Low-temperature heat insulation box heat insulation cotton filling device of liquefied natural gas ship liquid cargo maintenance system

A technology for liquefied natural gas and maintenance system, which is applied in the field of low temperature insulation box processing device of liquefied natural gas marine liquid cargo maintenance system, can solve the problems of low efficiency, high labor intensity, excessive tightness, etc., so as to improve efficiency, reduce auxiliary time, and reduce labor effect of intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

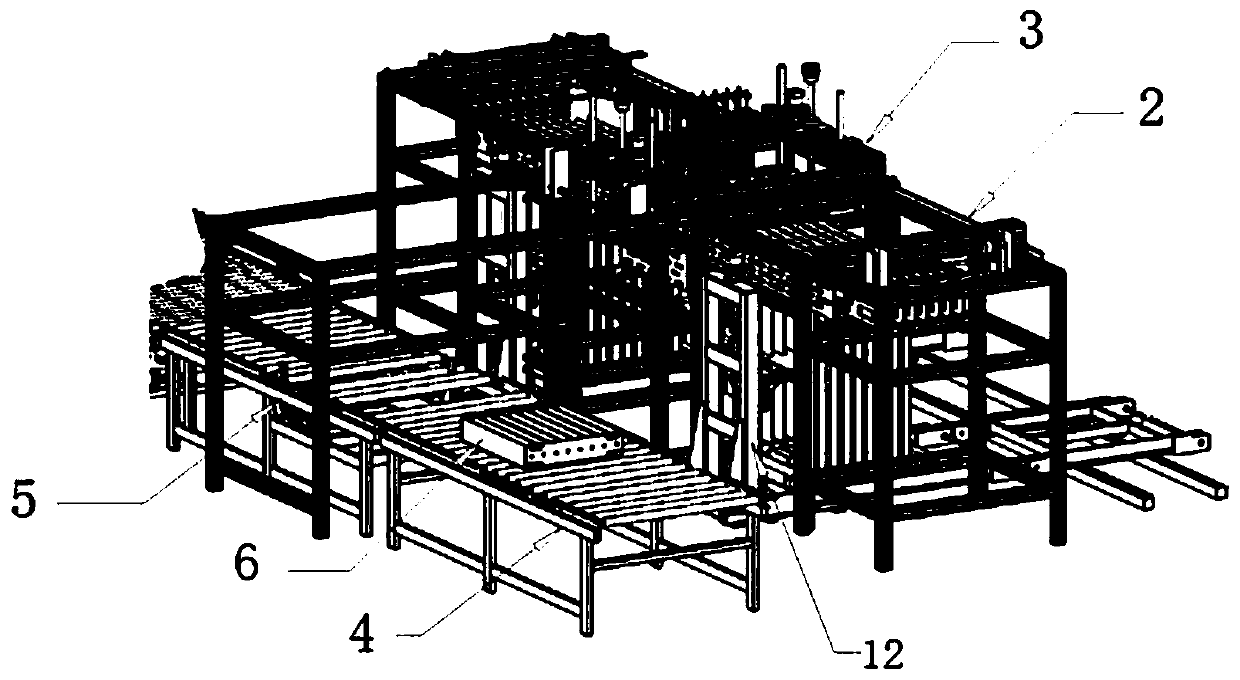

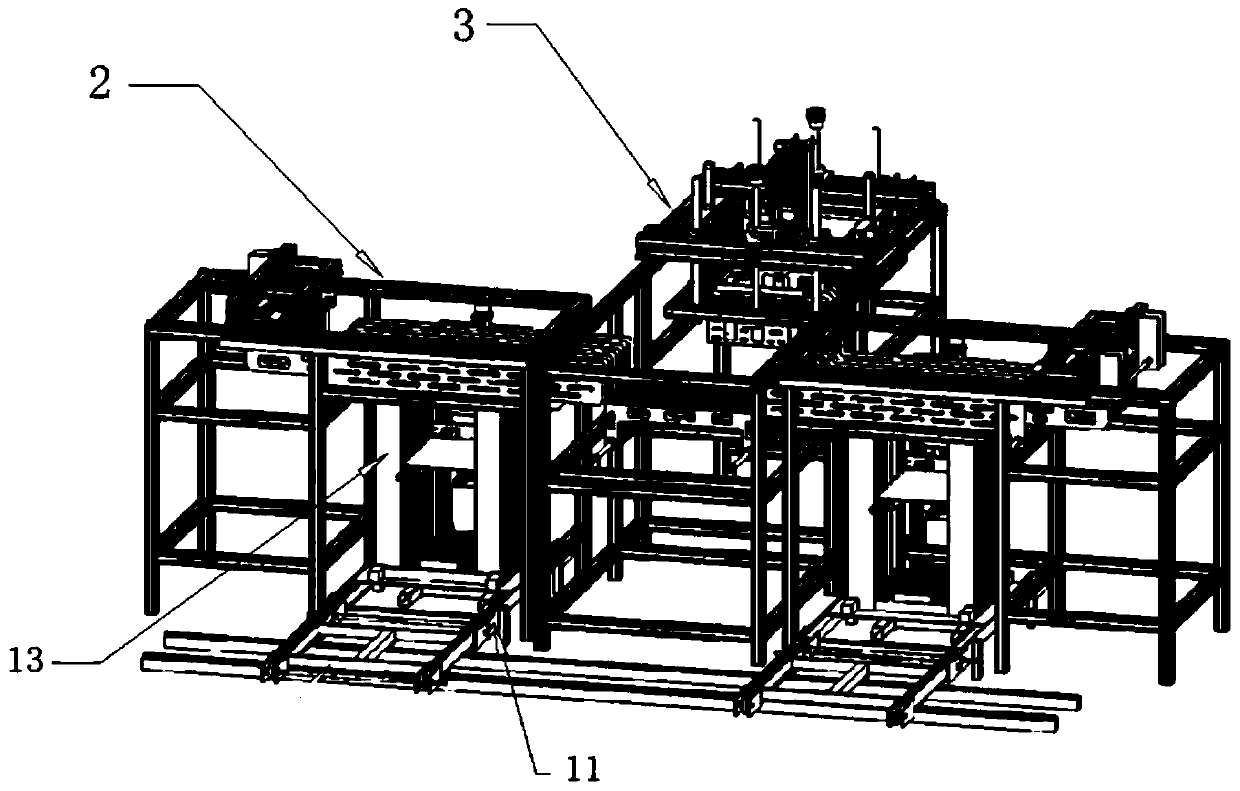

[0091] In order to achieve the Figure 22 The filling of the thermal insulation cotton in the insulation box 6 shown, this embodiment proposes a kind of thermal insulation cotton filling device for the low-temperature thermal insulation box of the liquid cargo maintenance system for liquefied natural gas ships, and its structure is shown in Figure 1-Figure 2 shown, including:

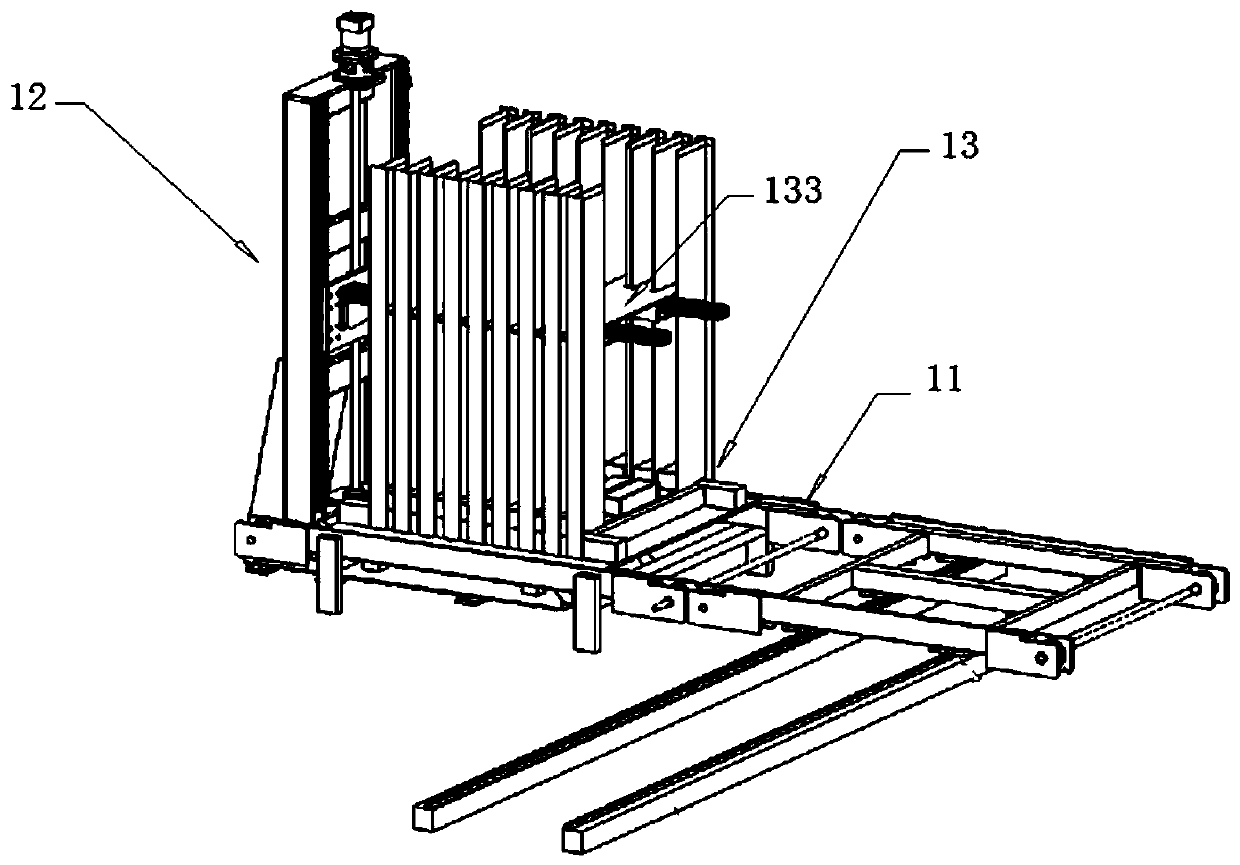

[0092] Insulation cotton feeding and conveying part 1: its structure see Figure 3-Figure 7 As shown, it includes a thermal insulation cotton feeding roller table 11, a lifting bracket 12 arranged at the end of the thermal insulation cotton feeding roller table 11, and a tray material rack 13 that can move along the thermal insulation cotton feeding roller table 11. The frame 13 includes a material frame base 131 that is movably arranged on the thermal insulation cotton feeding roller table 11, two rows of first vertical partitions 132 that are vertically arranged side by side on both sides of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com