Material loading and unloading conveying mechanism

A conveying mechanism and conveyor technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of incompatibility with modern production, manpower consumption, and low conveying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

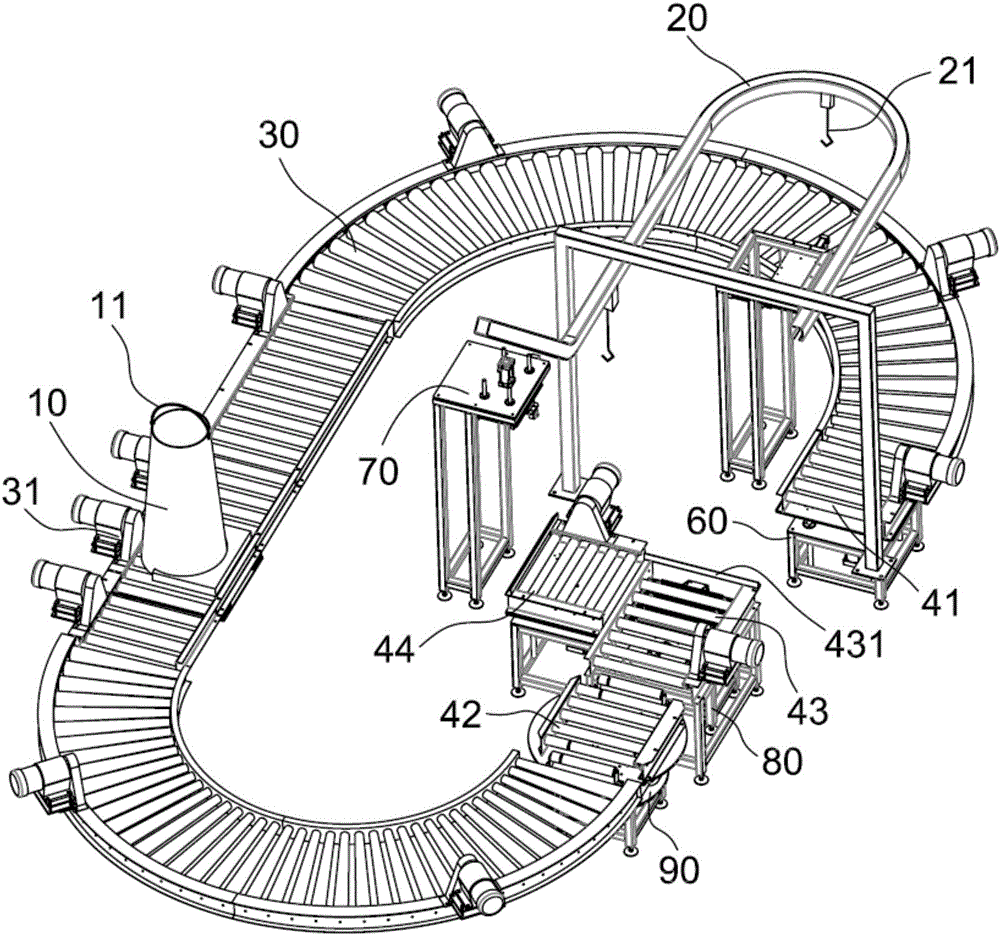

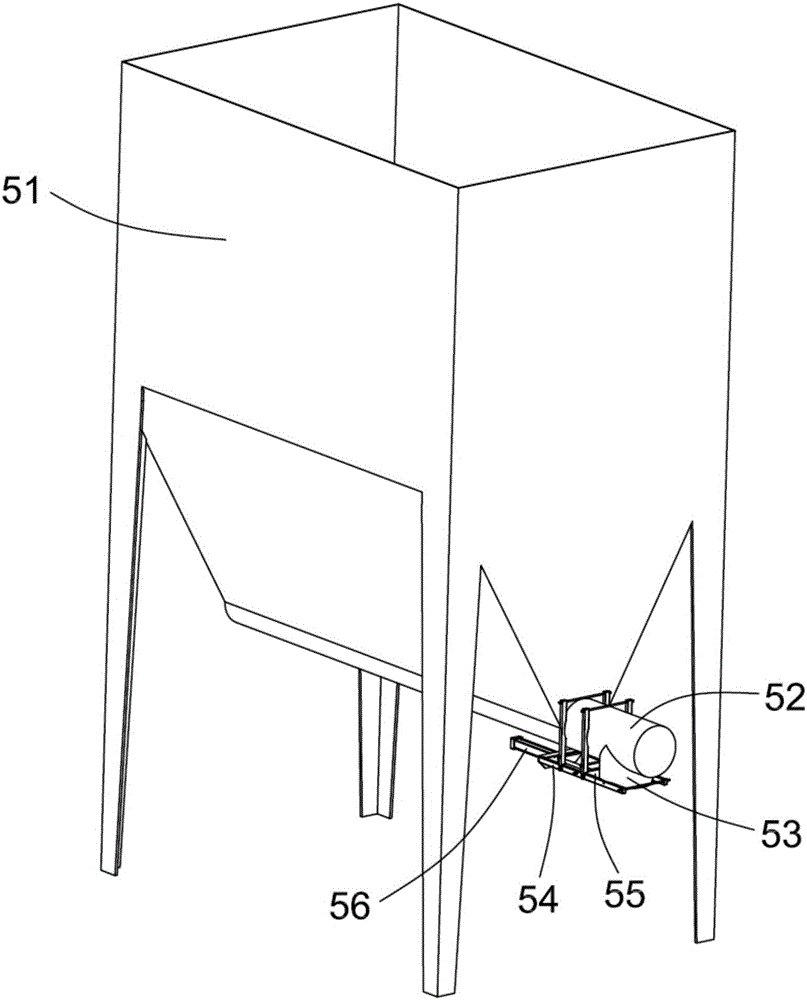

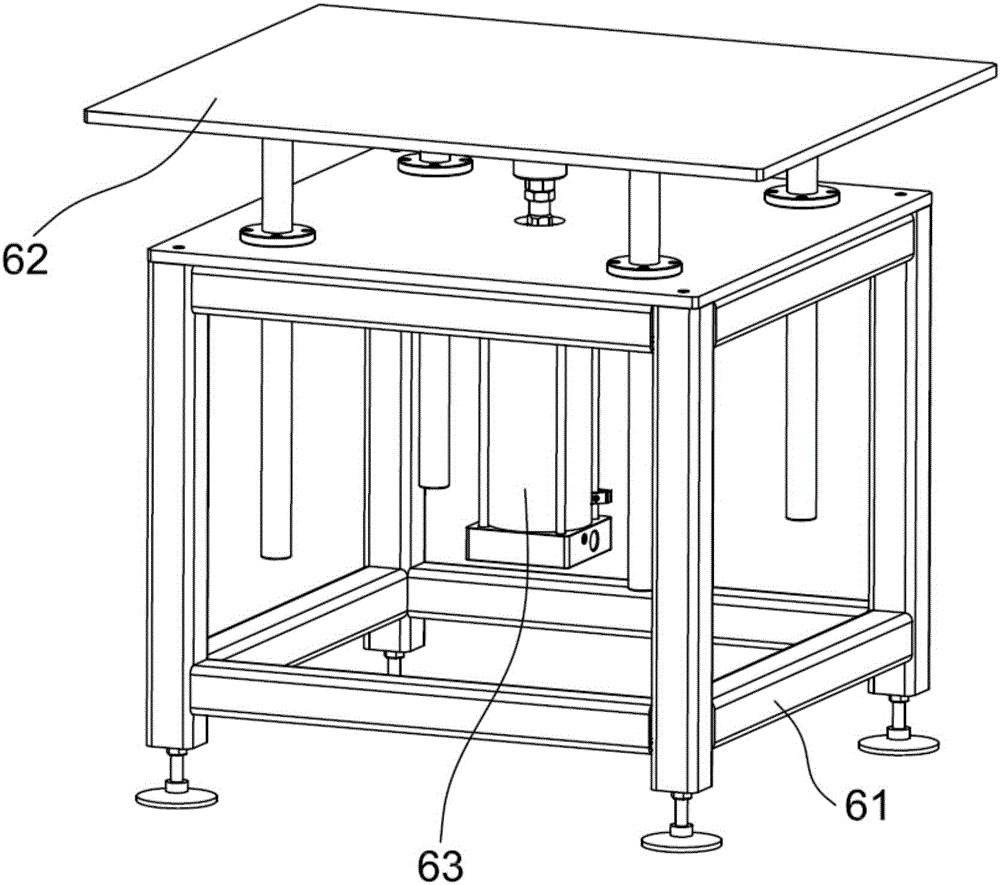

[0023] refer to Figure 1-Figure 7 , the present invention provides a loading and unloading conveying mechanism, comprising a bucket 10, the top of the bucket 10 is hingedly connected with a bucket handle 11, and also includes a suspension rail 20, a roller conveying assembly 30, a descending conveyor 41, a feeding machine 51, a rotary conveying Machine 42, tail conveyor 43, lifting conveyor 44, a pair of elevating mechanism 60 and a pair of toggling mechanism 70 that is used to stir barrel handle 11, and suspension track 20 below is provided with some conveying hooks 21, and roller conveying assembly 30 Including a material receiving conveyor 31 , a feeding pipe 52 is arranged below the feeding machine 51 , a discharge port 53 is provided below the feeding pipe 52 , and the receiving conveyor 31 is arranged below the discharge port 53 .

[0024] The descending conveyor 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com