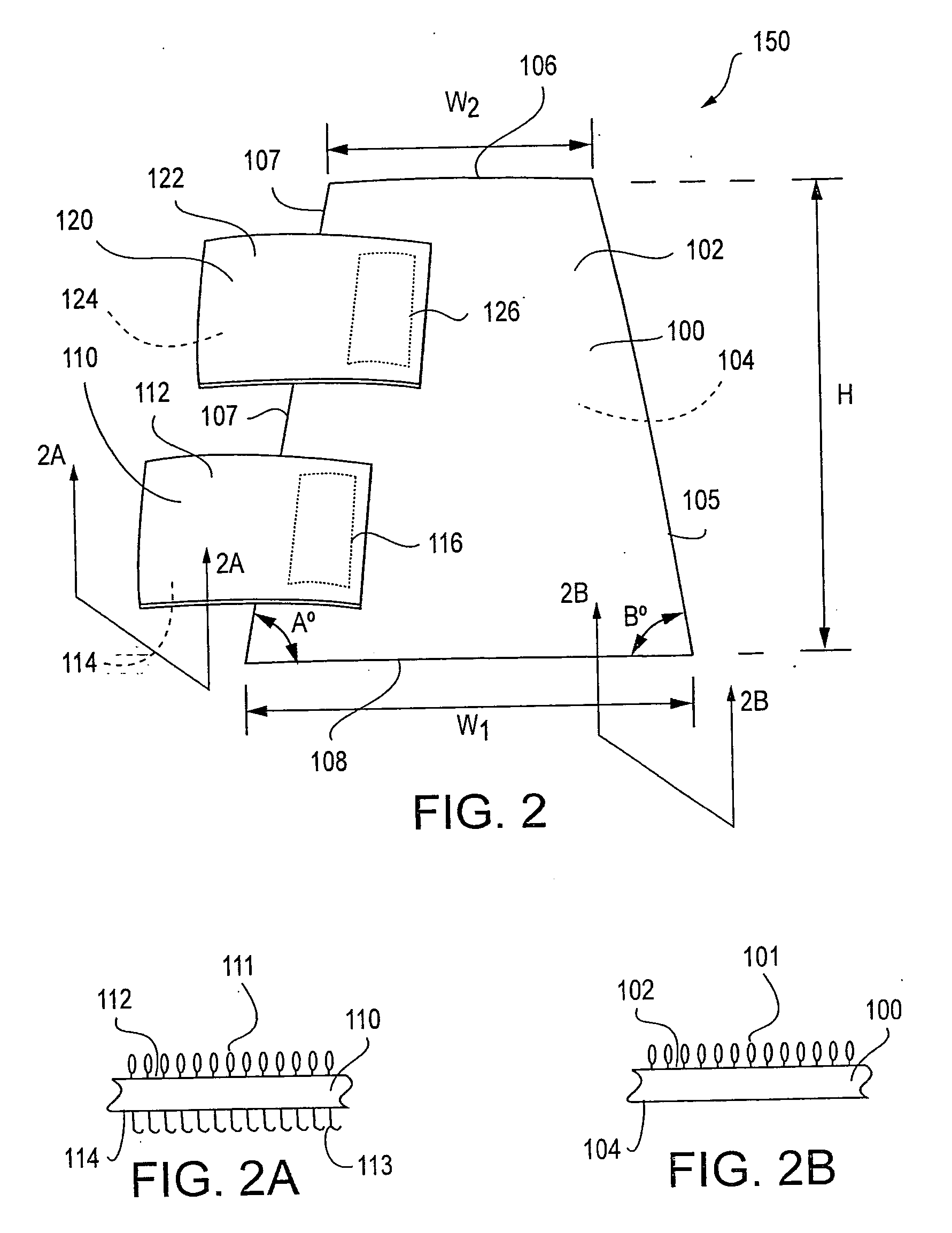

Multi-purpose mop system and method of use

A multi-purpose mop system includes a mop having a mop handle and a cleaning attachment removably mounted thereon, the mop handle further comprising a base and a grip installed thereon for manipulating the mop during use, and a bucket having a basin and a bucket handle removably and pivotally attached thereto, the basin being formed with at least one basin channel bounded by opposite, substantially upwardly-extending basin fingers, and the bucket handle being formed in a central portion inter-connecting opposite leg portions with at least one respective handle channel bounded by opposite handle fingers, whereby the basin channel and the handle channel cooperate in wringing the mop during wet use. The cleaning attachment may be a mop material cinched onto the base of the mop handle using a drawstring or may be a squeegee strapped thereto. A removable extension handle may be pivotally installed on the mop handle.

Owner:DIHN MINH T

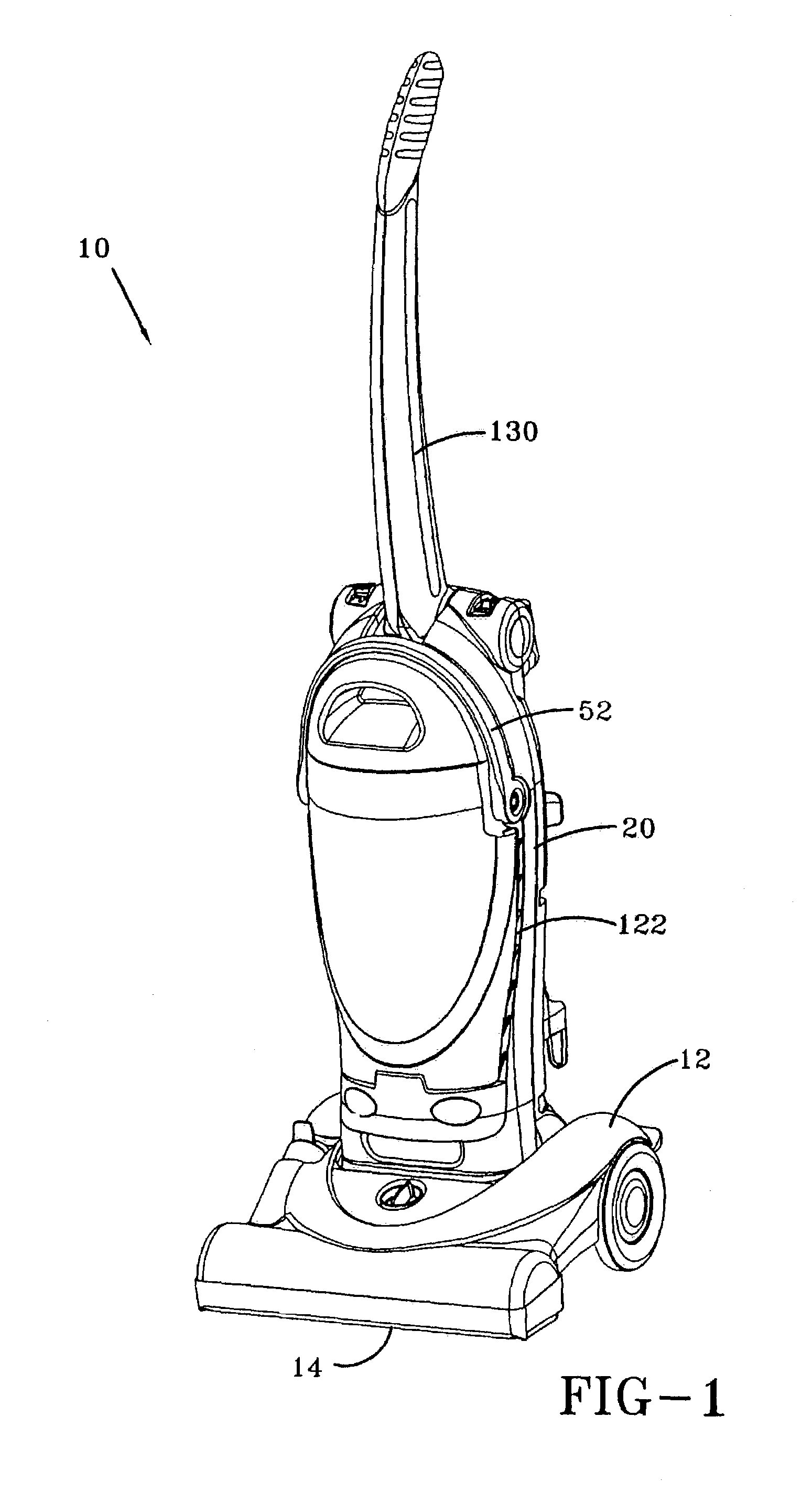

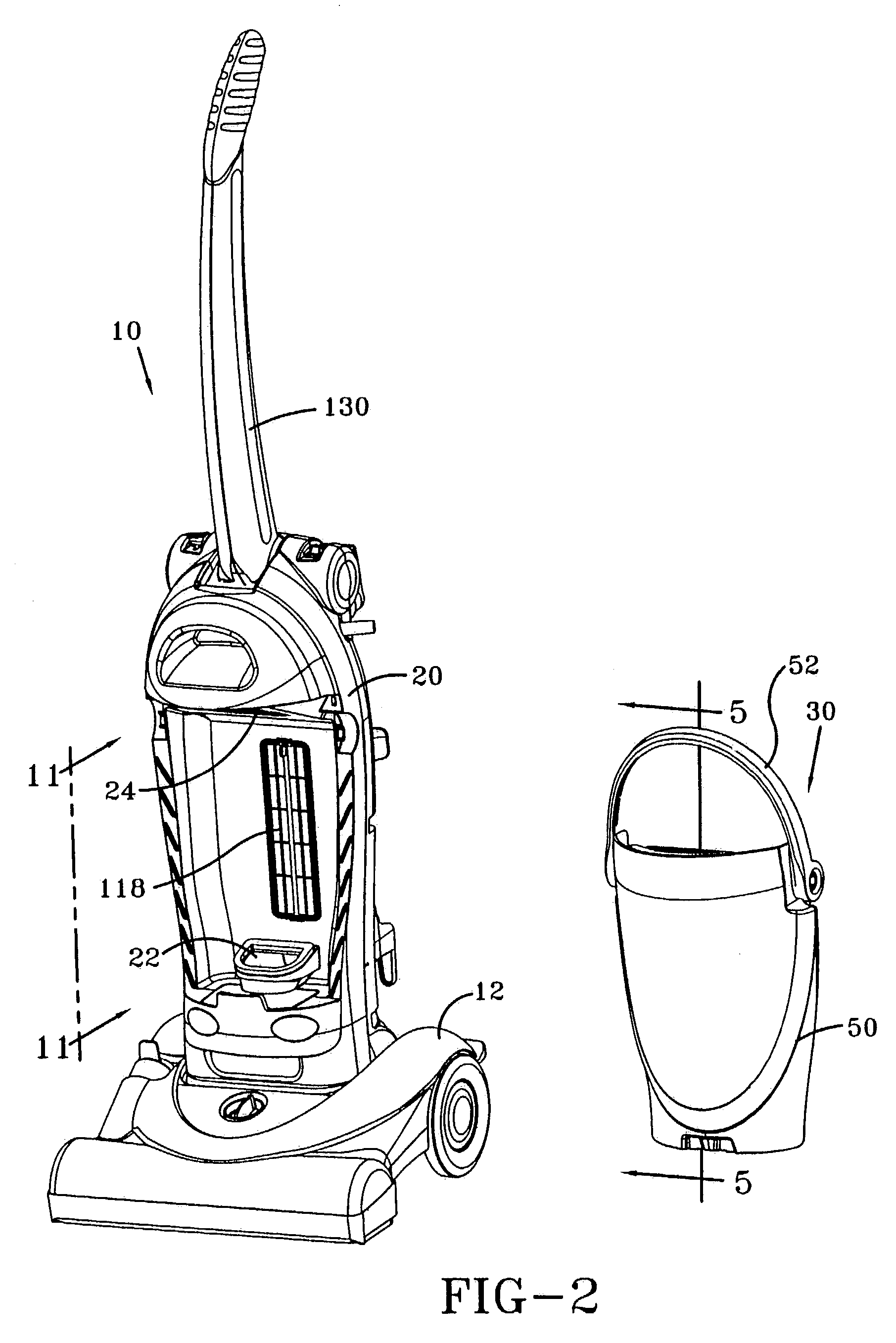

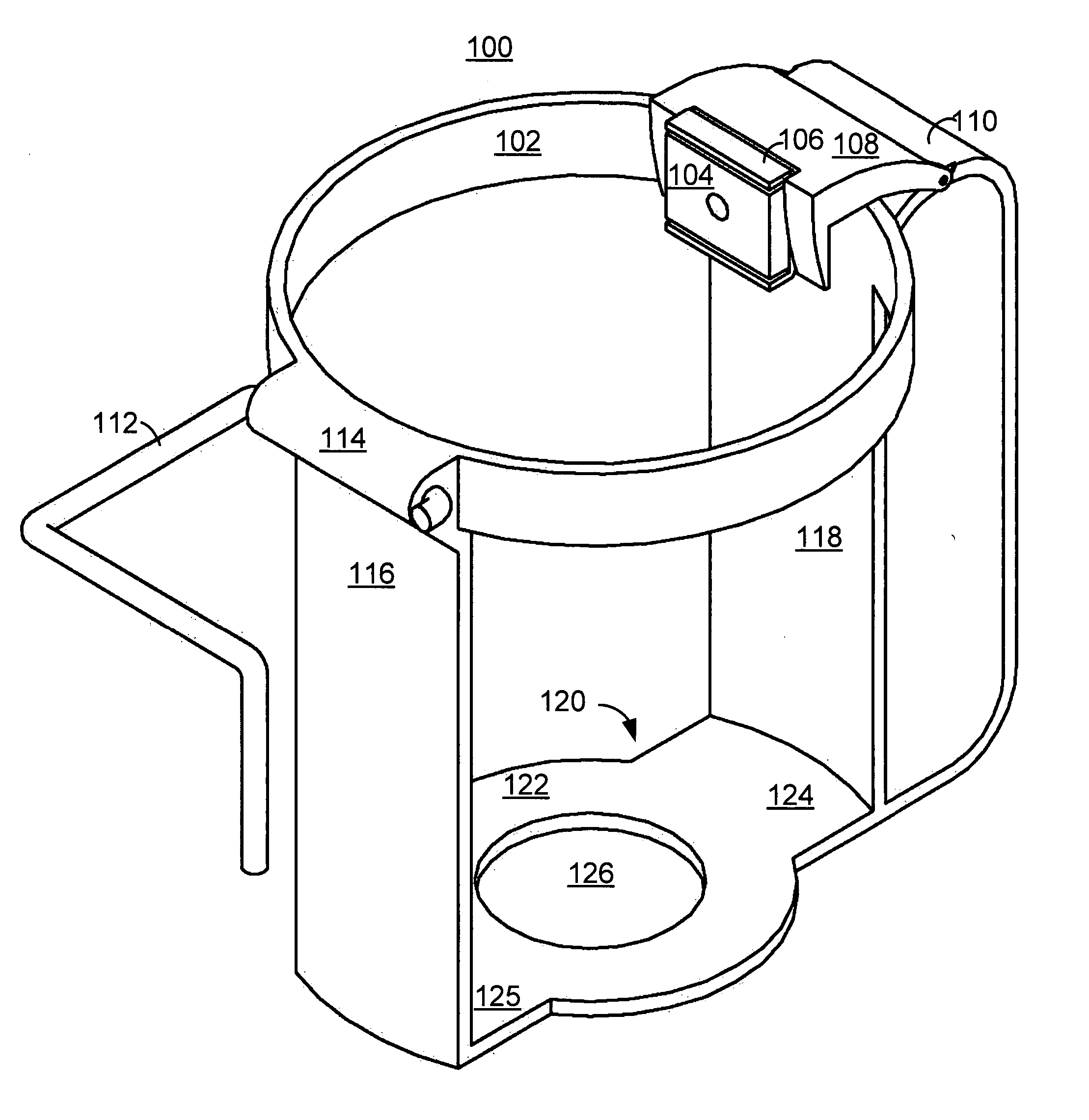

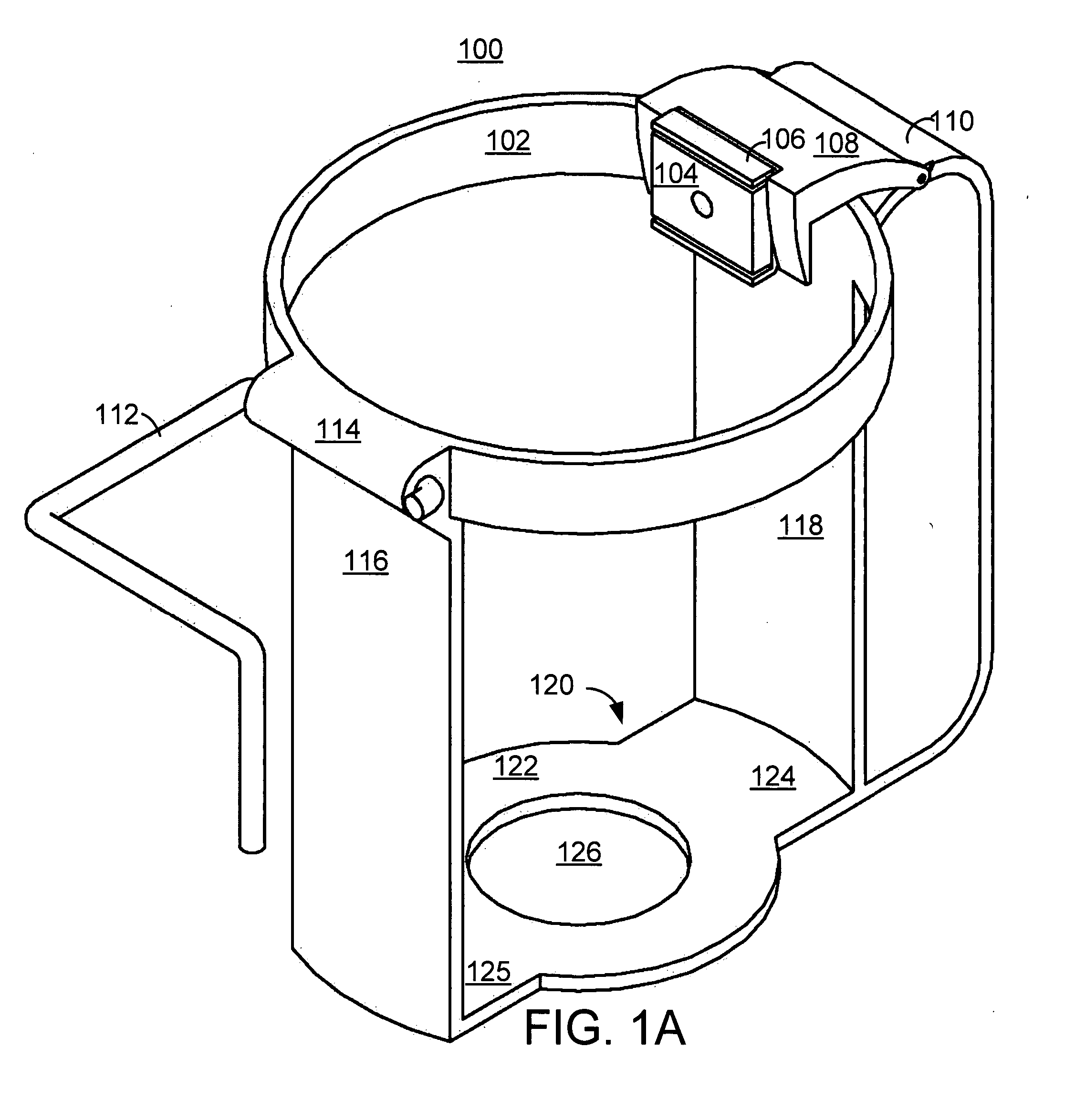

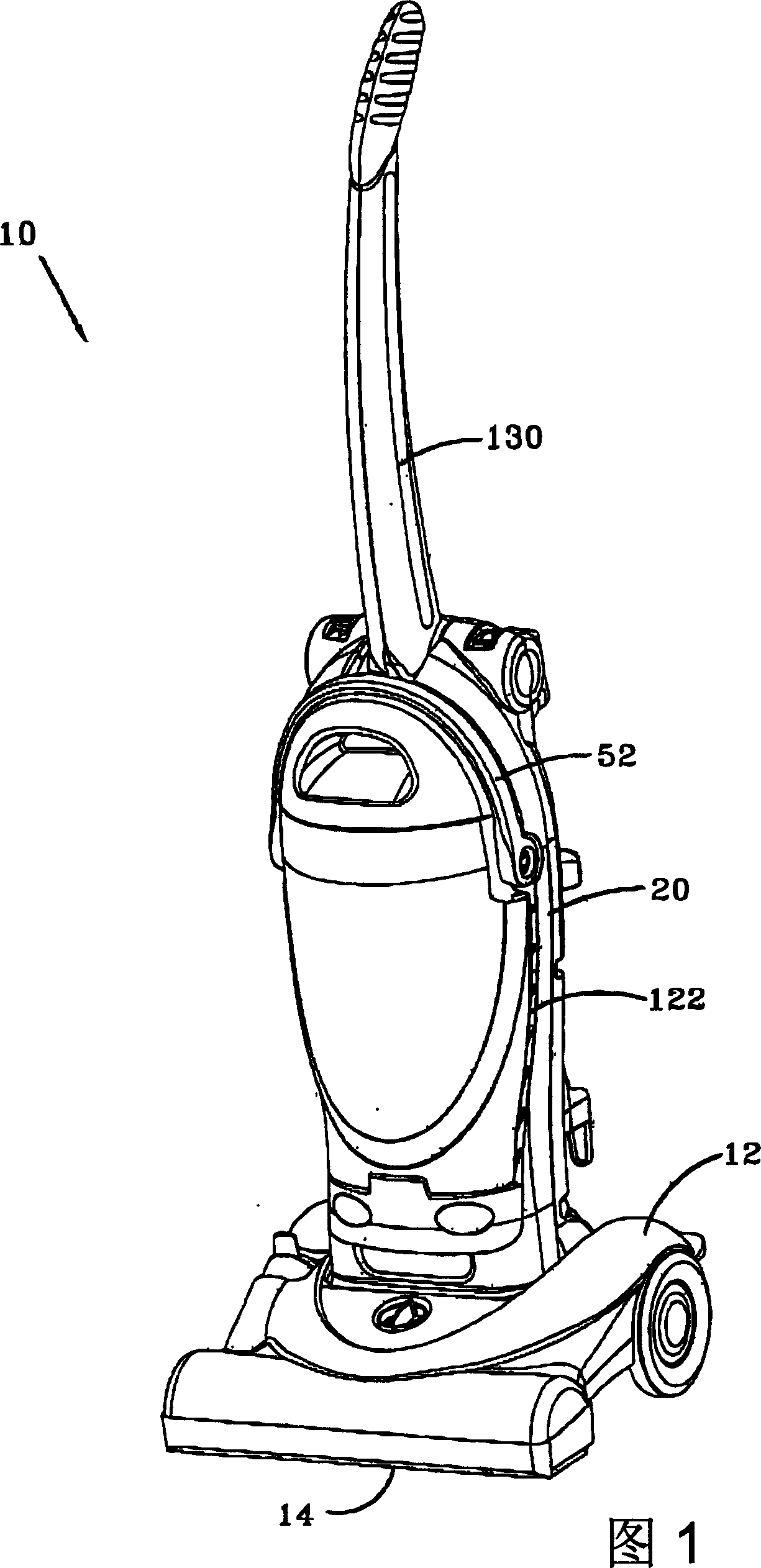

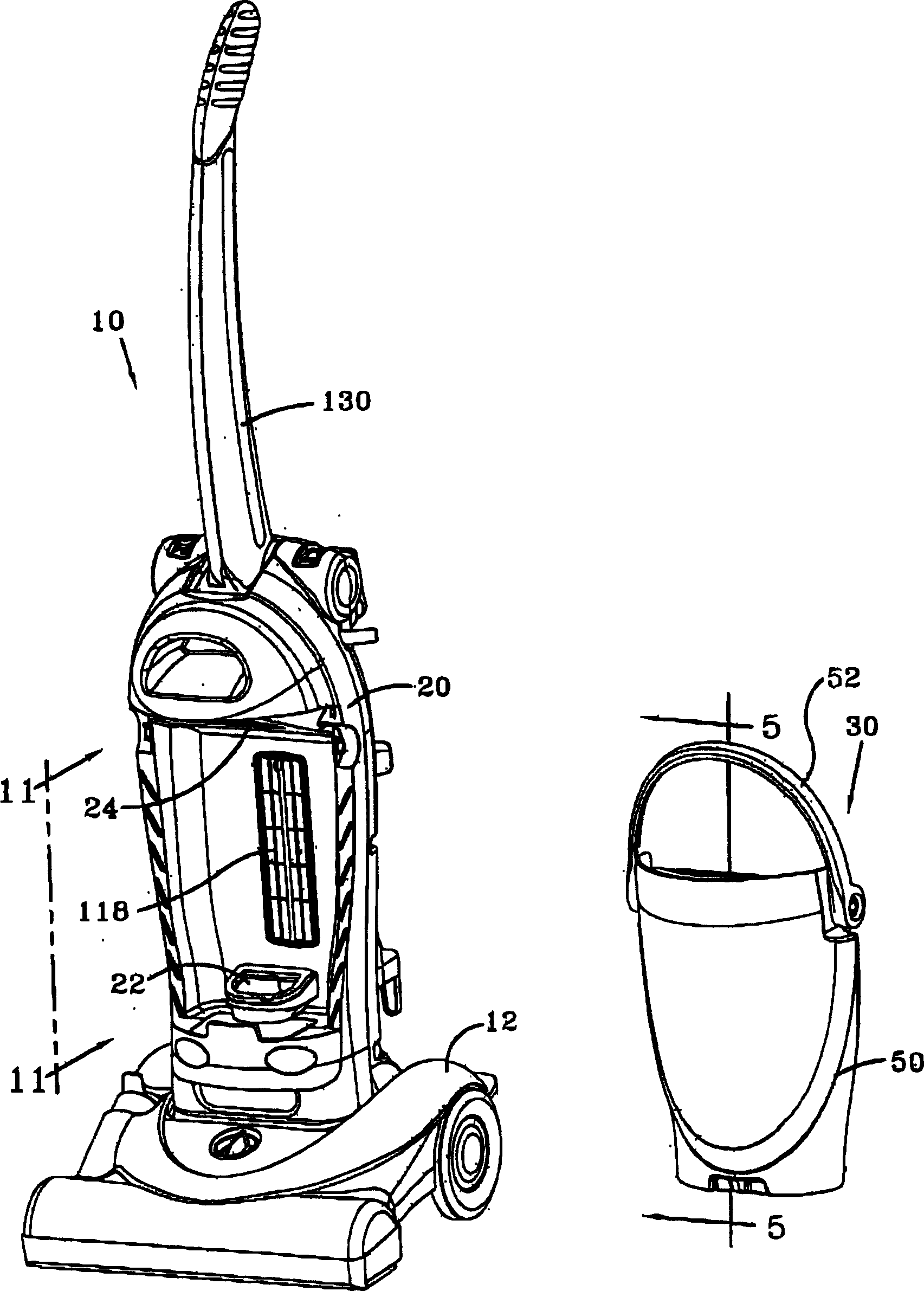

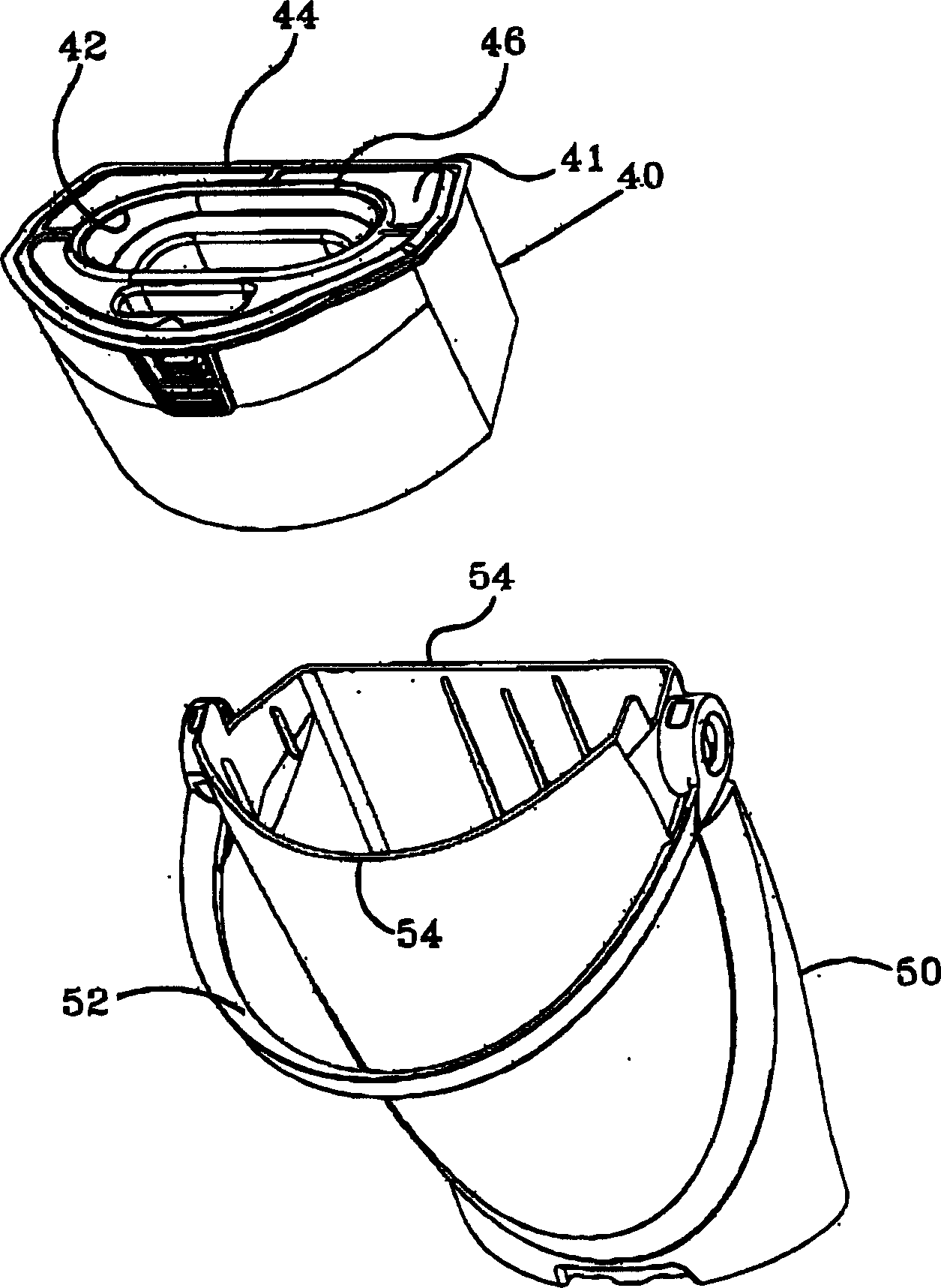

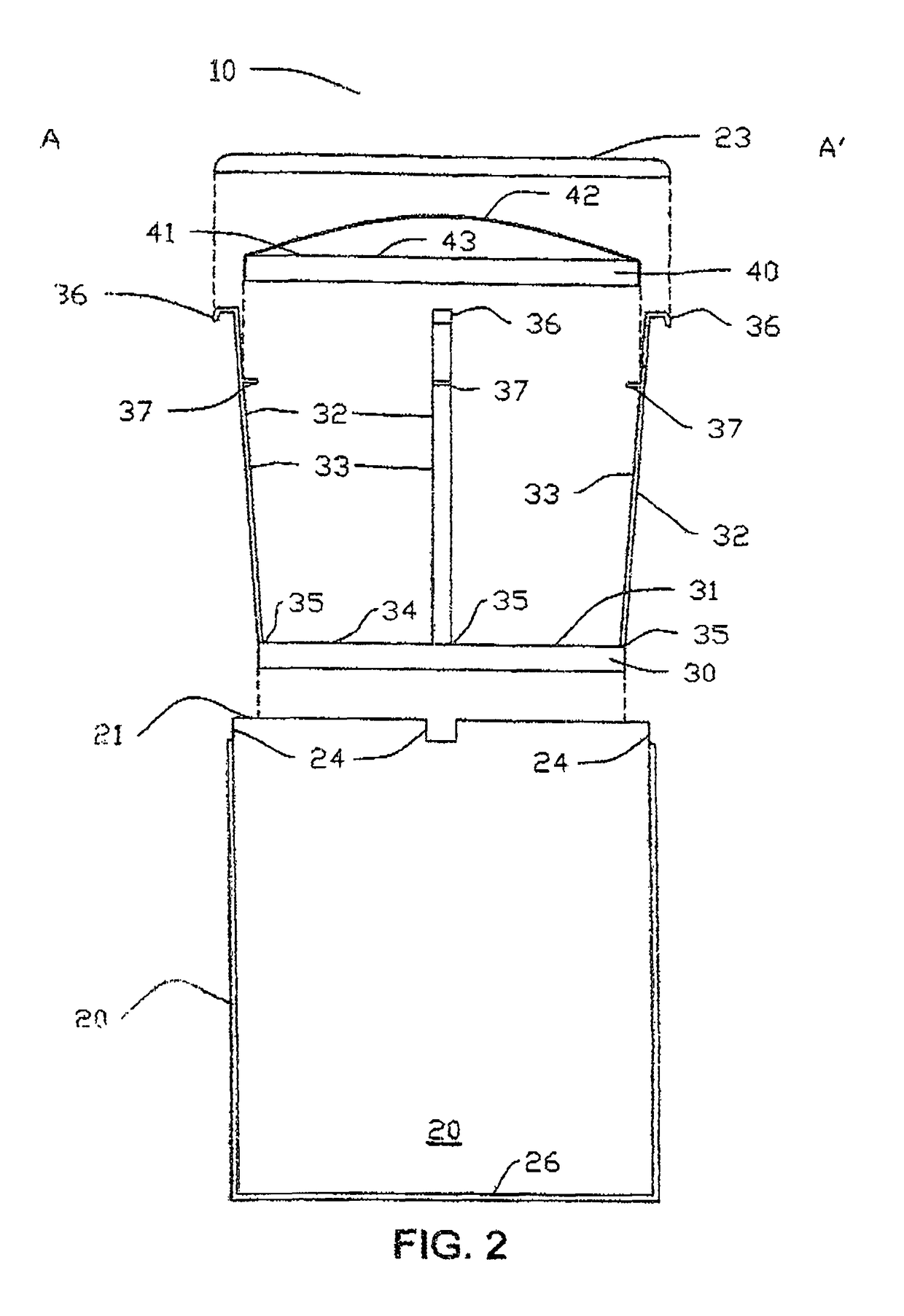

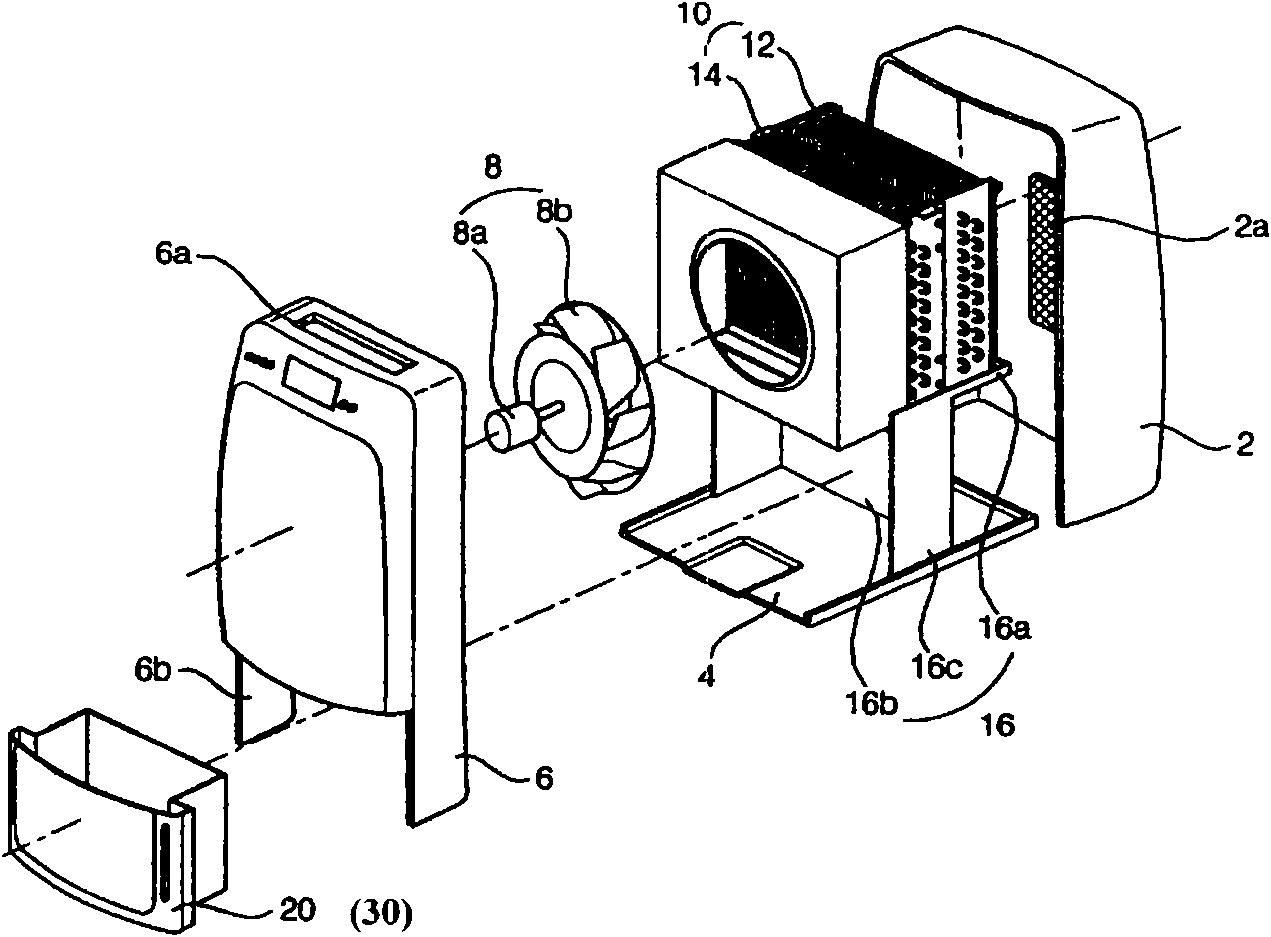

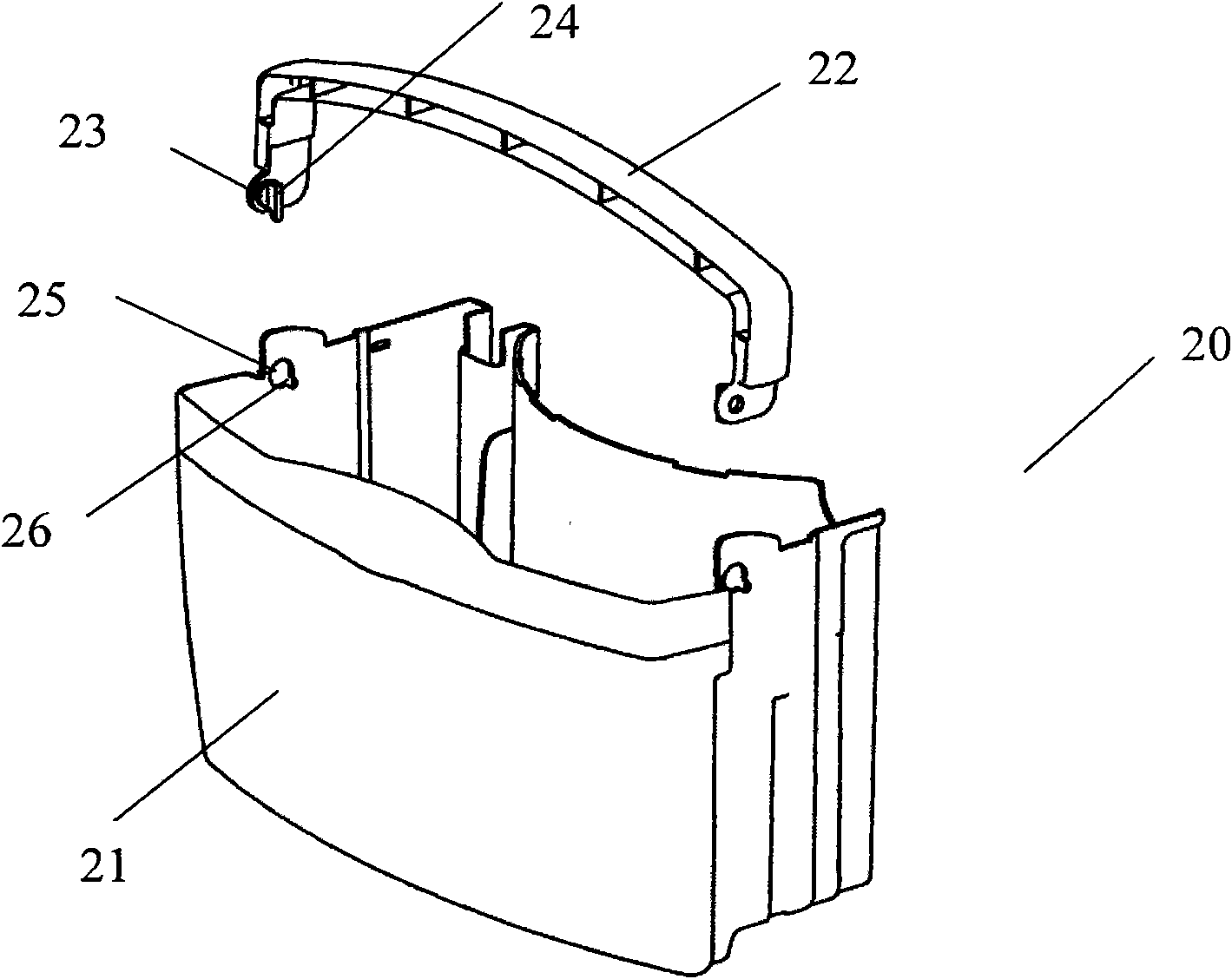

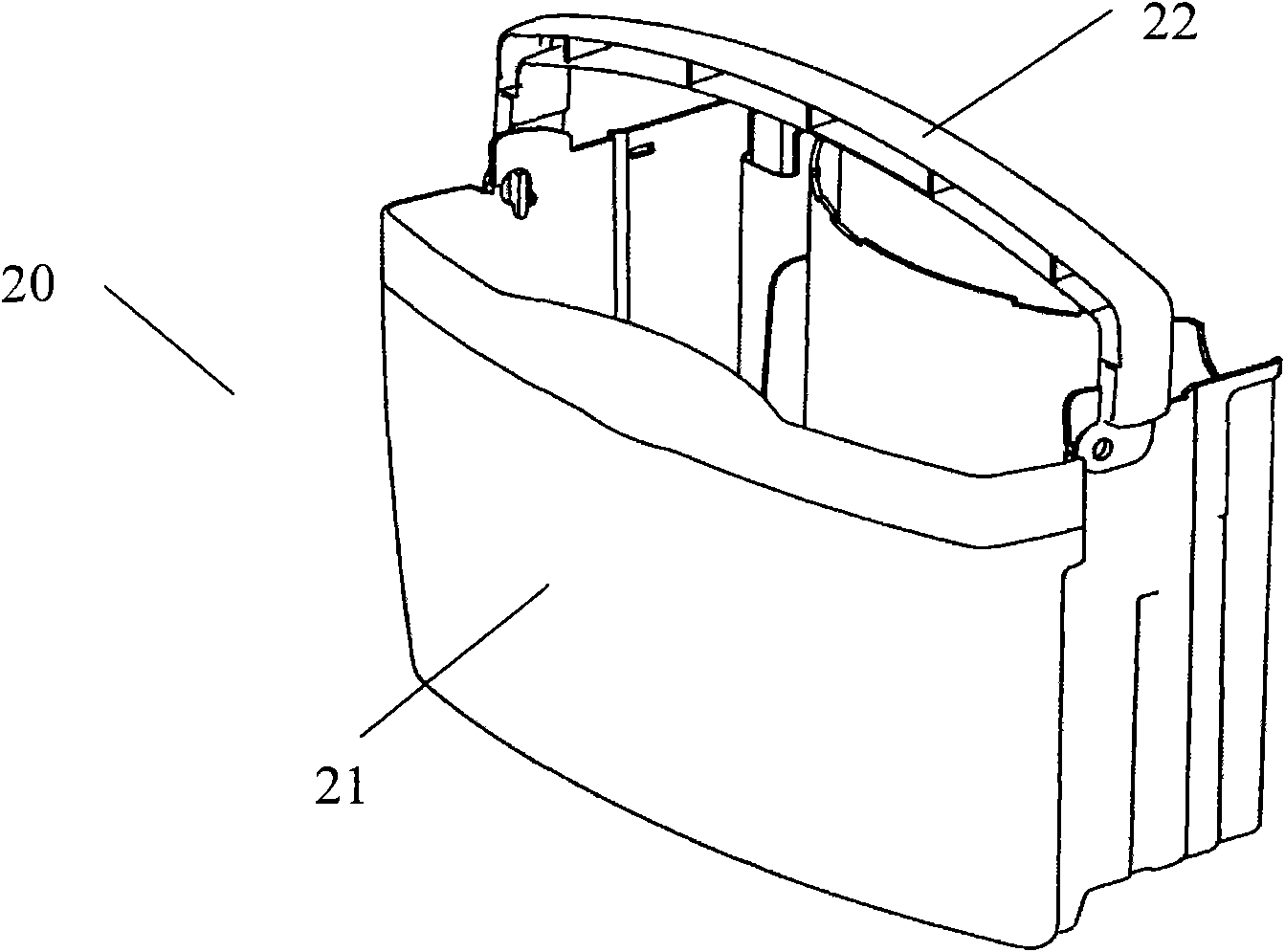

Handle and latch for a removable dirt separation system

An upright vacuum cleaner is disclosed. The upright vacuum cleaner includes a carpet engaging nozzle base and an upper housing pivotally attached to the nozzle base. The upright vacuum cleaner further includes a removable bucket releasably secured to the upper housing and a bucket handle rotatably attached to the bucket and movable between a first position and a second position. The upright vacuum cleaner yet further includes a latch adapted to secure the bucket to the upper housing when the handle is in the first position and release the bucket from the upper portion when the handle is in a second position. The bucket may be removed from the upper housing when the latch is released from the upper housing. The bucket is re-secured to the upper housing by returning the bucket handle to the first position. A method of operating a upright vacuum cleaner is also disclosed.

Owner:HEALTHY GAIN INVESTMENTS

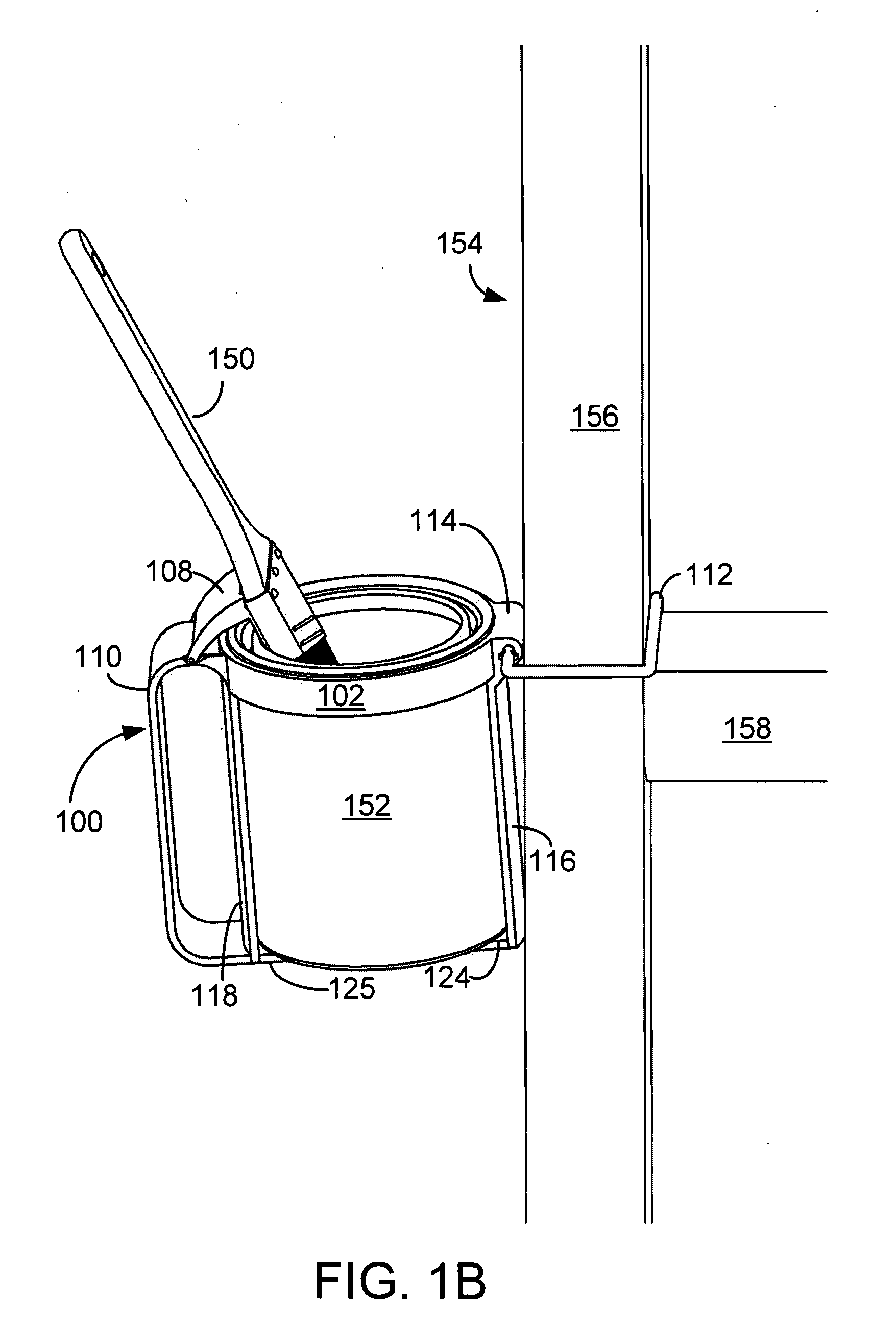

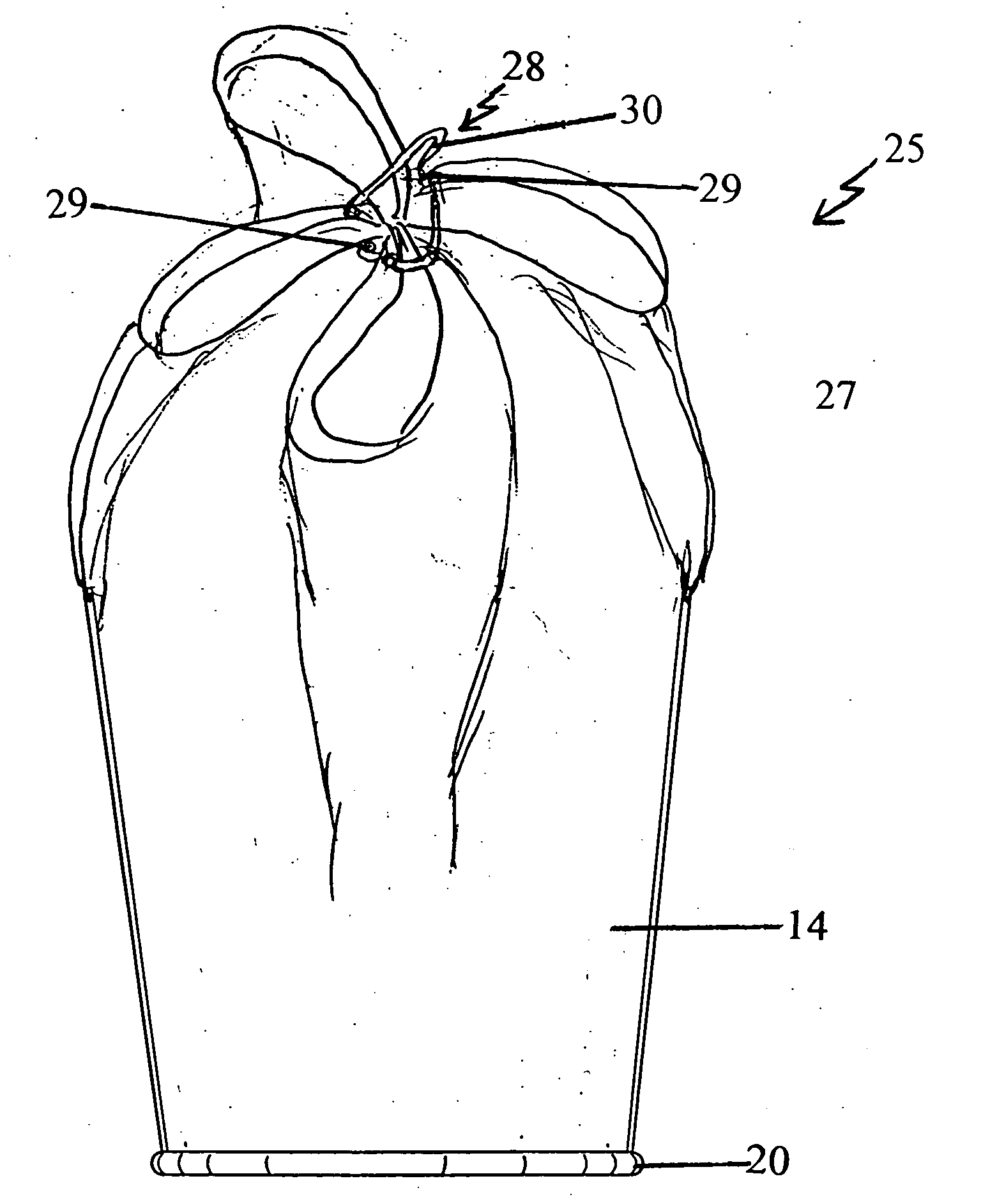

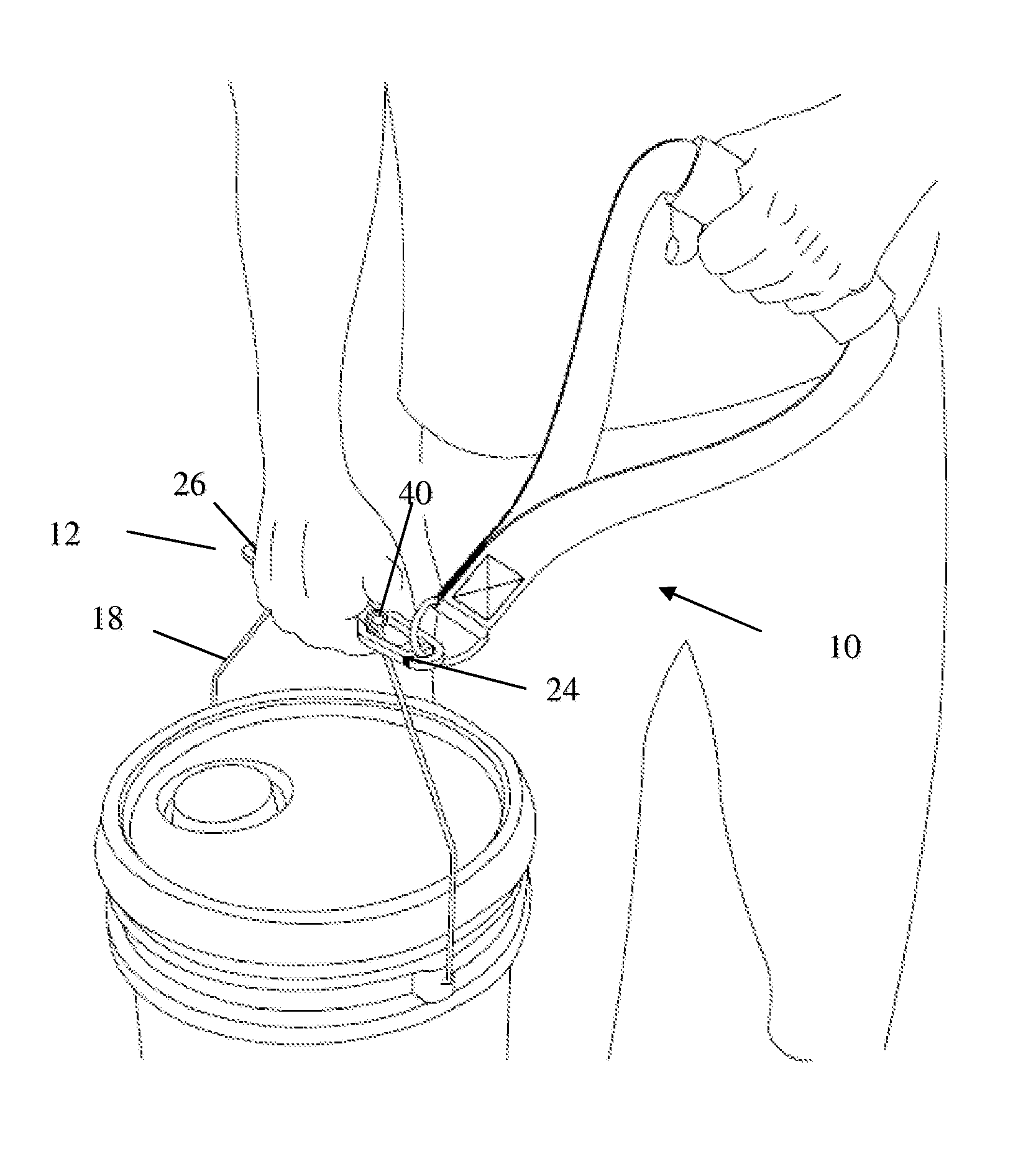

Applying a fluid

In an embodiment, a holder for an applicator for a fluid may include a magnet for holding the applicator over the container. The holder for the applicator may attach to the rim of the container or may be attached to a container holder. The container holder may include a handle and may be used with a container having bucket handles. In an embodiment, the container holder may include a band with notches for receiving a pivot where the handles connect to the container. In an embodiment, the container holder may include a clip for attaching to a ladder and / or may not necessarily include a applicator holder.

Owner:ALEJANDRO DIAZ

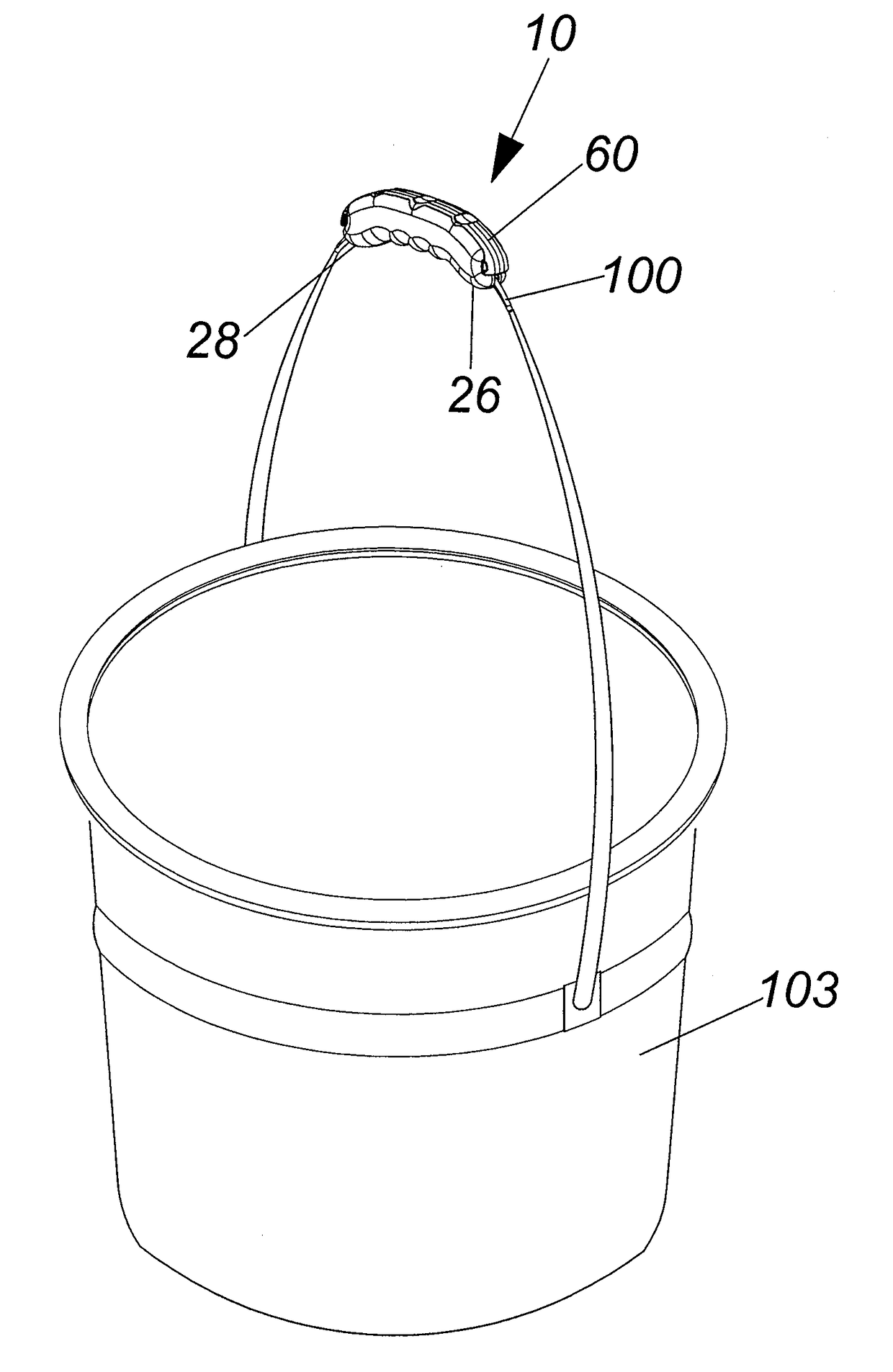

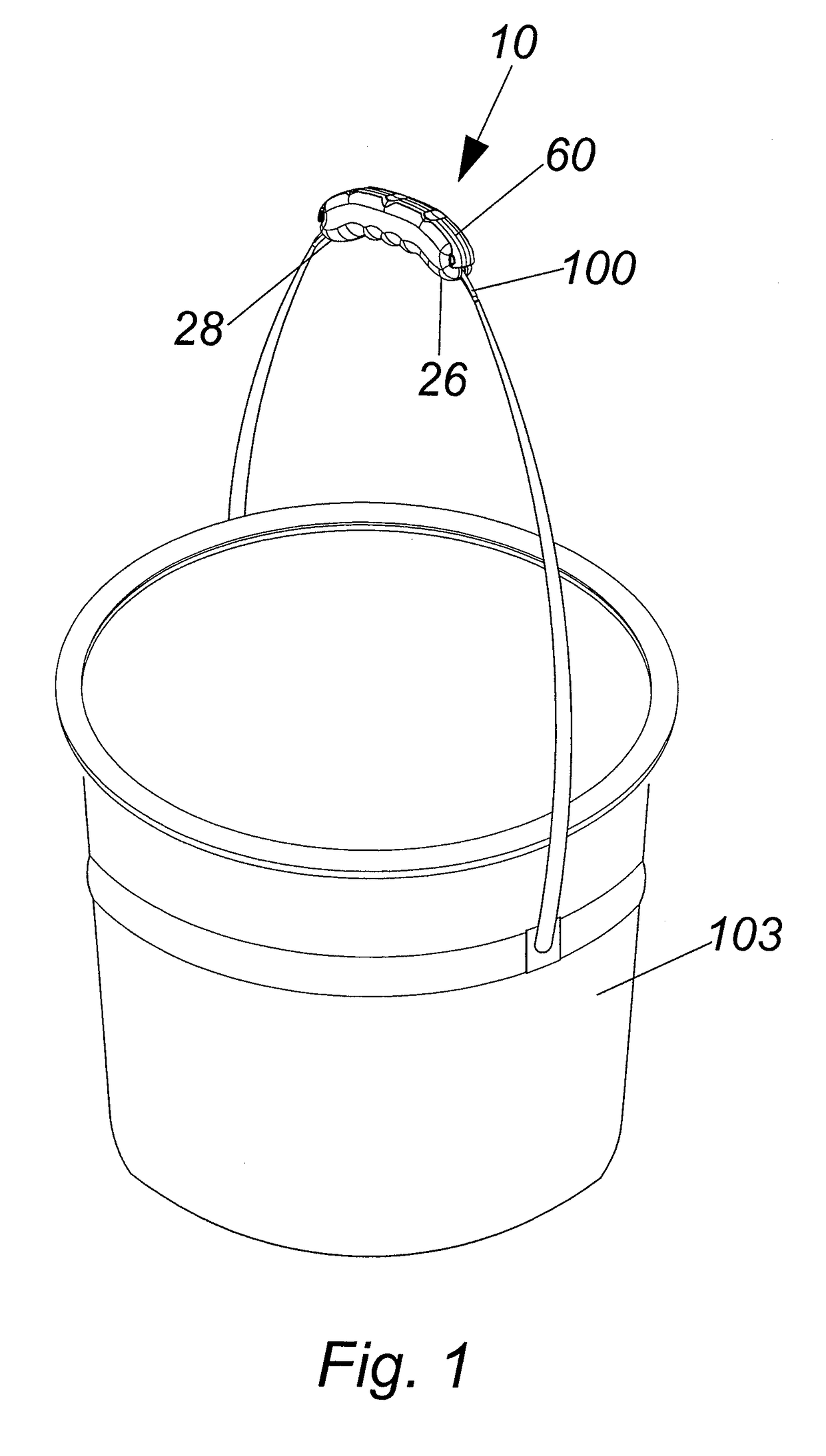

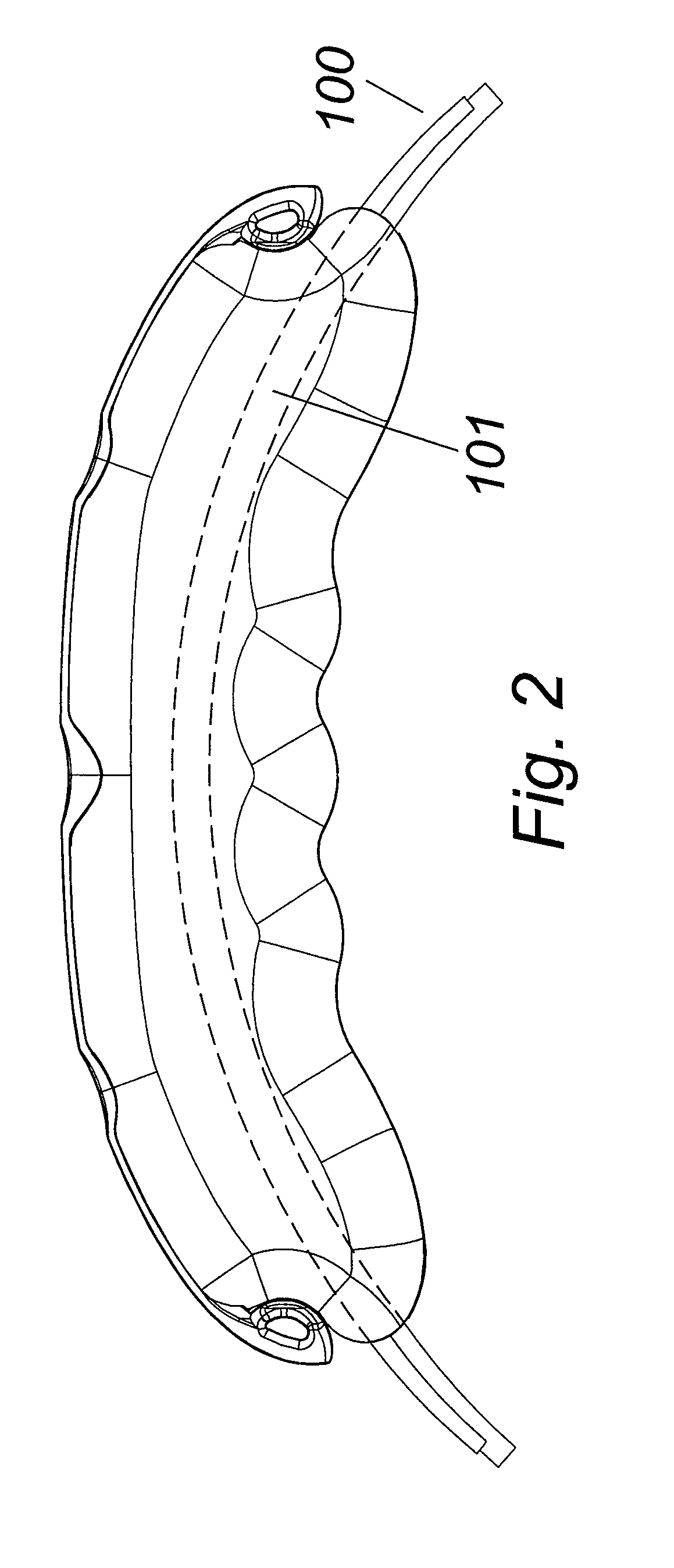

Bucket handle

ActiveUS20170073114A1Low cost manufacturingNeed to dissembleTravelling carriersHoldersBucket HandleEngineering

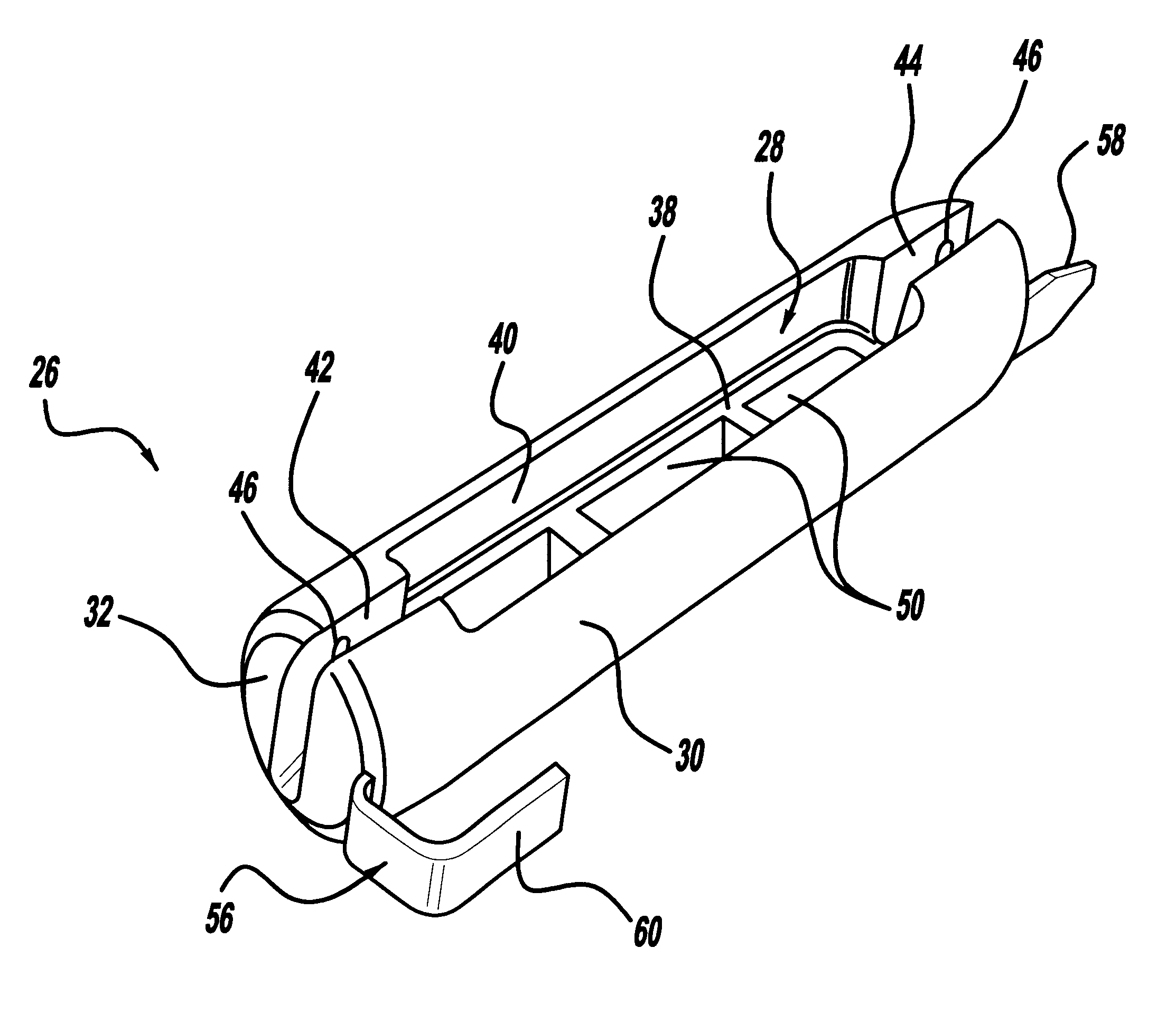

A handle for attachment to a bail member of a bucket is disclosed. The handle includes a base formed from two interlocking members, a first member frictionally engages a second member, locking the two members together without tools. Upon the interlocking of the first member and second member, a base structure is formed providing a receptacle constructed in a range for receipt of the bail member along an upper section. A centrally disposed cavity may be included in the upper section for receipt of a tubular sleeve commonly found on buckets and employing bail members for carrying heavy weights. The base structure is positioned beneath the bail member wherein a portion of the bail member is insertable into the receptacle. A cover member is secured to the top section of the base structure to conceal the receptacle and secure the bail member within the handle.

Owner:CARTLIDGE ROBERT D

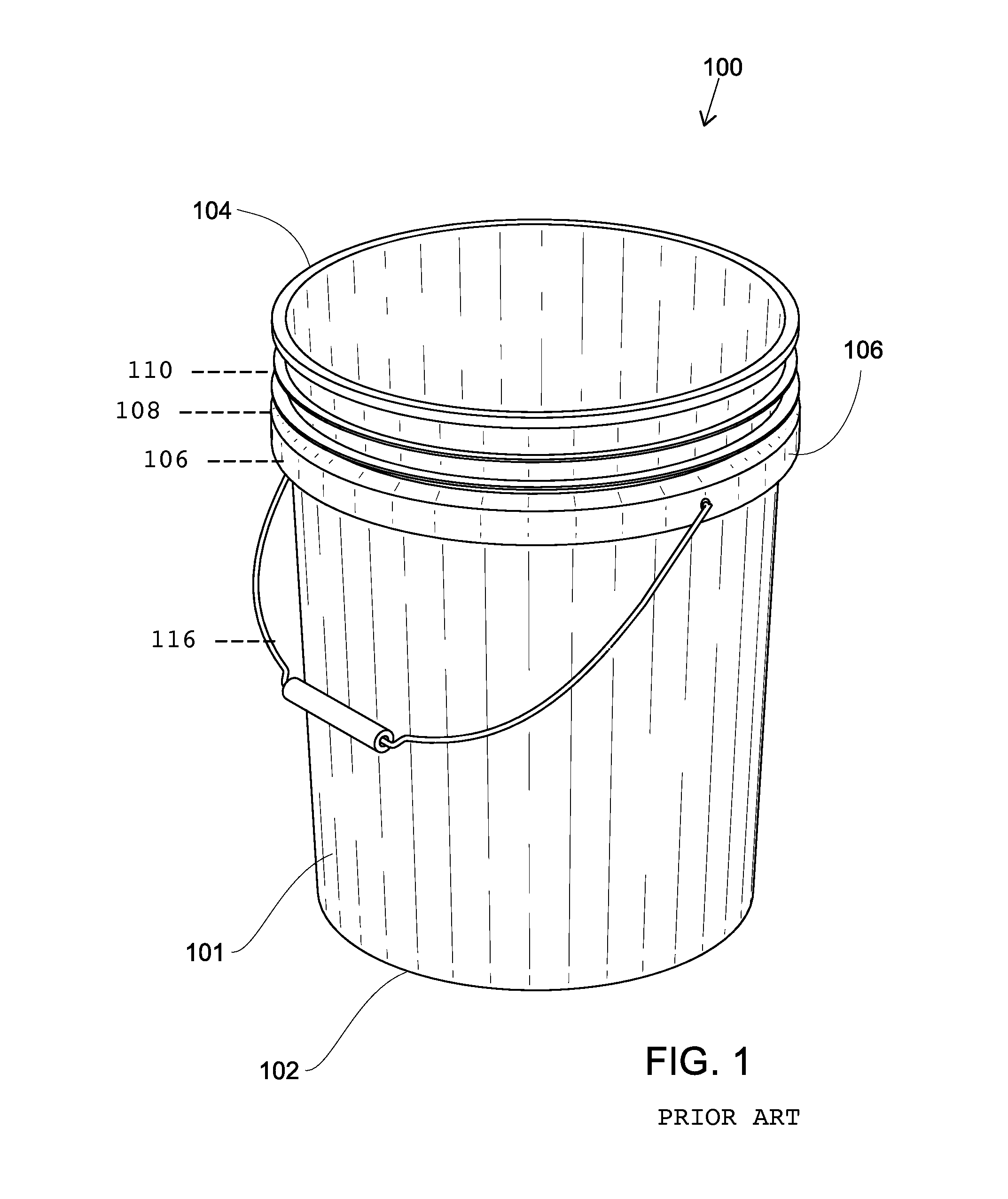

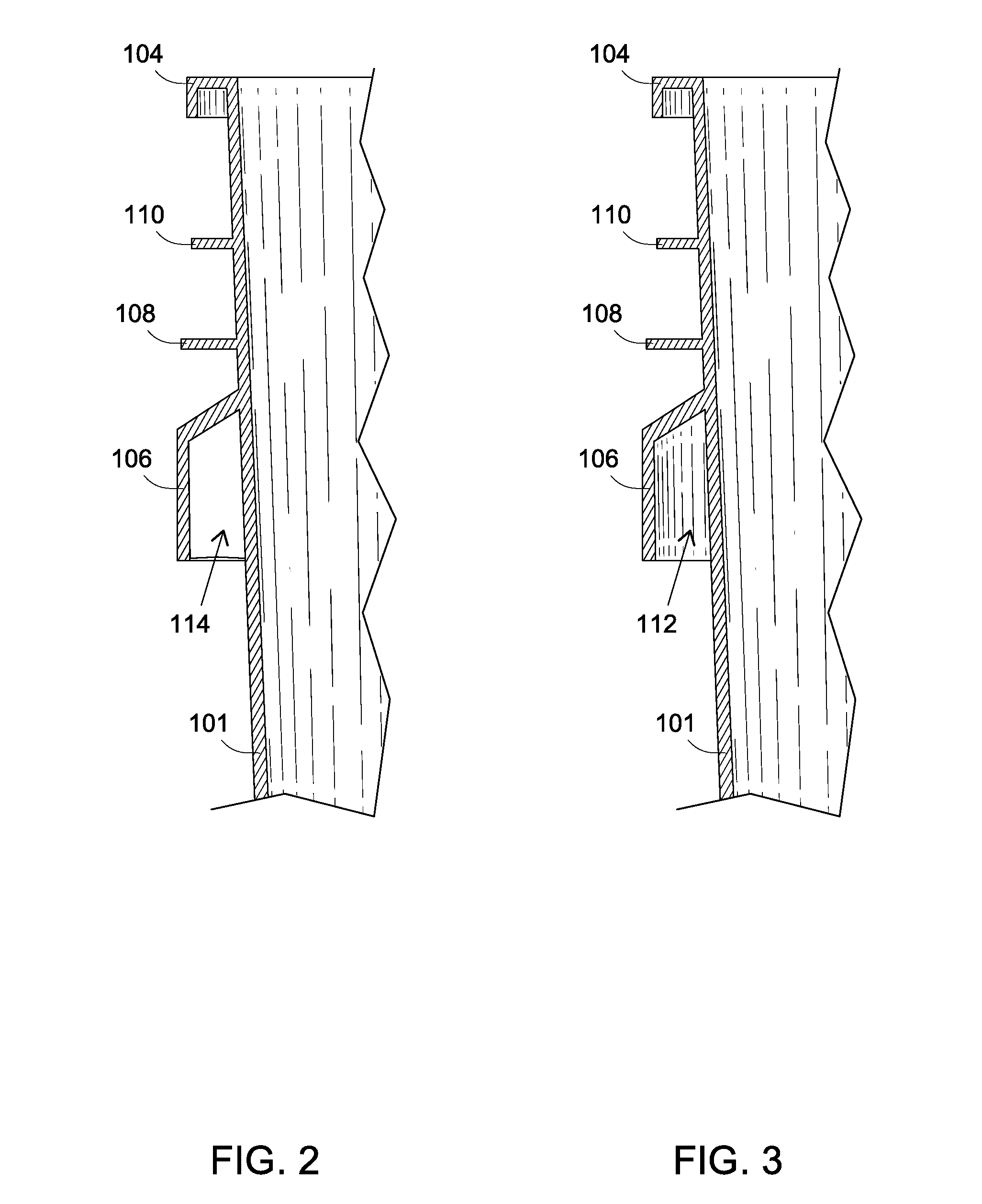

Bucket handle retainer

InactiveUS20180079555A1Easily removableEasily replaceableMachine supportsKitchen equipmentBucket HandleEngineering

A bucket handle retainer with a substantially flat rectilinear resilient plate. The plate has an upper tip that corresponds to the inside dimension of the internal cavity of the handle holding portion of a standard five gallon bucket. The plate includes a spring biased finger capable of frictionally engaging the inside wall of the handle holding portion. The plate also includes a holding portion capable of being grasped by a user's fingers to insert or remove the plate from the handle holding portion of the bucket. A preferred embodiment includes the handle retainer is injection molded from nylon plastic.

Owner:LEE JR JAMES ARTHUR

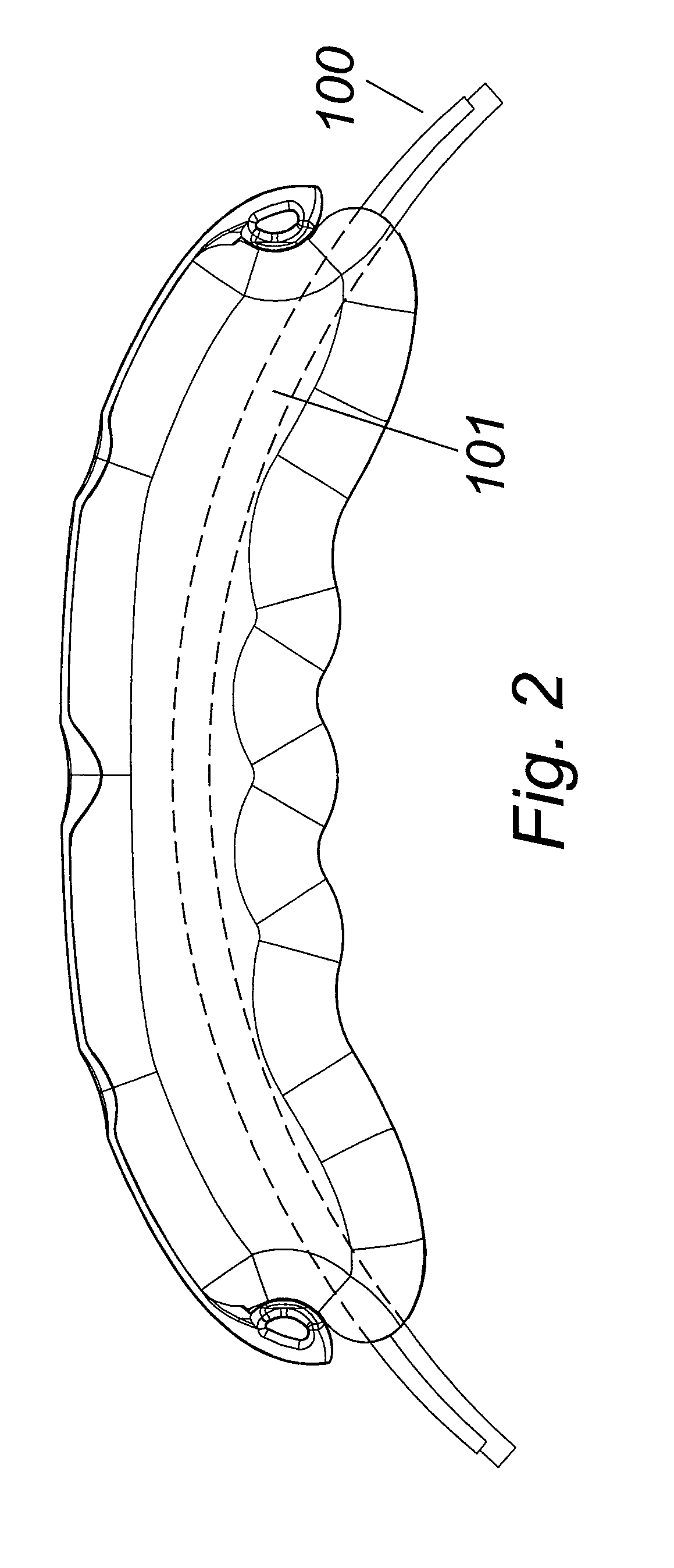

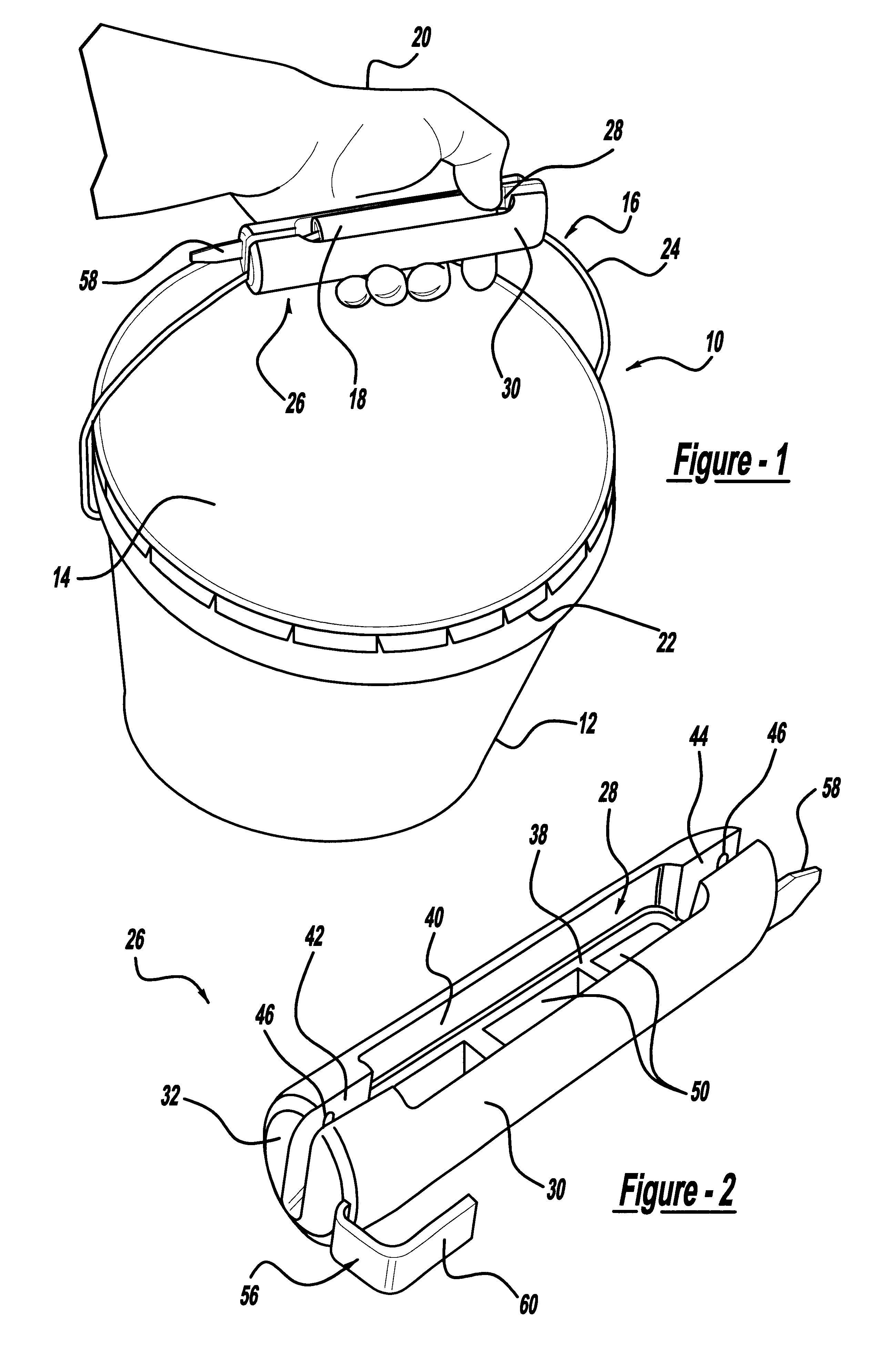

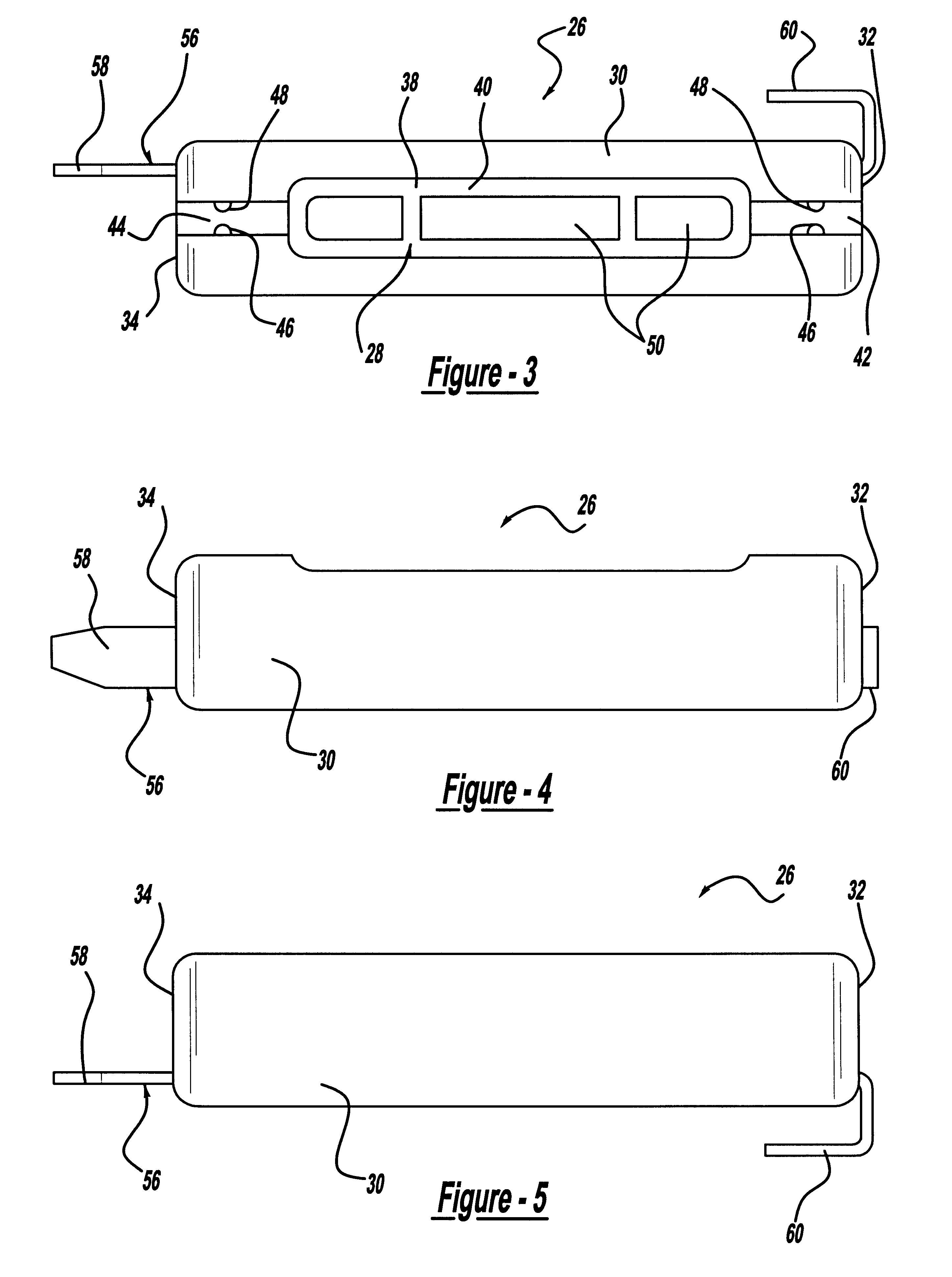

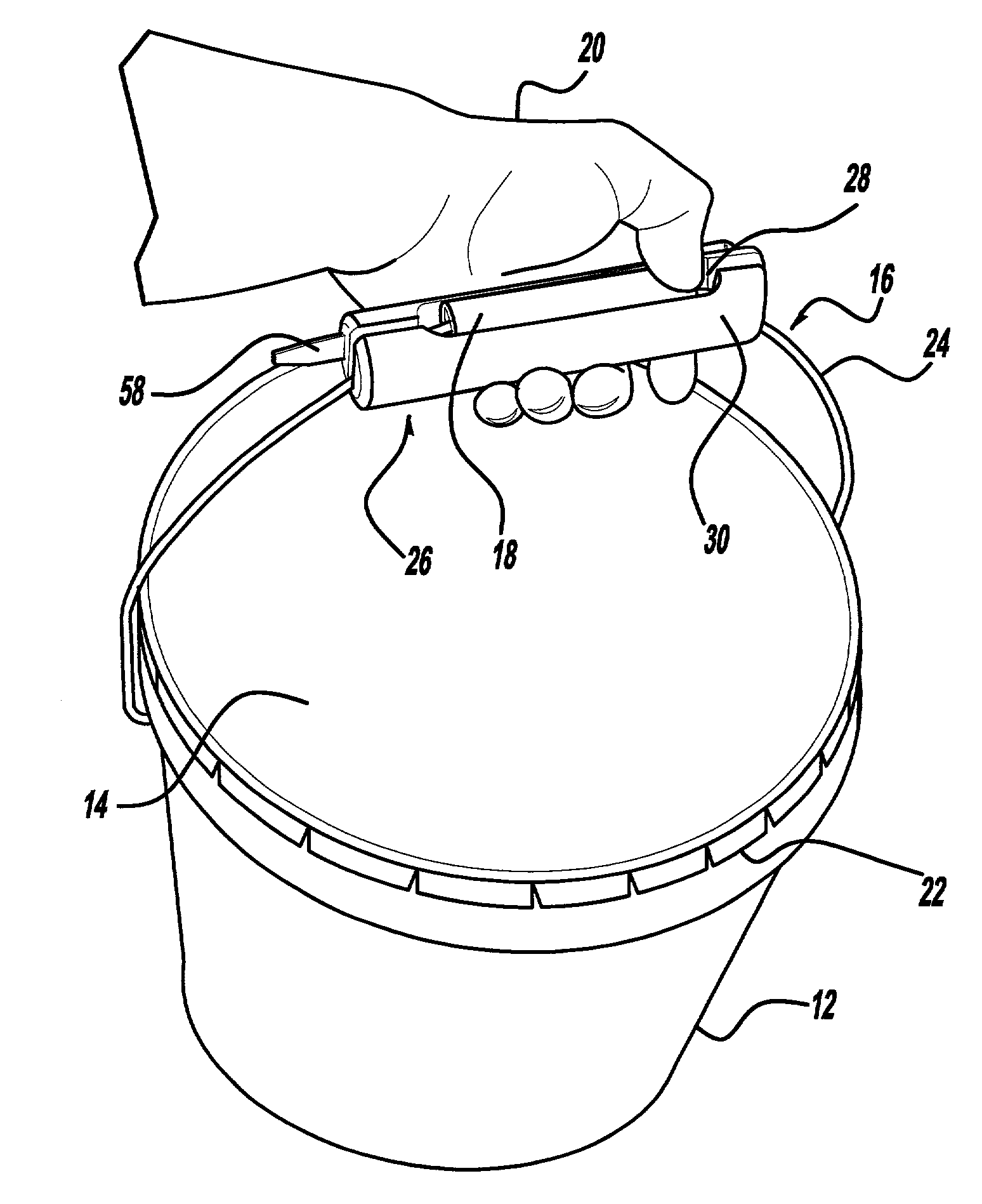

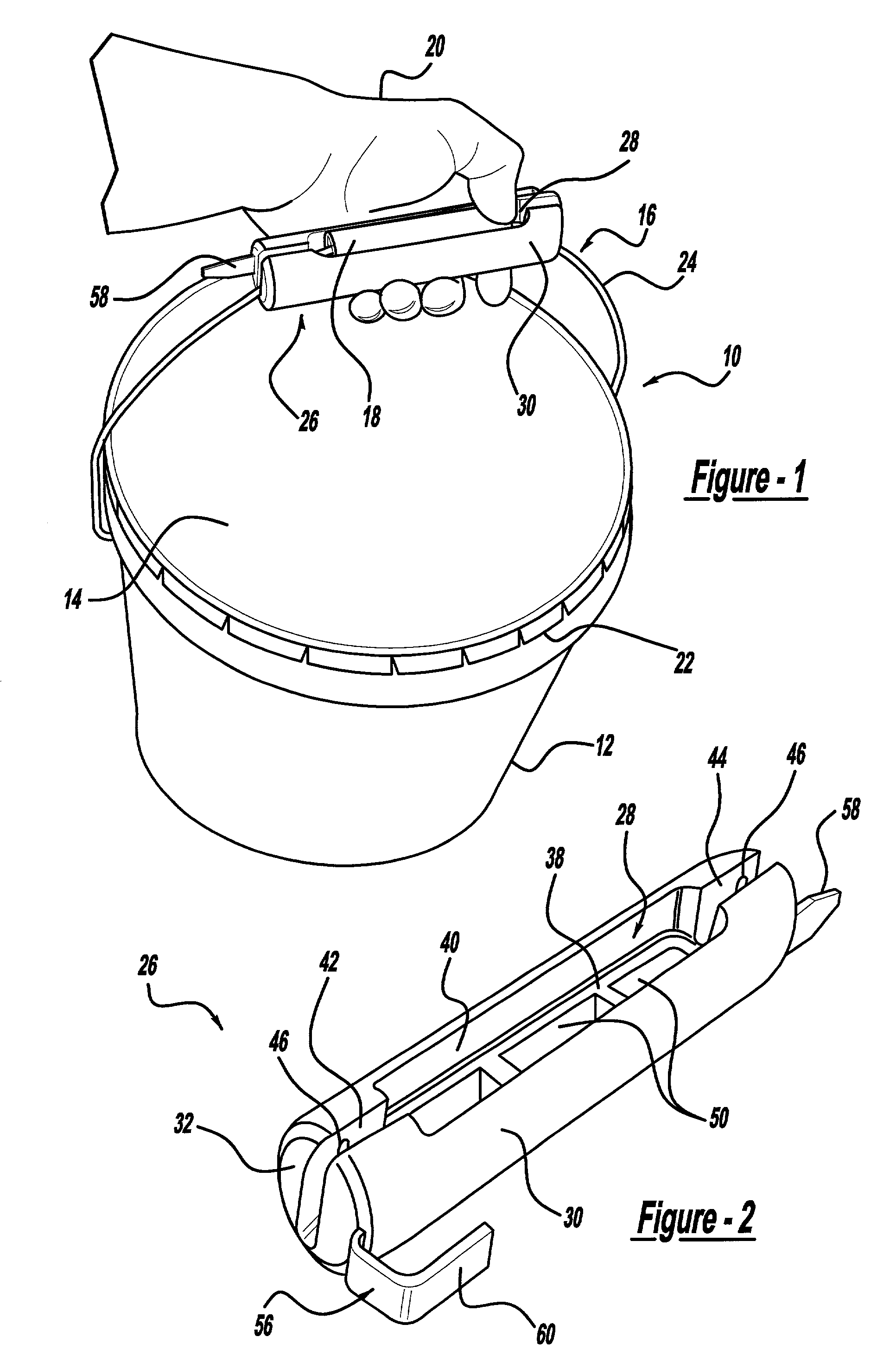

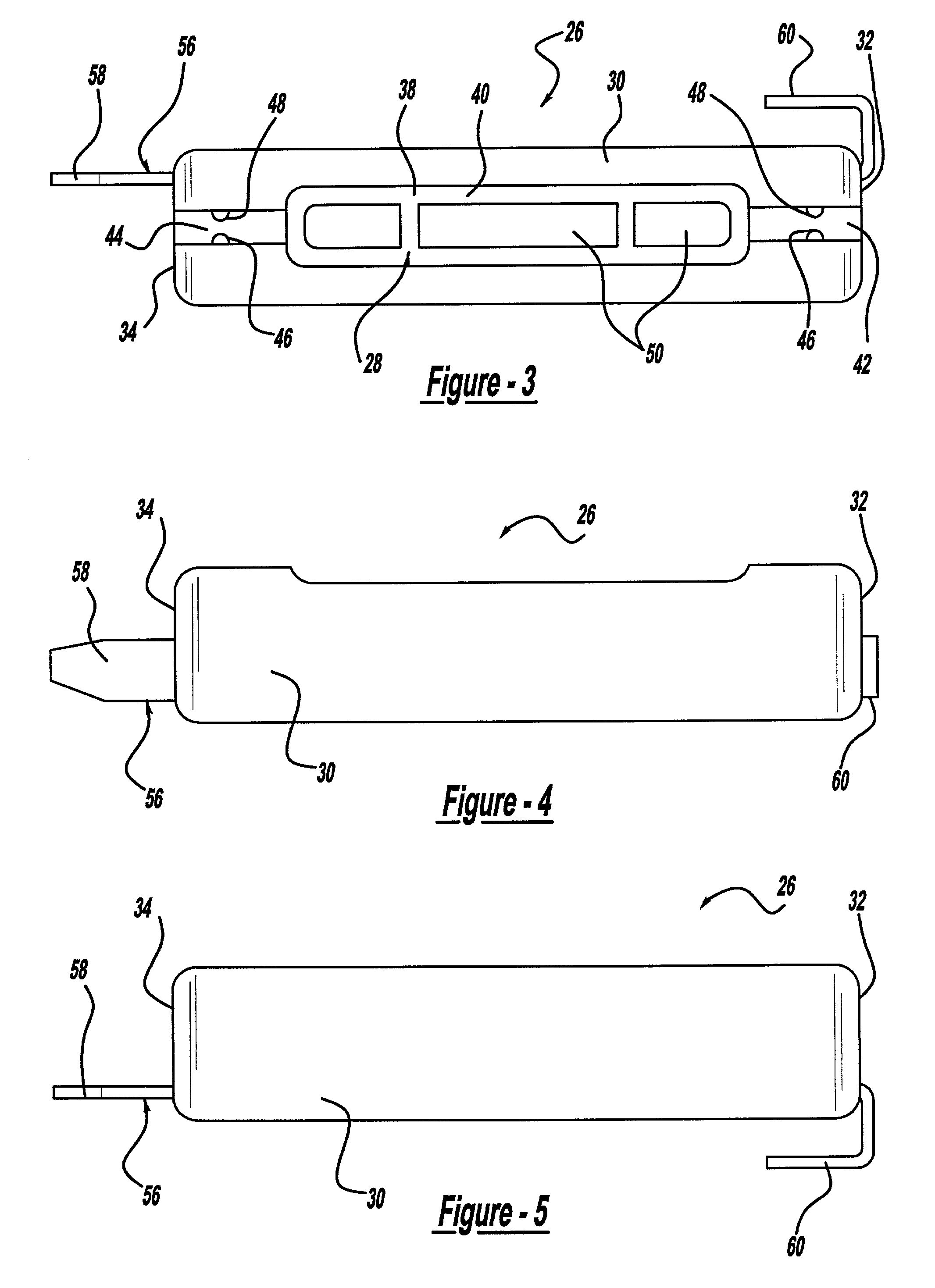

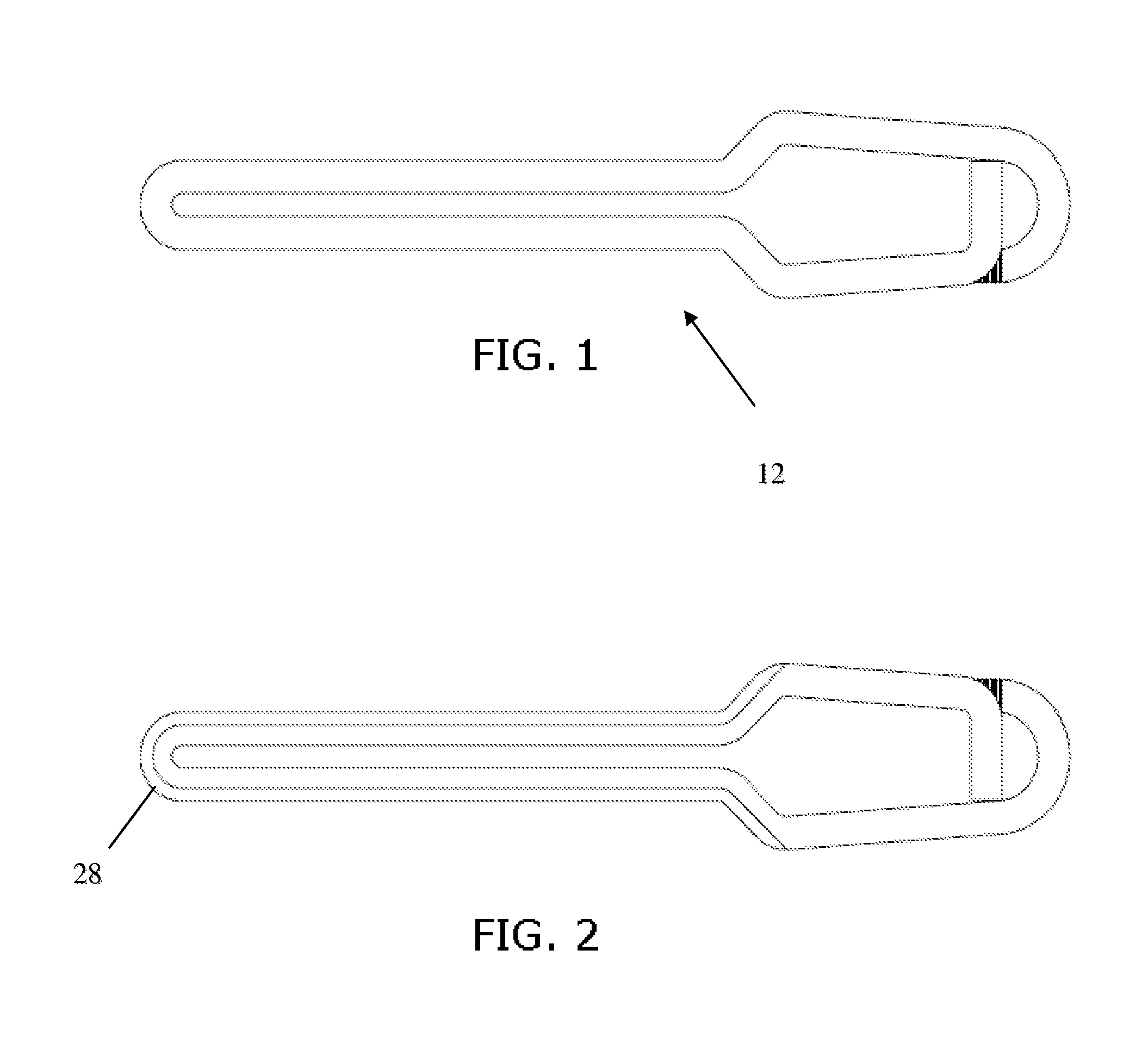

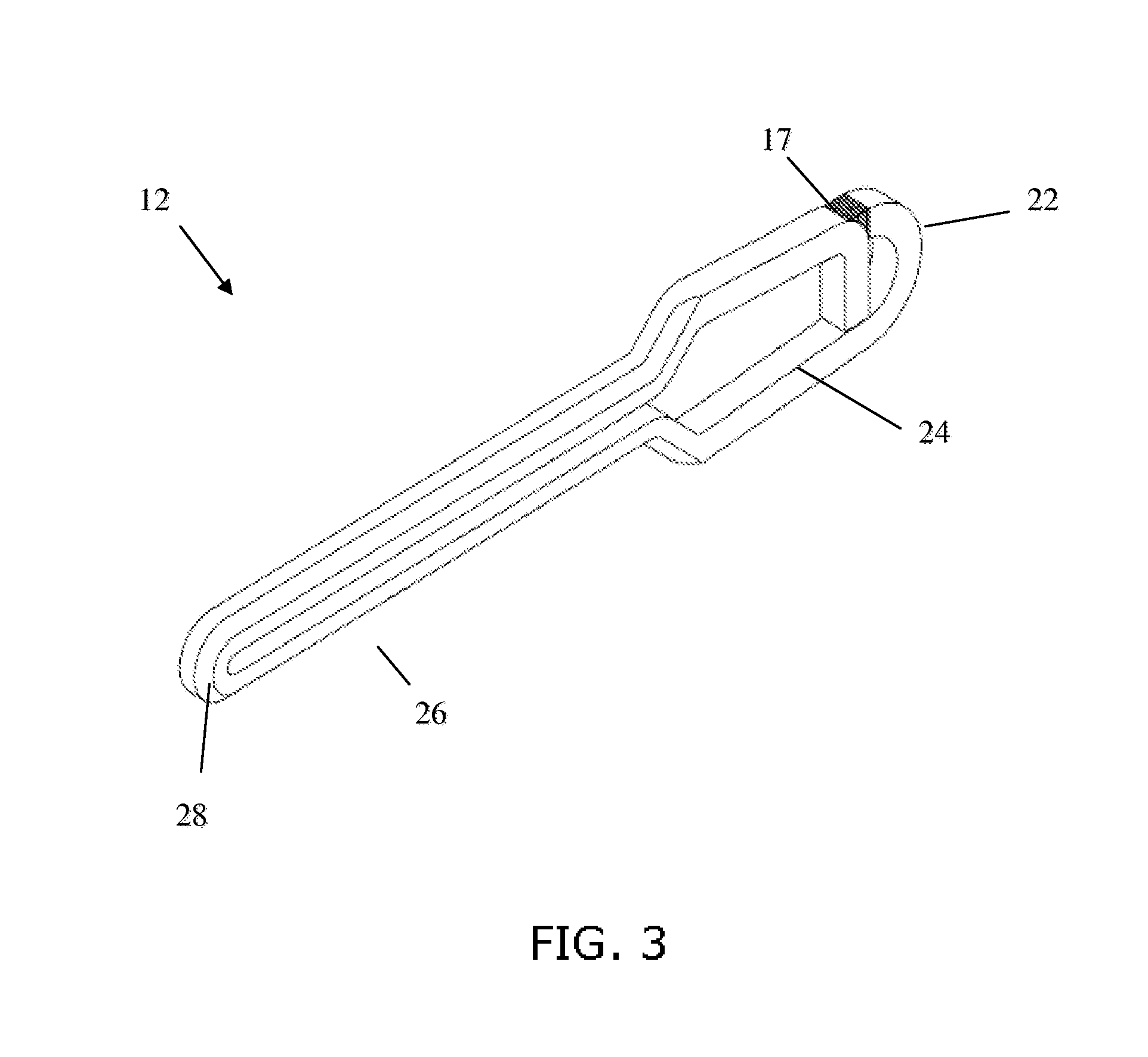

Removable grip for a bucket

A removable grip for a five-gallon bucket that includes a prying tool for removing a lid of the bucket. The grip includes an elongated body in which a channel is formed. The channel includes a centrally disposed widened portion that is configured to accept an existing grip formed on a bail of the bucket handle. The channel also includes narrow portions at each end of the widened portion that accept the bail. Flexible tabs within each narrow portion lock the grip onto the bail. The prying tool includes a flat end and a hooked end. The flat end can be used to pry open the lid of a paint bucket and can be a screwdriver end. The hooked end can be used to pry up the tangs of the lid of the five-gallon bucket to remove the lid.

Owner:GALLUP ERIC M

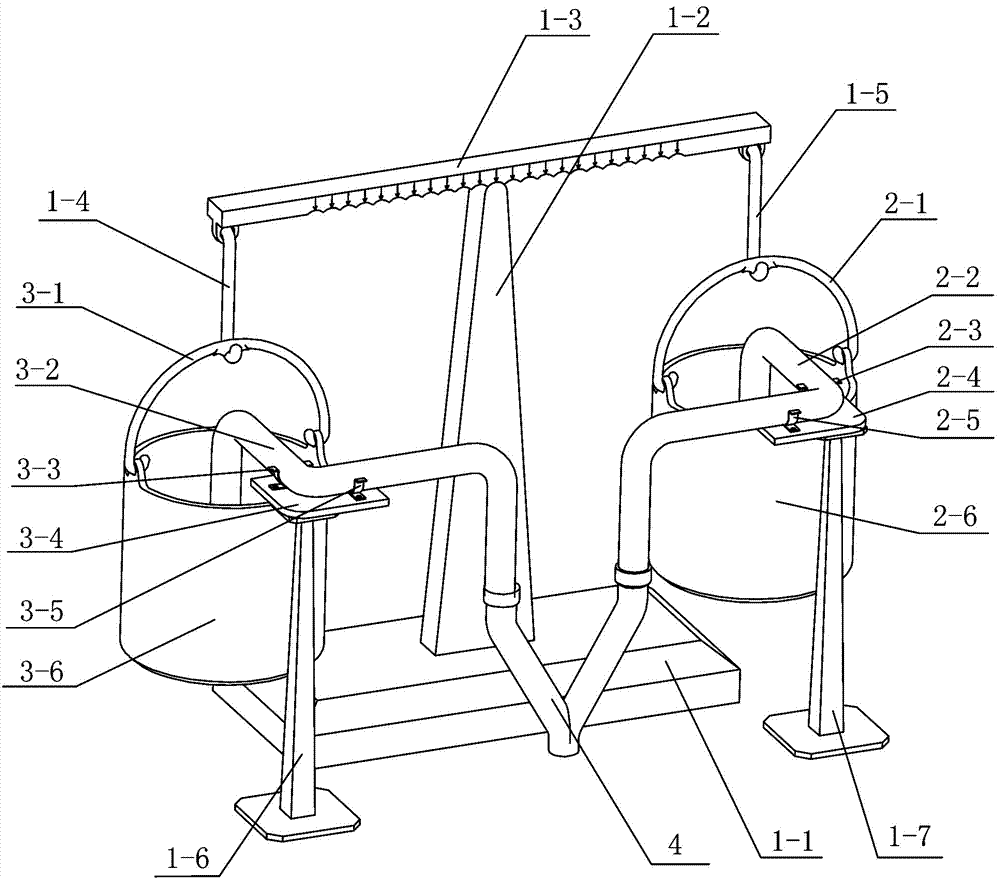

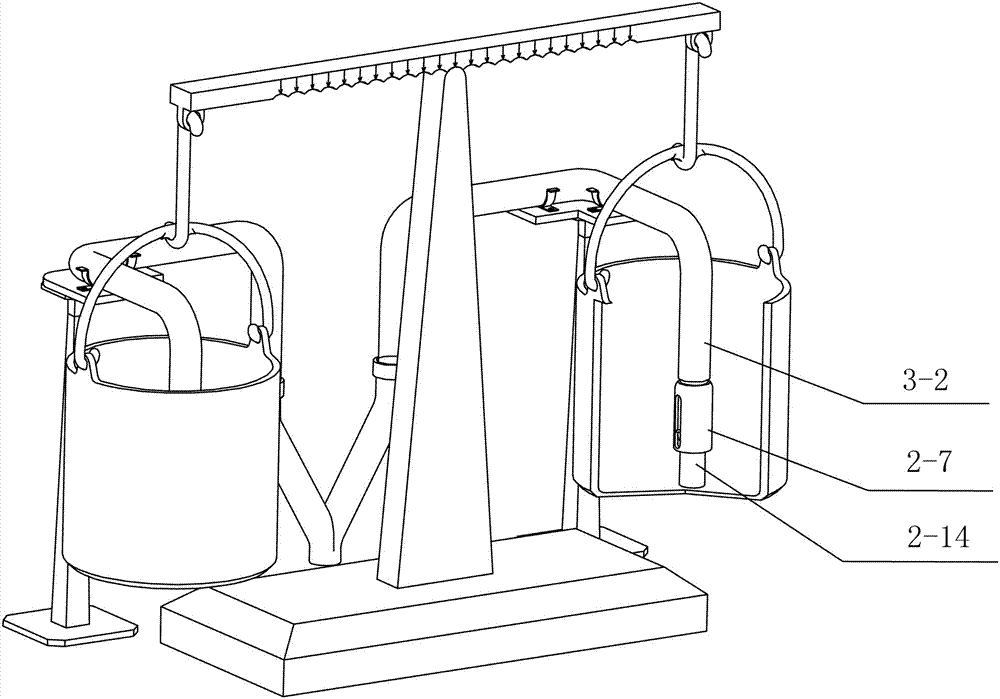

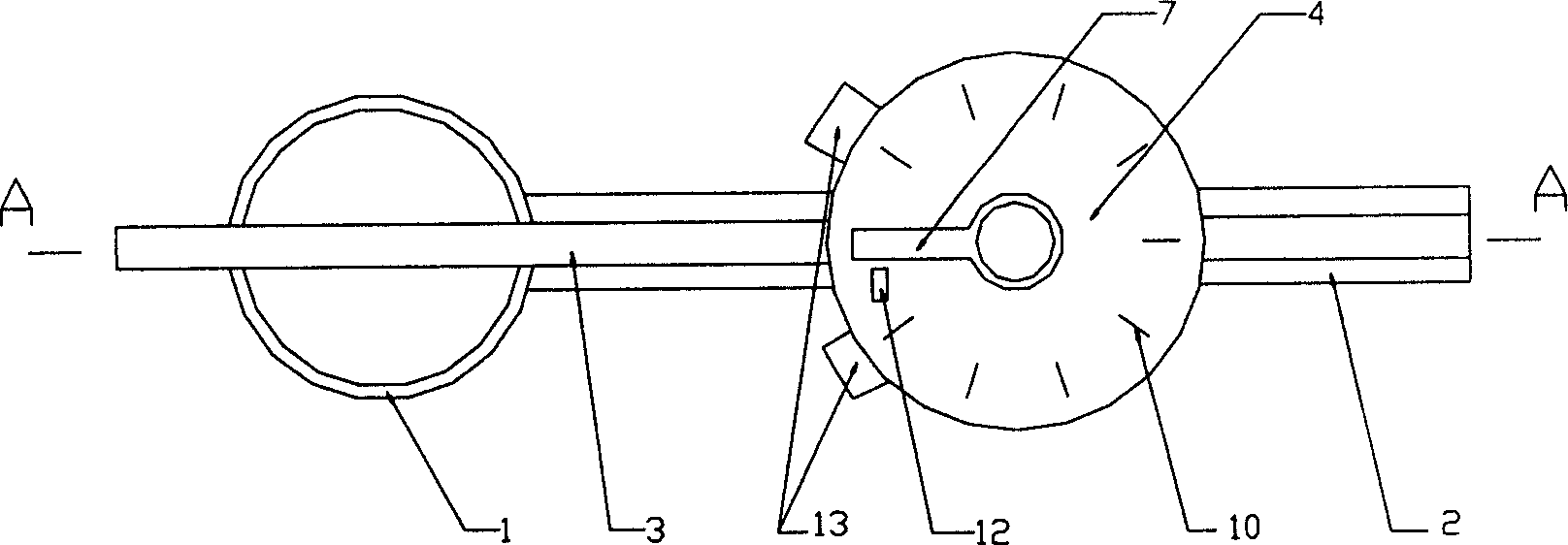

Balance type apparatus for mixing two liquids according to arbitrary ratio, and operating method thereof

ActiveCN106853345ASmall outflow rateIncrease outflow rateFlow mixersTransportation and packagingBucket HandleEngineering

The invention relates to a balance type apparatus for mixing two liquids according to an arbitrary ratio, and an operating method thereof. The apparatus comprises a pedestal, a support is fixed at the top of the pedestal, a crossbeam is supported on the top of the support, a first hook and a second hook are respectively hinged to two ends of the crossbeam, a first liquid storage cylinder hangs on the first hook through a first bucket handle, a second liquid storage cylinder hangs on the second hook through a second bucket handle, an A liquid guiding tube is arranged in the first liquid storage cylinder, a B liquid guiding tube is arranged in the second liquid storage cylinder, and the A liquid guiding tube and the B liquid guiding tube are connected with two liquid outlets of a three-way piece. When the flow-out proportions of the two liquids are imbalanced, a balance tips and drive solid slide blocks in a two-flow regulator at the bottom of the guiding tubes to change the sizes of the liquid outlets in order to afresh reach balance. The apparatus has a simple structure, is convenient for a worker to operate, allows liquids to stably flow out in proportion in real time, and realizes mixing of the liquids according to an arbitrary ratio.

Owner:CHINA THREE GORGES UNIV

Handle and latch for a removable dirt separation system

An upright vacuum cleaner is disclosed. The upright vacuum cleaner includes a carpet engaging nozzle base and an upper housing pivotally attached to the nozzle base. The upright vacuum cleaner further includes a removable bucket releasably secured to the upper housing and a bucket handle rotatably attached to the bucket and movable between a first position and a second position. The upright vacuum cleaner yet further includes a latch adapted to secure the bucket to the upper housing when the handle is in the first position and release the bucket from the upper portion when the handle is in a second position. The bucket may be removed from the upper housing when the latch is released from the upper housing. The bucket is re-secured to the upper housing by returning the bucket handle to the first position. A method of operating a upright vacuum cleaner is also disclosed.

Owner:HOOVER LIMITED

Removable grip for a bucket

A removable grip for a five-gallon bucket that includes a prying tool for removing a lid of the bucket. The grip includes an elongated body in which a channel is formed. The channel includes a centrally disposed widened portion that is configured to accept an existing grip formed on a bail of the bucket handle. The channel also includes narrow portions at each end of the widened portion that accept the bail. Flexible tabs within each narrow portion lock the grip onto the bail. The prying tool includes a flat end and a hooked end. The flat end can be used to pry open the lid of a paint bucket and can be a screwdriver end. The hooked end can be used to pry up the tangs of the lid of the five-gallon bucket to remove the lid.

Owner:GALLUP ERIC M

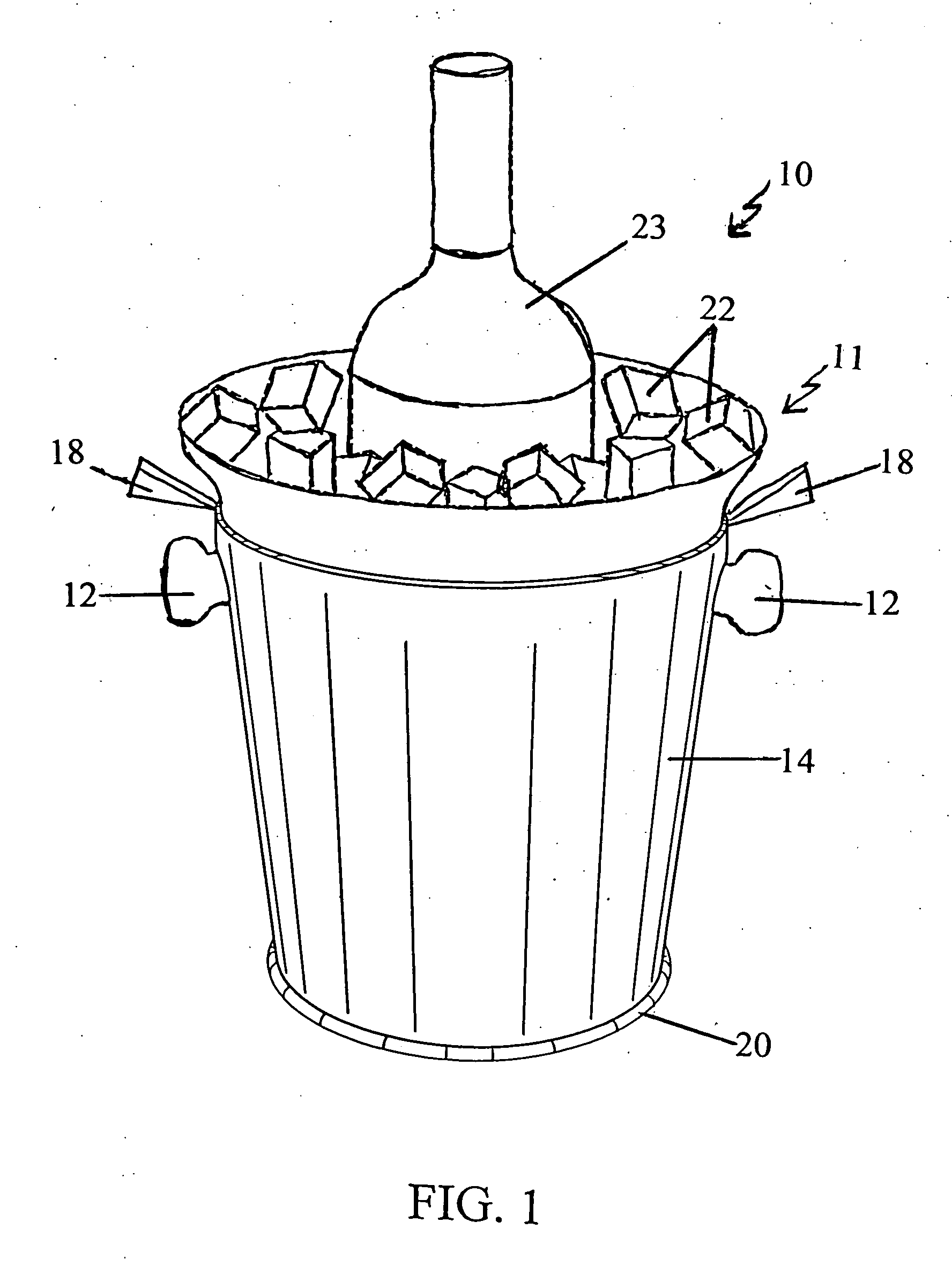

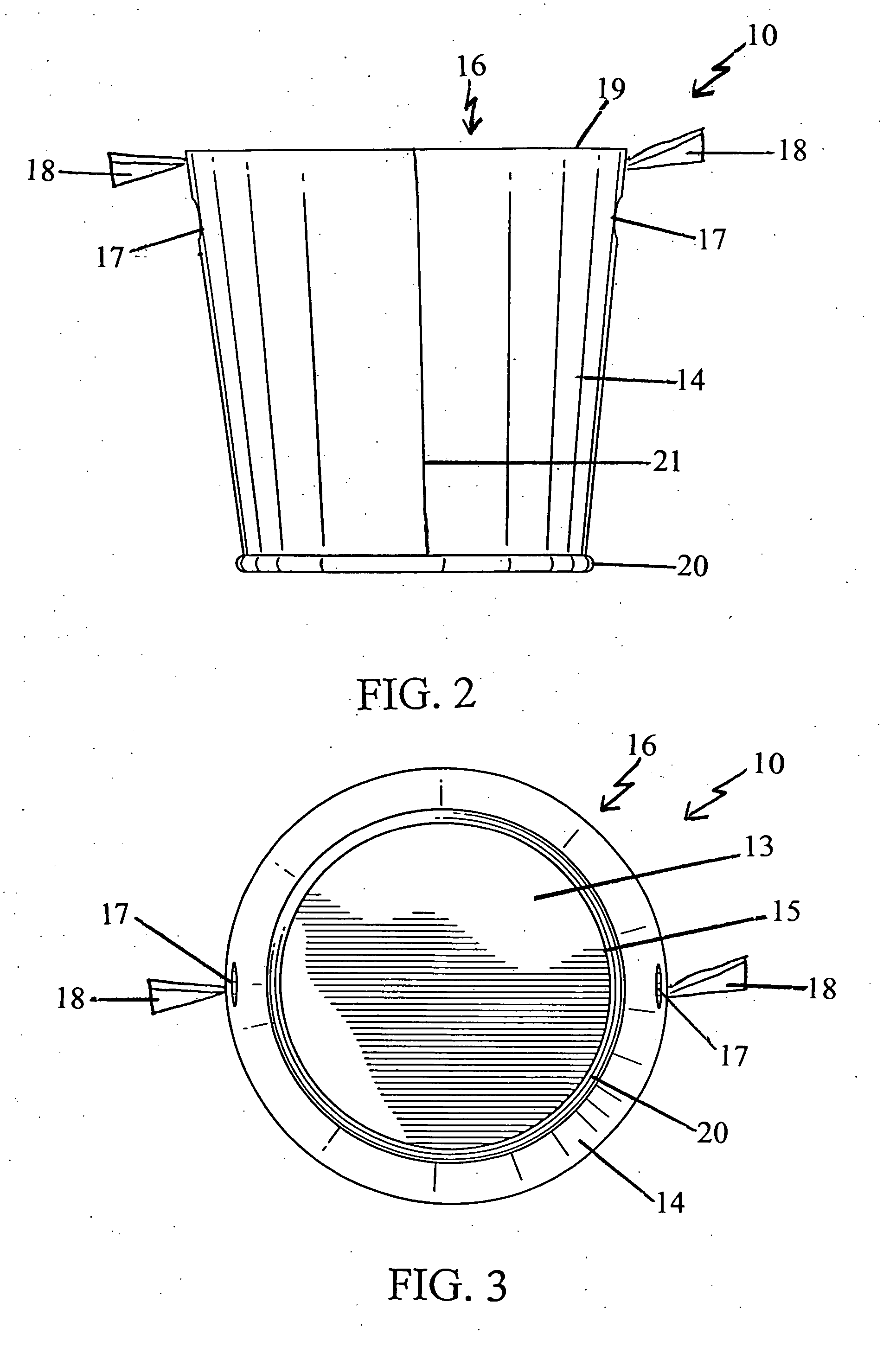

Neoprene ice bucket cover

InactiveUS20070074795A1Stay dry and warmVarious sizesFlexible coversWrappersBucket HandleEngineering

An ice bucket cover includes: (a) a substantially circular bottom wall; (b) a substantially cylindrically-shaped cover side wall attached at a bottom side wall edge to a periphery of the bottom wall, the side wall being made of a stretchable neoprene material; (c) a substantially circular, open top; (d) at least two same-sized ice bucket handle holes on opposite sides of the ice bucket cover; and (e) at least two pull tabs affixed to a top side wall edge of the ice bucket cover above the bucket handle hole, each pull tab being on an opposite side from the other pull tab; wherein the ice bucket cover is sized to closely fit over an outside surface of an ice bucket. Also included is a neoprene ice bucket cover pouch for enclosing and carrying an ice bucket, including: (a) the bottom wall; (b) the cover side wall attached at a bottom side wall edge to a periphery of the bottom wall, extending substantially perpendicularly from the bottom wall, and extending a substantial distance beyond an upper edge of the ice bucket; and (c) a closure mechanism for closing a top side wall edge of the pouch; wherein the ice bucket cover pouch has a substantially circular, open top when in an open position, the pouch being sized to closely cover an outside surface of the ice bucket.

Owner:LEP

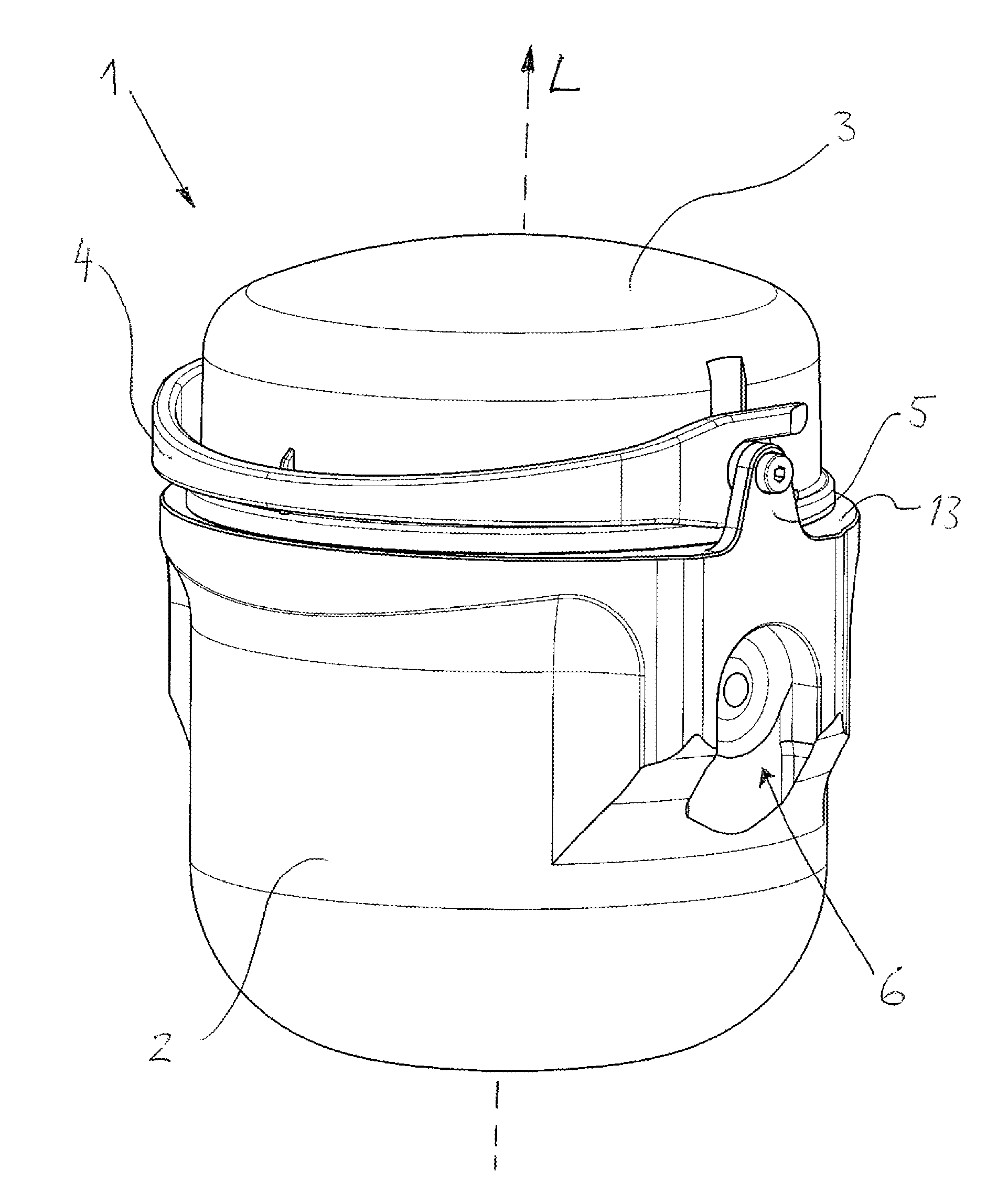

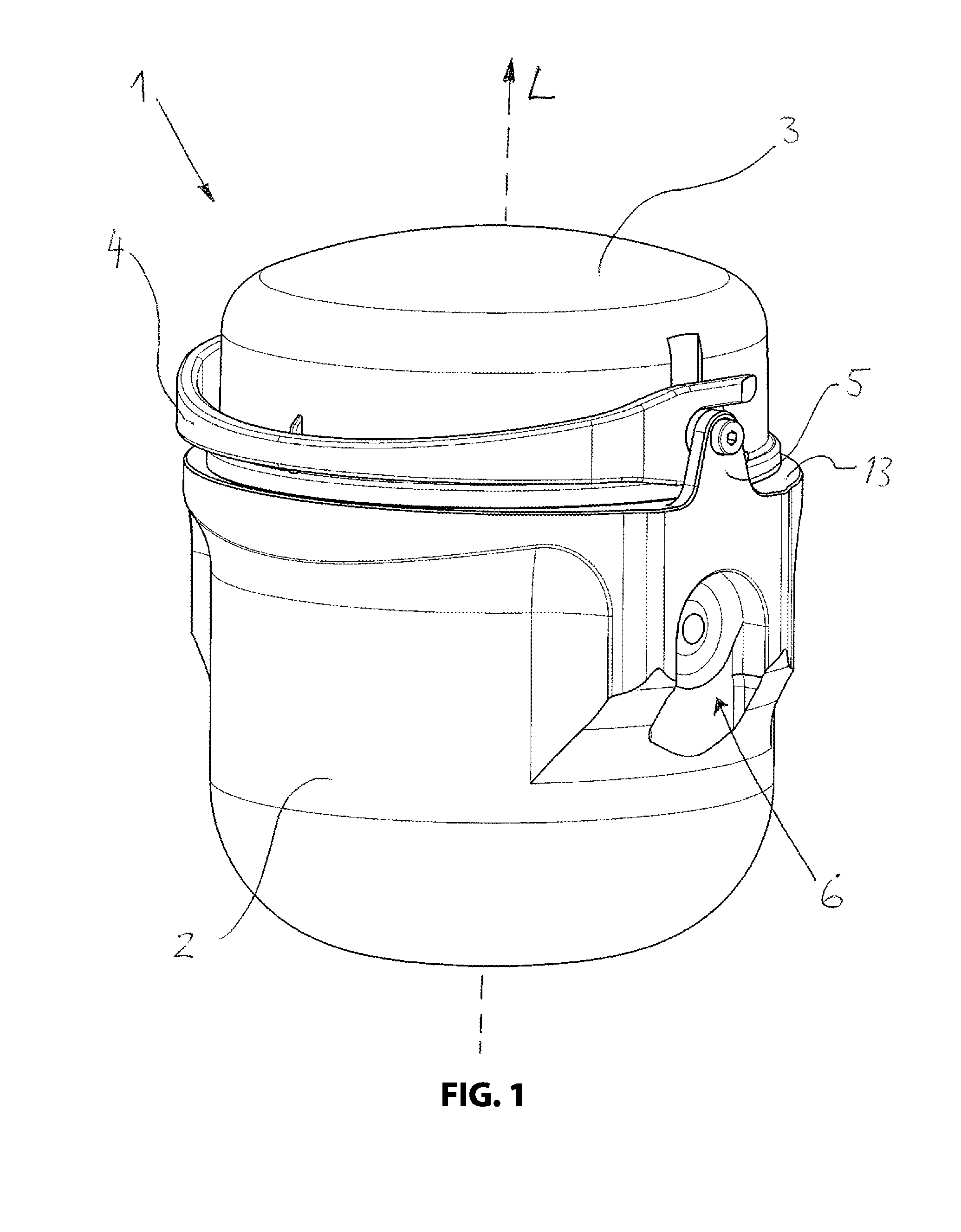

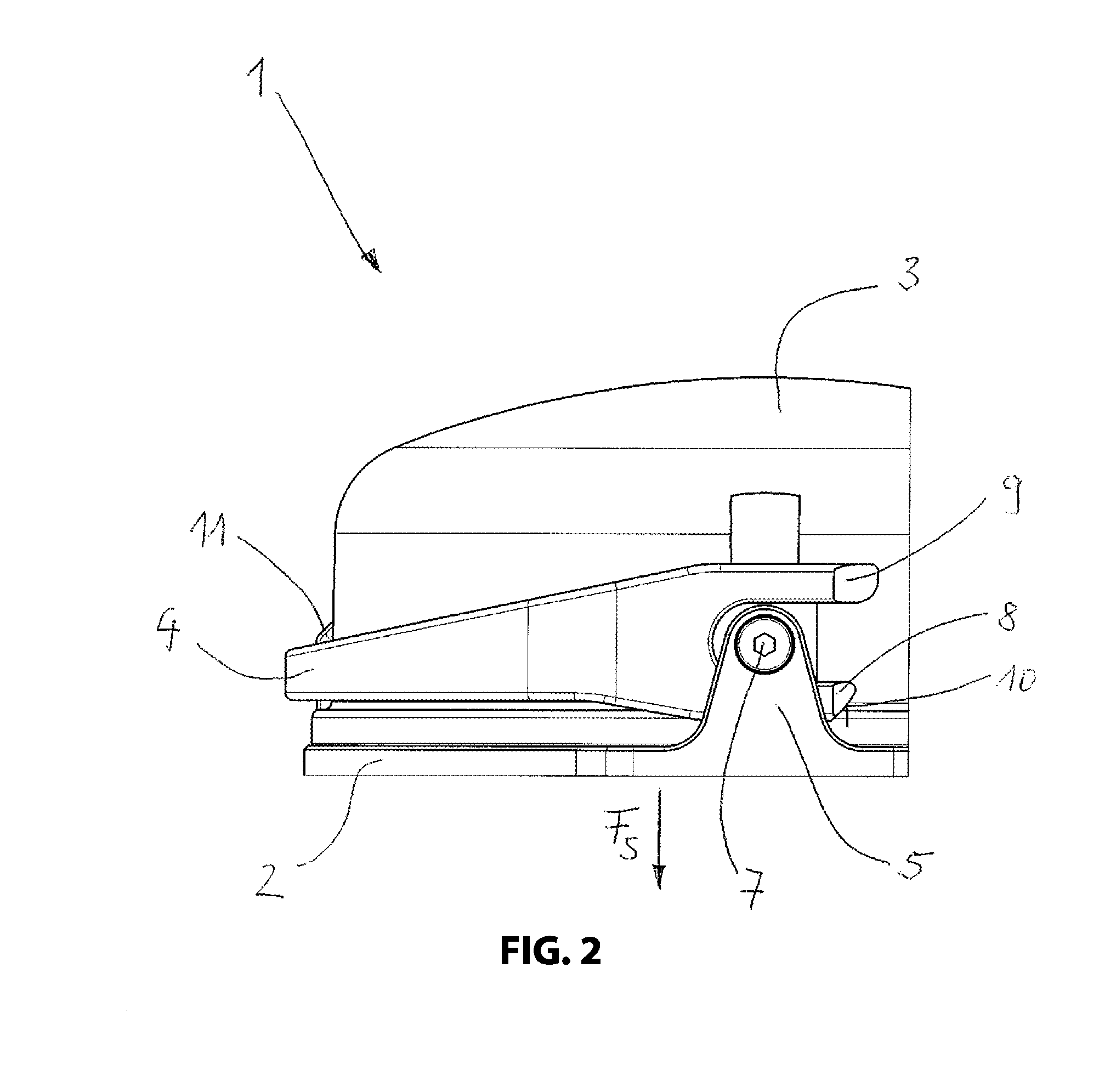

Centrifuge Bucket

A centrifuge bucket for centrifuging materials, in particular in laboratory centrifuges. The centrifuge bucket is operable in a very simple manner and facilitates safe and constant closure over the service life of the centrifuge bucket. Thus, the centrifuge bucket handles much better than known centrifuge buckets because real one hand operation without using a second hand is facilitated. Furthermore, the centrifuge bucket can be produced in a simpler and more cost-effective manner while being equally suitable for a given centrifugation power and centrifugation capacity.

Owner:EPPENDORF AG

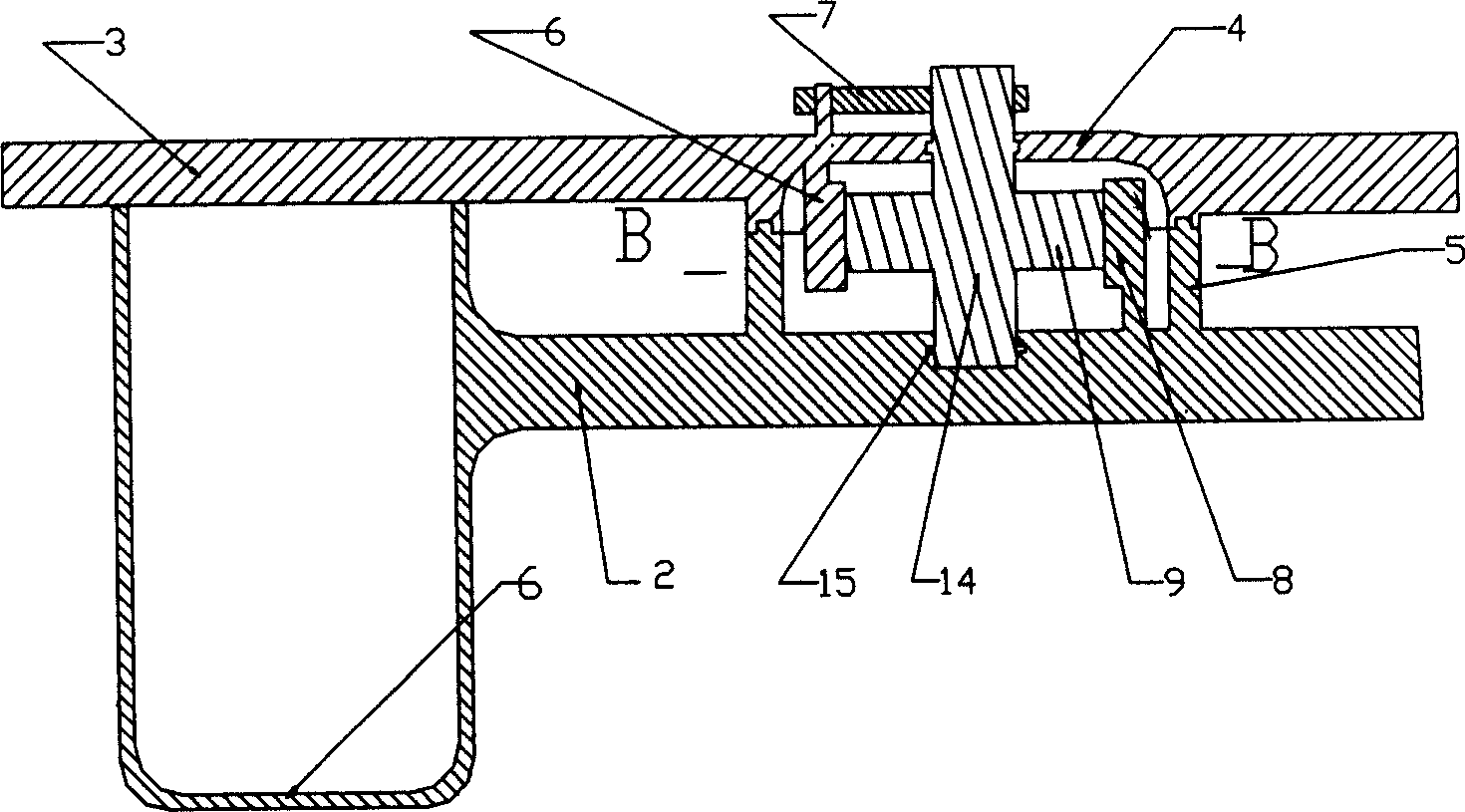

Measuring spoon

InactiveCN1657883AImprove the situation of separate placementAvoid reverse rotationVolume measurement apparatus/methodsBucket HandleOutflow boundary

This invention discloses a measure bucket with a bucket handle and a bucket as its main body, and consists of a ratchet mechanism, a scraping plate and a counting display mechanism linked with the ratchet mechanism. The ratchet is adopted with a double pawl mechanism in which the initiative pawl is fixed on the scraper, and the stopping pawl is fixed on the bucket handle. The two pawls and the notch wheel coordinate with each other. The counting mechanism and the notch wheel is connected. The scraper with the hinge joint on the bucket handle, front end the scraper clings in on the bucket body on end surface. In the above ratchet installs in respectively with the bucket handle, the scraper connection is a body on end cover and under between the end cover constitutes peacefully behaves affectedly. Counts the demonstration organization by on the needle pivot indicator and with on end cover surface scale division constitution which connects with the notch wheel. Also may be by on the ring-like notch wheel outflow boundary surface scale division constitution, this ring-like notch wheel in reason is the ratchet.

Owner:任莉

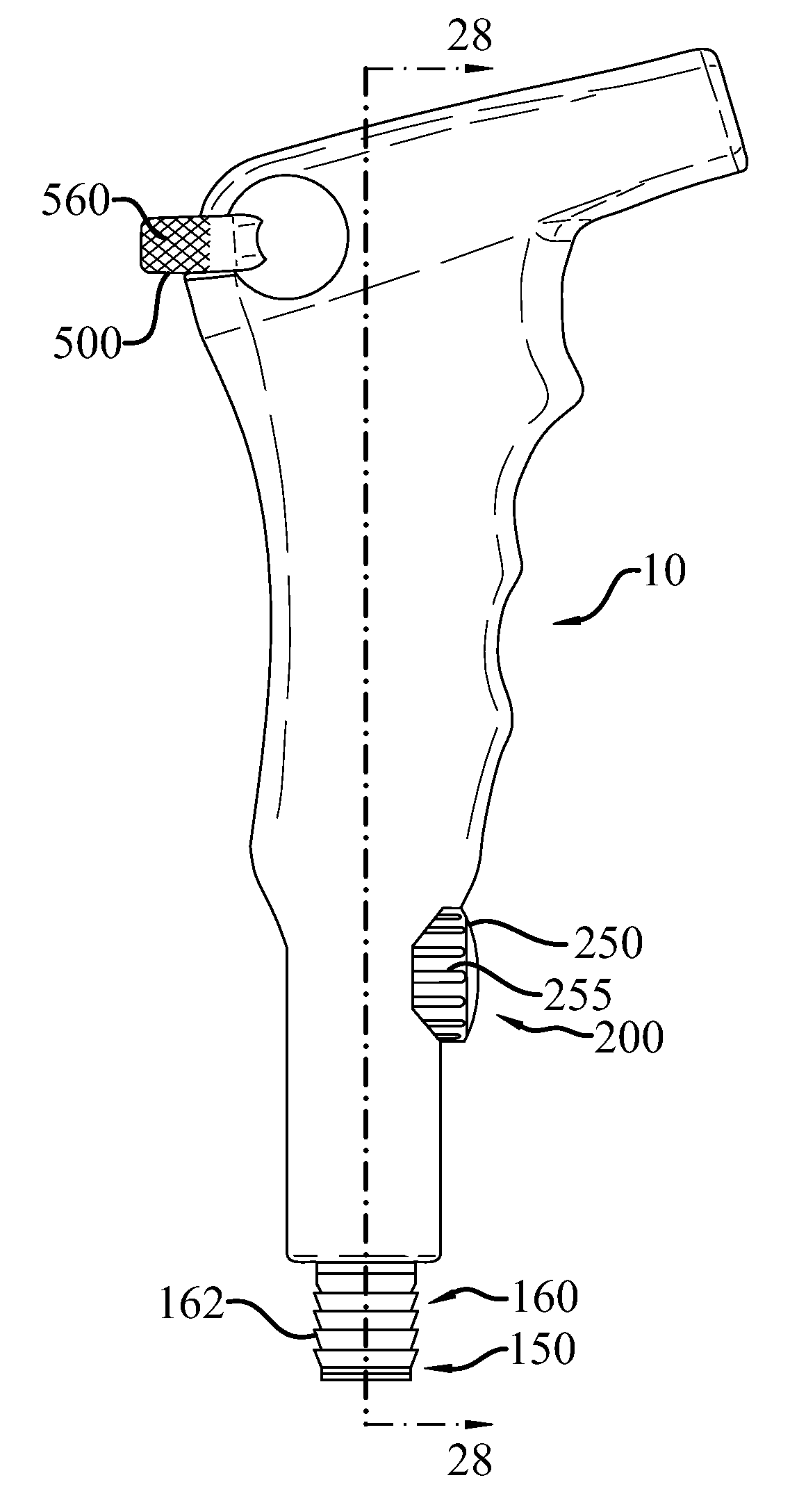

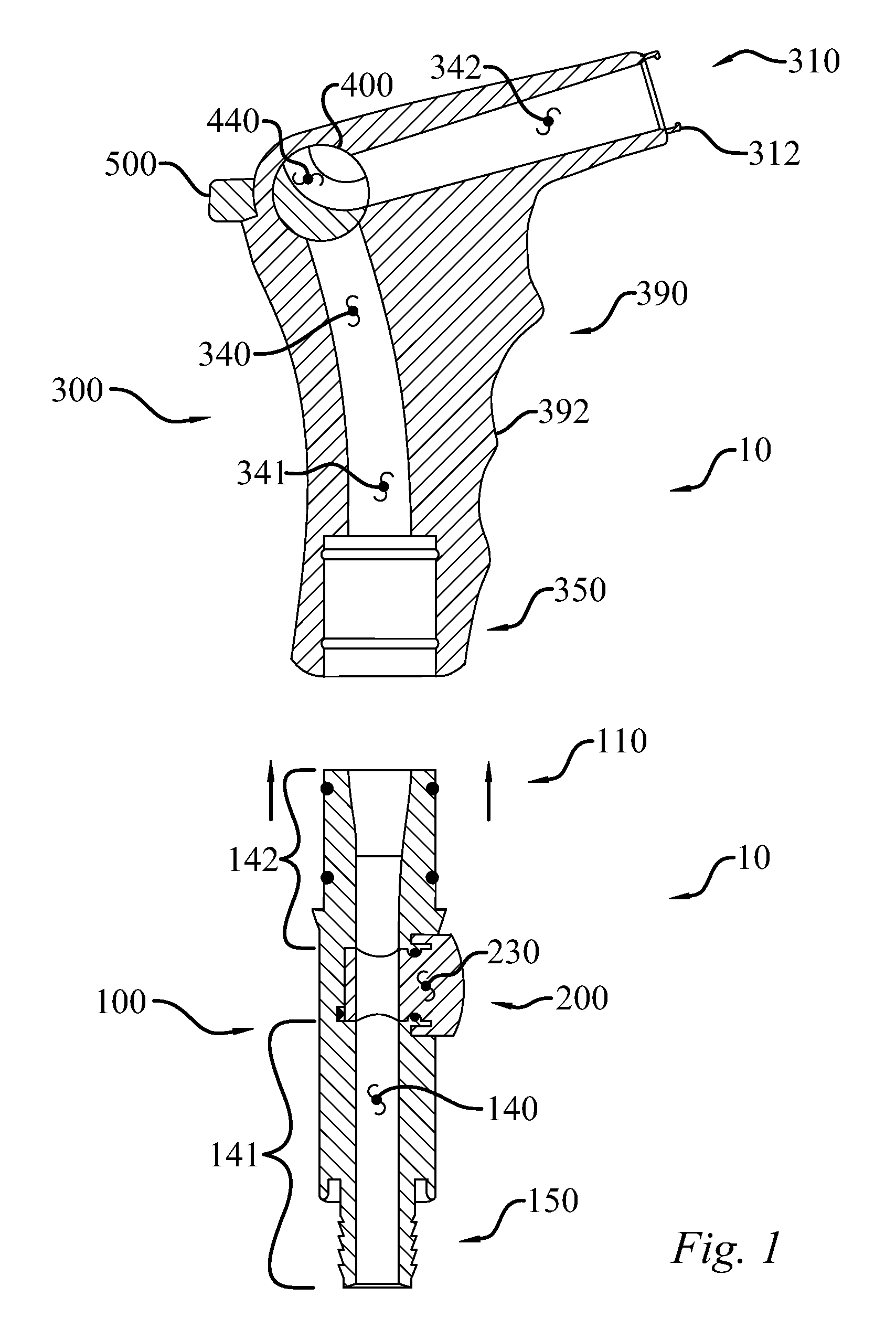

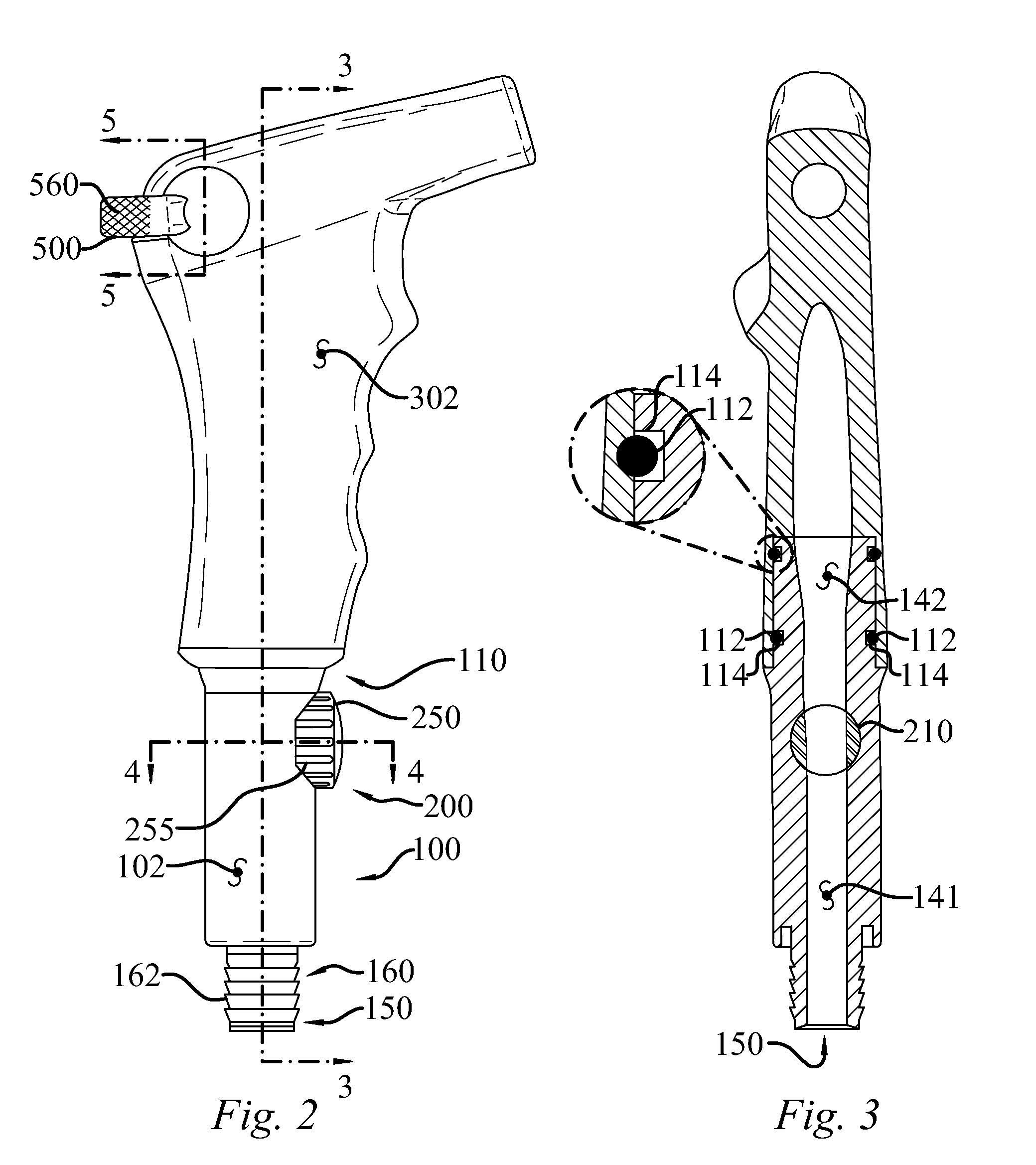

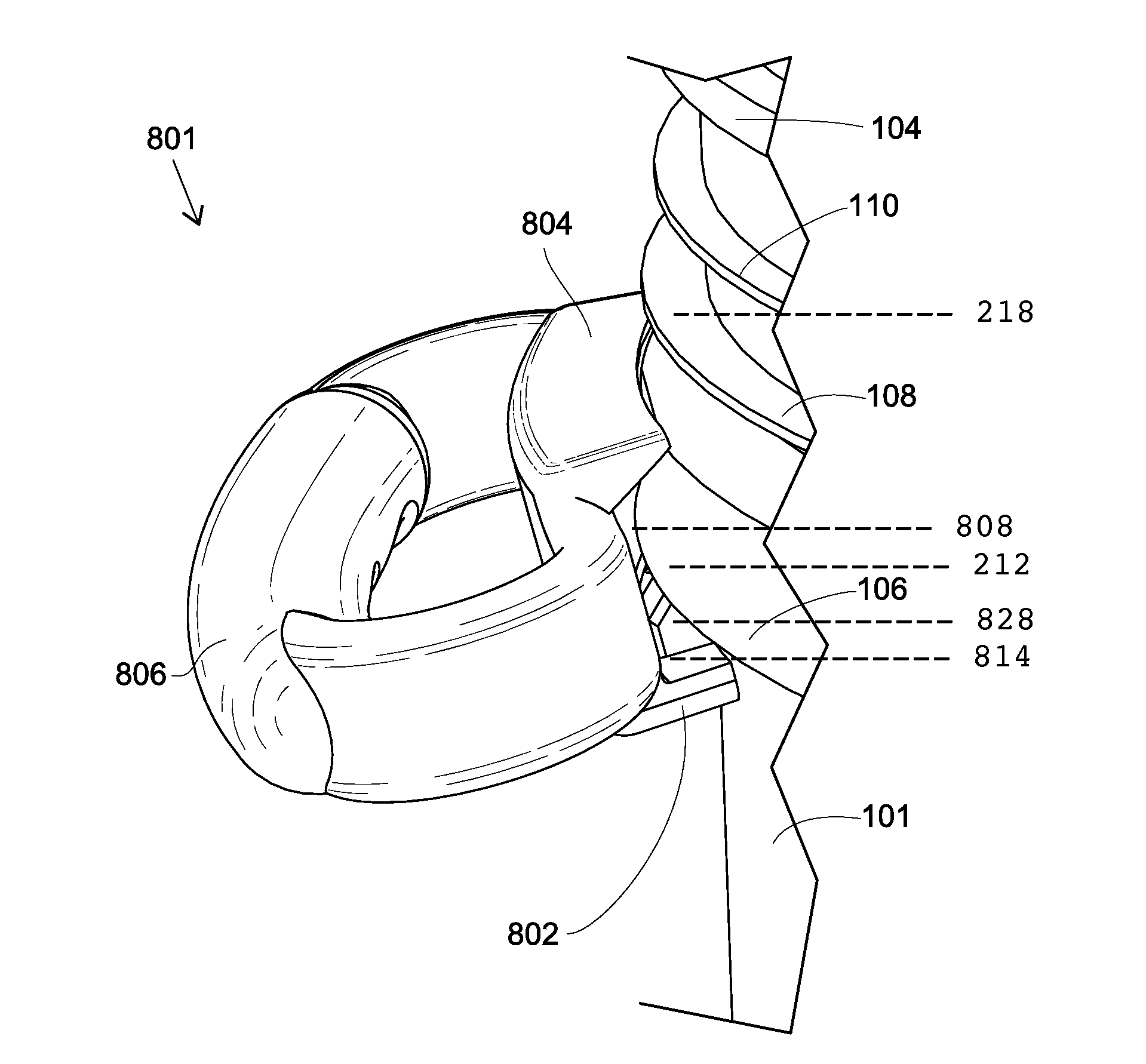

Sterilizable vacuum handpiece

InactiveUS20100249703A1Good conditionOvercomes shortcomingIntravenous devicesSuction drainage systemsBucket HandleO-ring

A sterilizable vacuum handpiece that may include a base unit reversibly coupled to a handle unit, having a central vacuum passage connecting proximal and distal ends. A hand-removable base unit valve may divide a base unit vacuum passage and a hand-removable handle unit valve may separate a handle unit vacuum passage, in adjustable fluid communication with each other. The valves may be retained within bores and counter-bores, and may achieve fluid-tight fit with O-rings retained within the valves. The valves may have vacuum passages with surface areas greater than or equal to a least diameter of the vacuum passage containing the valve. In at least one embodiment, the handle valve is releasably retained by the opposing ends of a “bucket-handle” shaped controller. Alternatively, the handpiece may be formed as a single combined unit, where the terms base unit and handle unit refer only to regions of an otherwise unified structure.

Owner:CLIFF JOHN A

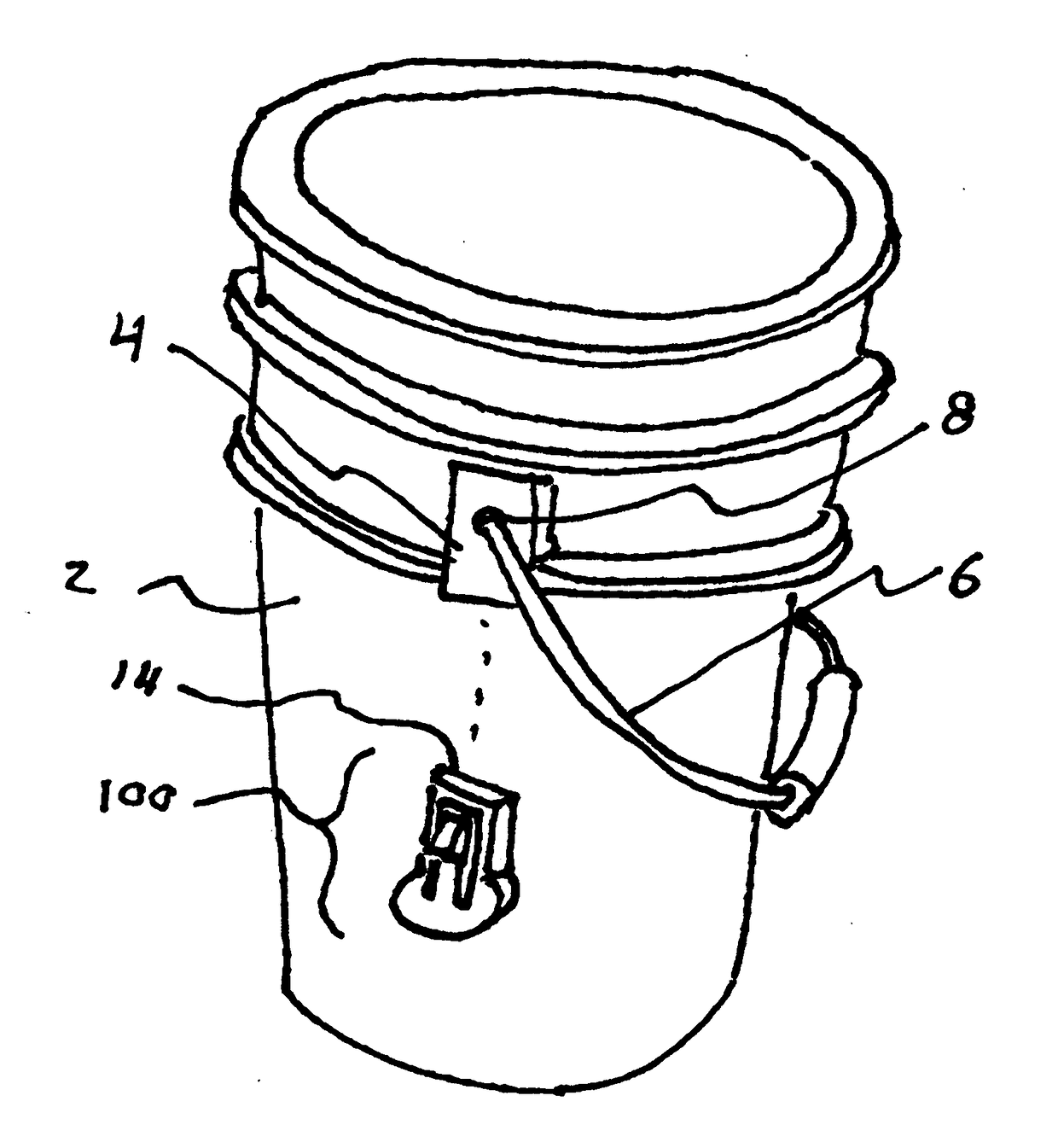

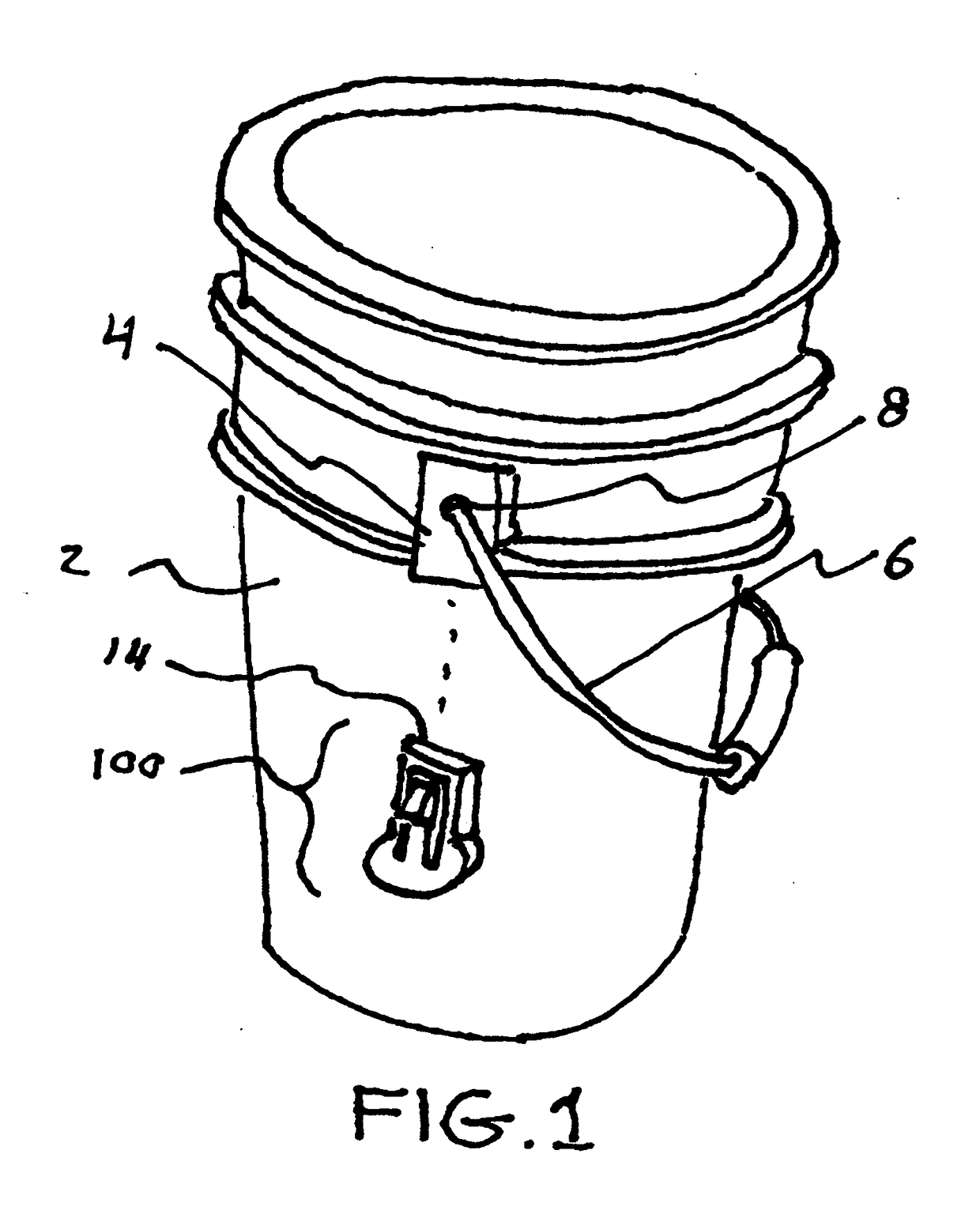

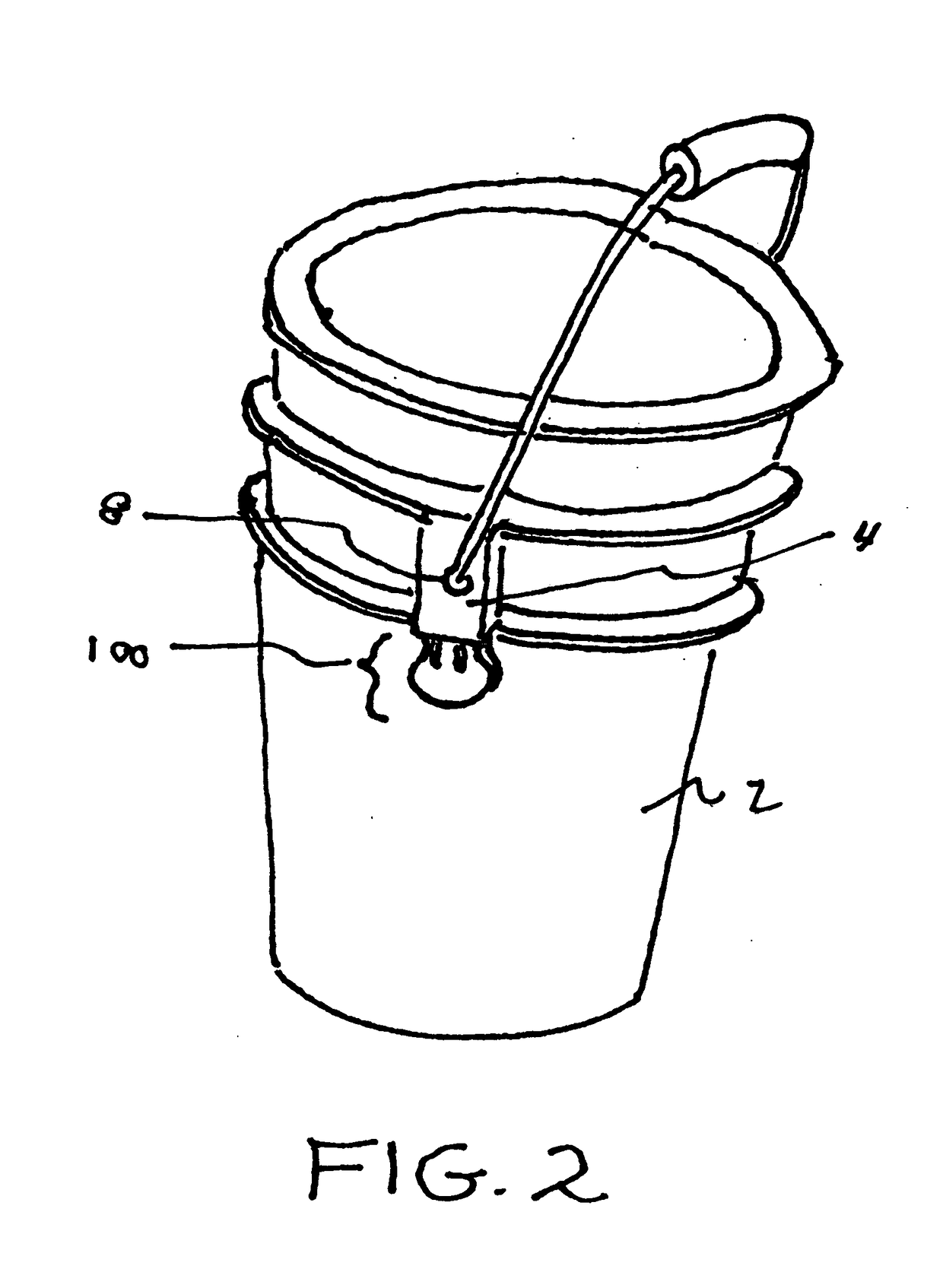

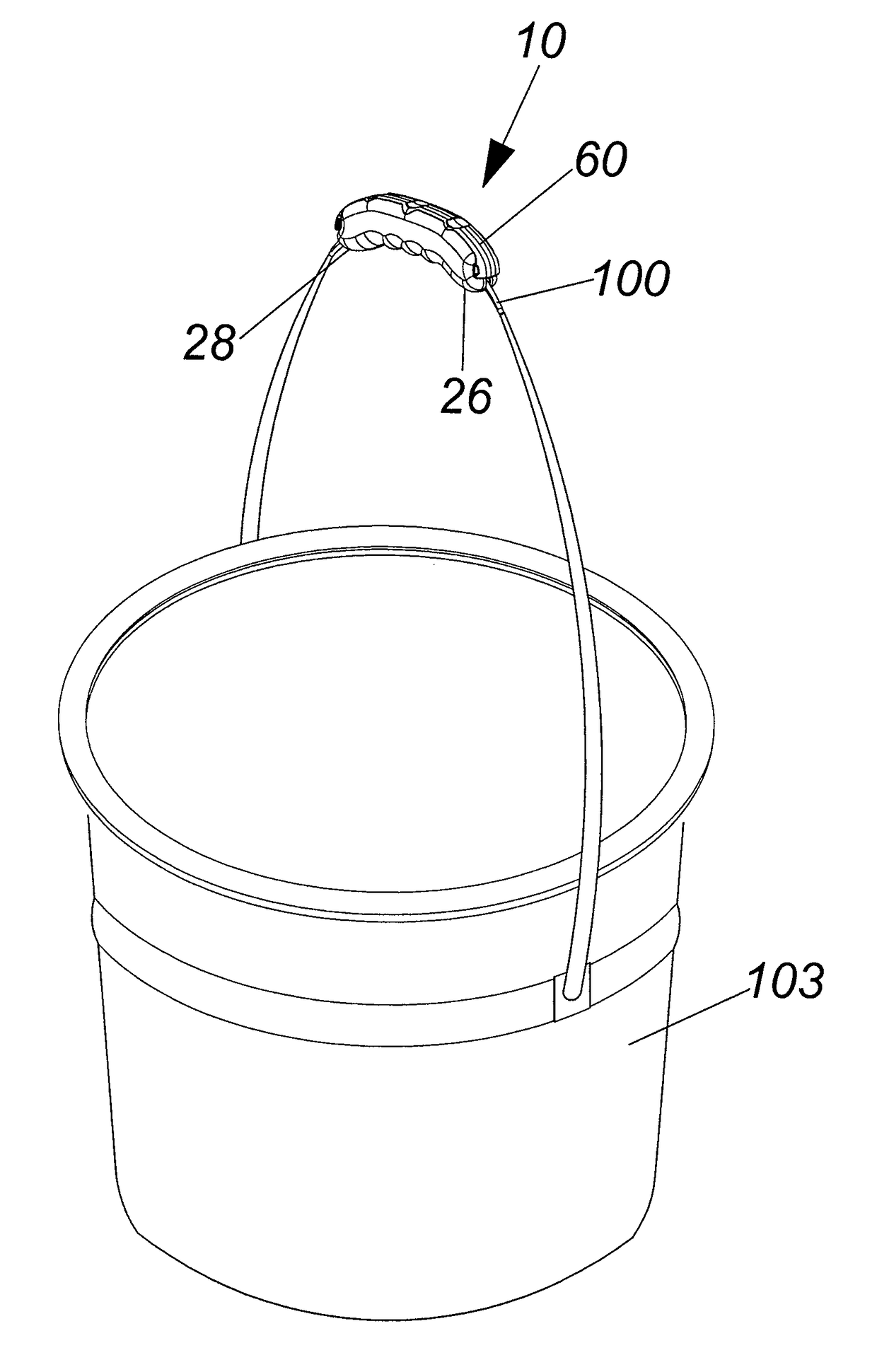

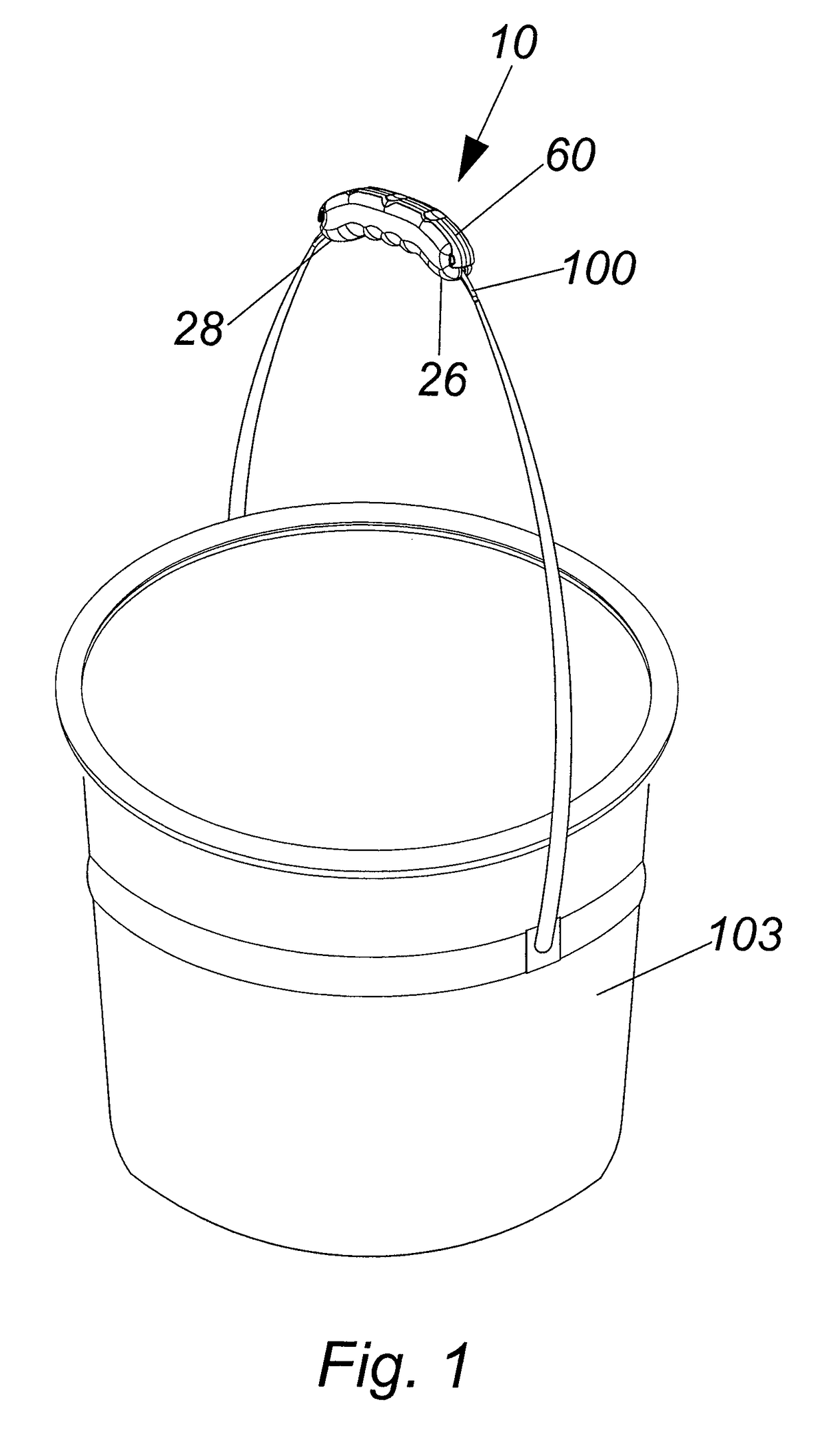

Selectively attachable bucket handle

InactiveUS20170043909A1Easy to disassembleFacilitating a stable stacking of the bucket handlesCans/barrels/drumsContainer handlesBucket HandleEngineering

A selectively attachable bucket handle for a bucket configured to detachably engage with, and accommodate, certain features of a bucket such that the bucket handle is rigidly secured to a bucket, and such that the bucket handle translates a lifting force, applied to the bucket handle, onto a bucket. The bucket handle is also configured to detachably engage with a bucket without preventing a bucket from receiving a lid. The bucket handle is configured to detachably engage with a bucket such that the rest of the bucket handle projects perpendicularly away from a side of a bucket.

Owner:HOUSEWORKS LTD

Portable prospecting and classifying self-contained apparatus

The invention is a portable prospecting and classifying self-contained apparatus having a bucket, a supporting classifier screen and a supported classifier screen setting freely within the bucket, having a bucket handle and a bucket lid closing securely over the bucket. The supported classifier screen has a screen mesh and a screen handle, allowing the user to lift the supported classifier screen from the bucket. The supporting classifier screen has a screen mesh which may be of a finer mesh than the supported screen mesh and a supporting classifier frame. A prospector uses the portable prospecting and classifying self-contained apparatus invention by scooping or pouring mineral material into the bucket with an earth digging scoop or gold pan. The supported classifier screen and the supporting classifier screen are adapted to classify and separate mineral material from coarse to finer grain material when poured into the bucket.

Owner:STOVER RICKY DEAN

Bucket handle

A handle for attachment to a bail member of a bucket is disclosed. The handle includes a base formed from two interlocking members, a first member frictionally engages a second member, locking the two members together without tools. Upon the interlocking of the first member and second member, a base structure is formed providing a receptacle constructed in a range for receipt of the bail member along an upper section. A centrally disposed cavity may be included in the upper section for receipt of a tubular sleeve commonly found on buckets and employing bail members for carrying heavy weights. The base structure is positioned beneath the bail member wherein a portion of the bail member is insertable into the receptacle. A cover member is secured to the top section of the base structure to conceal the receptacle and secure the bail member within the handle.

Owner:CARTLIDGE ROBERT D

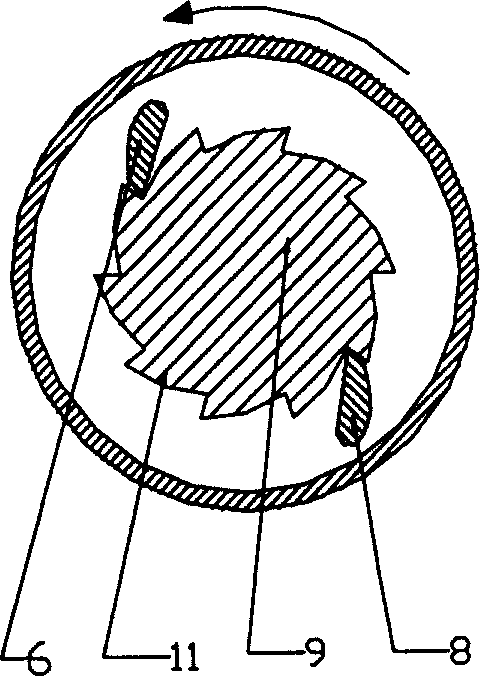

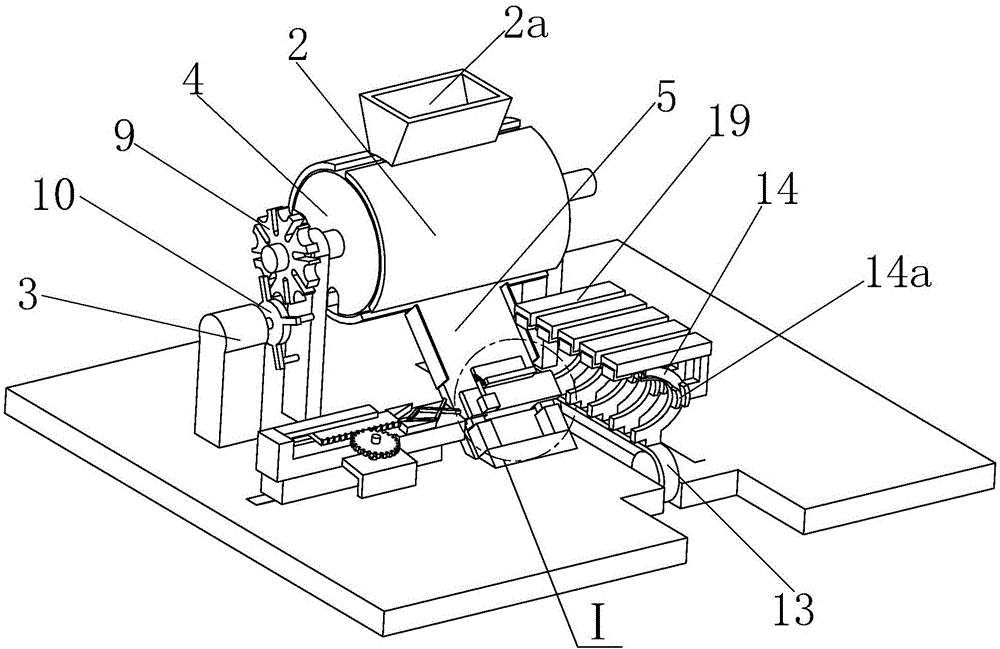

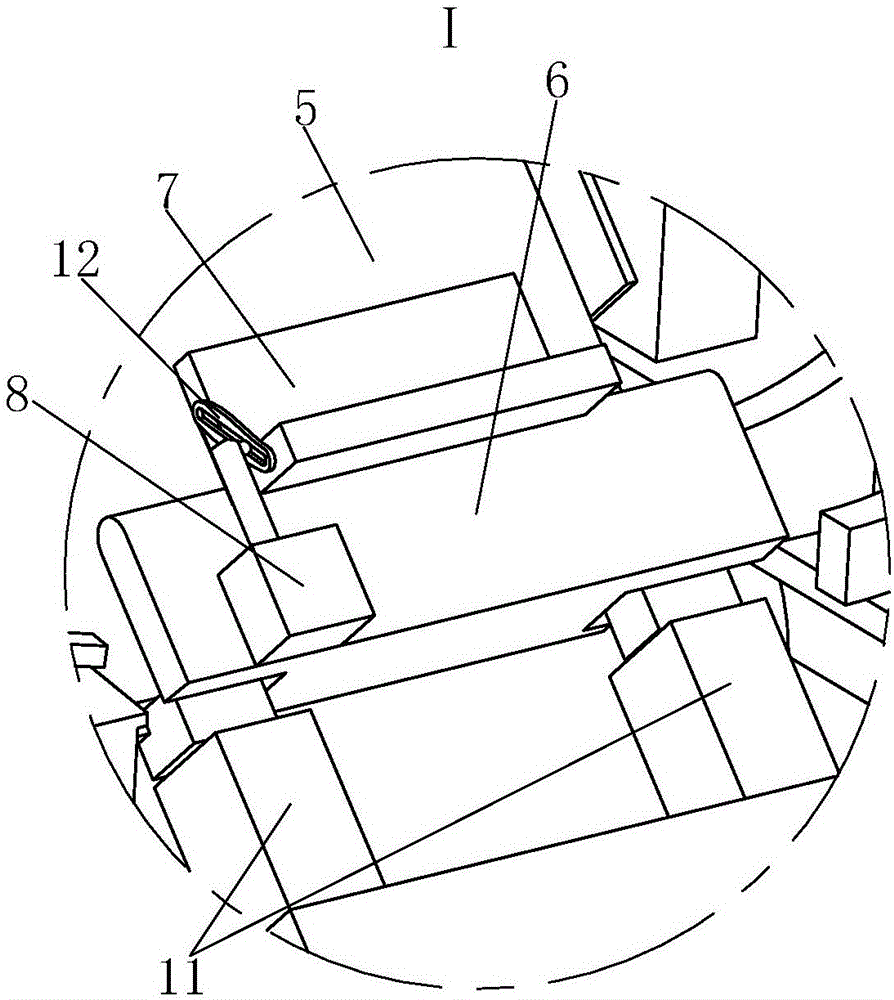

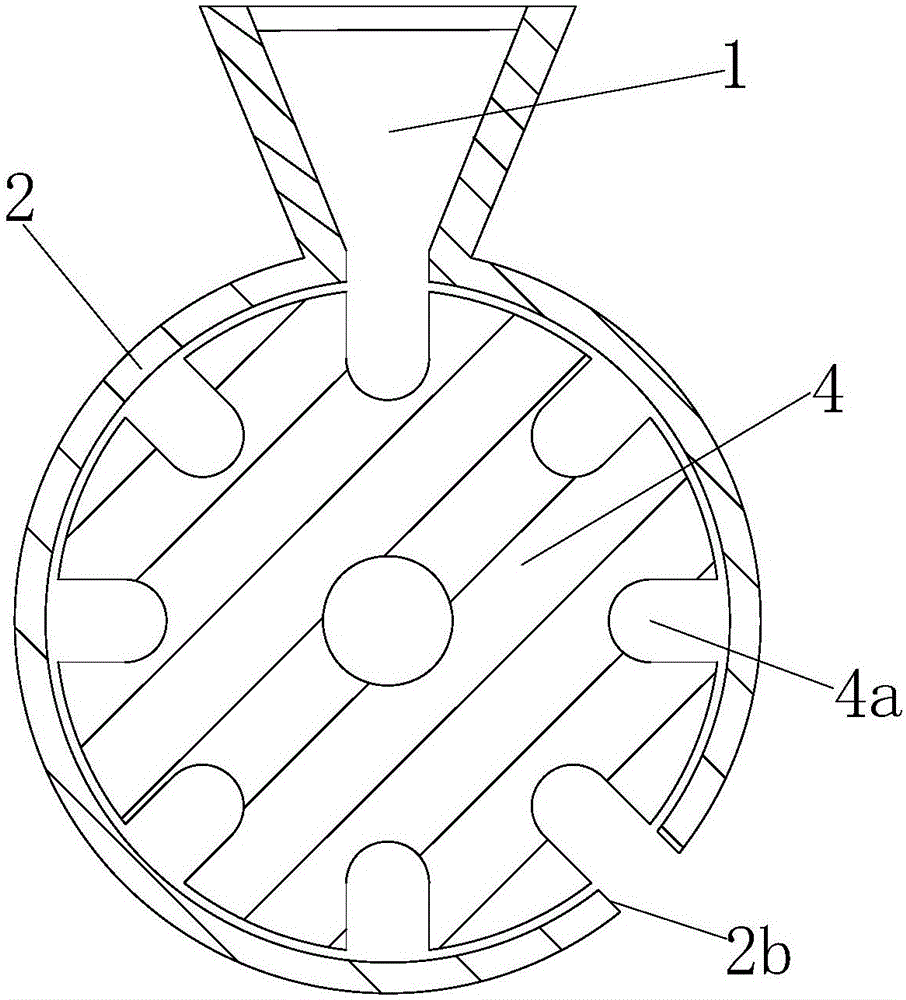

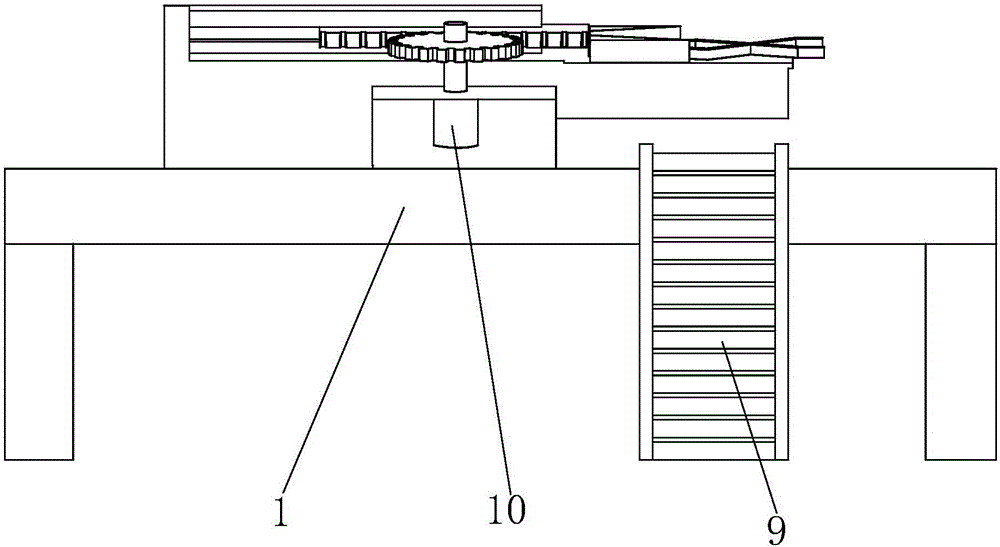

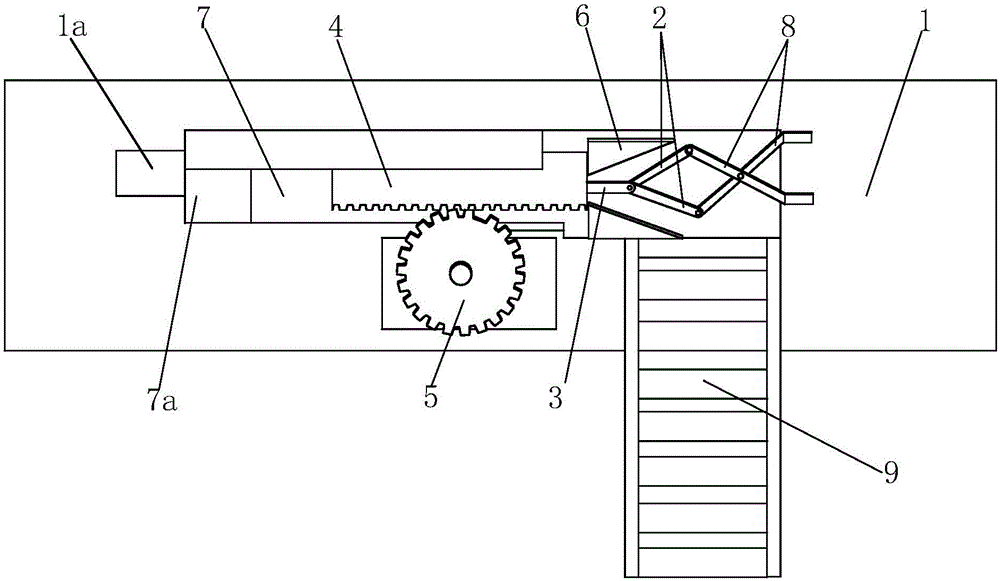

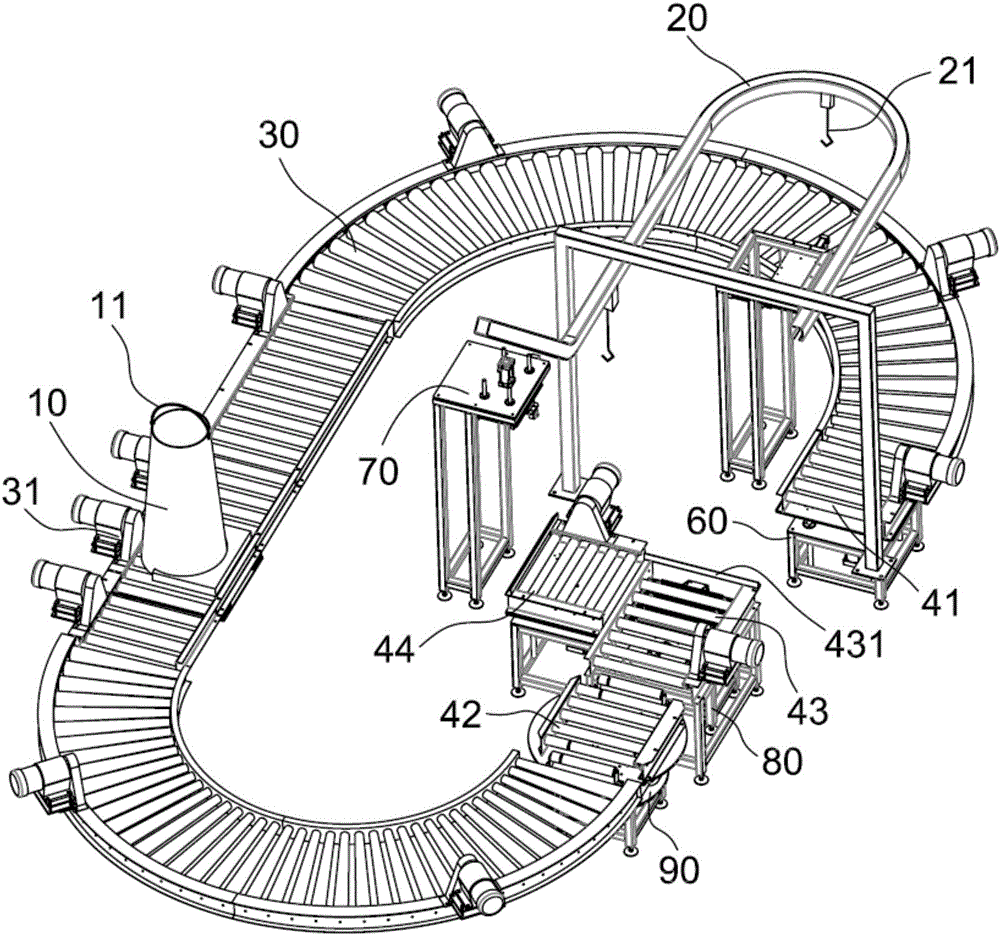

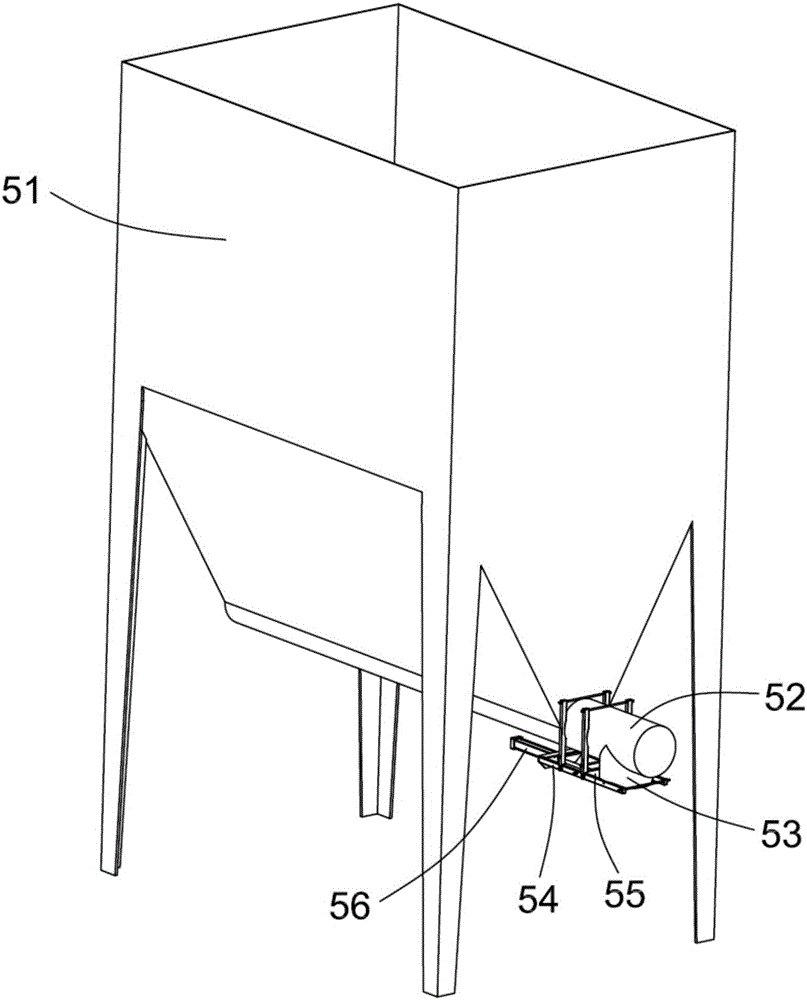

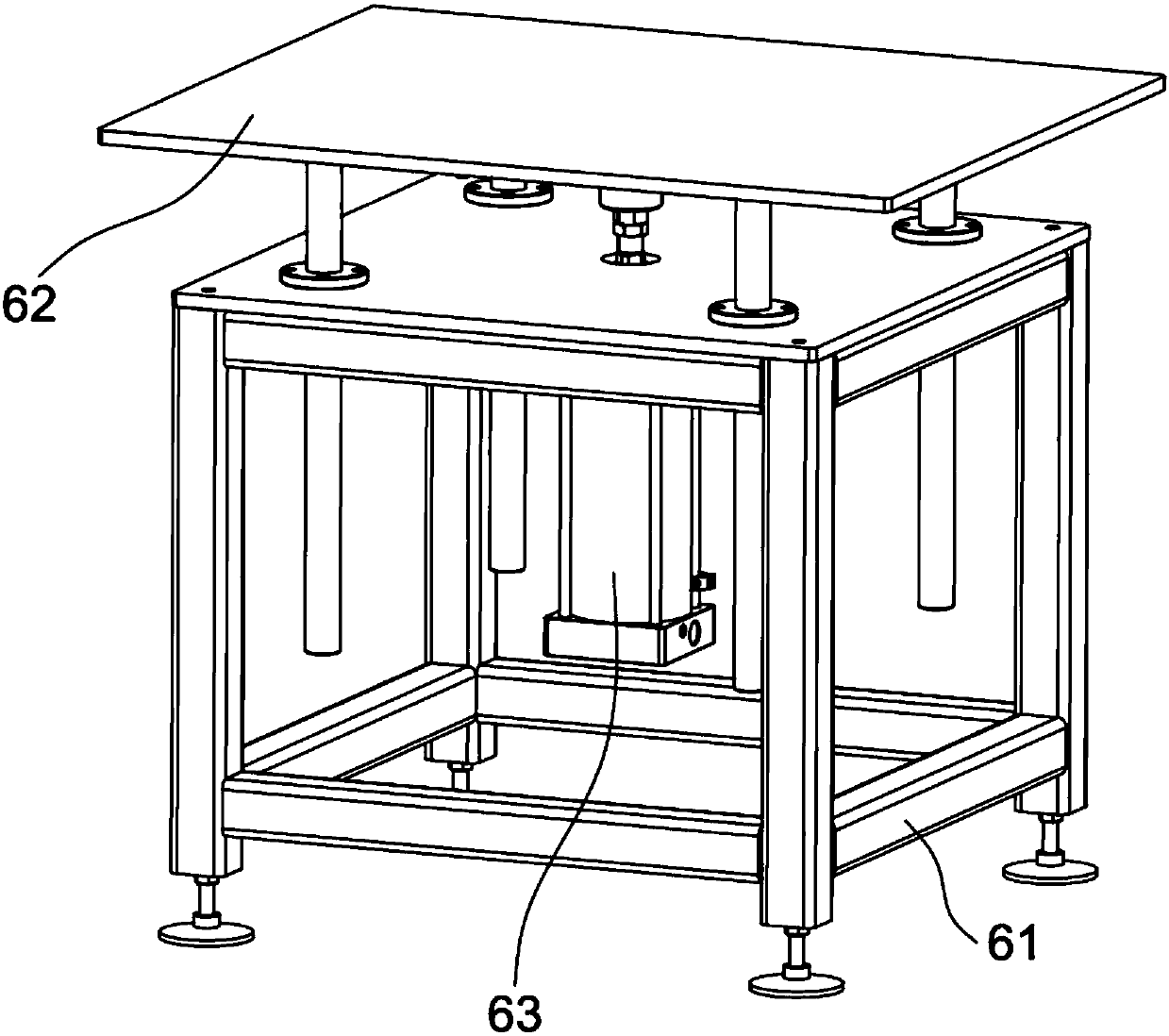

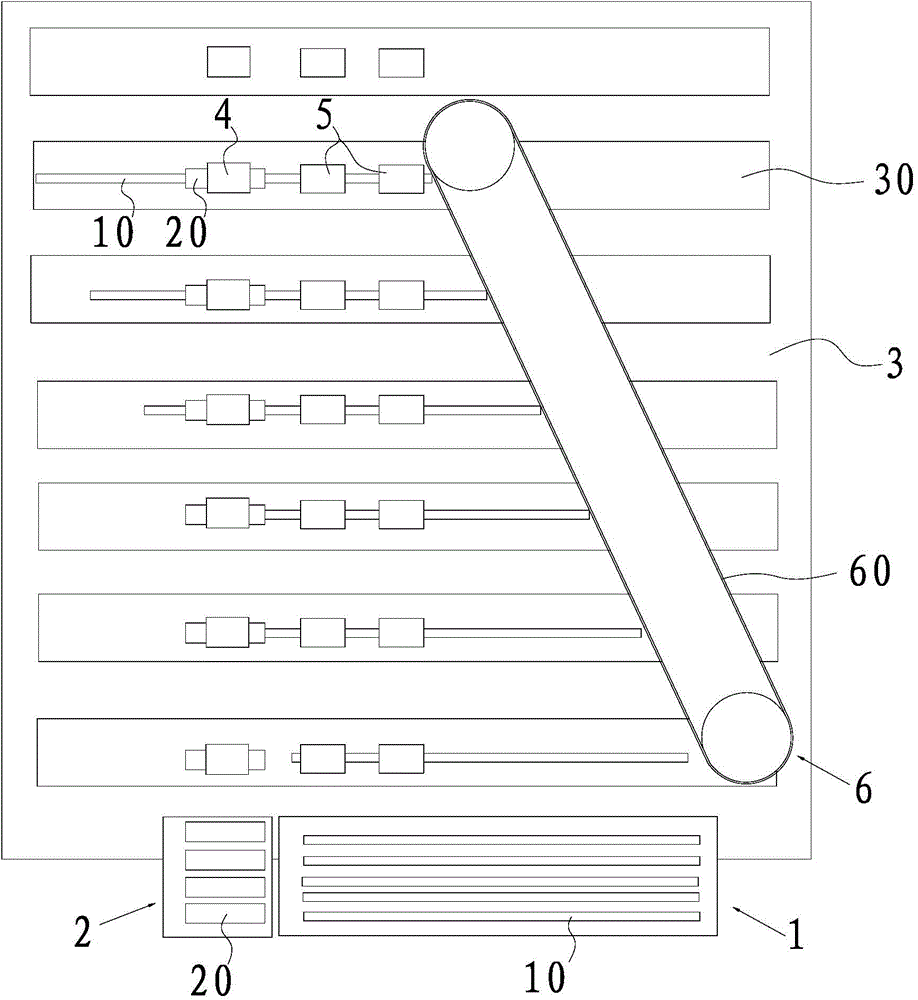

Bucket handle assembling machine

ActiveCN106584874ARealize feedingImplement automatic assemblyDomestic articlesBucket HandleEngineering

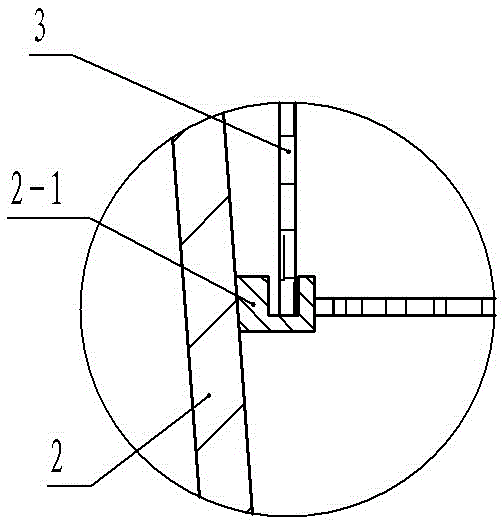

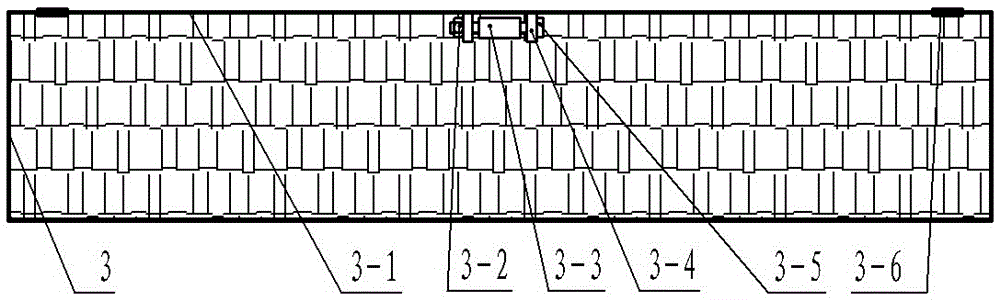

The invention relates to a bucket handle assembling machine. The bucket handle assembling machine comprises a bottom table. A restraining frame and a first motor are fixedly arranged at the rear end of the bottom table. A round roller is arranged on the inner side of the restraining frame, and storage grooves are evenly distributed in the round roller. A through groove is formed in the lower portion of the restraining frame and communicates with a sliding way. The lower end of the sliding way is connected with a braking frame. A pressing block is hinged to the braking frame. A pushing and pressing air cylinder is arranged at the rear end of the braking frame. A conveying belt is arranged on the right side of the sliding way and provided with bearing frames. The upper ends of outer arc faces of the bearing frames abut against push blocks. A base is arranged on the left side of the sliding way. Two clamping blocks are hinged to the right portion of the base. The bucket handle assembling machine is high in automation degree, handle feeding, iron wire supplying, automatic assembling and automatic discharging can be sequentially achieved, accordingly, assembling and forming of large-batch bucket handles can be finished, and the effects that manpower is saved, the assembling efficiency is improved, and assembling control is simplified are achieved.

Owner:安徽旭虹机械设备有限公司

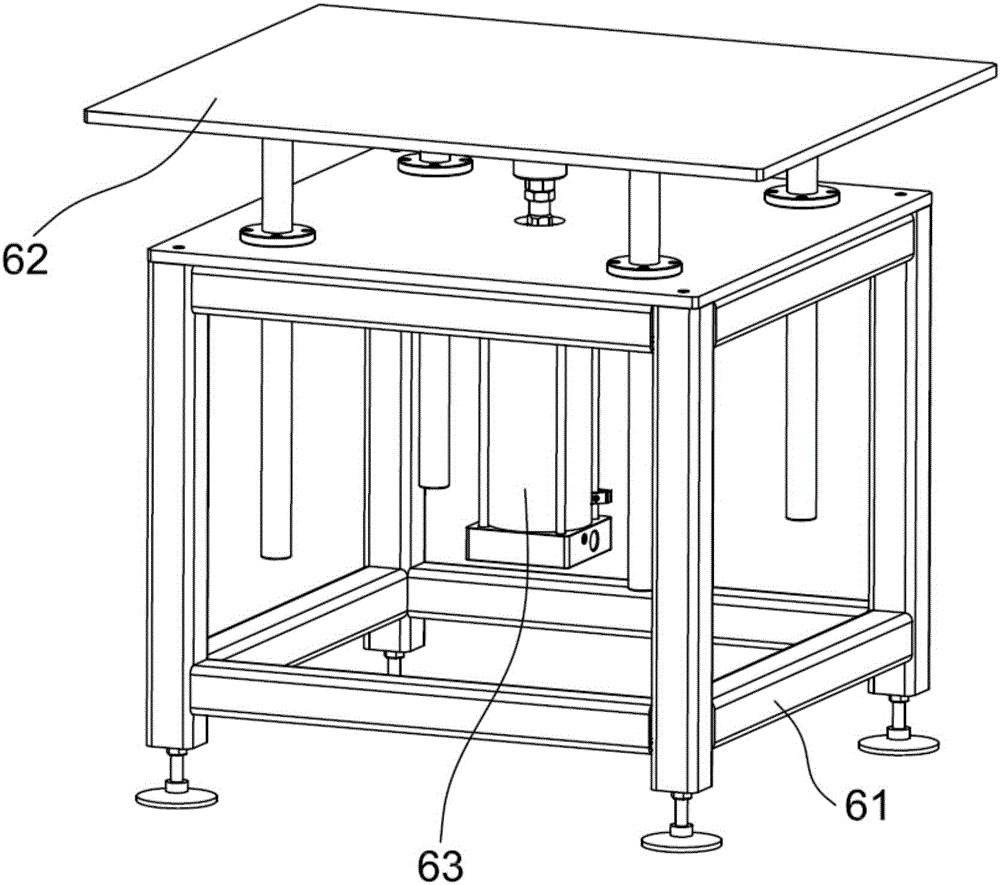

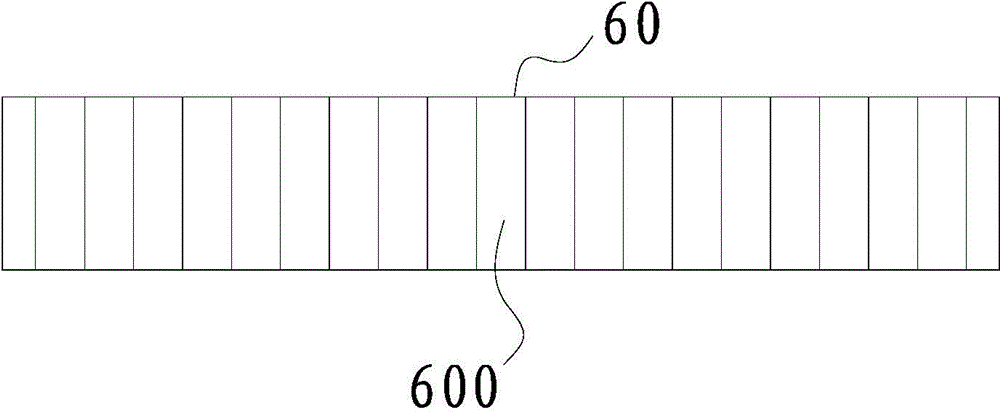

Discharging device for bucket handle assembling of plastic buckets

ActiveCN106553035AContinuous and automatic dischargeHigh degree of automationMetal working apparatusBucket HandleEngineering

The invention relates to a discharging device for bucket handle assembling of plastic buckets. The discharging device comprises a bottom platform which is provided with a horizontal sliding groove, a base is installed at the horizontal sliding groove in a sliding mode, two clamping blocks which are arranged in an X-shaped crossed mode are installed on the right portion of the base in a hinged mode, a connecting rod is connected to the left end of each clamping block in a hinged mode, and the left ends of the two connecting rods are jointly connected with a working stand which is horizontally installed on the base in a sliding mode in a hinged mode; and a rack is welded to the left end of the working stand, the right end of the rack abuts against two triangular supports fixed to the base in a matched mode, the rack is meshed with a gear, a motor is connected to the gear and fixedly installed on the bottom platform, and the left end of the base is provided with an adjusting block matched with the rack. The discharging device for bucket handle assembling of the plastic buckets is high in automation degree, by means of gear-rack transmission and sliding limiting matching of the rack with the adjusting block and the triangular supports, assembled bucket handles can be clamped and fixed, the bucket handles can be driven to be horizontally conveyed, and automatic resetting can be conducted on this basis. Therefore, the discharging device has the effect of continuously and automatically discharging the bucket handles.

Owner:安徽旭虹机械设备有限公司

Apparatus and Method for Facilitating the Lifting of Heavy Objects

InactiveUS20130270852A1Easy to deployCheap to makeTravelling carriersHoldersBucket HandleEngineering

A supplemental handle device that involves both sides of the body in the act of carrying buckets of heavy loads. The device comprises a Hitching Bar, and a Grab Loop with a hand grip and a ring connecting the Bar and Loop. The Hitching Bar comprises: a front eyelet for attaching the ring; a middle aperture for sliding the Bar over the bucket handle; and a rear U-shaped element underneath the bucket handle and with the bail fitted snuggly between the two arms of the “U”. The Grab Loop is for the user's hand on the opposing side of the bucket. In use, the Hitching Bar's middle aperture passes over the bucket handle, and slides forward until the U-shaped element lies beneath the handle, locking the bail. By simultaneously pulling up on the Hitching Bar-handle unit with one hand, and the Grab Loop with the other, the bucket is raised.

Owner:ADAMS MICHAEL E

Protective bucket handle guard

InactiveUS20070228055A1Prevent and reduce potentialPrevent and reduce injuryTravelling carriersHoldersBucket HandleEngineering

A guard is disclosed which aids in protecting animals and / or humans from contacting a body part or clothing on the handle of a bucket which could potentially cause injury. The guard is flexible and relatively puncture and tear resistant. The guard is wrapped around the region of the handle which is attached to the bucket, thereby covering that region. In another version, the handle guard is permanently engaged with the handle prior to attachment of the handle to the bucket. After attachment, the guard can then be positioned and secured directly over an end of the handle, thereby covering that end.

Owner:SCHNEIDER STANLEY K

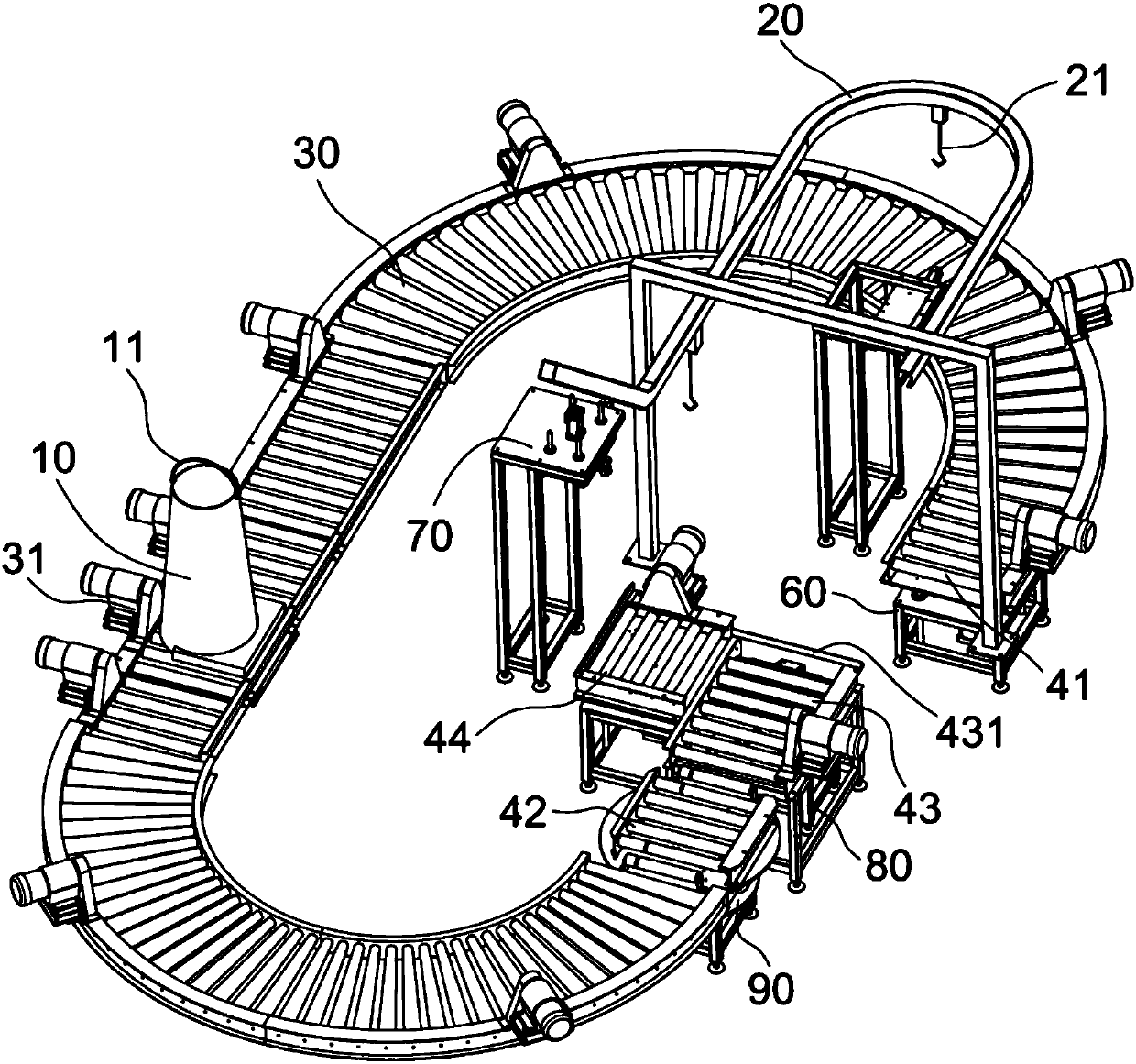

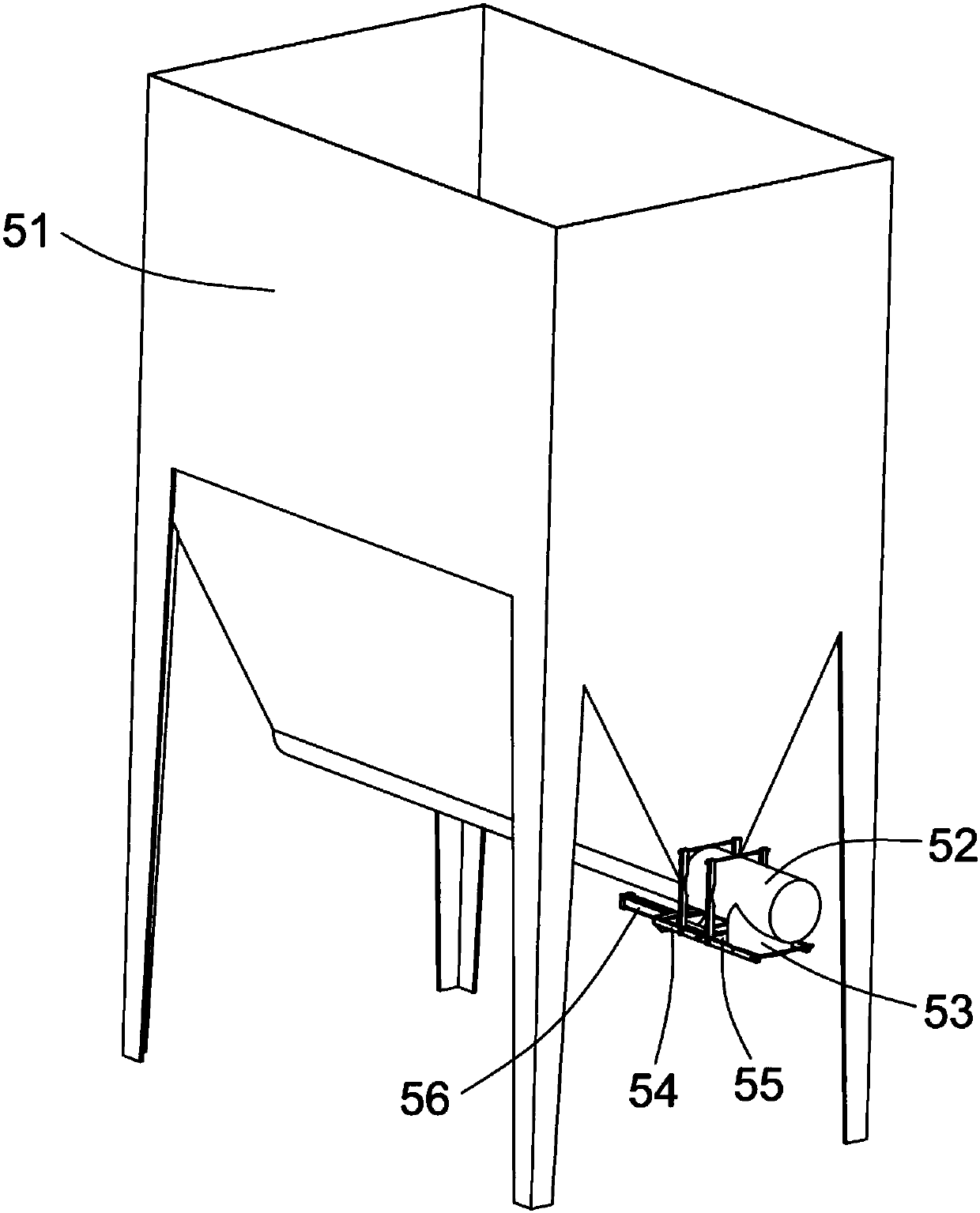

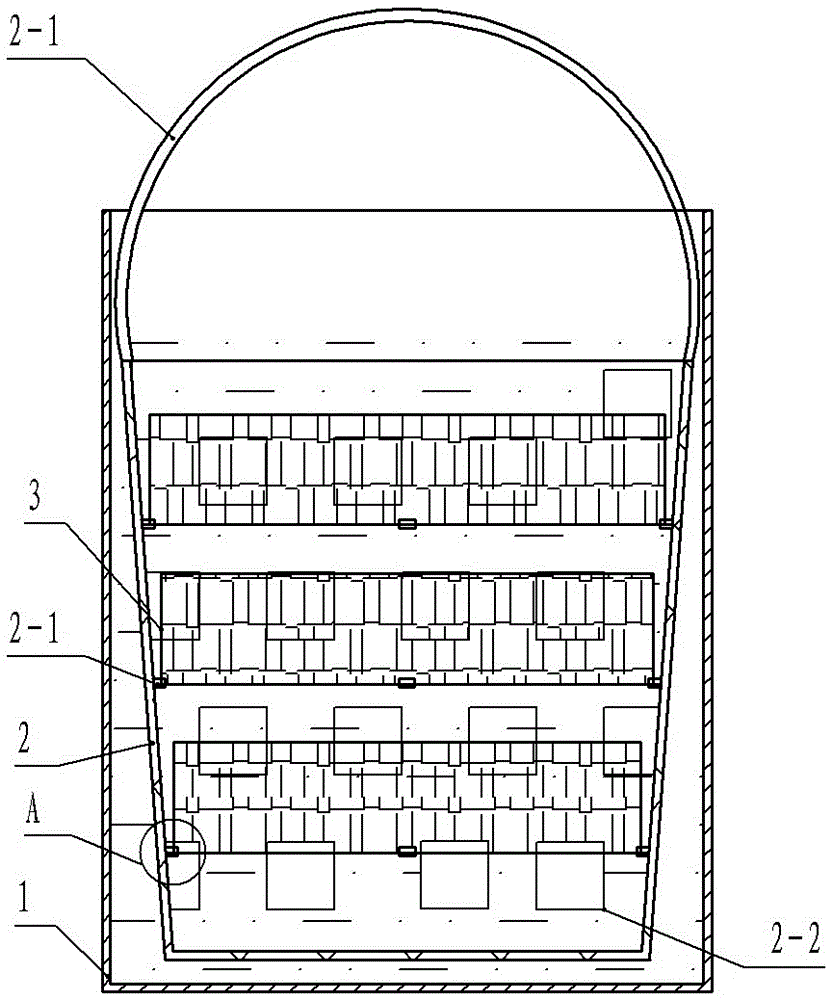

Material loading and unloading conveying mechanism

ActiveCN106315157AFully automatedContinuous actionMechanical conveyorsBucket HandleMechanical engineering

The invention discloses a material loading and unloading conveying mechanism. The material loading and unloading conveying mechanism comprises a material bucket, a hanging track, a roller conveying component, a descending conveyer, a material adding machine, a rotary conveyer, a tail section conveyer, a lifting conveyer, a pair of lifting mechanisms and a pair of pull mechanisms, wherein each pull mechanism is used for pulling the handle of a material bucket; a plurality of conveying hooks are arranged at the lower portion of the hanging track; the conveying hooks for hanging the bucket handles pass through the upper portion of the descending conveyer and the upper portion of the lifting conveyer. The handle of each material bucket is pulled to the side surface or is pulled to stand upright by a pull rod of the corresponding pull mechanism; the rotary conveyer is used for rotating each material bucket for 180 degrees; a jacking and moving multi-row chain conveyer is used for driving the material bucket to be conveyed to the lifting conveyer; the lifting conveyer is used for hanging each material bucket on the hanging track, and thus sequential material loading and unloading conveying is implemented; the conveying process is full-automatic, continuous in action and high in efficiency.

Owner:四川纽赛特工业机器人制造有限公司

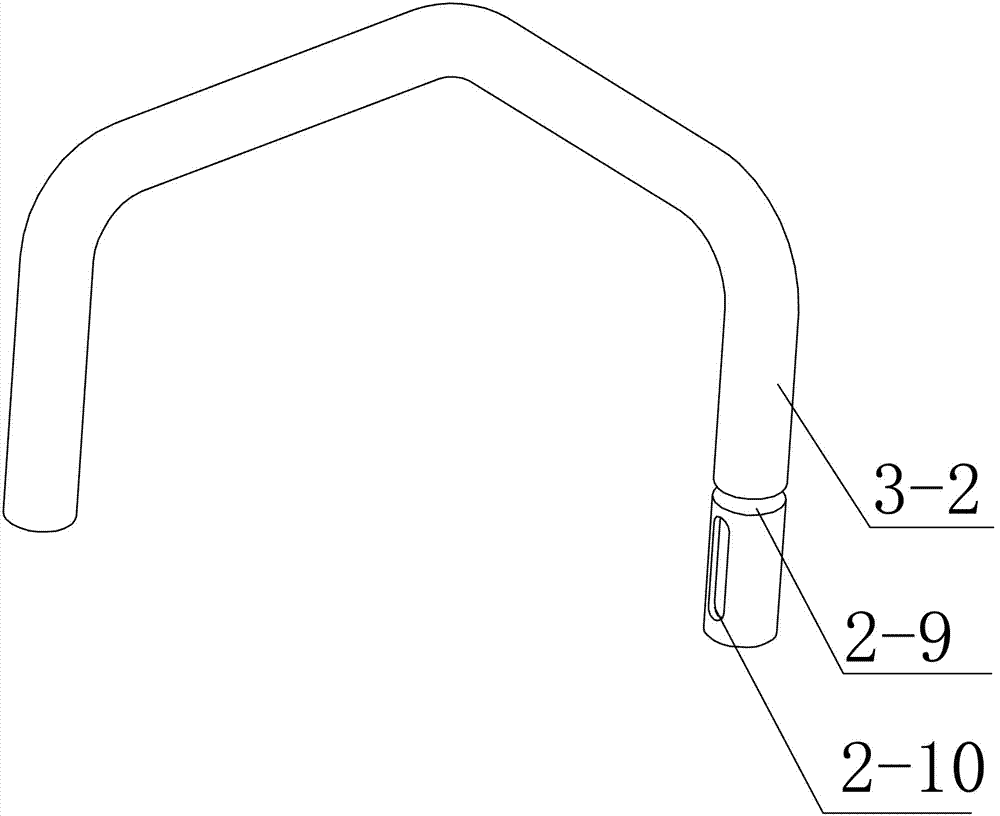

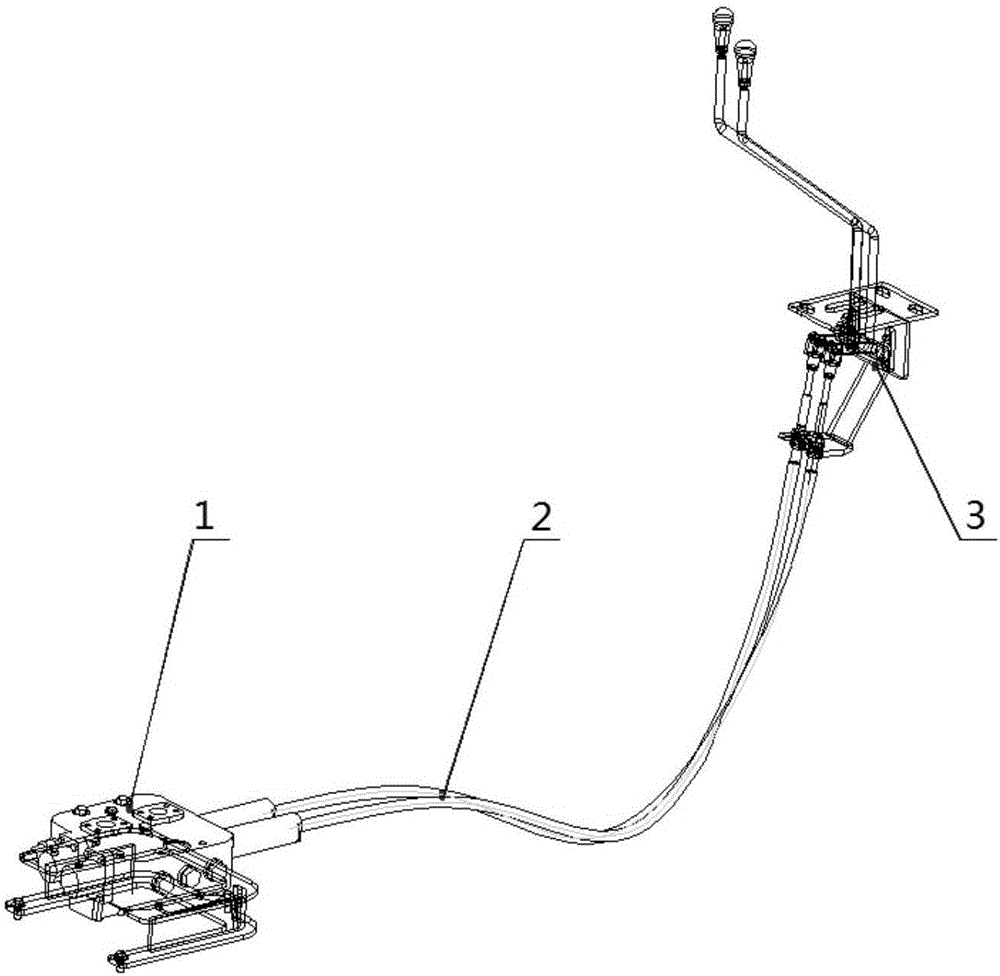

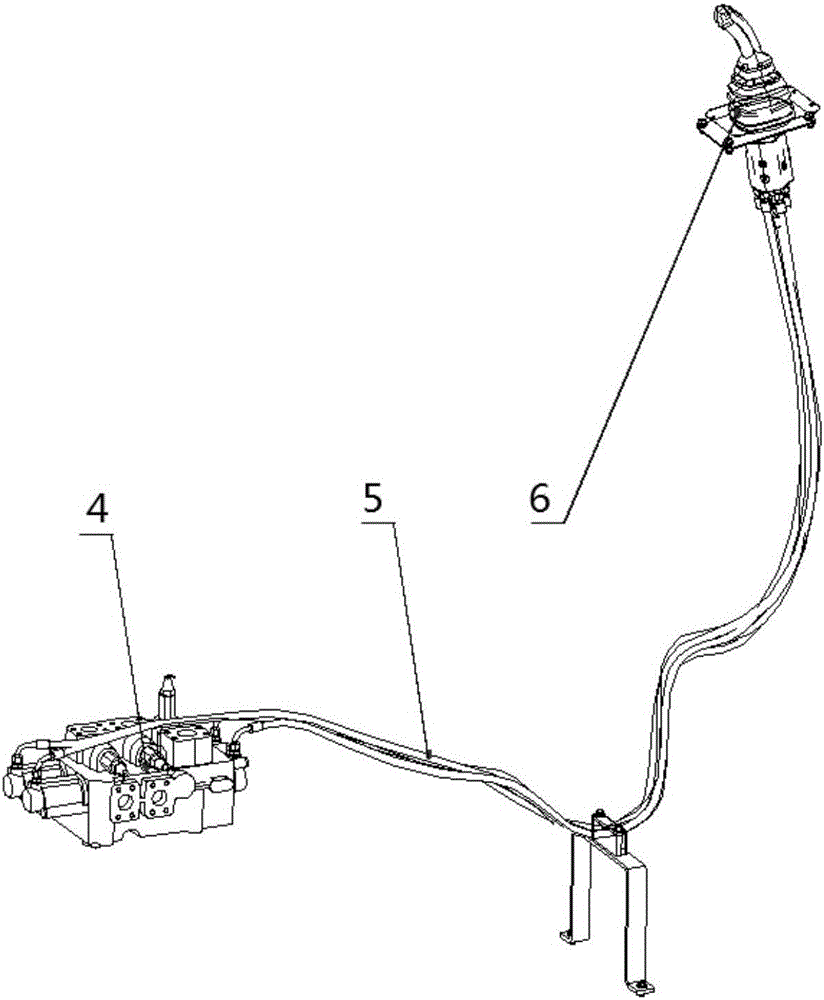

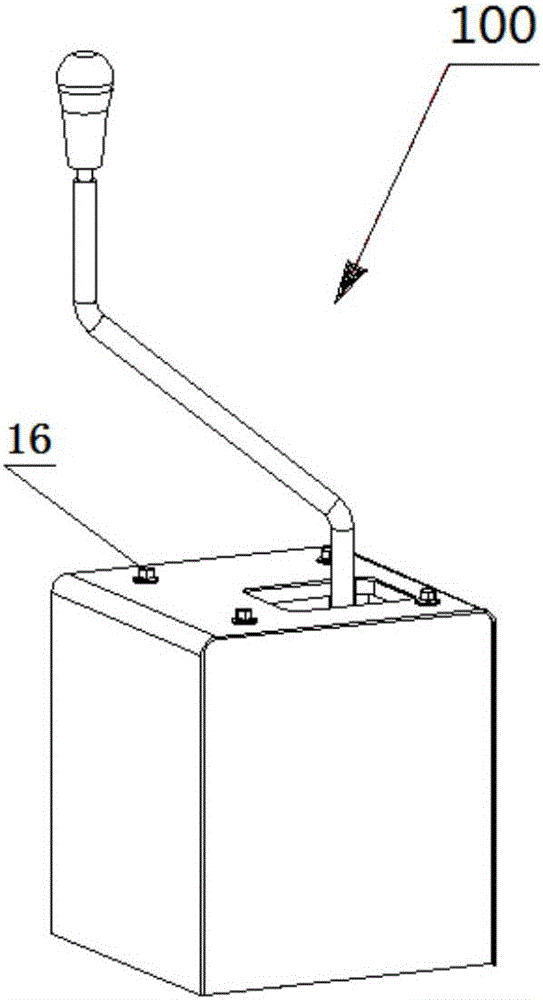

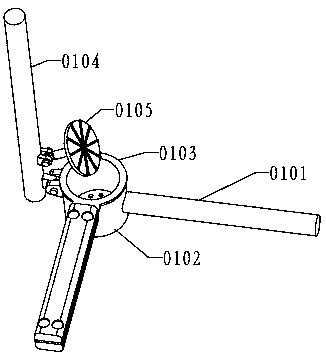

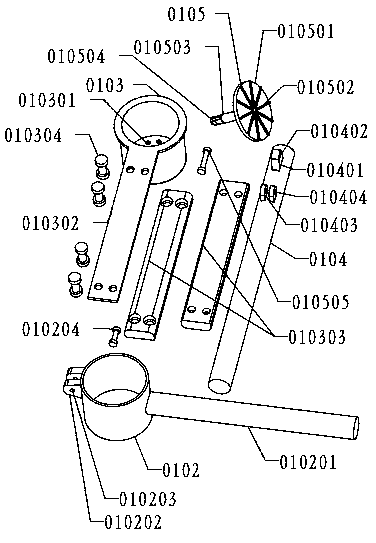

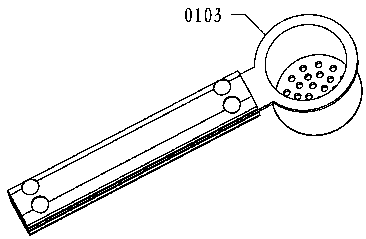

Single-rod control mechanism

ActiveCN106193172ANo frequent replacementReduce work intensityMechanical machines/dredgersBucket HandleBall bearing

The invention provides a single-rod control mechanism. The single-rod control mechanism comprises a control rod assembly, a bracket assembly, a movable arm rotating bucket handle ball and a protection box; the control rod assembly includes a control rod, a welding bracket, a first rocking arm and a second rocking arm; the bottom end of the control rod is welded with a sleeve; the first rocking arm is welded on the sleeve; the second welding arm is welded on the outer side of the welding bracket; the sleeve is mounted on the inner side of the welding bracket through matching a pin shaft with a deep groove ball bearing; the bracket assembly is a three-dimensional square frame built by peripheral brackets and upper and lower plates; a pair of short plates is mounted on the symmetric surfaces of the front and back sides of the frame; a pair of mounting holes is formed in the short plates; the control rod assembly and the bracket assembly are assembled through matching a pin shaft with a deep groove ball bearing; the protection box is fixed on the bracket assembly; and the movable arm rotating bucket handle ball is mounted at the tail end of the control rod. The single-rod control mechanism can realize control of multiple actions through single control rod, and prevents frequent replacement of multiple control rods.

Owner:QINGDAO LOVOL EXCAVATOR

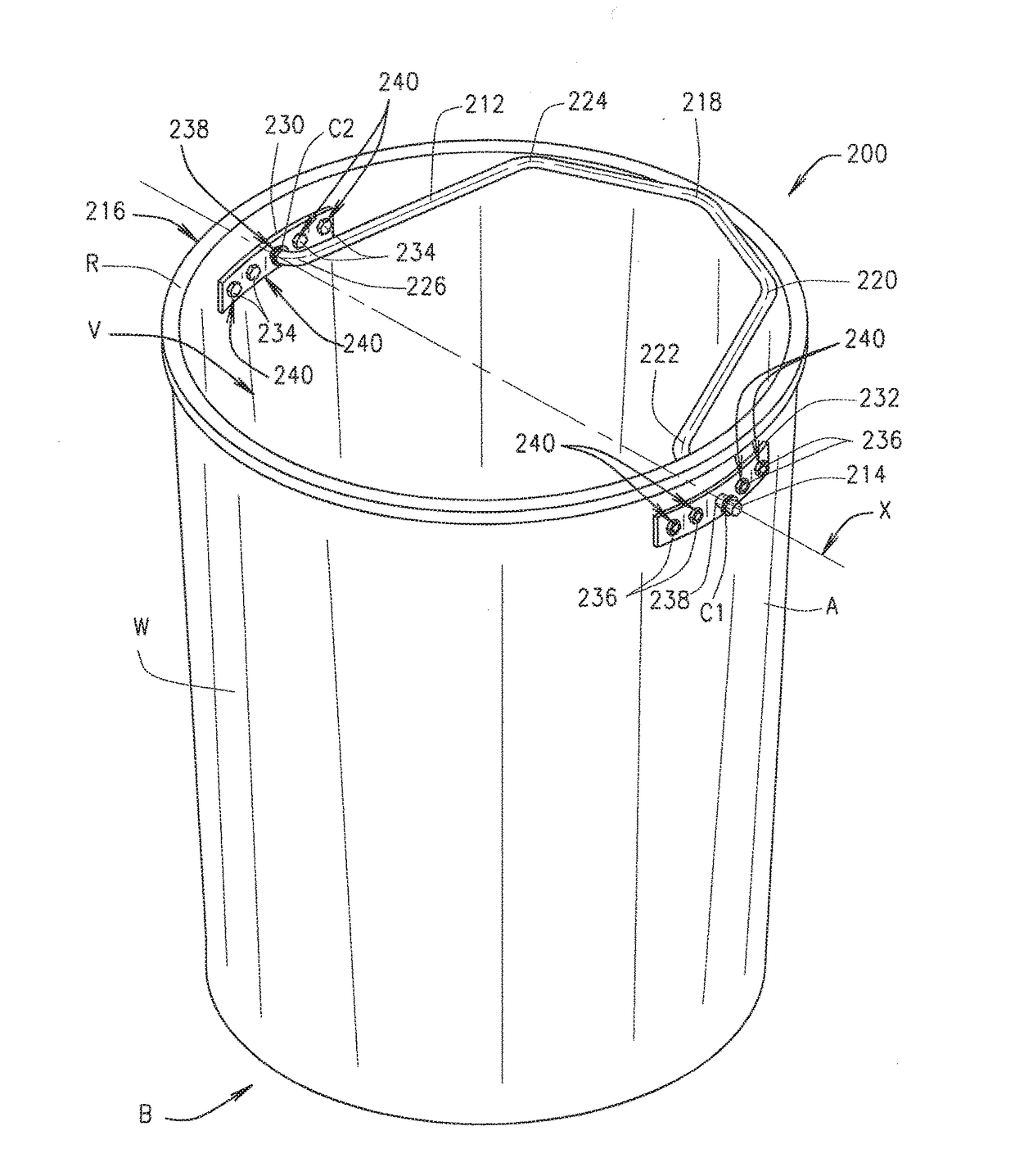

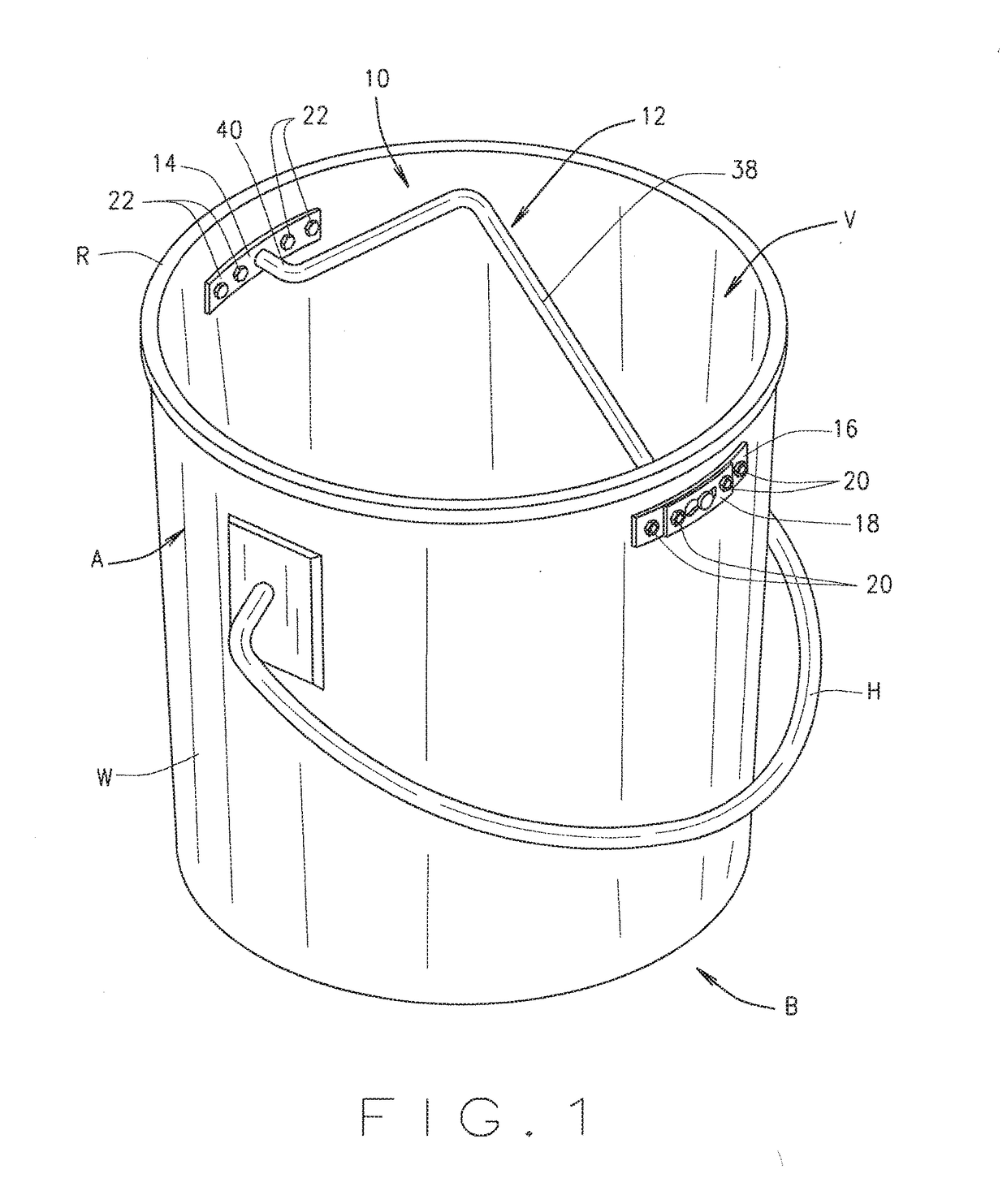

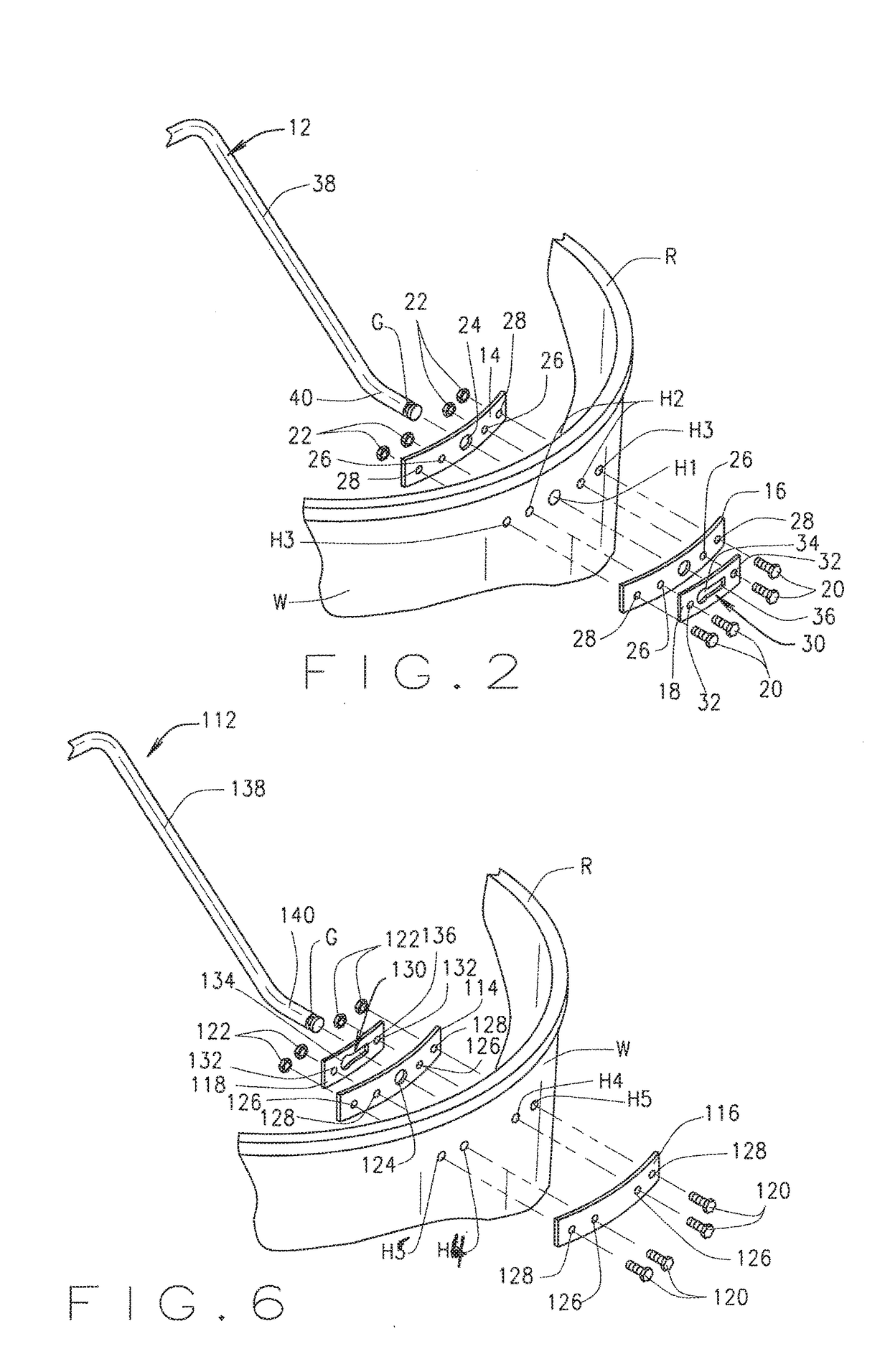

Bucket handle assembly

A handle and assembly for a bucket. The bucket has first and second attachment regions on the inner surface of the sidewall near the rim. The sidewall has a compressed condition in which compressive forces are applied to opposite sides to reduce the distance between the attachment regions, and a relaxed condition with forces. The handle has attachment ends with an axis between them. The attachment ends attach to the attachment regions such that the handle rotates about the axis and can also move laterally along the axis. The handle has a first rotational position in which the handle is above the rim, and a second rotational position in which the handle is below the rim. The handle cannot rotate between the first and second positions when the sidewall is relaxed, but can when the sidewall is laterally compressed.

Owner:FOSTER NORMAN

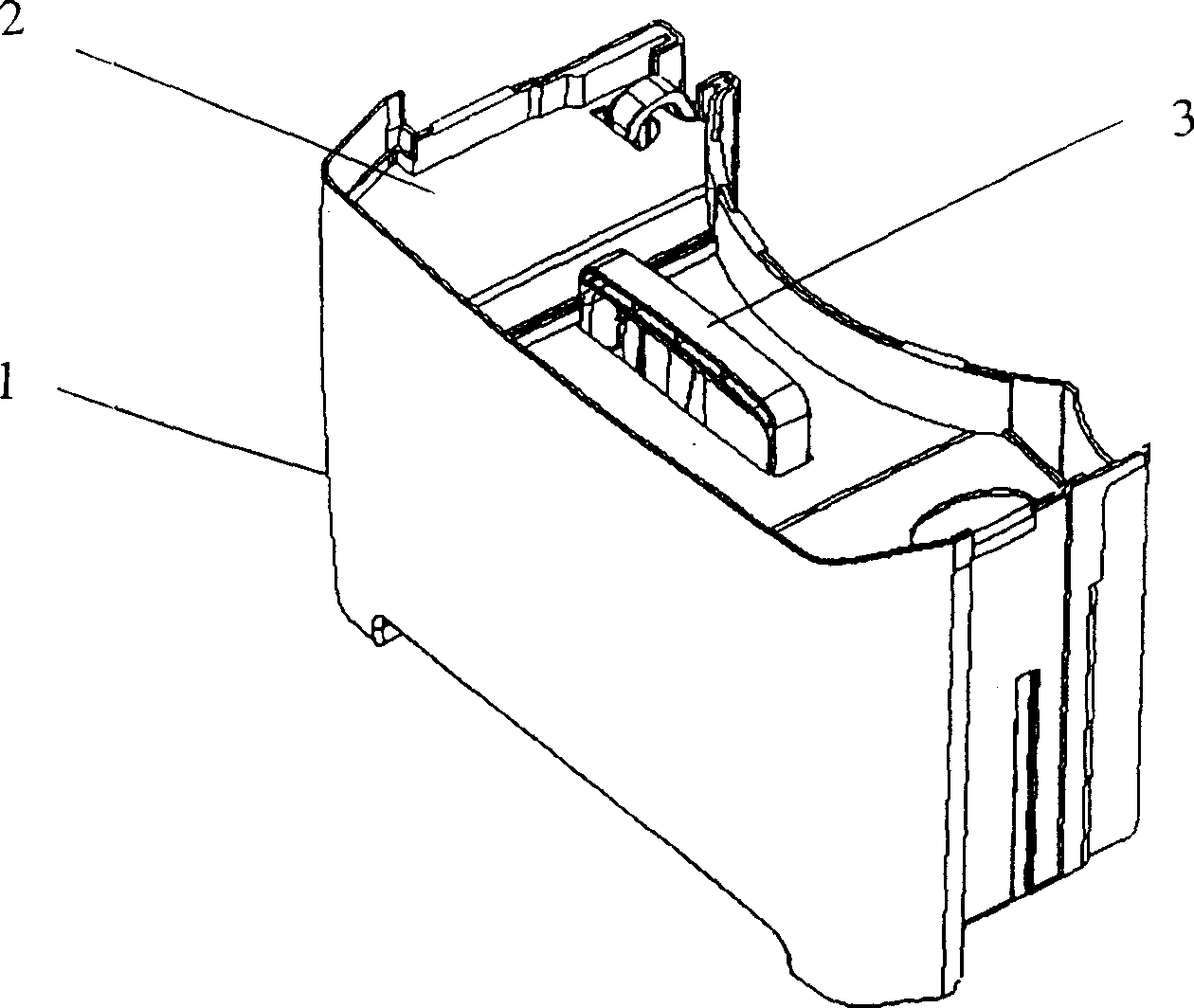

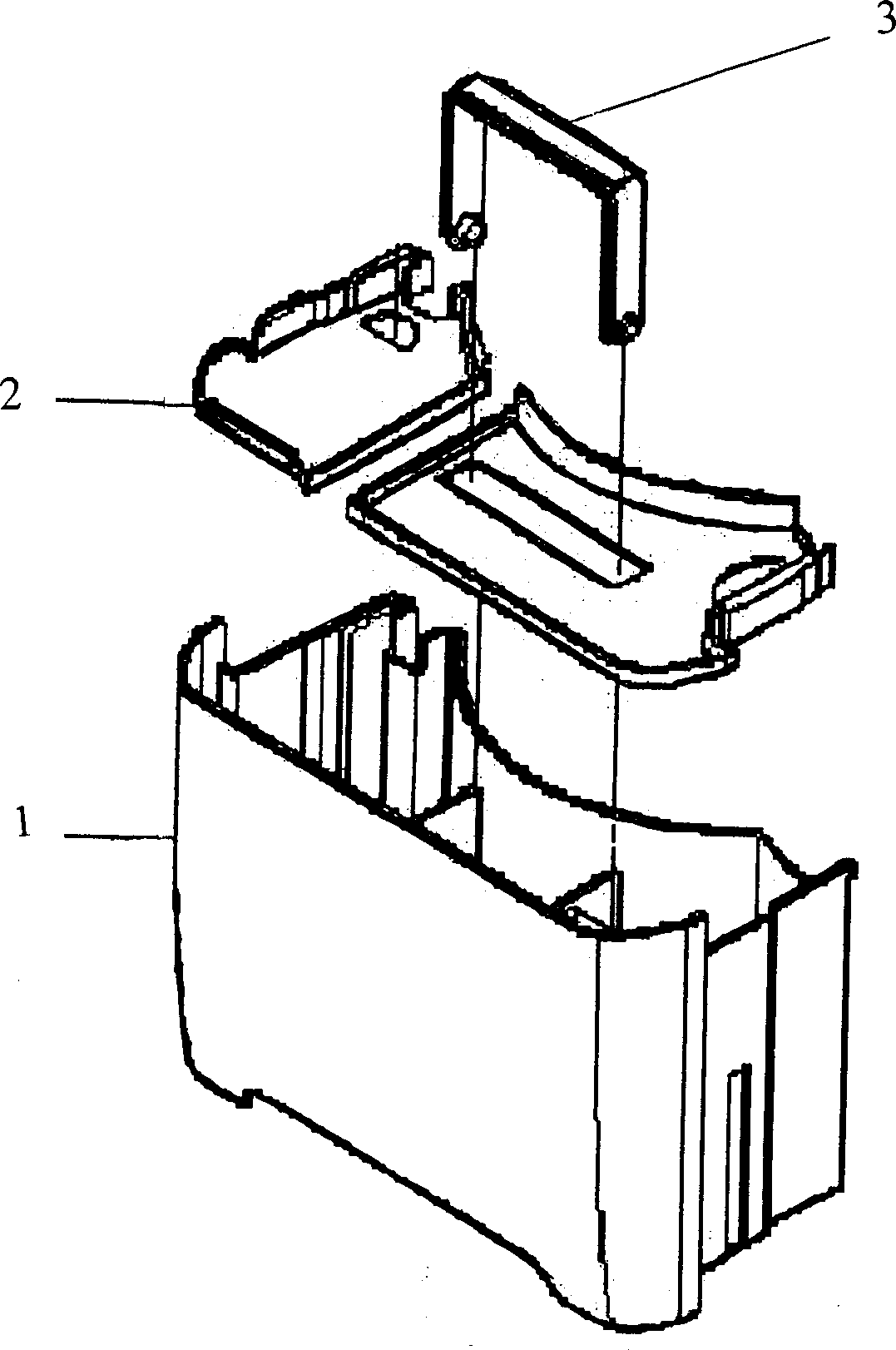

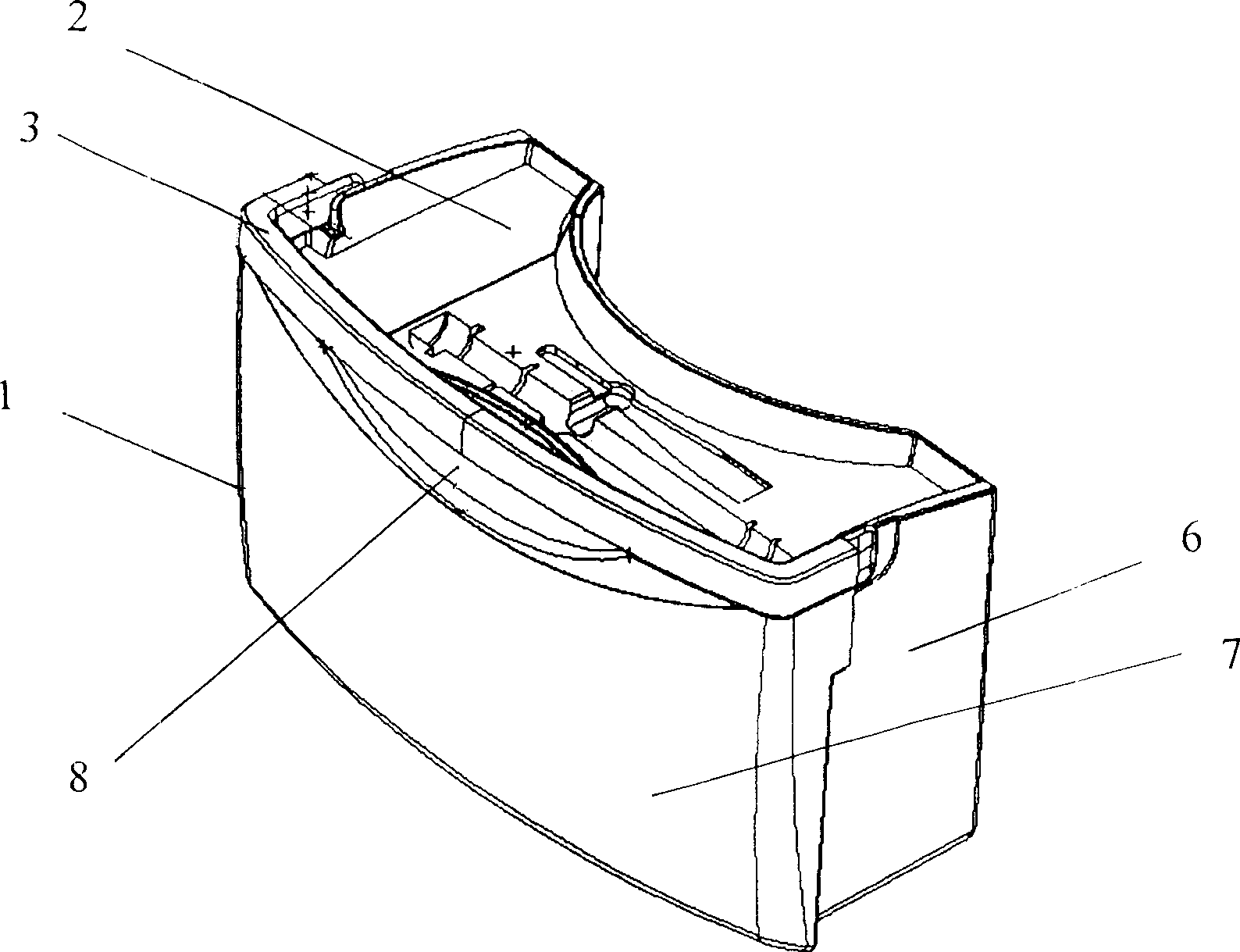

Water-receiving bucket of dehumidifier

InactiveCN101813365AIncrease the stress areaReduce adverse eventsCondensate preventionBucket HandleEngineering

The invention discloses a water-receiving bucket of a dehumidifier, comprising a bucket body and a bucket handle. Pear-shaped installing holes used for installing the bucket handle are respectively formed on the upper parts of two side surfaces of the bucket body; large circular holes of the pear-shaped installing holes are positioned in an oblique lower side, and small circular holes are positioned in an oblique upper side; a first cylindrical lug boss and a second cylindrical lug boss are sequentially formed at the internal sides of both ends of the elongated C-shaped bucket handle from inside to outside; the diameter of the second cylindrical lug boss is larger than that of the first cylindrical lug boss; the second cylindrical lug boss is slightly smaller than the large circular holes and can just pass through the large circular holes; and the diameter of the first cylindrical lug boss is designed to meet that the first cylindrical lug boss can just slide into the small circular holes from the pear-shaped large circular holes under the extrusion condition. The invention strengthens stresses positions of the bucket handle, changes the linear contact into the overall circumferential contact, reduces the defect rate and improves the product reliability.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Rotary garlic pressing device

The invention aims at providing a kitchen tool for more effectively pressing garlic. In order to realize the aim, the invention provides a rotary garlic pressing device. The rotary garlic pressing device comprises an upper handle, a base, a containing bucket and a pressing plate; specifically, the base is provided with a base handle; the containing bucket is mounted on the base in a detachable manner; the containing bucket is provided with a containing bucket handle, a containing bucket upper bottom surface and a through hole; an upper edge of the containing bucket through hole of the containing bucket has a quick opening form; the pressing plate is hinged to the upper handle; the upper handle is hinged onto the base; a bottom surface of the pressing plate is of a grinding sheet structurewhich is unevenly passivated relative to the bottom surface of the containing bucket; when the rotary garlic pressing device is used, garlic bulbs and onion bulbs are put into the containing bucket and the upper and lower handles are pressed to carry out squeezing; then the containing bucket handle is tightly gripped to rotate back and forth, so that the pressing plate and the containing bucket through hole with a rapid opening are mutually rolled to grind residues.

Owner:张新

A loading and unloading conveying mechanism

The invention discloses a material loading and unloading conveying mechanism. The material loading and unloading conveying mechanism comprises a material bucket, a hanging track, a roller conveying component, a descending conveyer, a material adding machine, a rotary conveyer, a tail section conveyer, a lifting conveyer, a pair of lifting mechanisms and a pair of pull mechanisms, wherein each pull mechanism is used for pulling the handle of a material bucket; a plurality of conveying hooks are arranged at the lower portion of the hanging track; the conveying hooks for hanging the bucket handles pass through the upper portion of the descending conveyer and the upper portion of the lifting conveyer. The handle of each material bucket is pulled to the side surface or is pulled to stand upright by a pull rod of the corresponding pull mechanism; the rotary conveyer is used for rotating each material bucket for 180 degrees; a jacking and moving multi-row chain conveyer is used for driving the material bucket to be conveyed to the lifting conveyer; the lifting conveyer is used for hanging each material bucket on the hanging track, and thus sequential material loading and unloading conveying is implemented; the conveying process is full-automatic, continuous in action and high in efficiency.

Owner:四川纽赛特工业机器人制造有限公司

Water bucket handle structure of dehumidifier

InactiveCN1766437AEasy to liftEasy to pourCondensate preventionLighting and heating apparatusBucket HandleEngineering

The invention discloses a dehumidifier bucket handle structure of front-plug type, which is characterized by the following parts: plugging two ends of handle projection in the jack on the top of bucket side wall; connecting two ends of handle on the top of bucket side wall and front wall with handle extending forward; putting the hand in the arc flute of front wall top end center when needing to pour condensing water; pulling the handle out of the dehumidifier; turning the handle uprightly. The invention is convenient to put and gain bucket and pour condensing water for user, which improves the producing and working efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

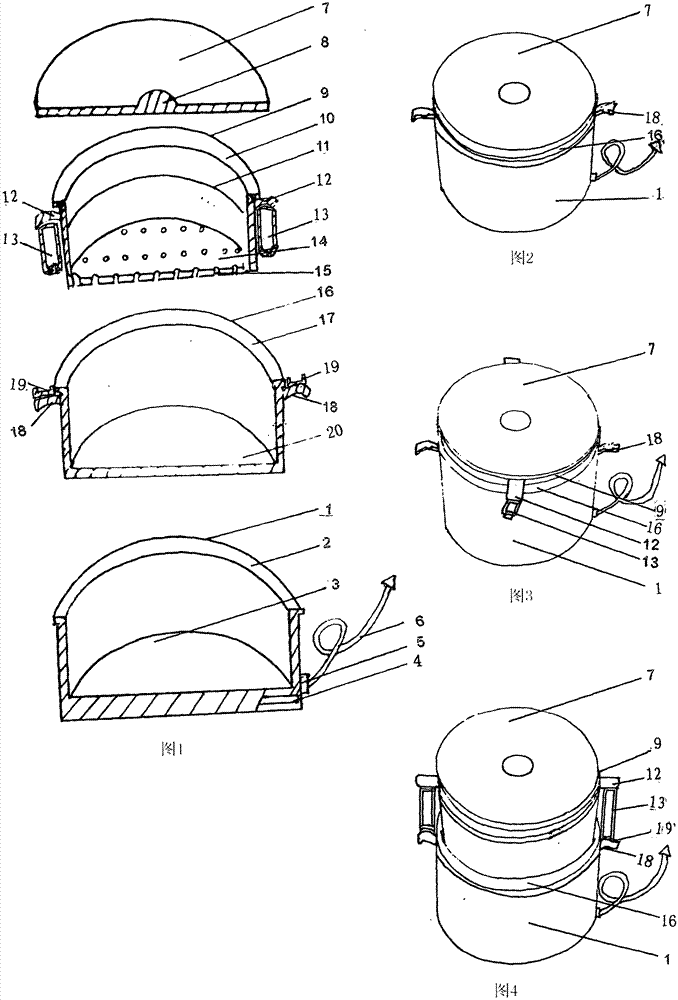

Inserting plate lifting electric cooker

The invention provides an inserting plate lifting electric cooker. The electric cooker comprises a cooker body (1), a cover (7), a drainage bucket (9) and a water storage bucket (16), and an inserting plate (13) on a drainage bucket handle (12) is adaptive to an insert opening (19) of a water storage bucket handle(18); through misaligned arrangement, the inserting plate (13) is separated from the insert opening (19), a drainage bucket bottom (14) is in contact with a water storage bucket bottom (20), and then a cooking procedure is started; when draining rice, the drainage bucket (9) is lifted for aligned arrangement, the inserting plate (13) is inserted into the insert opening (19), so that the drainage bucket (9) is suspended in the air above the water surface of the water storage bucket (16), the automatic rice draining is realized and a rice steaming procedure is started. Since hot rice soup is utilized for directly steaming rice without additionally boiling water, the fuel and time are saved, in the whole operation process, only the drainage bucket (9) is needed to be moved, the operation is simple and convenient, the electric cooker is used for steaming and cooking drained rice which is prepared by automatically draining rice without additionally boiling water, and the taste of people loving to eat drained rice is met.

Owner:王德普

Disinfection bucket

The invention discloses a disinfection bucket, relating to the technical field of manufacturing of medical apparatus and instruments. The disinfection bucket comprises a bucket body, wherein a liquid soaking bucket with a bucket handle is arranged in the bucket body, and a plurality of through holes are formed in the bucket wall and the bucket bottom of the liquid soaking bucket; a plurality of screen boxes are arranged in the liquid soaking bucket in an up-down separation manner, positioning holes are formed in the bottoms of the screen boxes, and the screen boxes are buckled with positioning buckles arranged on the bucket wall of the liquid soaking bucket through the positioning holes; and the screen boxes comprise box bodies and box covers hinged to the box bodies, and buckles buckled with the box bodies are arranged on the box covers. Compared with the prior art, the disinfection bucket has the advantages that the problems that existing small medical supplies are difficult to be taken out during disinfection, and the skin of an operator is injured because disinfection liquid is easily touched by the operator are solved.

Owner:LIUZHOU PEOPLES HOSPITAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com