Continuous production method of modified nitro-amine compound explosive

A technology for ammonium nitrate explosives and production methods, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as inability to realize continuous automatic production of products, restrictions on the popularization and application of modified ammonium nitrate explosives, friction of wheel mills, etc., and achieve Achieve safe production, reduce labor intensity, and improve the effect of crushing fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

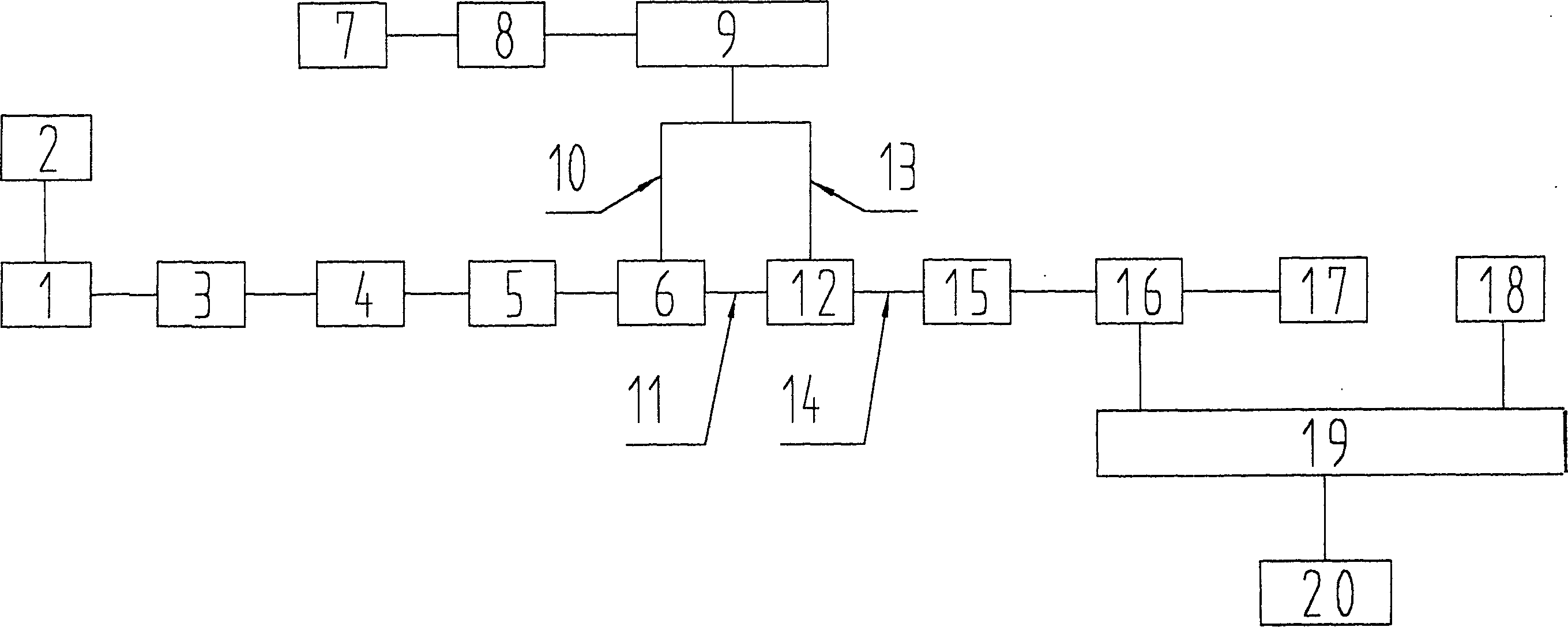

[0019] The content of the present invention will be described in further detail below in conjunction with the drawings and the embodiments shown in the drawings. But they are not limitations of the present invention.

[0020] Two cam pulverizers 6,12 are installed in series for stand-by. Add 0.3% modifier 2 quantitatively into the packaging bag of ammonium nitrate 1, and put the mixture into the roller crusher 3 for coarse crushing. Use a magnet sieve 4 for iron removal and primary mixing, and then transport it to the primary cam pulverizer 6 for pulverization through the screw quantifier 5; then enter the secondary cam pulverizer 12 through the ammonium nitrate drying pipeline 11 for secondary pulverization. After the air 7 passes through the fan 8 and the heat exchanger 9 to become hot air at 130°C, it enters the ammonium nitrate delivery pipes 11 and 14 through the hot air pipe 10 through the primary cam pulverizer 6, and enters through the hot air pipe 13 through the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com