A method for loading and unloading box blanks

A technology for warehousing and box blanks, which is applied in packaging and other directions, can solve the problems of different binding and stacking of box blanks, restrictions on wide-scale promotion and application, and automatic unwinding of box blanks, etc., so as to reduce labor intensity and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with the accompanying drawings, the box blank storage and storage operation method of the present invention will be described in detail.

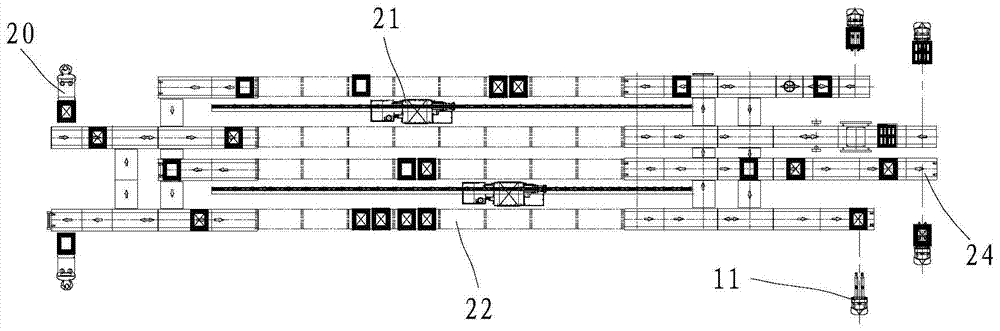

[0050] Such as figure 1 As shown, the system for implementing the method of the present invention includes: a storage area where shelves 22 are placed, an inlet opening 20 located at the inlet end of the storage area, and an outlet opening 24 located at the outlet end of the storage area.

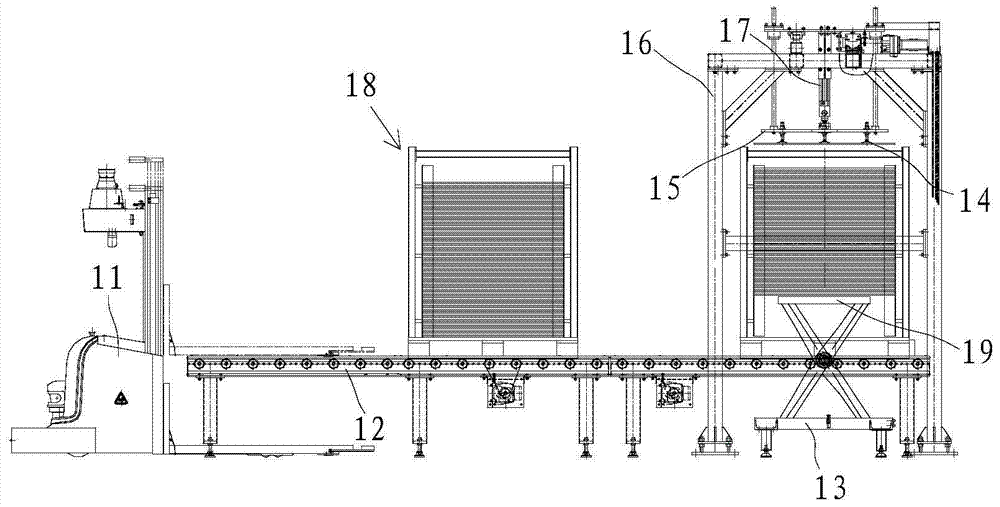

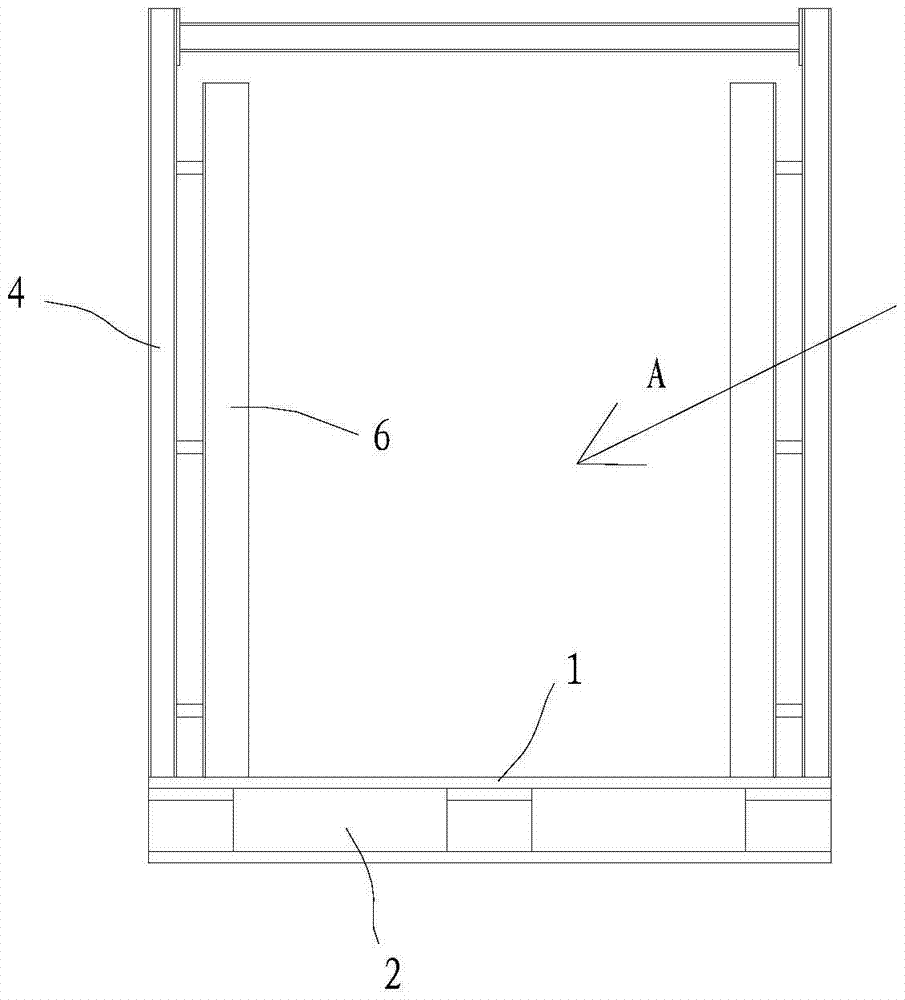

[0051] The discharge channel 24 located at the exit of the storage area transfers the box blanks through the AGV trolley 11 and the roller conveyor 12, and the box blank fixing device 18 containing the box blanks located at the discharge channel is transported to the roller conveyor by the AGV trolley 11 12, and then complete the automatic adding process of the box blank, such as figure 2As shown, the automatic adding device of the box blank includes: a roller conveyor 12 for transferring the box blank fixing device 18, a ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com