Patents

Literature

340results about How to "Realize safe production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for second mining mining-stopping line coal column in super thick coal layer

ActiveCN107313778ARecovery is safe and reliableAvoid safety accidentsUnderground miningSurface miningEconomic benefitsEngineering

The invention discloses a method for second mining a mining-stopping line coal column in a super thick coal layer. The method comprises the following steps that (1), positions of a coal column second mining working surface transporting gate trough and a rail gate trough are stimulated; (2) comprehensive probing is conducted on an original working surface goaf area where the super thick coal layer mining-stopping line coal column is located, and potential safety hazard is removed; (3) a roadway in the propelling direction of the coal column second mining working surface is dug at the upper part of the super thick coal layer, and the roadway is filled; (4) a coal column second mining working surface mining returning roadway and a affiliated oblique roadway are dug, so that the coal column second mining working surface mining returning roadway and the affiliated oblique roadway form a completed producing system, and the coal column second mining working surface is arranged; (5) a bottom plate of the roadway is drilled from top to bottom for using as a filled pipeline; (6) filling paste is prepared, the filling paste is evenly injected into one side, close to the original working surface goaf area, of the transporting gate trough along the filled pipeline; and (7) comprehensive mining is conducted on the coal column second mining working surface. According to the method for second mining the mining-stopping line coal column in the super thick coal layer, the compressed coal amount is reduced, waste of coal resources is avoided, the economic benefits of enterprises are improved, and the service life of mines and mining areas is prolonged.

Owner:TAIYUAN UNIV OF TECH

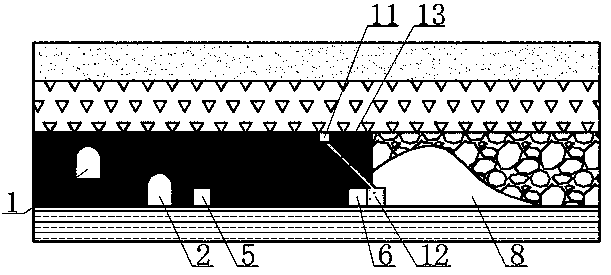

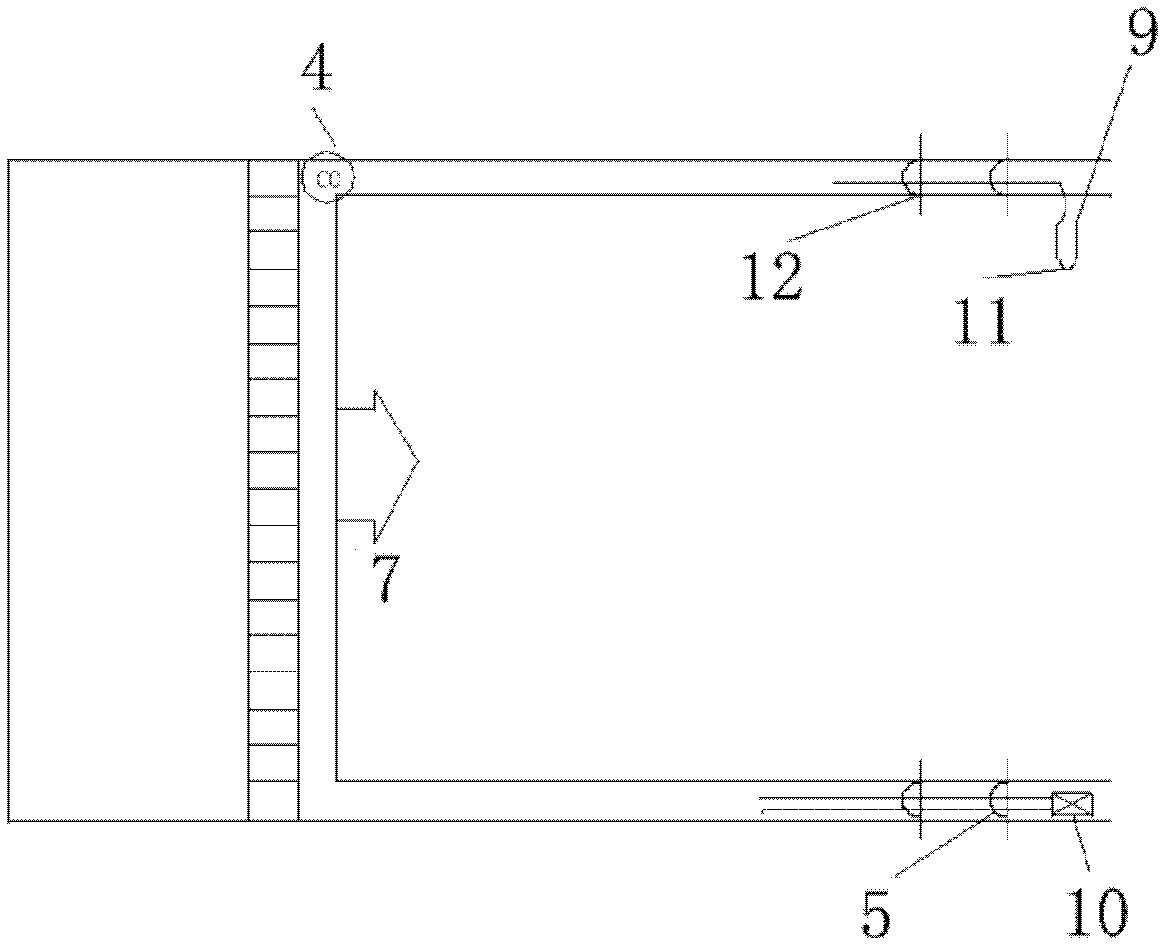

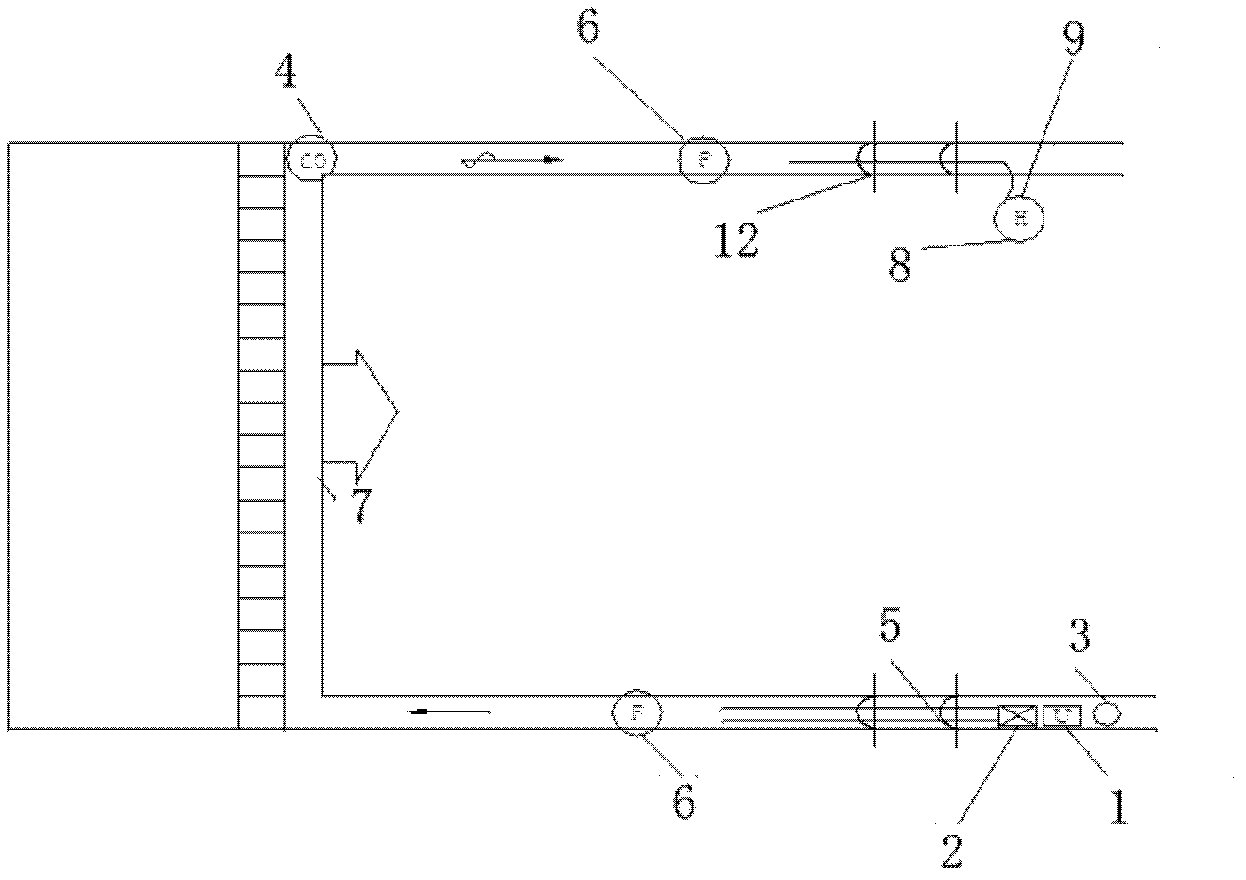

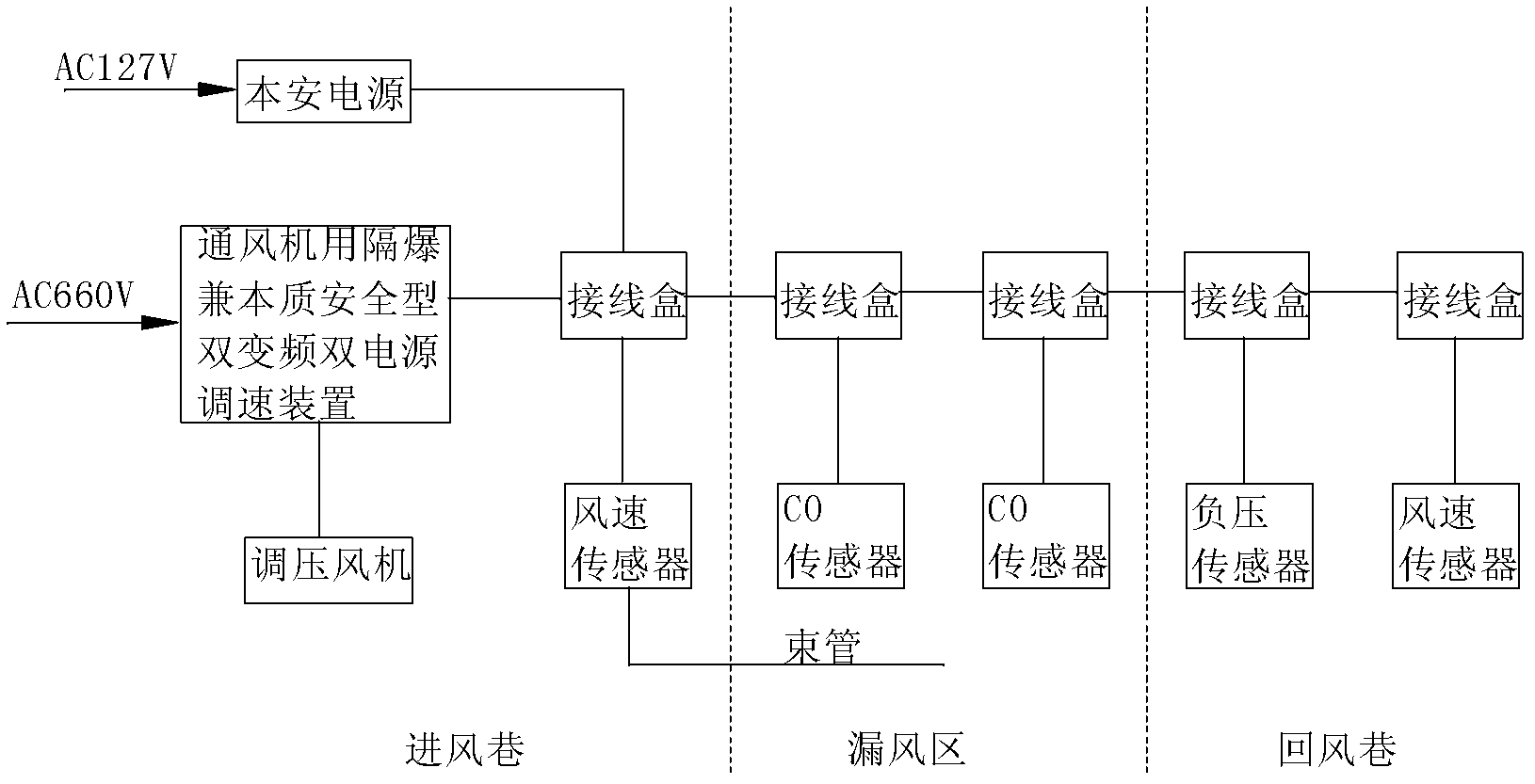

Fan frequency conversion control system and method for air pressure dynamic balance of mine stope

ActiveCN102444606AReduce investmentWith energy saving effectTunnel/mines ventillationPump controlFrequency changerConverters

The invention discloses a fan frequency conversion control system and method for air pressure dynamic balance of a mine stope. The fan frequency conversion control system comprises an alternating-current frequency converter console, a counter rotating axial flow fan, carbon monoxide sensors, air speed sensors, a differential pressure sensor, an intrinsically safe power supply, and an intrinsically safe junction box, wherein the alternating-current frequency converter console has two sets of alternating-current frequency converters; the frequency converters, the counter rotating axial flow fanand the intrinsically safe power supply are arranged in an inlet alley; the air speed sensor 1 is arranged in the air inlet alley; the differential pressure sensor and the air speed sensor 2 are arranged in an air return alley; and the two carbon monoxide sensors are arranged in an air return corner region. Data such as carbon monoxide content, air quantity, air pressure and the like is real-timemonitored, ventilation quantity of a mining working surface is automatically controlled, so that the mining working surface and the environment air pressure automatically achieve dynamic balance, thus the safety production of the mining working surface is achieved when a plurality layers of mine goafs are communicated with each other, the working efficiency, the precision degree and the safety degree are improved; the fan is driven by frequency conversion, so that the fan has energy-saving effect, broad adaptability, social benefits and economic benefits.

Owner:DATONG COAL MINE GRP +2

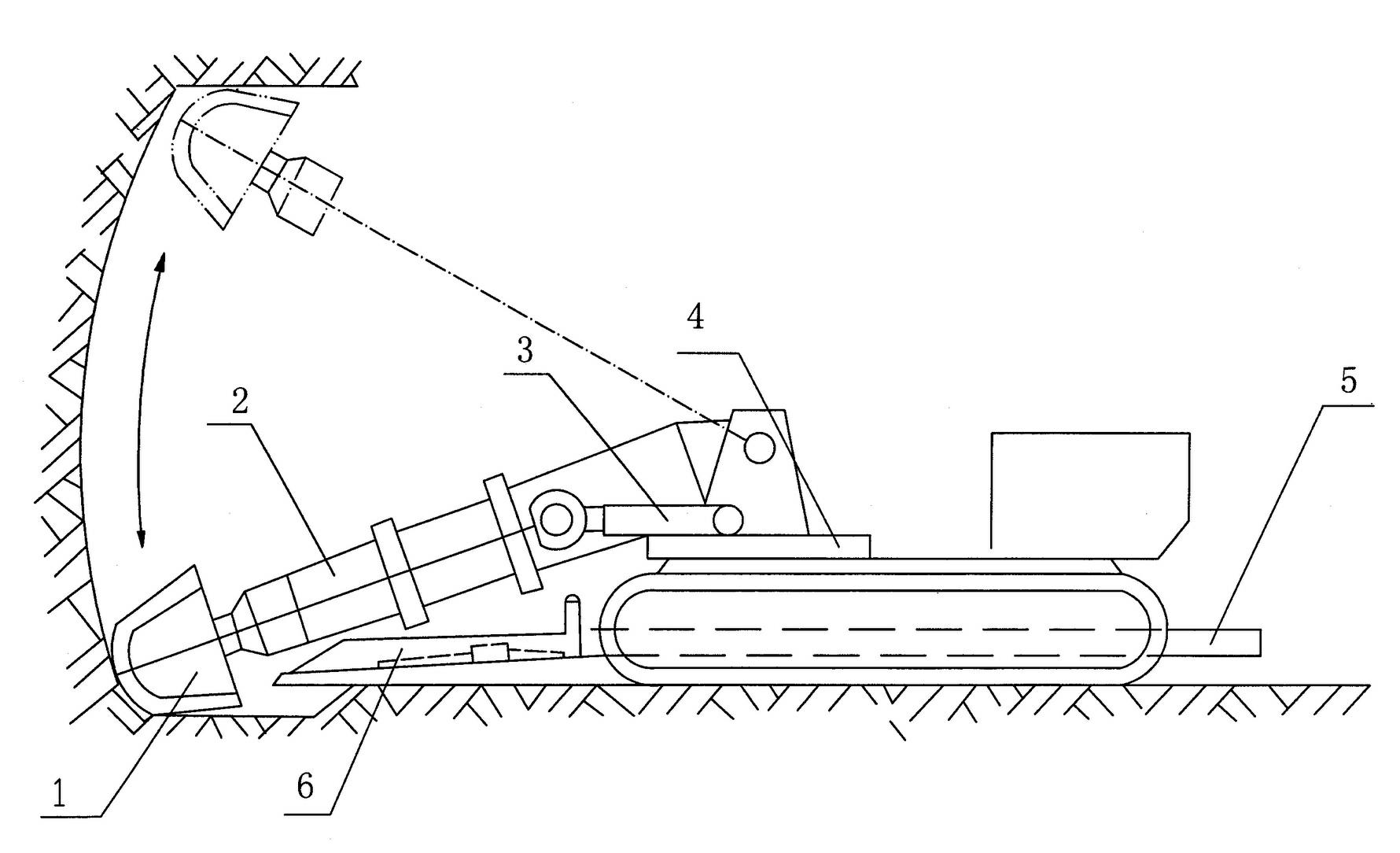

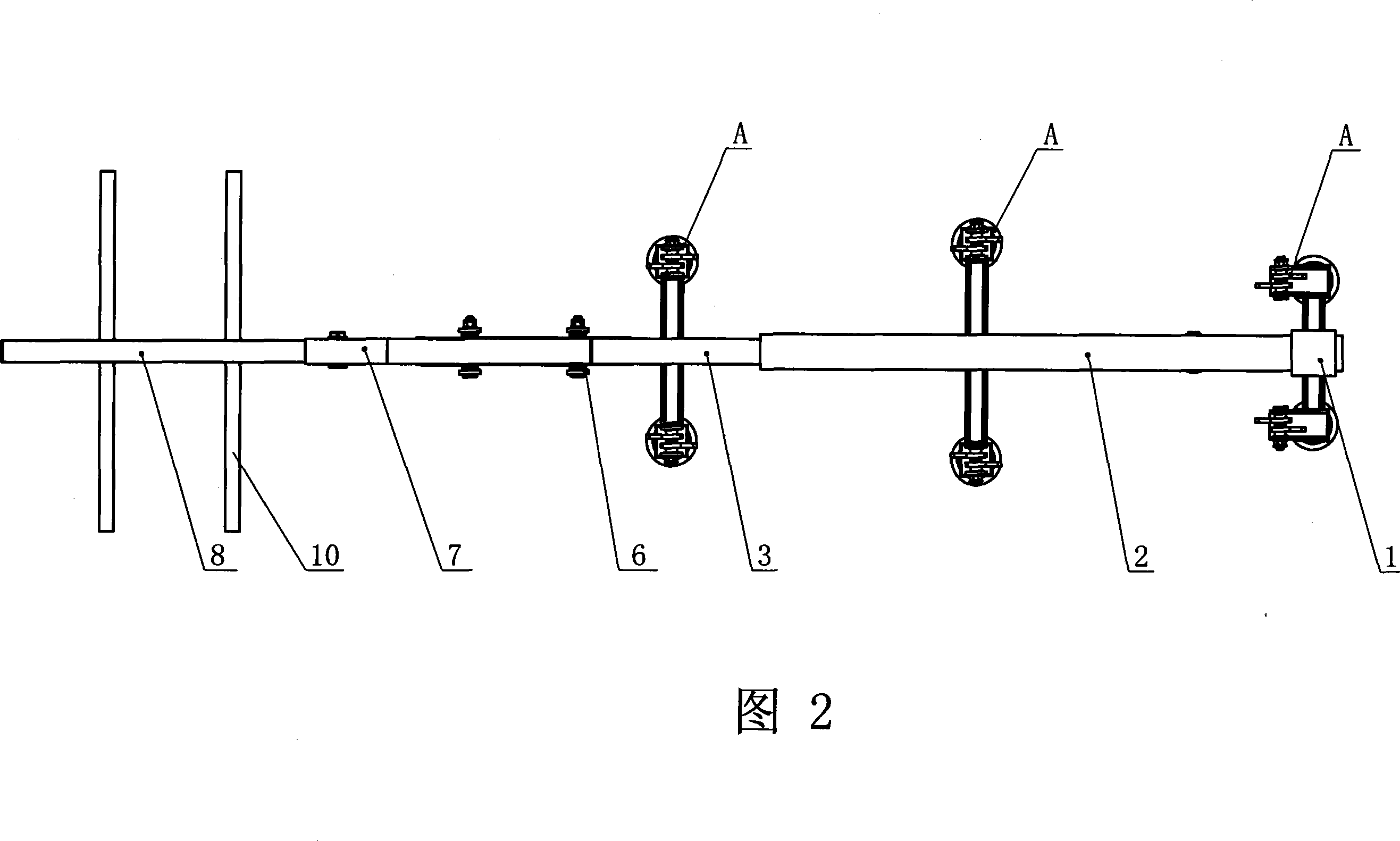

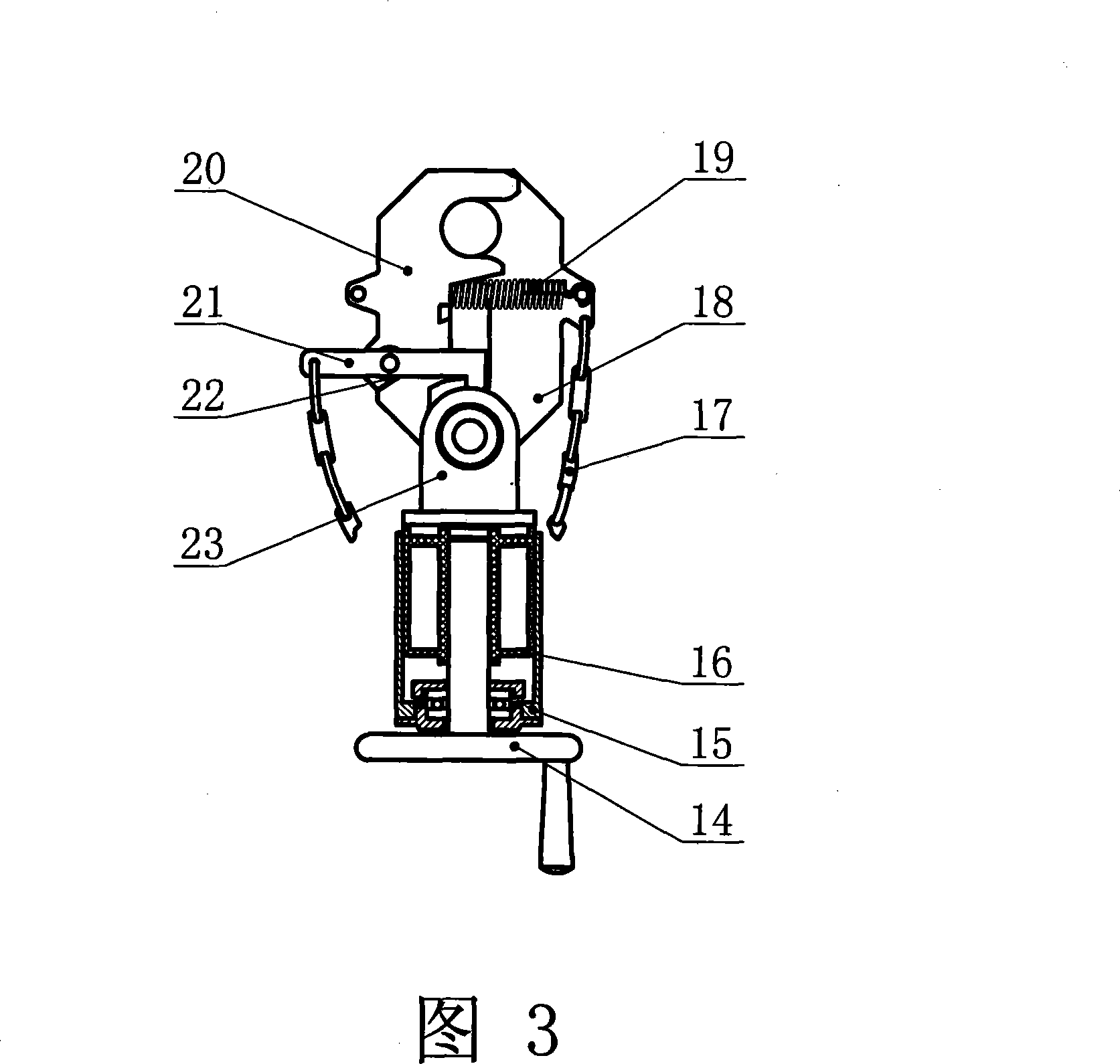

Method for mechanically mining coal by using steep seam pseudo inclination bracing type retractable flexible shield support

InactiveCN102562066ARealize mechanized miningStrong thicknessUnderground miningSlitting machinesHigh probabilityWorking environment

The invention discloses a method for mechanically mining coal by using a steep seam pseudo inclination bracing type retractable flexible shield support. By the method, a steep seam coal mining machine and a bracing type retractable flexible shield support are provided. The method comprises the following steps of: 1, mining, namely mining by arranging the coal mining machine on a pseudo inclination working surface; 2, loading and transporting the coal, namely raking a falling coal body to a conveying mechanism and conveying the falling coal body to the rear part of the coal mining machine by using left and right gathering arms of the coal mining machine, sliding the falling coal body to a coal sliding hole truck loading point through a sliding chute, loading and transporting; 3, supporting an operating area, namely arranging the bracing type retractable flexible shield support in the operating area; 4, ventilating the working surface; 5, atomizing for dust removal; 6, exploiting upper triangle coal; and 7, recycling lower triangle coal, namely dredging a finishing cut, lowering the shield support to a horizontal position gradually, disassembling and decomposing the coal mining machine, transporting to the next stoping working surface and completely recycling the shield support when the working surface is propelled to a place neara district rise hole. By the method, the problems of low recovery ratio, low mechanization degree, low single yield of the working surface, severe working environment, high probability of malignant accidents and the like in domestic and oversea steep seams can be radically solved.

Owner:袁野 +2

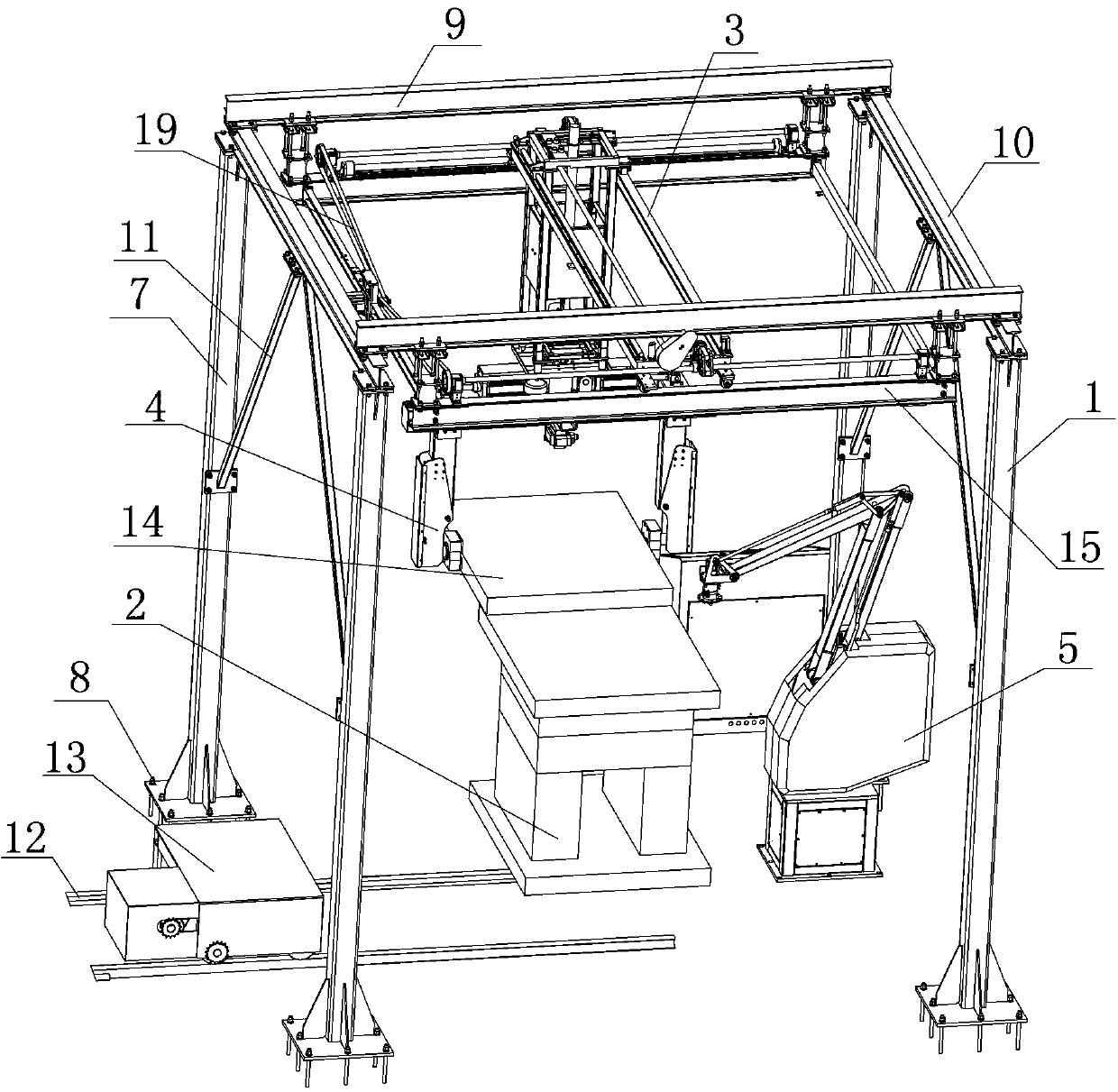

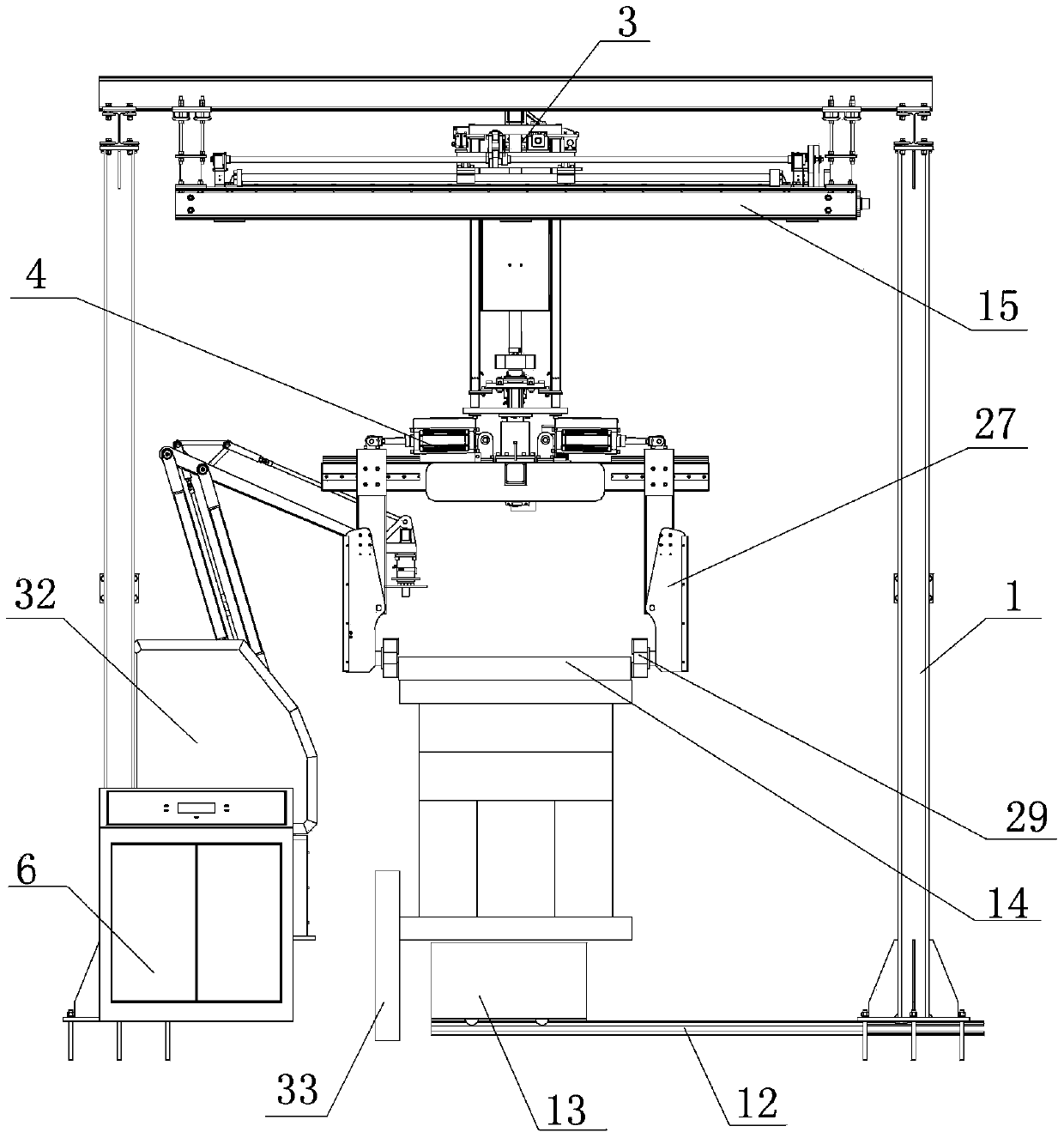

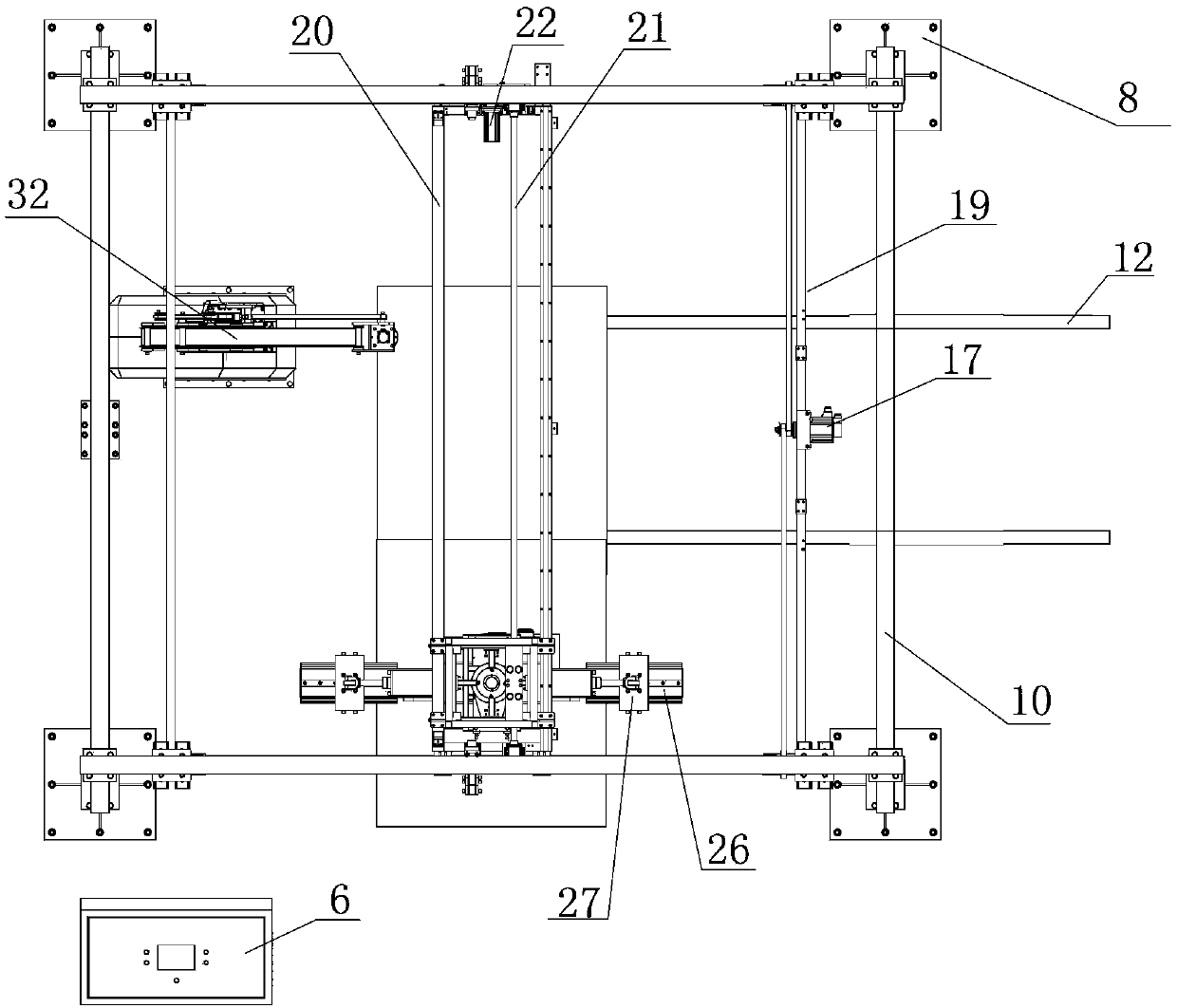

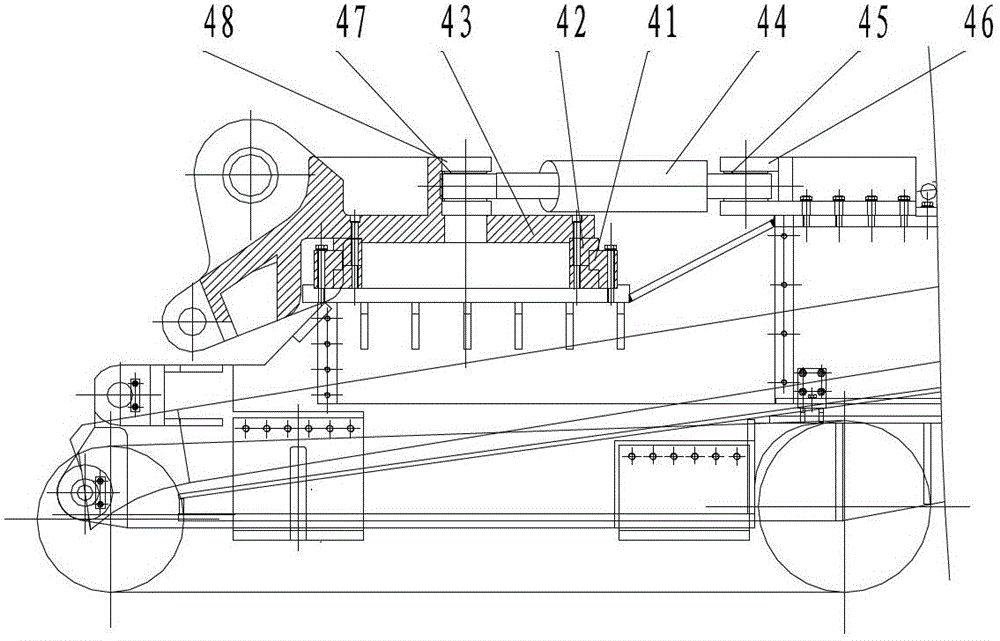

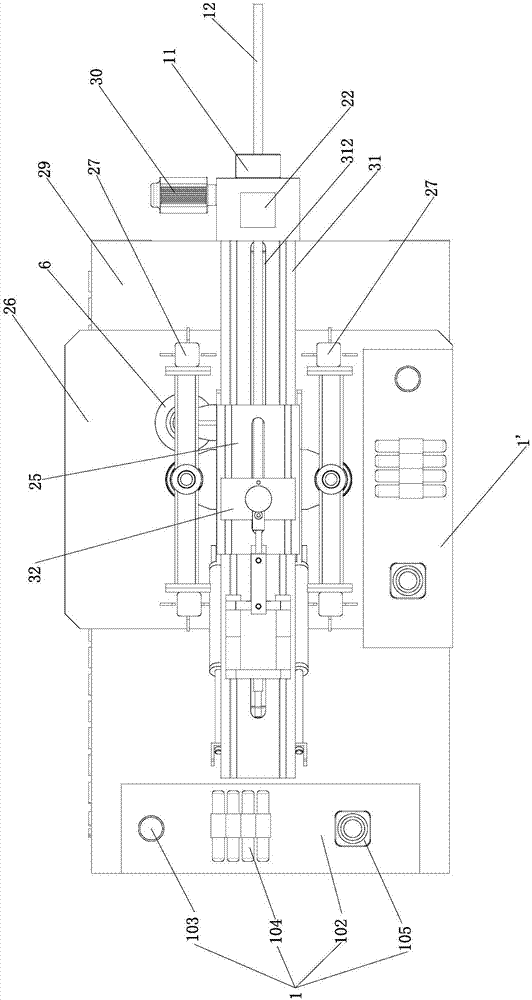

Injection mold automatically-disassembling device

The invention relates to an injection mold automatically-disassembling device. The injection mold automatically-disassembling device comprises a portal frame, a workbench for bearing a mold, a travelling mechanism for driving the mold to travel in the X-axis direction, the Y-axis direction and the Z-axis direction, a clamping and turnover mechanism for clamping and turning over the mold, a disassembling mechanism for disassembling the mold, and a control cabinet. The traveling mechanism is mounted on the portal frame, the clamping and turnover mechanism is mounted on the travelling mechanism, and the travelling mechanism, the clamping and turnover mechanism and the disassembling mechanism are connected with the control cabinet. The disassembling mechanism achieves disassembly of screws on the mold, and the clamping mechanism and the travelling mechanism achieves turnover, automatic hoisting and transportation of the mold, so that the injection mold automatically-disassembling device achieves automatic process of mold disassembly, facilitates mass assembly line operation, greatly improves the production efficiency, achieves safe production, reduces the labor intensity and labor costs, and meanwhile, by disassembling the mold through mechanical force, avoids damage to the mold and is safe and reliable.

Owner:QINGDAO HAIER MOLDS

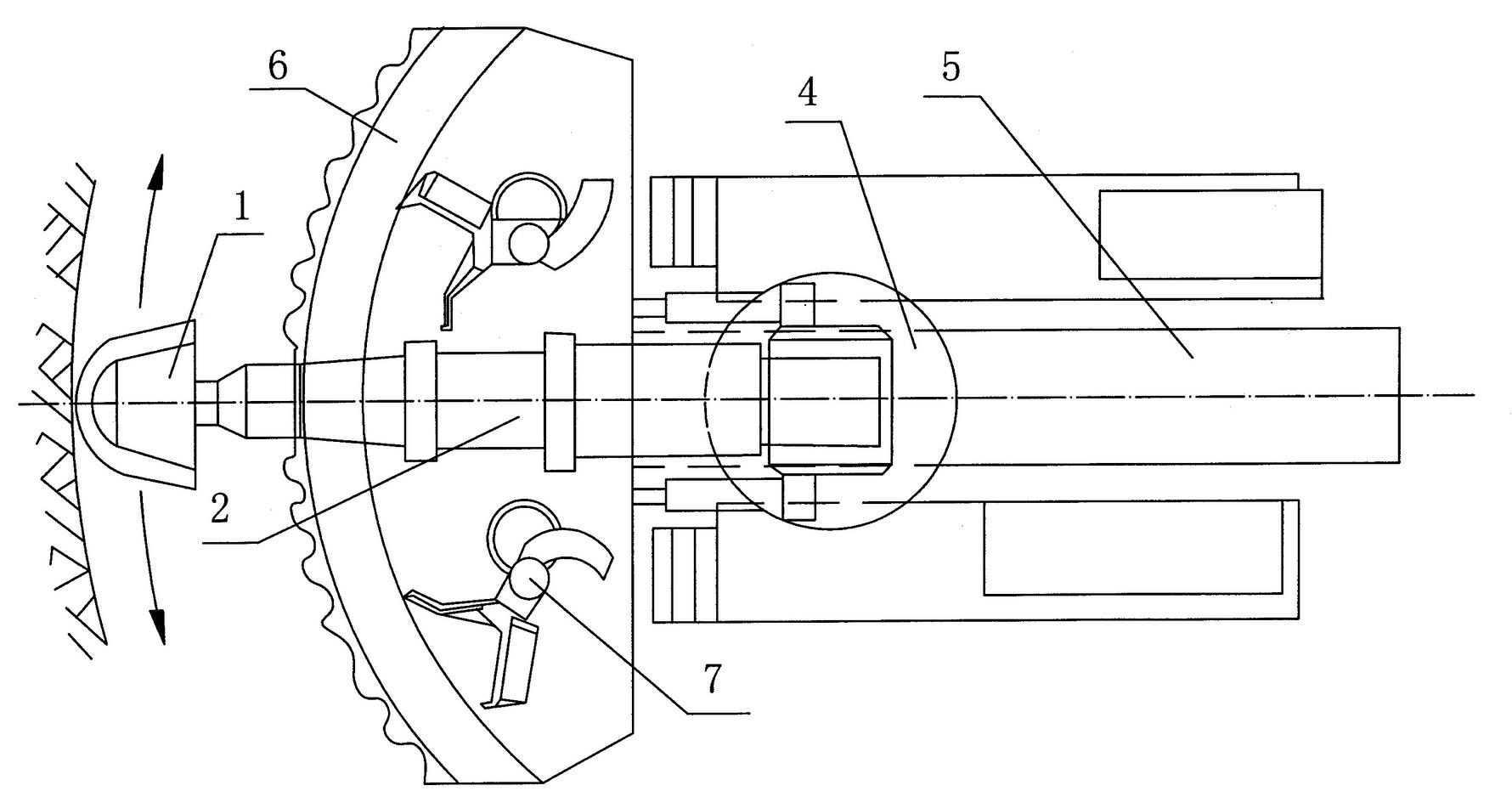

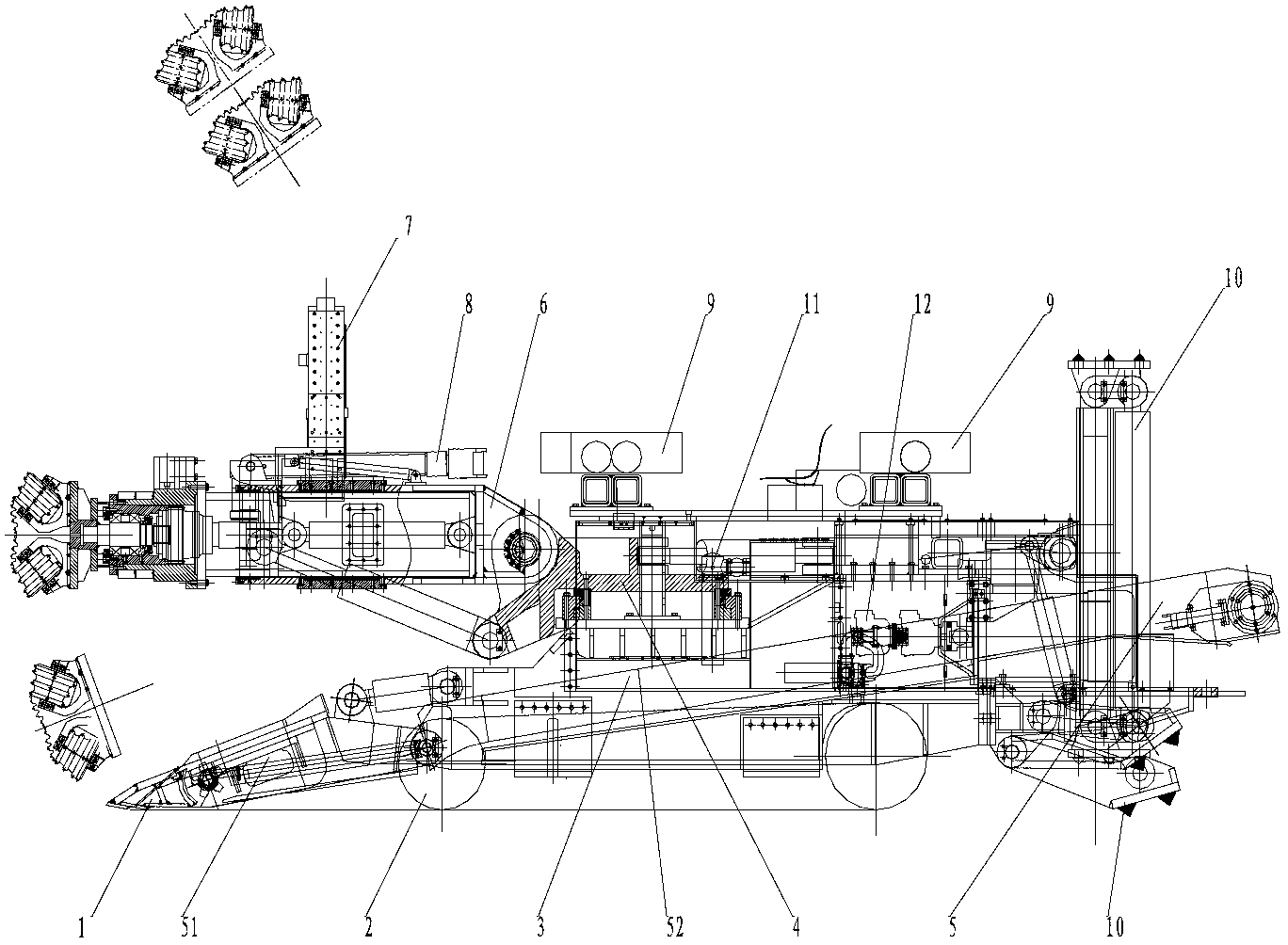

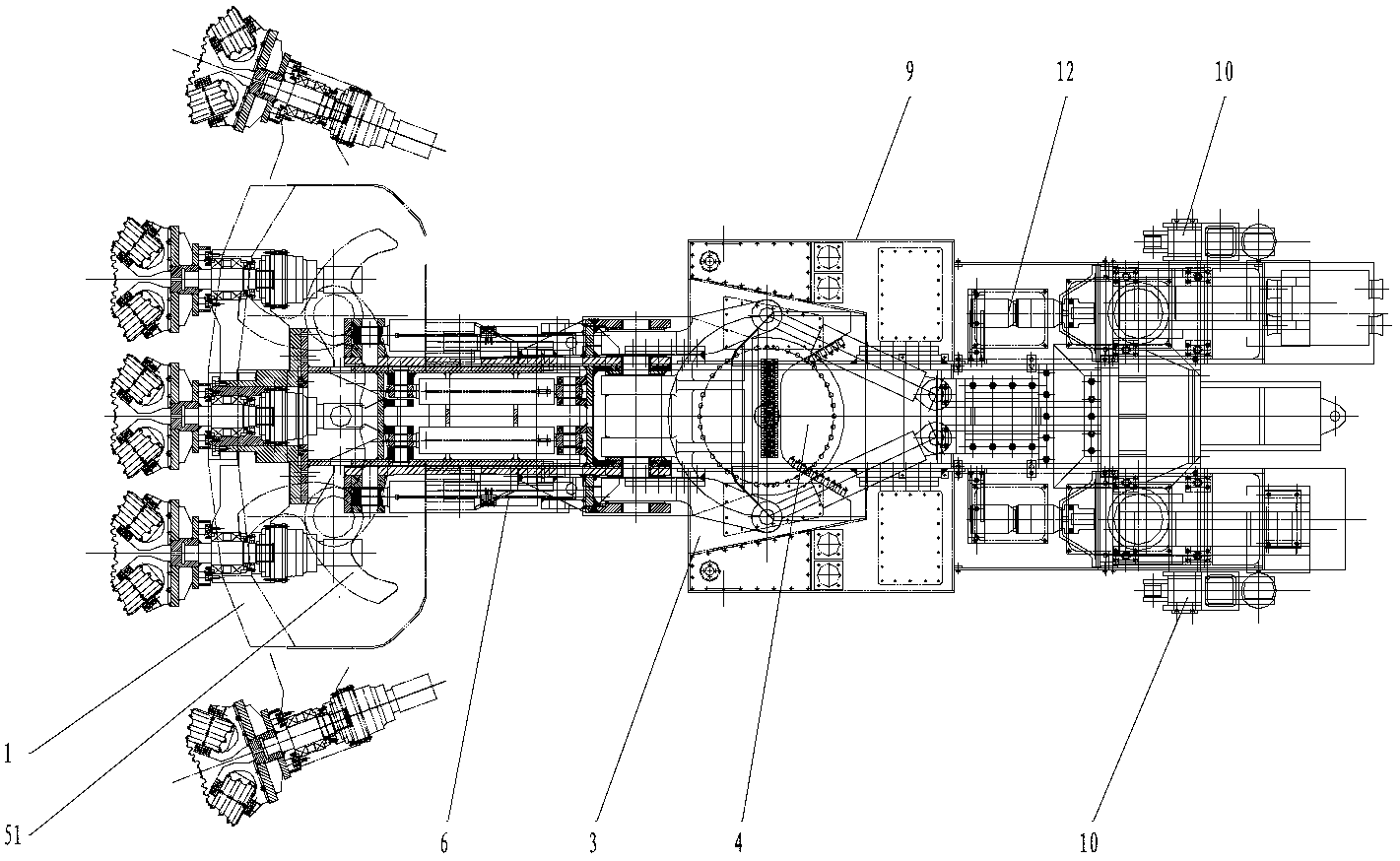

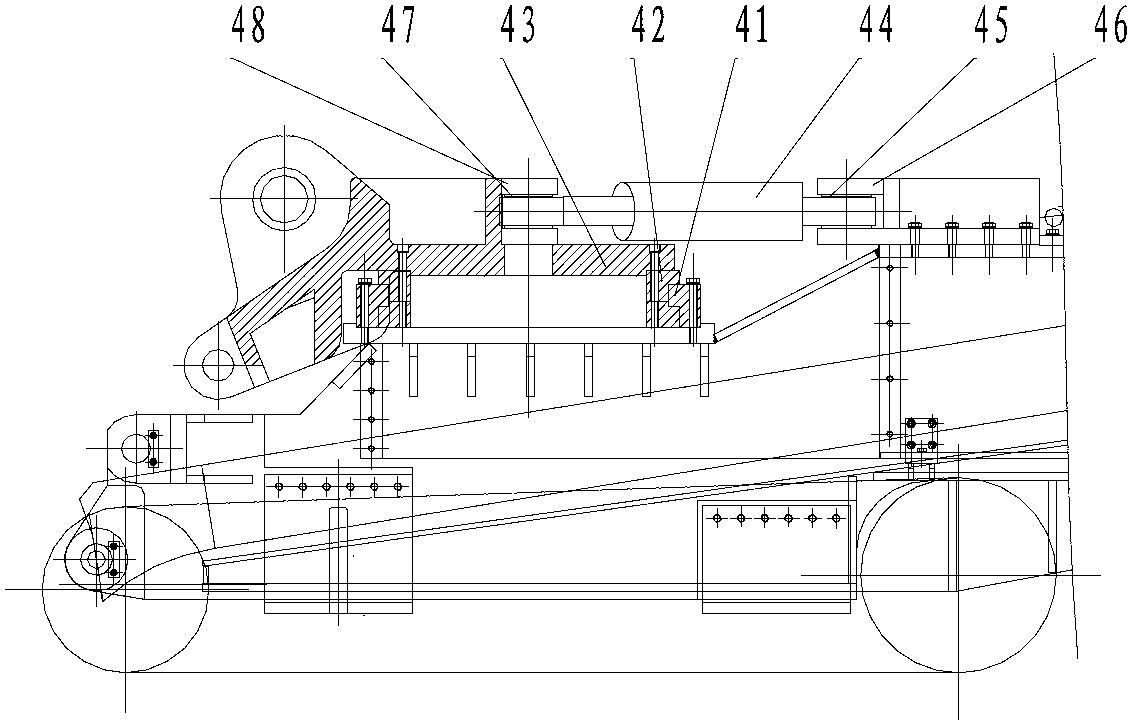

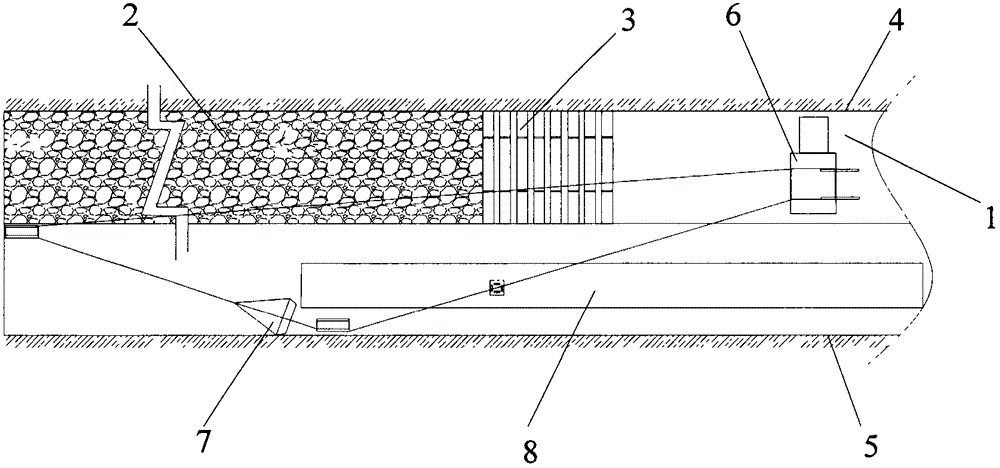

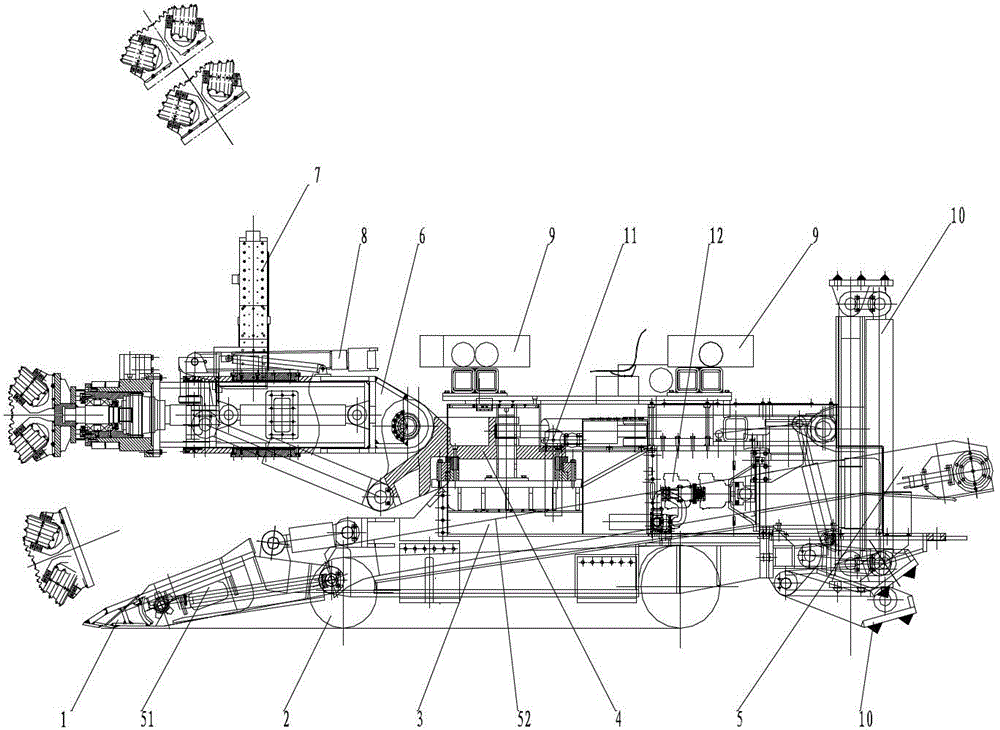

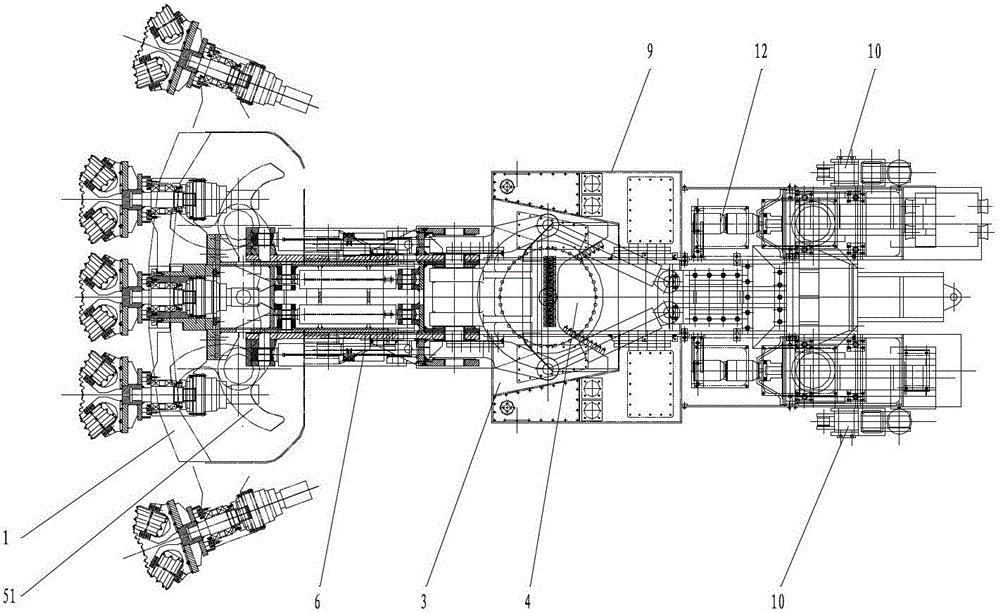

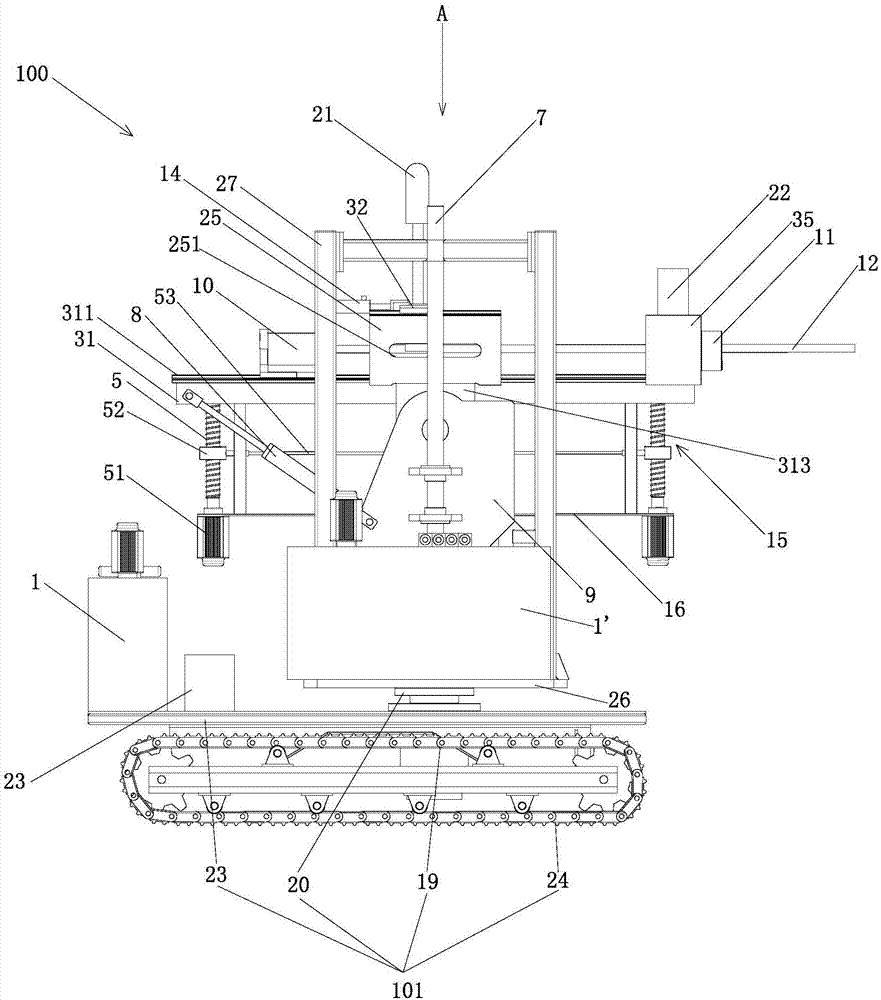

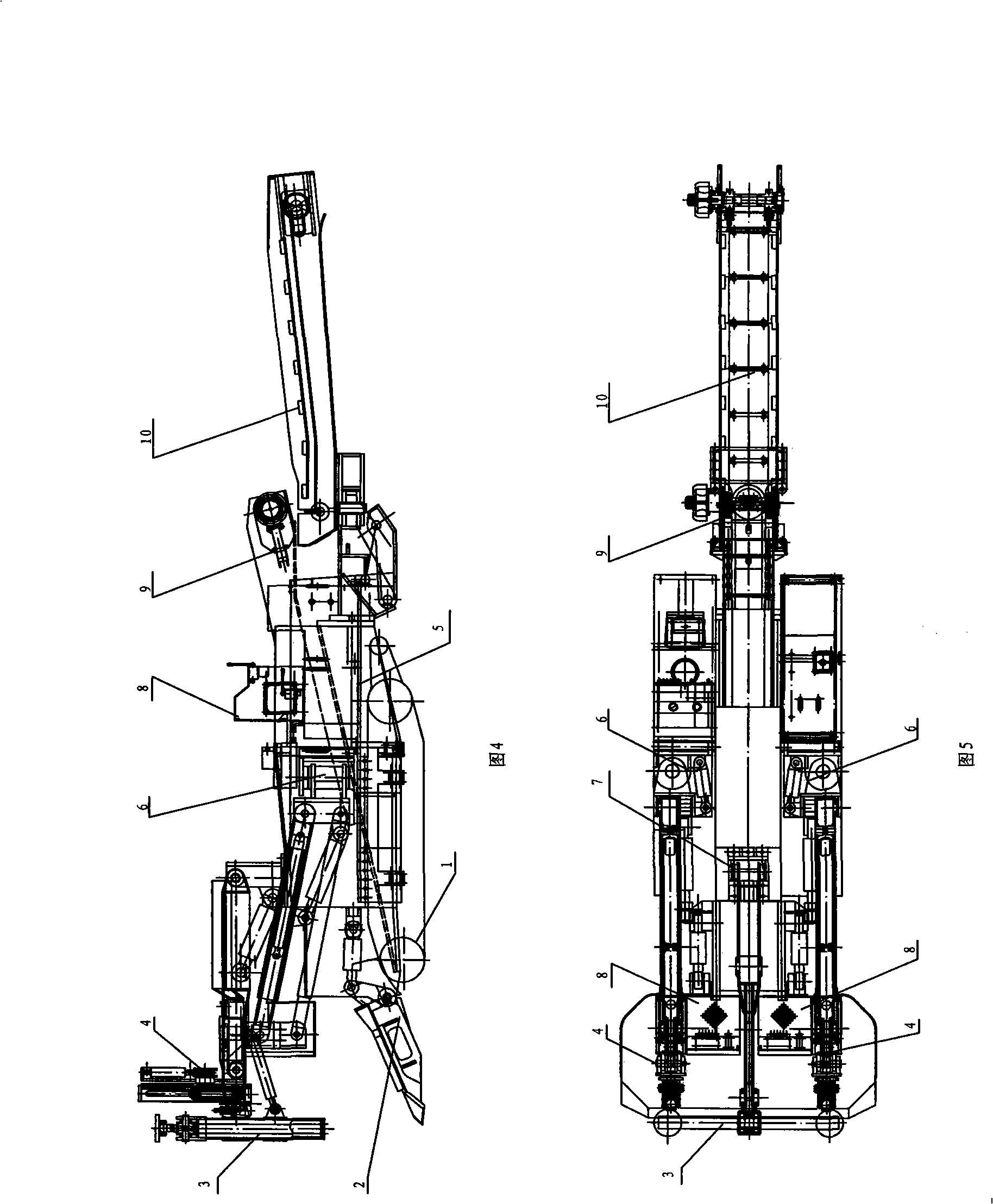

Comprehensive mechanization stone drift heading machine set

InactiveCN102704927AGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemEngineering

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

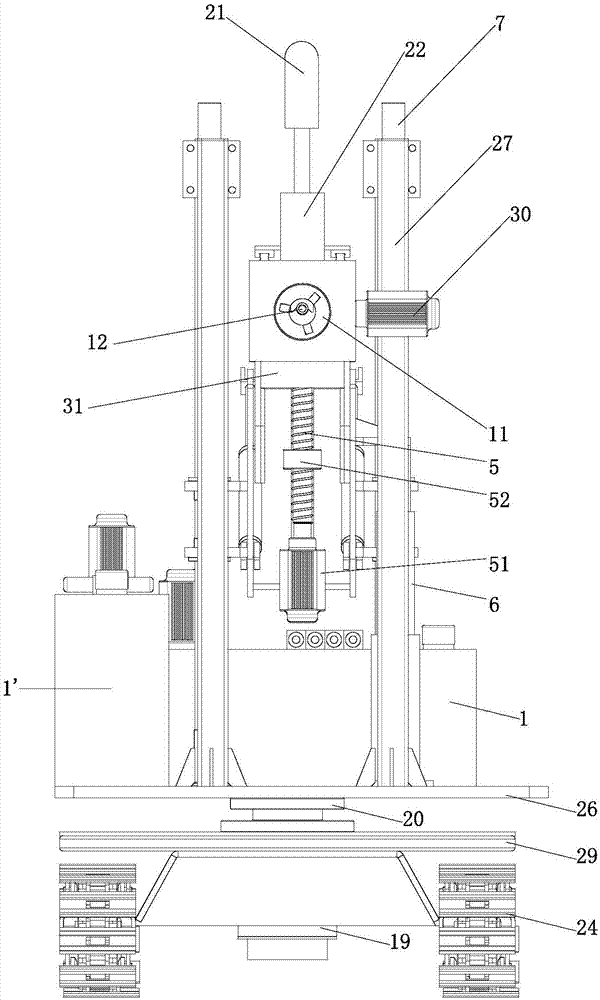

Intelligent robot capable of high-speed feeding and discharging

InactiveCN104440898AReduce volumeSmall inertia forceProgramme-controlled manipulatorGripping headsBall screwManipulator

The invention relates to an intelligent robot capable of high-speed feeding and discharging. An existing feeding and discharging device is complicated to operate. Accordingly, the intelligent robot capable of high-speed feeding and discharging comprises a stand column and a cross arm, wherein the stand column s provided with a vertical linear guide rail, a lifting block is arranged on the vertical linear guide rail, the cross arm is fixed to the lifting block, the lifting block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a lifting servo motor and sleeved with nuts of the ball screw pair, and the nuts and the lifting block are fixed together. The cross arm is provided with a horizontal linear guide rail provided with a slide block, a telescopic arm is fixed to the slide block, a sucker rack or a manipulator grabbing device is fixed to the front end of the telescopic arm, the slide block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a telescopic serve motor and sleeved with nuts of the ball screw pair, and the nuts and the slide block are fixed together. The intelligent robot has the advantages of being convenient to use, safe and efficient, thereby being suitable for various production enterprises needing workpiece carrying.

Owner:范克健

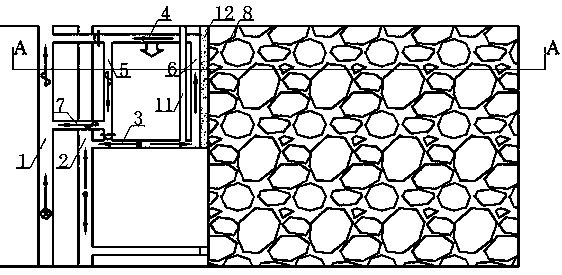

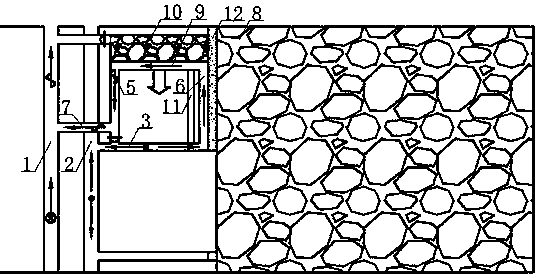

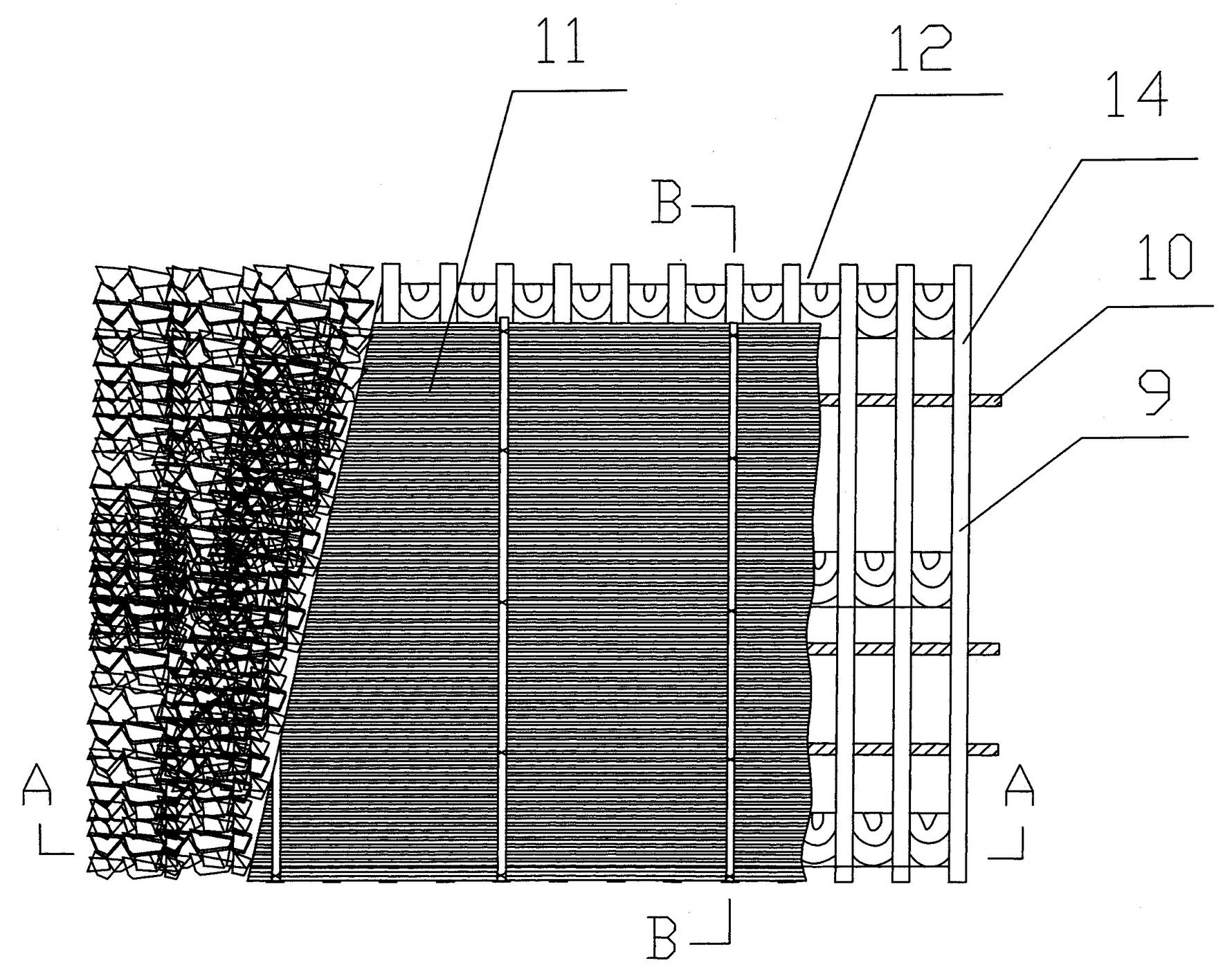

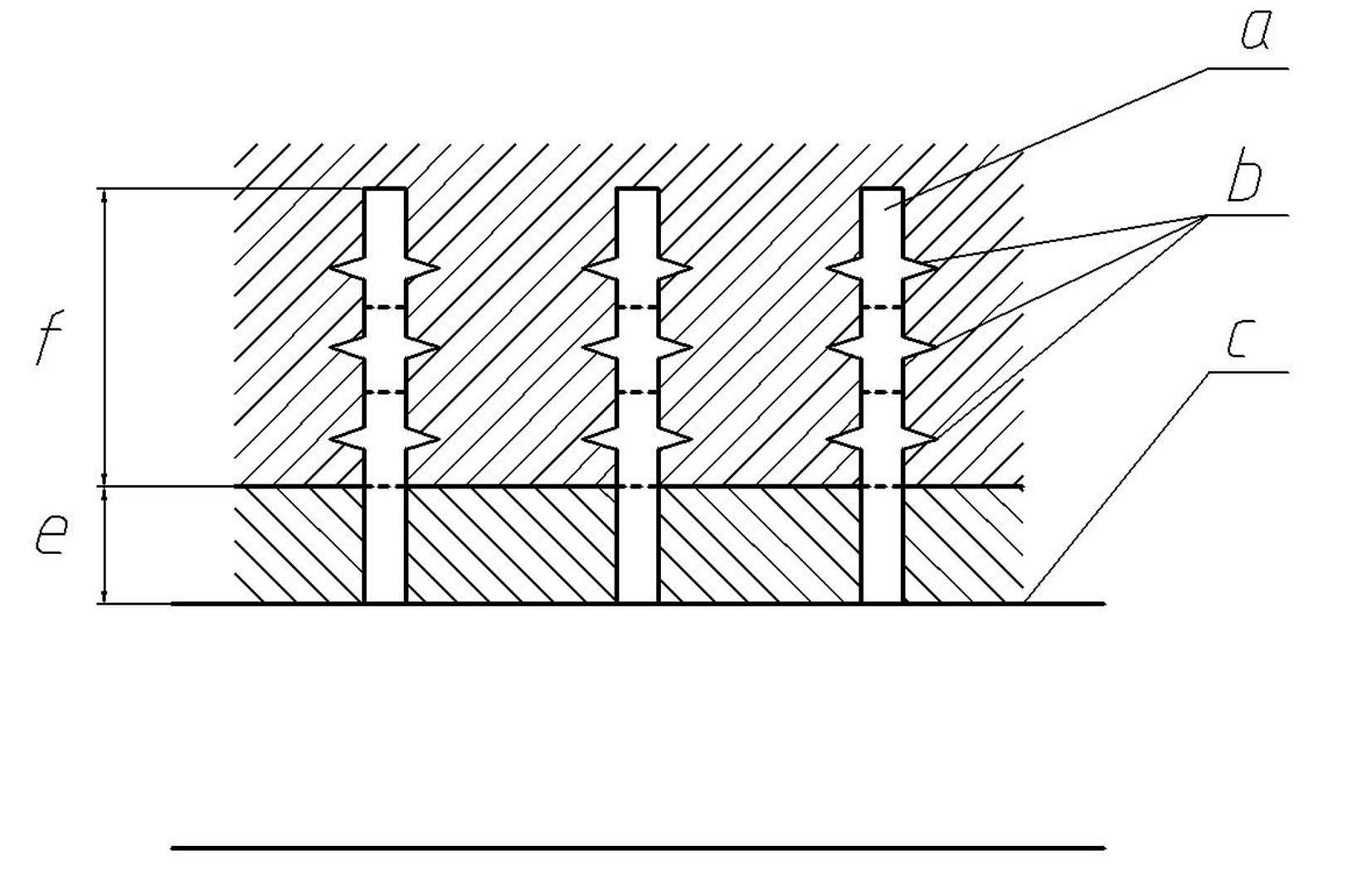

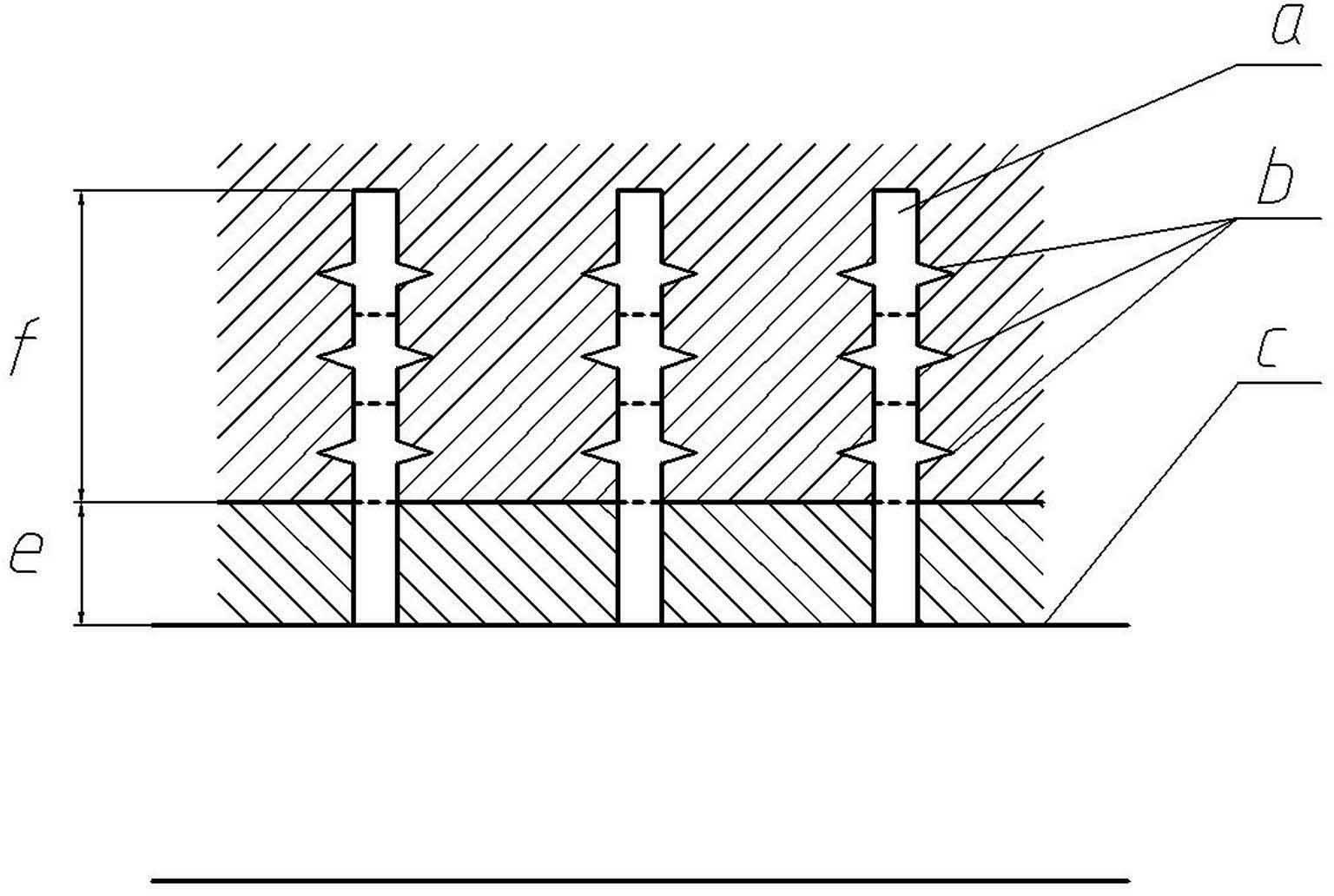

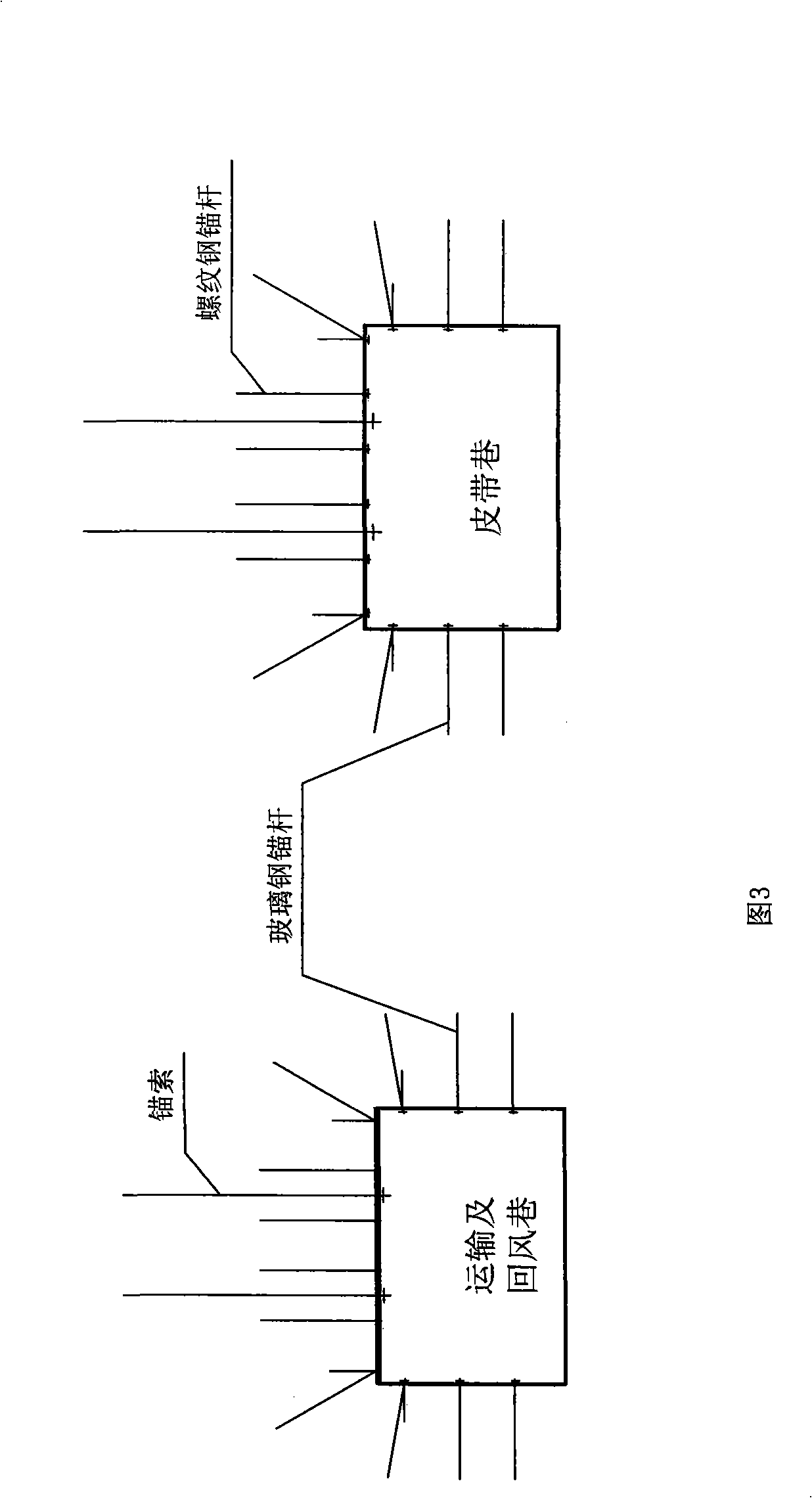

Goaf waste rock filling coal mining method of flexible shield support in half-edge coal seam

ActiveCN103061764ARealize safe productionAvoid pollutionUnderground miningSurface miningEngineeringSteel rope

The invention discloses a goaf waste rock filling coal mining method of a flexible shield support in a half-edge coal seam, comprising the following steps: firstly arranging an alley way before coal mining, wherein the inclined alley way is arranged along a pitching surface according to an angle of 23-25 degrees, mining along the inclined direction from top to bottom and along the trending from east to west; secondly using a flexible shield support for coal mining with coal mining method, using the flexible shield support on a mining surface, tightening among the flexible shield supports by using back boards, using a steel rope to connect into an integral flexible shield support, and separating the goaf waste rock and coal mining space; and finally carrying out goaf waste rock filling. Through the method, safe production of half-edge coal seam can be realized, and simultaneously the handling problem of waste rock produced in underground coal mine can be solved.

Owner:BEIJING HAOHUA ENERGY RESOURCE

Phytoremediation method for cadmium polluted farmland

InactiveCN102114490ALarge biomassMake the most of planting timeContaminated soil reclamationPotassiumPhytoremediation

The invention relates to a phytoremediation method for a cadmium polluted farmland, comprising the following steps of: in a cadmium polluted farmland containing cadmium of below 8mg / kg, planting grain amaranth and red leaf amaranth in a crop rotation mode, applying potassium fertilizer, harvesting for many times, and concentrating all plant materials for landfill. According to the phytoremediation method for a cadmium polluted farmland, planting is performed thrice per year, wherein the grain amaranth is planted twice, and the red leaf amaranth with a short crop rotation period is planted between double planting of the grain amaranth, thus optimizing the arrangement of crop rotation; and on management, the grain amaranth planted for the first time is cut twice to fully utilize the favorable growing conditions in summer and accumulate more biomass, and the grain amaranth planted finally is not cut but grows to be ripe, thus optimizing the accumulation of biomass and the work efficiency. Such a crop rotation mode fully utilizes the planting time in a year, and is conductive to the growth of the grain amaranth planted thirdly. The invention has the advantages of high efficiency, easiness in operate, no secondary pollution and low cost.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Stratified blasting method for coal mine hard roof

Owner:DATONG COAL MINE GRP

Data-based urban sewage pumping station system modeling method

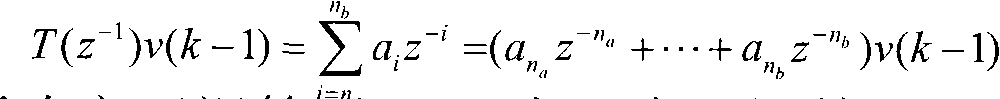

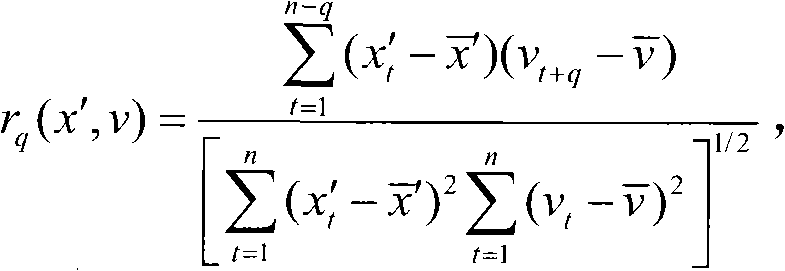

The invention relates to a data-based urban sewage pumping station system modeling method. The conventional modeling for a drainage pipeline network pumping station model has high complexity. The method comprises the following steps: firstly, establishing a predicting model for a drainage pipeline network pumping station; secondly, preprocessing original data acquired by an SCADA system; thirdly, determining a model set type and identifying a model structure and a model parameter; and finally, performing online dynamic modification on the model parameter. The method of the invention breaks through a constraint that mechanism characteristics are required to be understood completely in the conventional modeling, the modeling time is relatively short and the obtained model structure is relatively simple.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

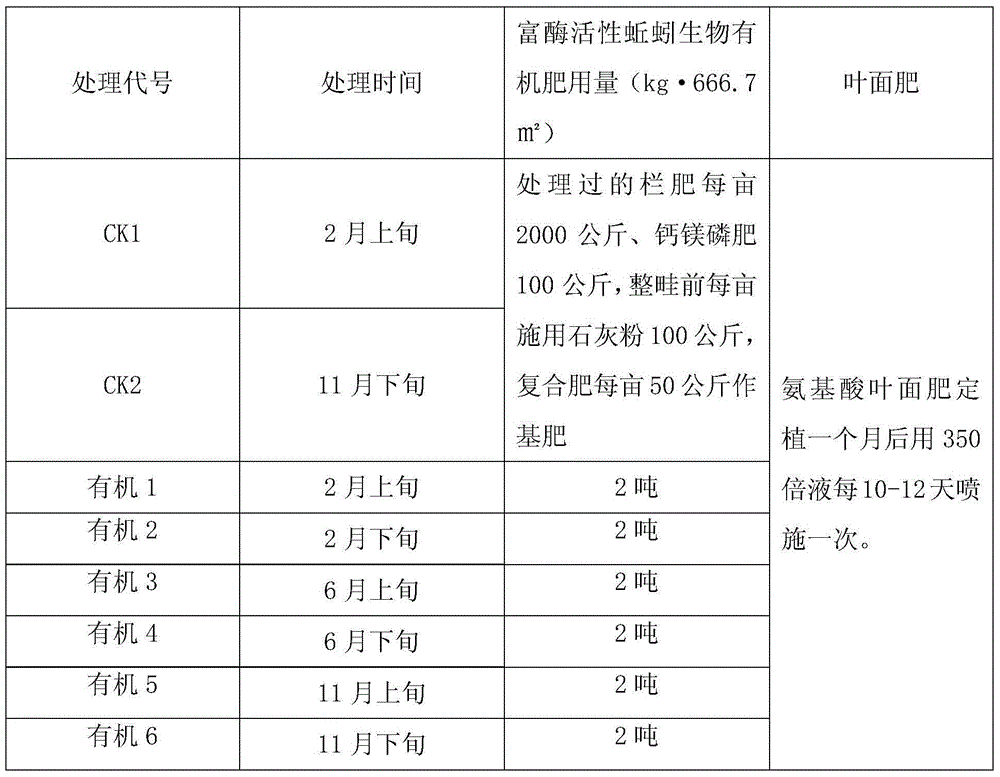

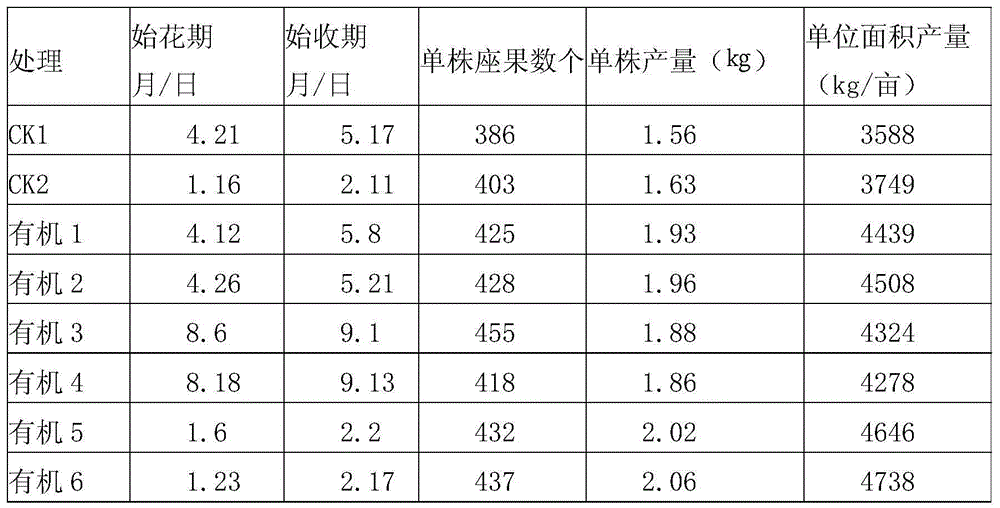

Organic tomato health cultivating method

InactiveCN104429581ASolving Chemical PollutionIncrease cationic fertilizer sourceFertilising methodsCultivating equipmentsFlavorNutritional quality

The invention provides an organic tomato health cultivating method which is the health growing cultivating technology combining a biological organic fertilizer system, an endogenous hormone control system and a pest control and prevention system. The method systematically solves the four problems of how to prevent nitrite accumulation and pesticide environmental pollution and poor nutritional quality and flavor quality perplexing organic plantation for a long time. Low-cost production of organic tomato growth cultivation is achieved, chemical fertilizer and chemical pesticide pollution is eliminated for planted tomato products, the soil environment is improved, and the requirements for health, high yield and high efficiency are met.

Owner:GUANGXI POLYTECHNIC

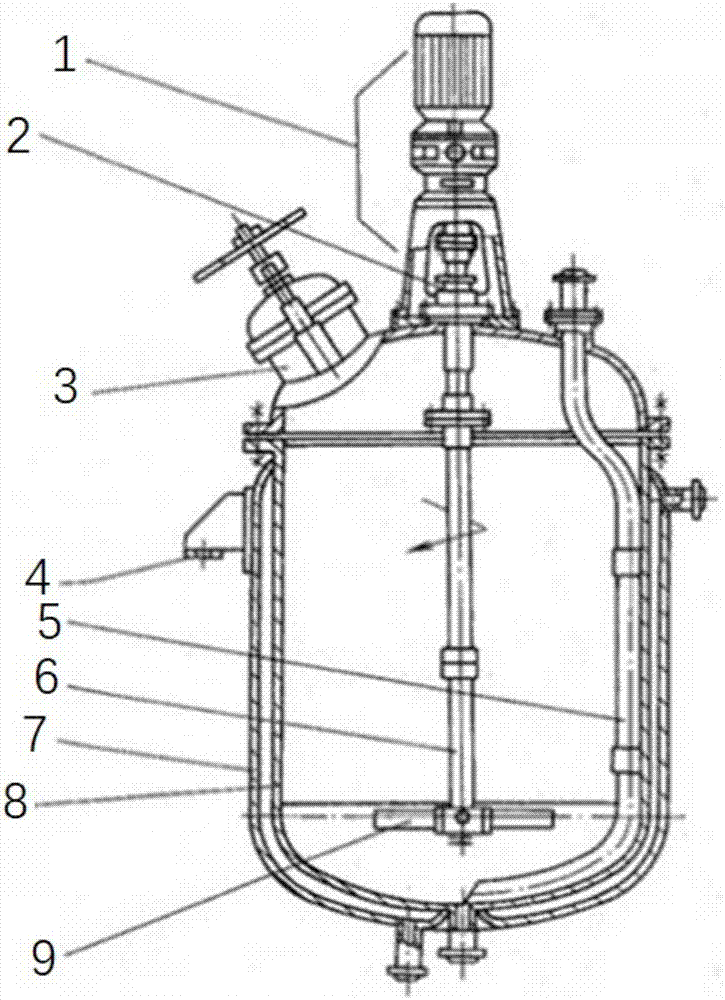

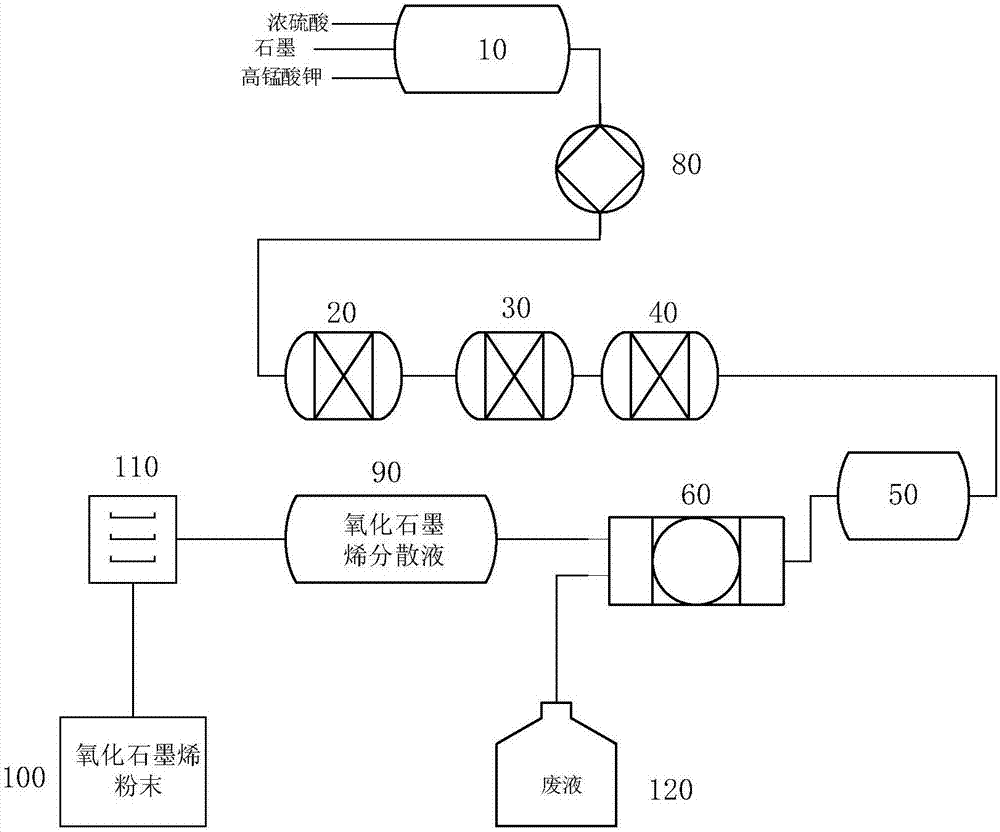

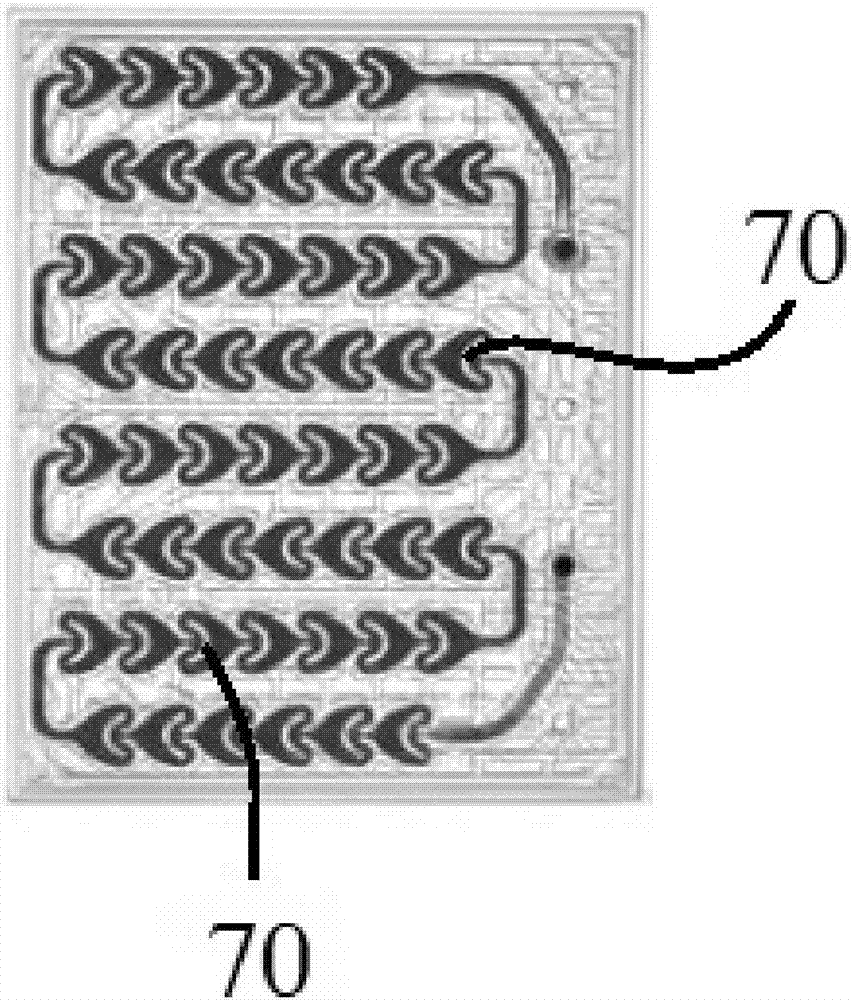

Method and equipment for preparing graphene oxide

PendingCN107879337ARealize safe productionImprove reaction yield and selectivityCarbon compoundsCross-flow filtrationGraphite oxide

The invention provides a method and equipment for preparing graphene oxide. The equipment comprises a premixer, a microchannel reactor, a collecting tank and a cross flow filtration device which are sequentially connected. According to the equipment provided by the invention, the microchannel reactor is used as a reaction device and is designed according to the characteristics of a reactant and areaction process, and the premixer, a metering pump, a cross flow reaction device and the collecting tank are organically assembled, so that the reaction efficiency is increased, and the production safety is improved. The equipment provided by the invention is more suitable for large-scale production of graphene oxide.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

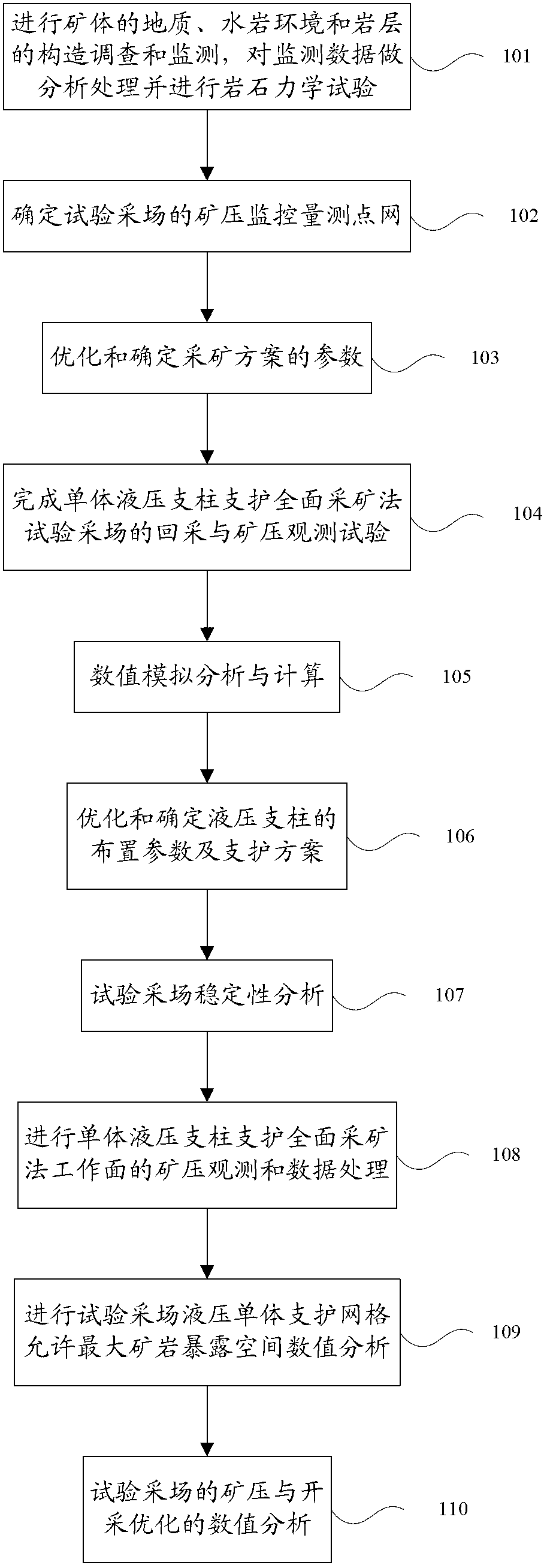

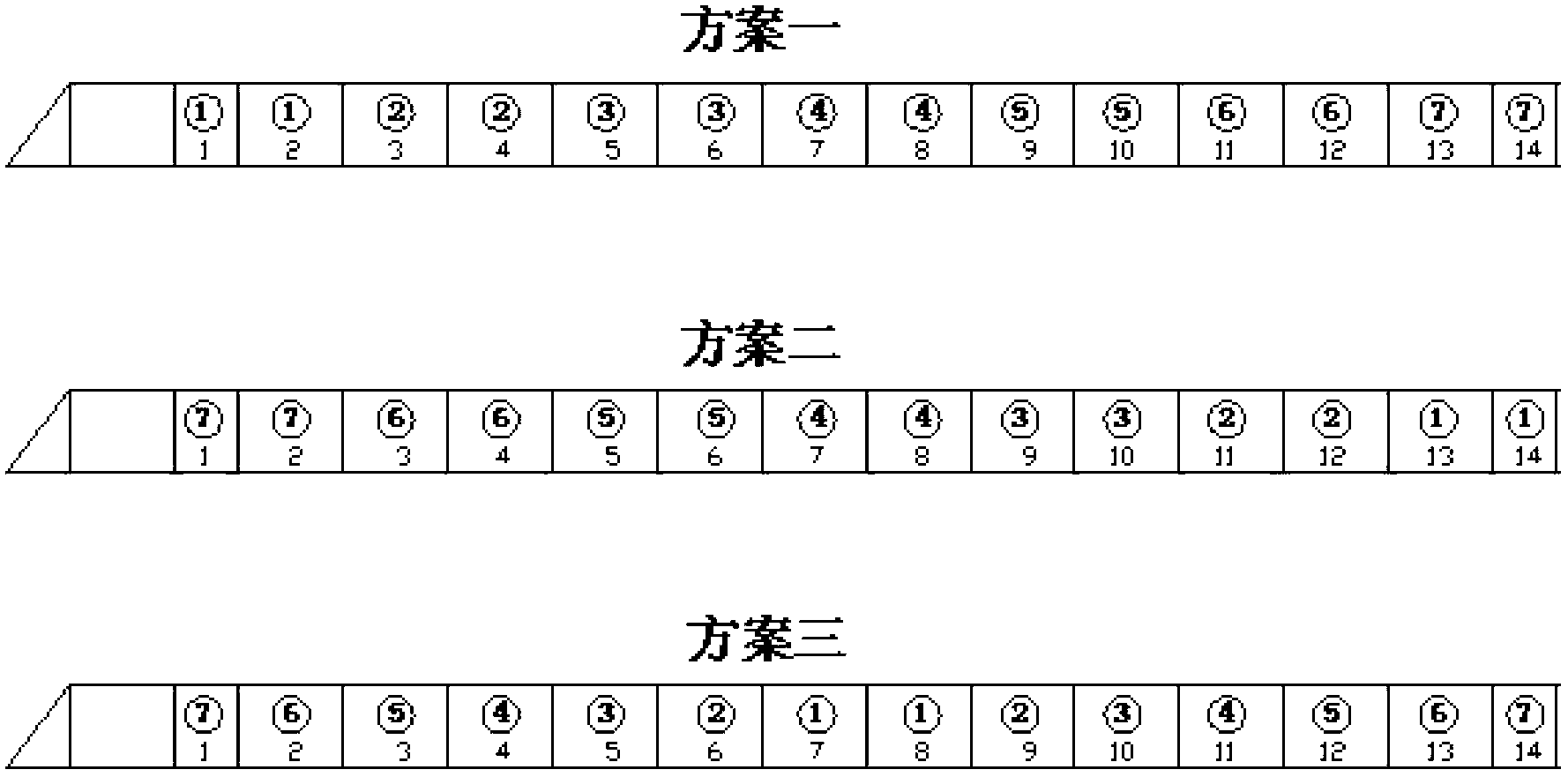

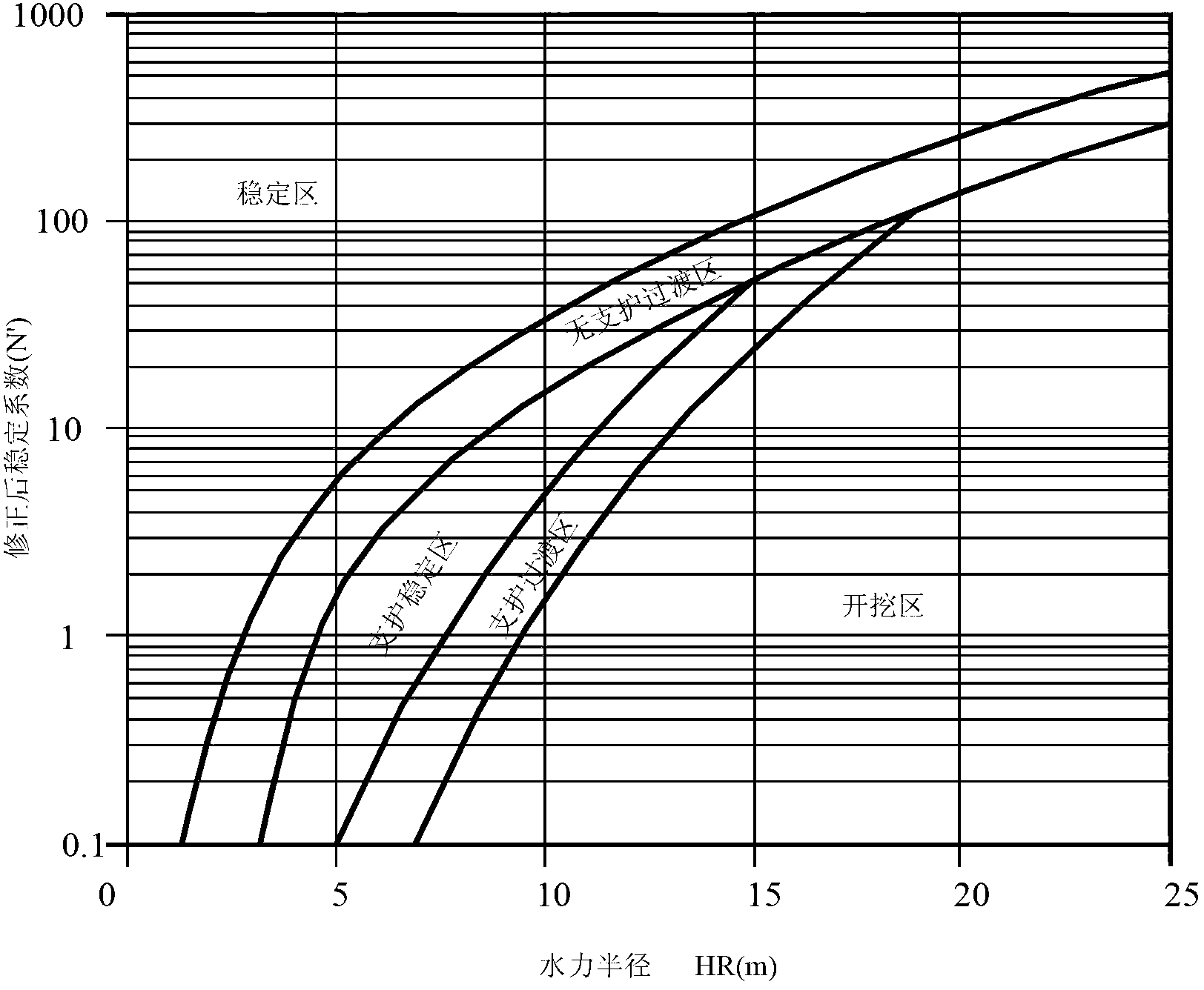

Method for utilizing hydraulic support to improve bauxite recovery rate

ActiveCN102852524AImprove recovery rateReduce consumptionUnderground miningSurface miningNonferrous metalData treatment

The invention discloses a method for utilizing a hydraulic support to improve a bauxite recovery rate and belongs to a nonferrous metal mining technology. The method comprises the steps of carrying out analysis treatment on monitoring data and carrying out rock mechanical test; determining a mine pressure monitoring measuring point net of a test mining field and parameters of a mining scheme to complete recovery of the test mining field and a mine pressure observation test; determining distribution parameters and a support manner of the hydraulic support; carrying out mine pressure observation and data treatment on a working surface; carrying out maximal allowable mine rock exposing space numerical value analysis of a hydraulic single body support gridding of the test mining field; and carrying out numerical value analysis on the mine pressure and the mining optimization of the test mining field. A single hydraulic support and a comprehensive mining method mining technology are combined to create a novel recovery process of a slowly-inclined thin ore; and the hydraulic support is used for replacing a natural ore column to recover the ore to the greatest extent, so that the recovery rate of the bauxite ore is improved, the consumption amount of pit woods is reduced and the production efficiency is improved. According to the method disclosed by the invention, the safe production is realized, the cost is saved, the benefit is increased and the service life of a mine is prolonged.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

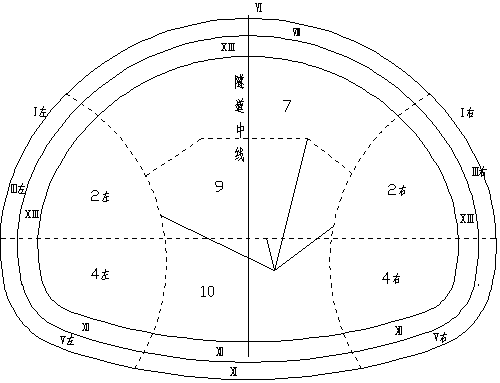

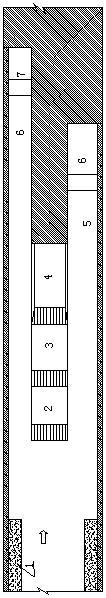

Underpass superhighway tunnel trunk excavation static blasting construction method

The invention relates to a tunnel blasting excavation method, in particular to an underpass superhighway tunnel trunk excavation static blasting construction method. Trunk excavation and support include the following steps of pilot tunnel ahead ductile grouting pre-supporting, left or right pilot tunnel upper half section excavation, left or right pilot tunnel upper half section preliminary supporting, left or right pilot tunnel lower half section excavation, left or right pilot tunnel lower half section preliminary supporting, main tunnel ahead ductile grouting pre-supporting, main tunnel upper annular excavation, main tunnel arch pre-supporting, main tunnel middle core soil excavation, main tunnel inverted arch partial excavation, main tunnel inverted arch pre-supporting, main tunnel inverted arch pouring, and using a static blasting method for construction. By means of the underpass superhighway tunnel trunk excavation static blasting construction method, damage to tunnel preliminary supporting and the adverse effect on stratum by blasting vibration are reduced, existing structures are protected, and safety production is achieved.

Owner:CHINA RAILWAY 16TH BUREAU GRP 5TH ENG

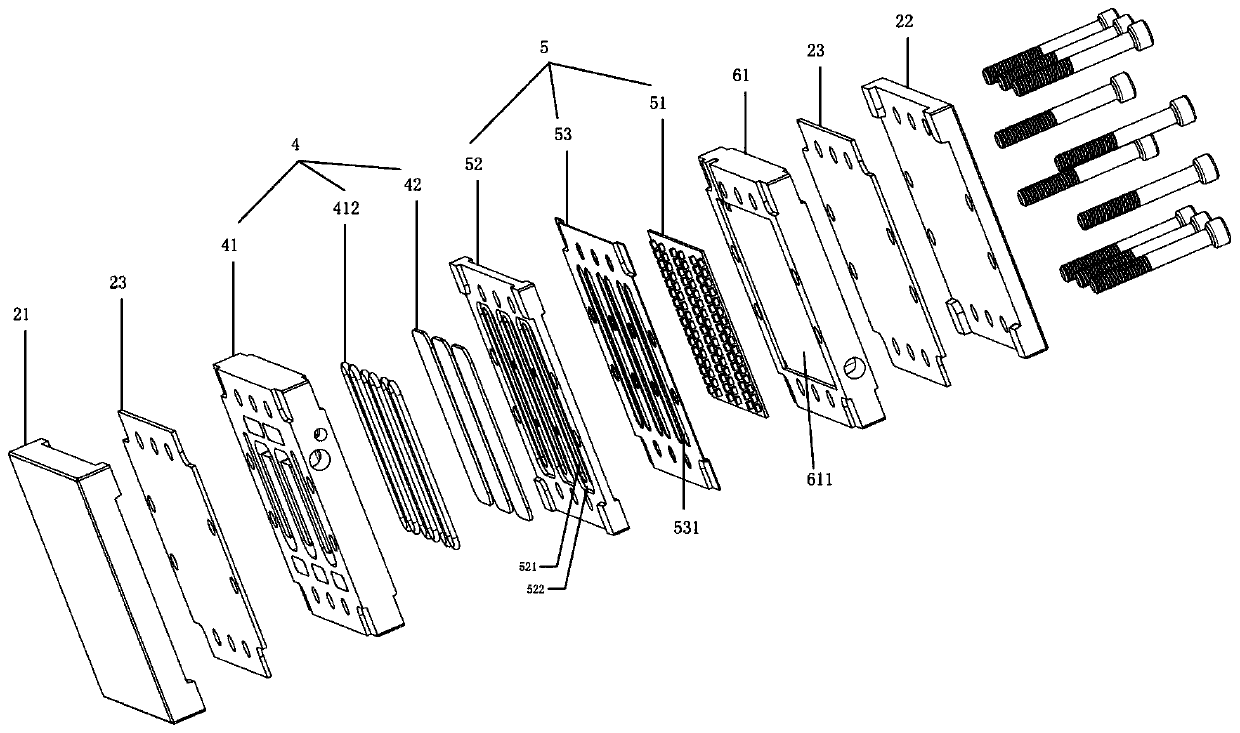

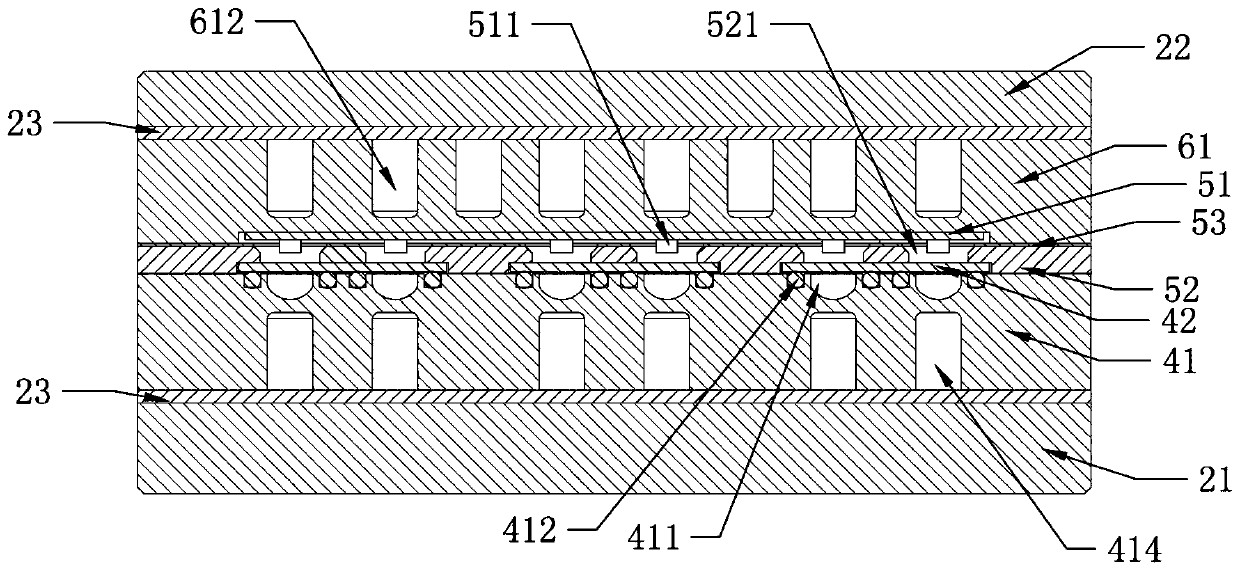

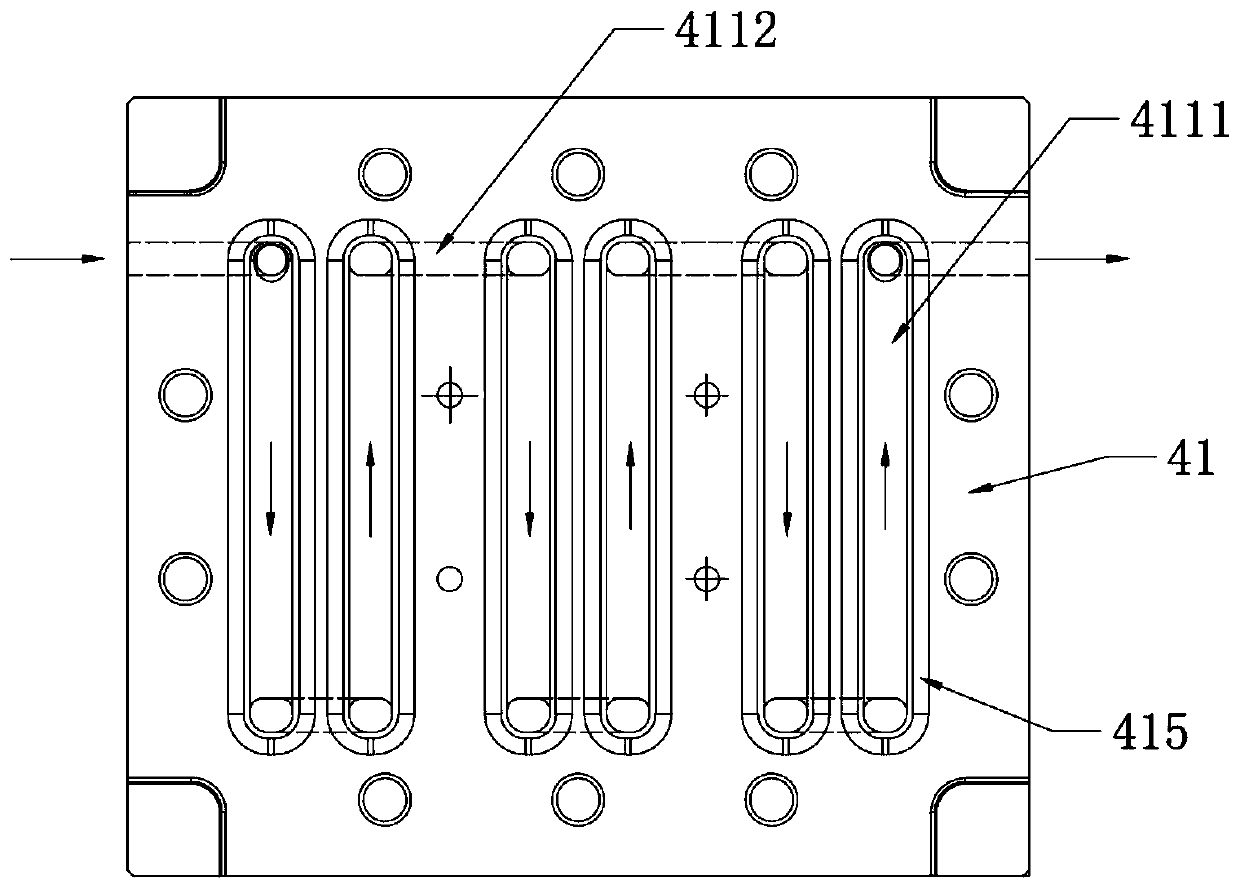

Continuous flow photochemical reactor

ActiveCN110252224ASmall device sizeCompact structureEnergy based chemical/physical/physico-chemical processesContinuous flowLight source

The invention discloses a continuous flow photochemical reactor, which comprises a reaction chamber for photochemical reaction, a temperature control chamber for temperature control of the reaction chamber and a light source control chamber for light source regulation. Specifically, the reaction chamber comprises a shell and a reactor module located in the shell, and the reactor module comprises a photochemical reaction unit, a light source module arranged outside the photochemical reaction unit, a light source heat dissipation module and a reactant temperature control module. Specifically, the reactor module comprises a reaction bin plate, a quartz glass board, a quartz plate fixed cover plate and a light source plate that are stacked sequentially. The continuous flow photochemical reactor not only can realize all-range photochemical reaction in all-ultraviolet band and visible light band, but also has the advantages of compact structure, small volume, good sealing performance, high product yield, large output, long service life, convenient maintenance, highly controllable temperature and reaction process, is suitable for industrial application, and meets the requirements of green chemical pharmacy.

Owner:黄位凤

Control method for free oxygen in ultralow-carbon and low-aluminum steel

ActiveCN108998613ARealize safe productionBillet quality without defectsManufacturing convertersSlagOxygen

The invention relates to a control method for free oxygen in ultralow-carbon and low-aluminum steel. The ultralow-carbon and low-aluminum steel production technology includes molten iron pretreatment,converter smelting, RH furnace vacuum refining and continuous casting. Powder spraying desulfuration is adopted in molten iron pretreatment, converter boiling and tapping are conducted, top slag modification is conducted, RH refining is conducted, decarburization and deoxygenation are finished, the weight percent of the free oxygen in the steel is finally controlled to range from 0.002% to 0.005%, and the weight percent of Als is smaller than or equal to 0.003%. By means of the control method, safety production of a continuous casting machine can be achieved, a casting blank is free of defects in quality, and the continuous casting furnace number is three or more.

Owner:ANGANG STEEL CO LTD

Comprehensive mechanization stone drift heading machine set

InactiveCN102704927BGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemElectric control

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

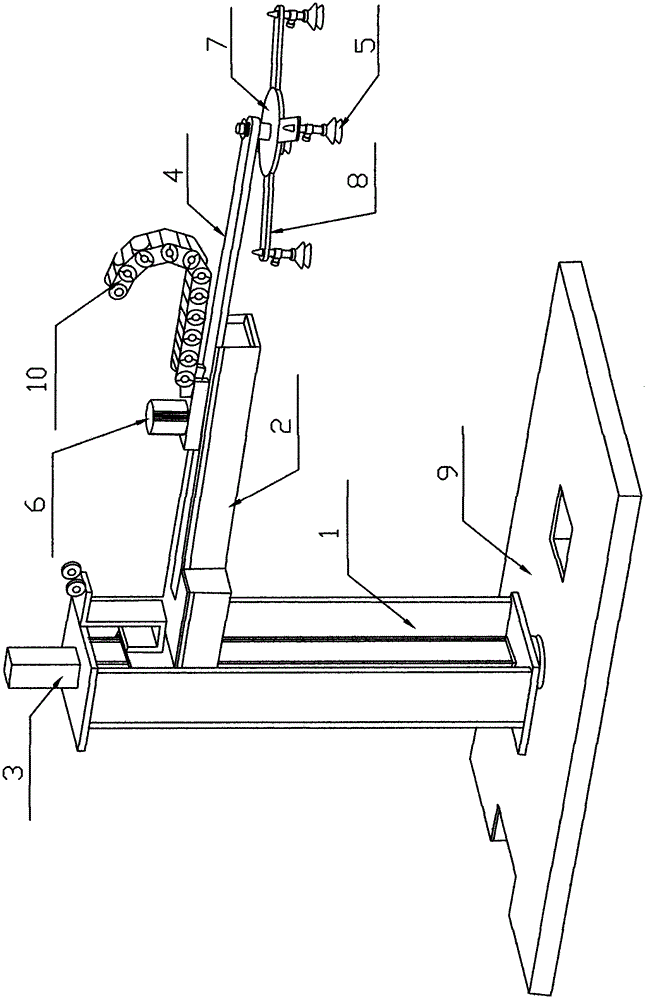

Unattended automatic driving system for gas high-outburst roadway

InactiveCN107575225AAvoid fatal accidentsRealize safe productionMining devicesDisloding machinesIntrinsic safetyControl system

The invention discloses an unattended automatic driving system for a gas high-outburst roadway. The unattended automatic driving system comprises an intelligent mining drill carriage and a remote control system for controlling the intelligent mining drill carriage. The intelligent mining drill carriage comprises a power system and an execution system driven by the power system. The execution system comprises a track-type rotating chassis, a supporting plate, two vertical columns, two fixing plates, corner lifting oil cylinders and a rod-replacing drilling system. The functions of automatic positioning hole-drilling, automatic drill-up, automatic drill connection, automatic drilling, automatic monitoring, intelligent identification and processing, automatic drill detaching and the like canbe achieved; mechanical, intelligent and unattended driving hole-drilling is achieved; casualty accidents caused by outburst of coal and gas in the coal roadway driving process are avoided; and intrinsically-safe production of driving of the gas high-outburst roadway is formed, the current situation of frequent major and extraordinarily-serious gas outburst accidents in the mine driving period inChina is turned around fundamentally, and safety production of gas high-outburst mines is achieved.

Owner:GUIZHOU INST OF TECH

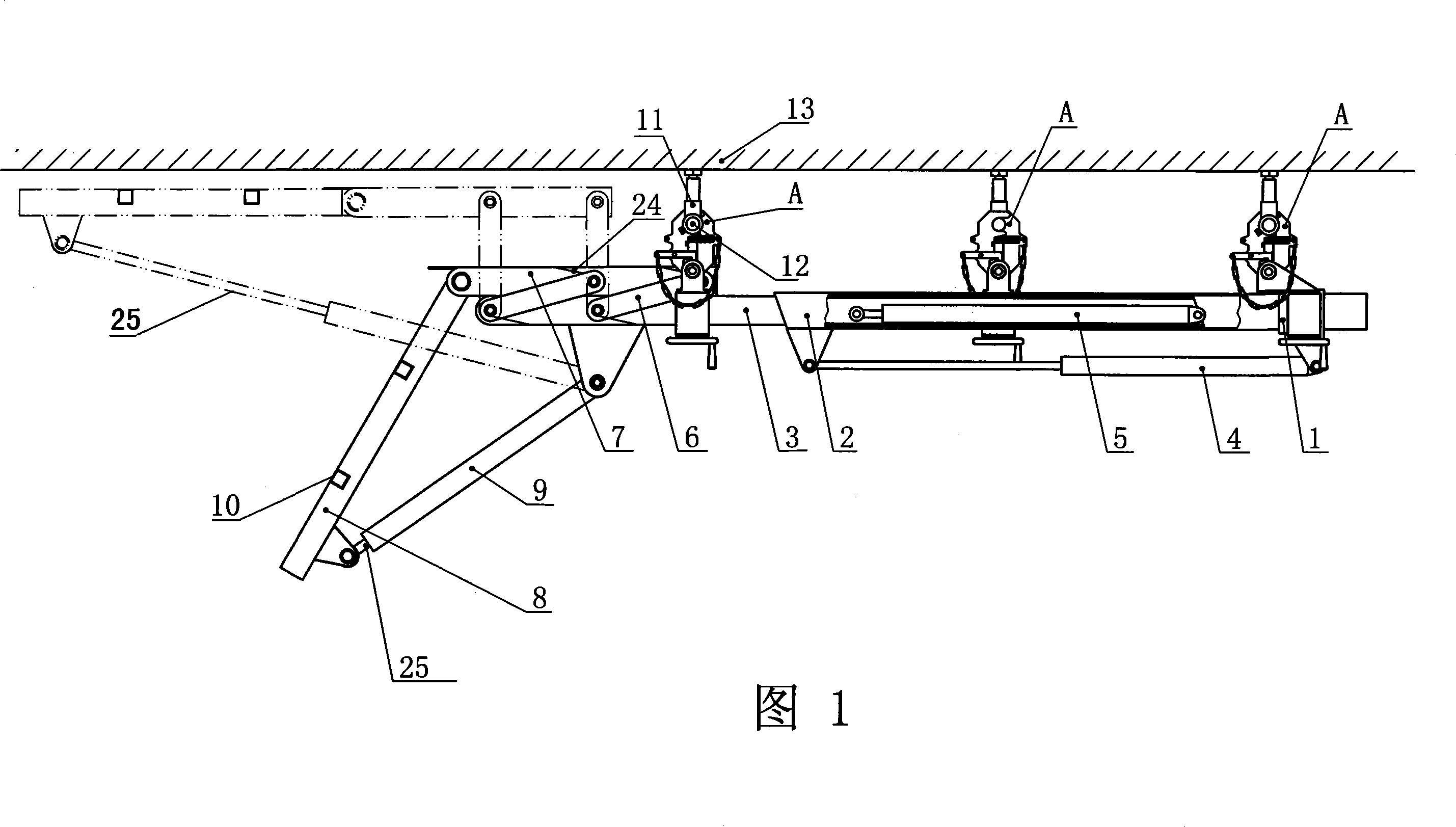

Down-hole tunnel suspended stepping self-moving advance timbering

Owner:CHINA UNIV OF MINING & TECH +1

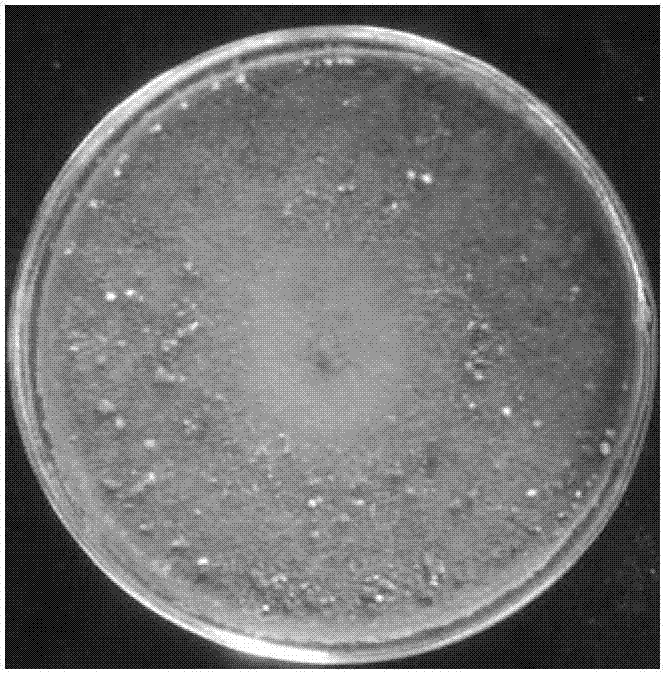

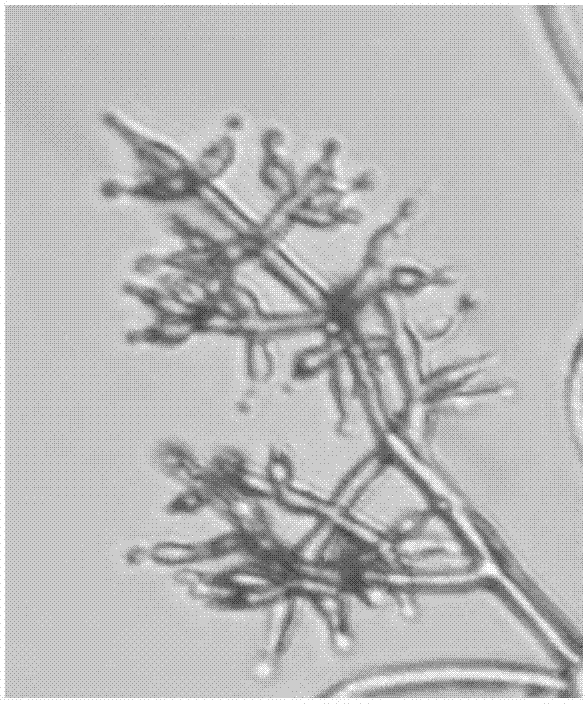

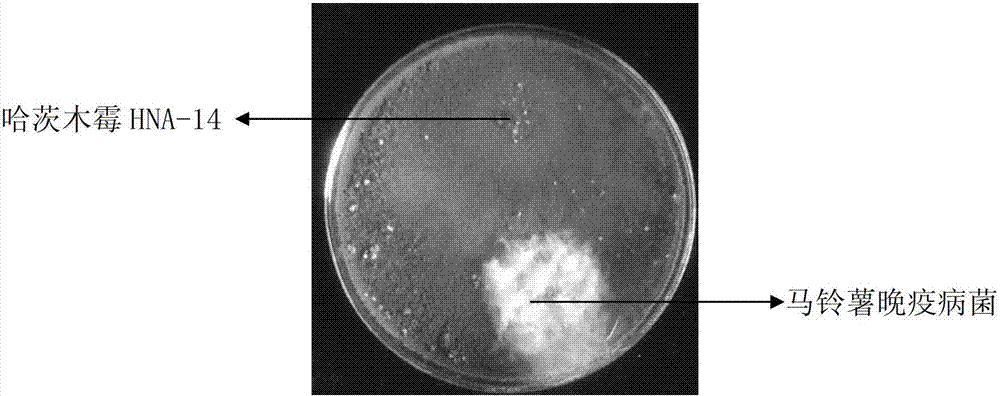

Trichoderma harzianum strain, and its application in control of potato late blight

ActiveCN102732434ANo pollutionGood antibacterial effectPlant growth regulatorsBiocideBiotechnologySolanum tuberosum

The invention discloses a Trichoderma harzianum strain, and its application in the control of potato late blight. The Trichoderma harzianum strain HNA-14 provided in the invention has a preservation number of CGMCC No.5990. The Trichoderma harzianum strain HNA-14 can be used for inhibiting pathogens, promoting the growth of potato plants, and controlling the potato late blight generation of the potato plants. The Trichoderma harzianum strain has a wide application prospect in the sustainable agriculture development.

Owner:CHINA AGRI UNIV

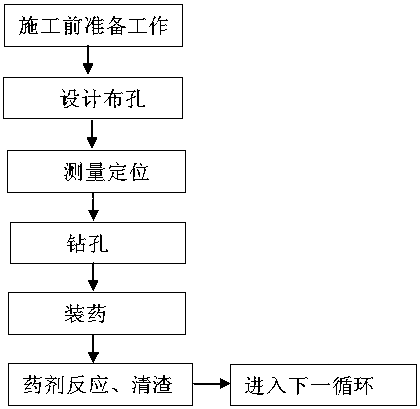

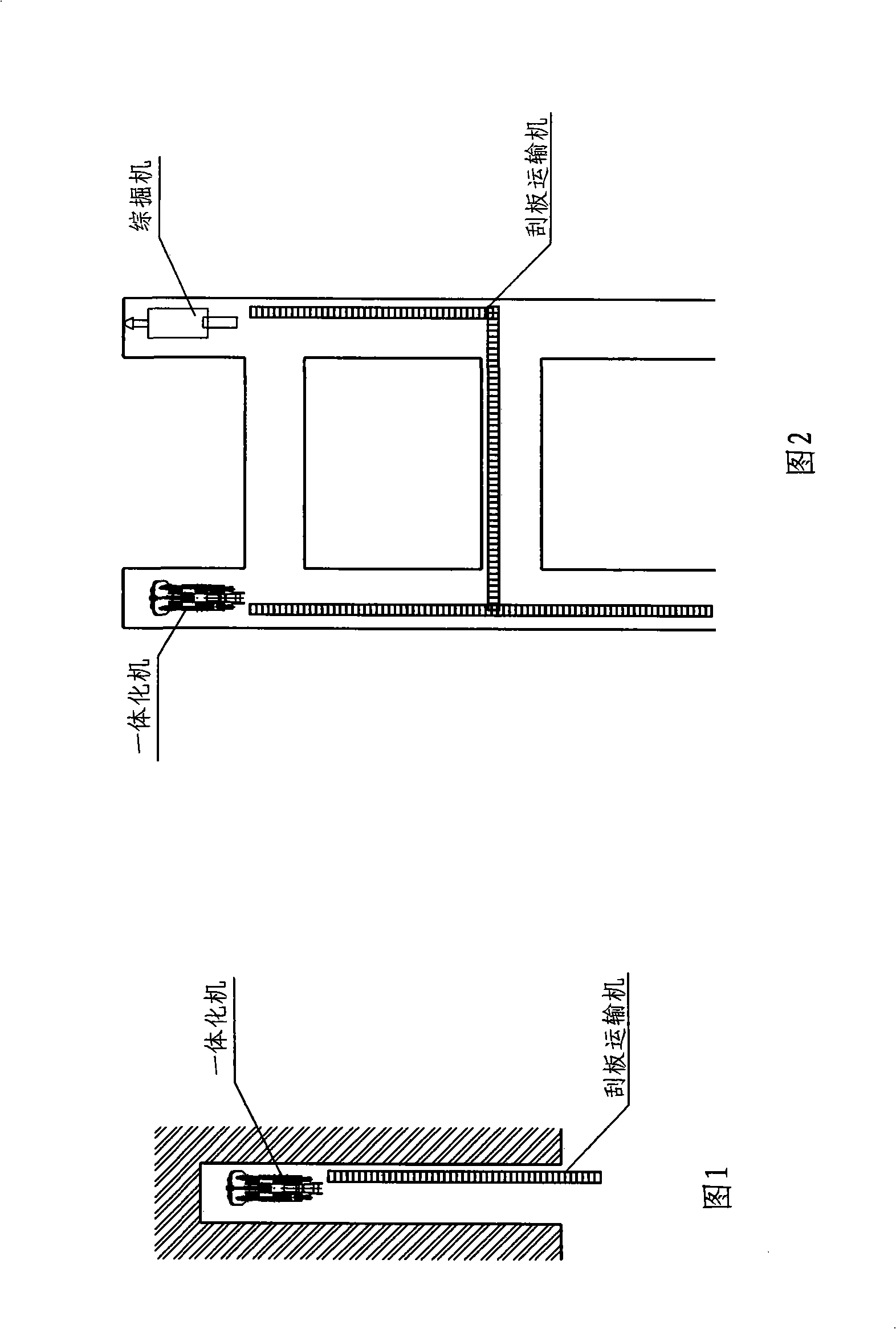

Rock drivage process for four-arm hydraulic drill rig and breaking-loading-transporting-guniting integrated machine

InactiveCN101824990AIncrease the level of mechanizationHigh degree of mechanizationTunnelsPetrologyOperating environment

The invention relates to a rock drivage process for a four-arm hydraulic drill rig and a breaking-loading-transporting-guniting integrated machine. The process is mainly characterized by adopting the four-arm hydraulic drill rig to carry out porthole drilling, hole supporting and anchor bolt and cable supporting, and adopting a rock breaking-loading-transporting-guniting integrated machine combining the functions of rock breaking, rock loading, rock transporting and guniting to cooperate to complete rock operation. The process comprises the specific steps of hole drilling, charging, blasting, temporary supporting, supporting, guniting and the like, and the four-arm hydraulic drill rig and the rock breaking-loading-transporting-guniting integrated machine alternately go into a rock driving face area to perform construction operation in the rock drivage process. The process adopts advanced technical equipment, makes the improvement on the existing rock drivage technology, entirely realizes the comprehensive mechanical operation for rock construction, and has the obvious advantages of improving rock drivage footage level, reducing labor intensity of workers, saving human power, raising efficiency, improving field operating environment, reducing the occurence of occupational diseases, effectively ensuring safe production and the like.

Owner:闫振东

Method for underground chamber digging and laneway opening digging

InactiveCN101302932AImprove concentrationIncrease flexibilityUnderground miningBlastingEngineeringMechanical equipment

The invention relates to a method for advancing the port and the underground chamber of a roadway. The method of the invention adopts the technologies of hole drilling, coal blasting and smooth blasting, coal loading and transporting, hole drilling and supporting, etc., and is characterized in that the technologies of coal loading and transporting as well as hole drilling and supporting use a coal roadway drilling, loading and transporting integrated anchor windlass and a scraper blade transporter system to realize the single and double-roadway advancing with more flexibility, convenience, higher yield and efficiency, thus improving the mechanical equipment level of an advancing operating face; the method of the invention can be applicable to large, medium and small-sized coal mines.

Owner:闫振东

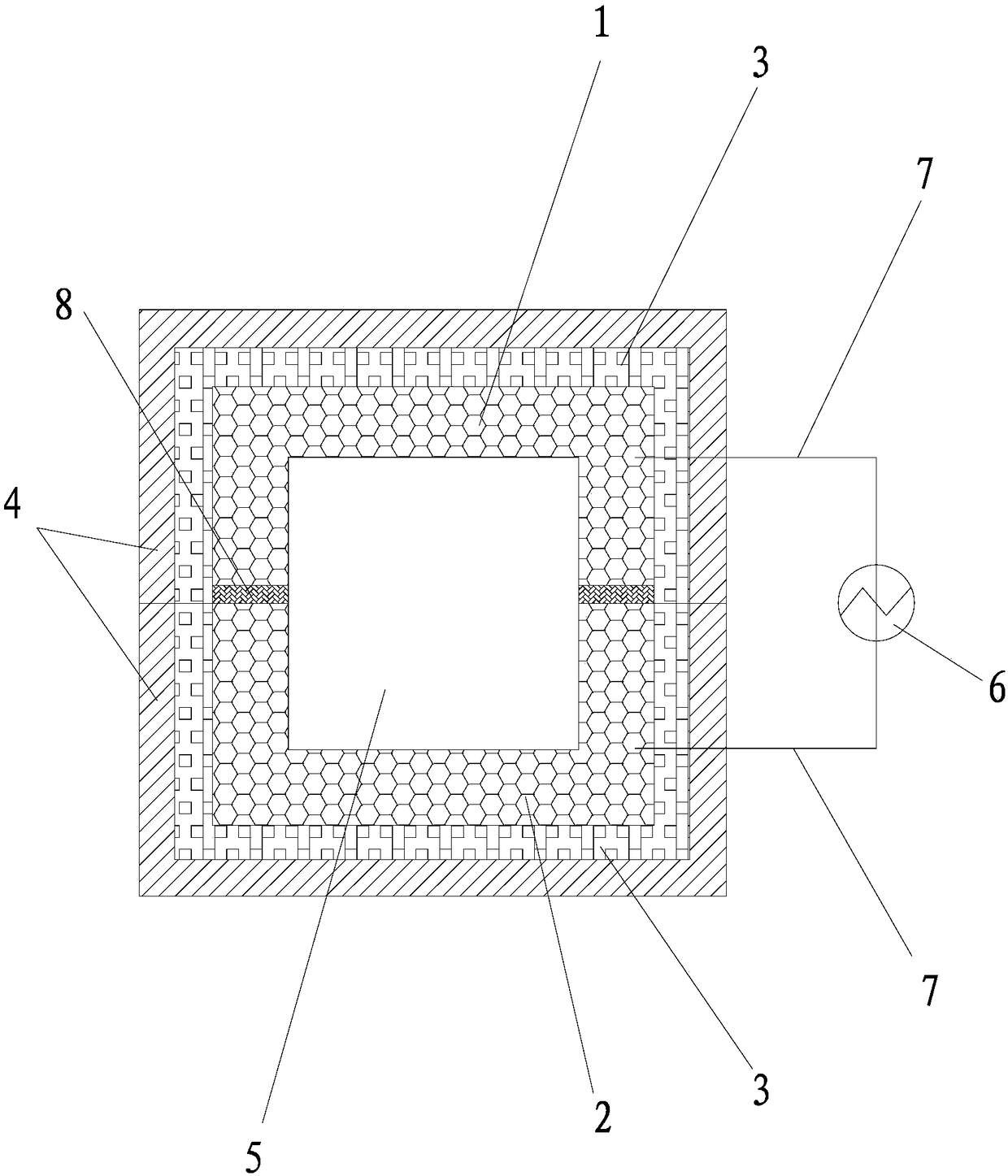

High-molecular material foaming device and application method thereof

The invention discloses a high-molecular material foaming device. The high-molecular material foaming device mainly comprises a foaming mold and a high-frequency electric source, wherein the foaming mold comprises an upper mold and a lower mold, insulated spacers are arranged between the upper mold and the lower mold at intervals, after the high-frequency electric source is powered on, a high-frequency oscillation electric field is generated between the upper mold and the lower mold, in the high-frequency oscillation electric field, polar molecules and / or functional groups inside a to-be-foamed base metal can incessantly switch directions along with the high-frequency oscillation electric field to collide with each other, mutual friction generates heat so as to enable the temperature of the to-be-foamed base metal in a mold chamber to rise, a foaming agent can be heated and decomposed to generate gas, the foaming material expands to fill the whole mold chamber so as to realize foamingof the foaming material. By adopting the foaming device, the rapid, efficient and uniform foaming of a high-molecular material can be realized. The high-molecular material foaming device has a broad application prospect in the material foaming field.

Owner:QUANZHOU NORMAL UNIV

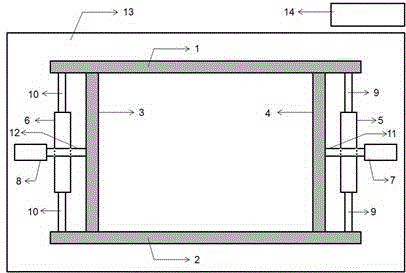

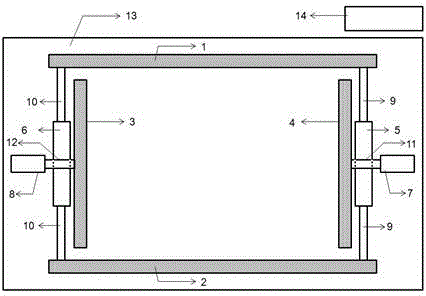

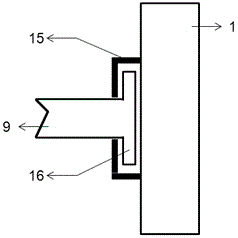

Automatic formwork release and assembly device

InactiveCN106182353ASimple structureEasy to operateCeramic shaping apparatusKey pressingHydraulic cylinder

The invention relates to an automatic formwork release and assembly device, in particular to an automatic formwork release and assembly device for a prefabricated reinforced concrete wallboard of a fabricated house. The automatic formwork release and assembly device comprises four frame parts, a platform, a control system, four hydraulic cylinders and connecting rods used for connecting the hydraulic cylinders and the frame parts. The four frame parts are located on the platform, and the four frame parts are pairwise opposite to form a rectangle in a surrounding manner. The control system comprises a display screen, adjusting keys and four control handles. The control system controls the work time of each hydraulic cylinder and the displacement of each connecting rod. Each frame part is connected with the corresponding hydraulic cylinder through the corresponding connecting rod. Automatic formwork release and assembly of the prefabricated reinforced concrete wallboard are achieved in the manner that the connecting rods are moved and driven according to the pressure changes in the hydraulic cylinders to extend or stretch. The automatic formwork release and assembly device is simple in structure and convenient to operate, achieves automatic formwork release and assembly of the prefabricated reinforced concrete wallboard and greatly saves labor, thereby achieving safe production and reducing the production cost.

Owner:RENQIU YONGJI CONSTR & INSTALLATION ENG

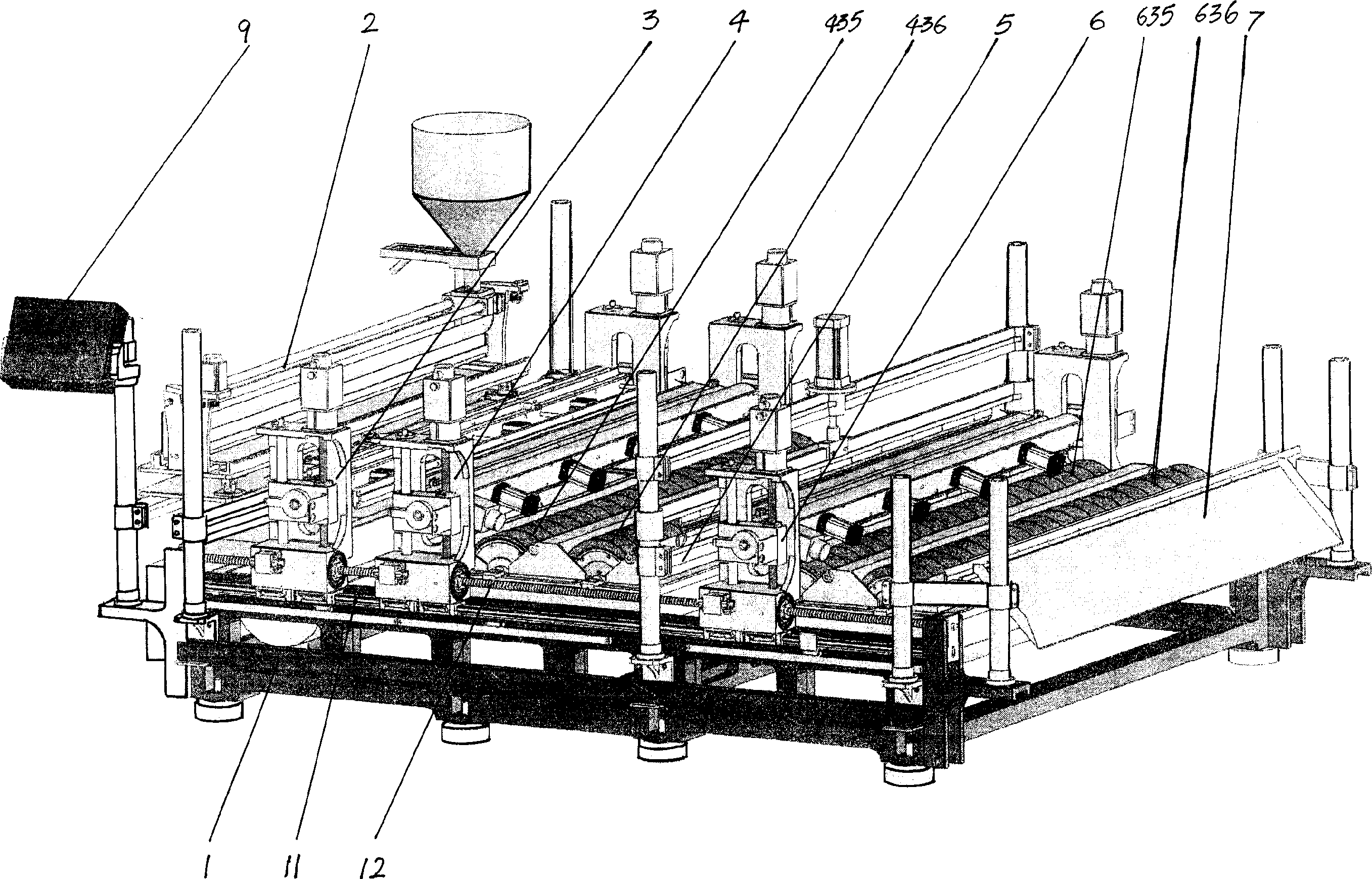

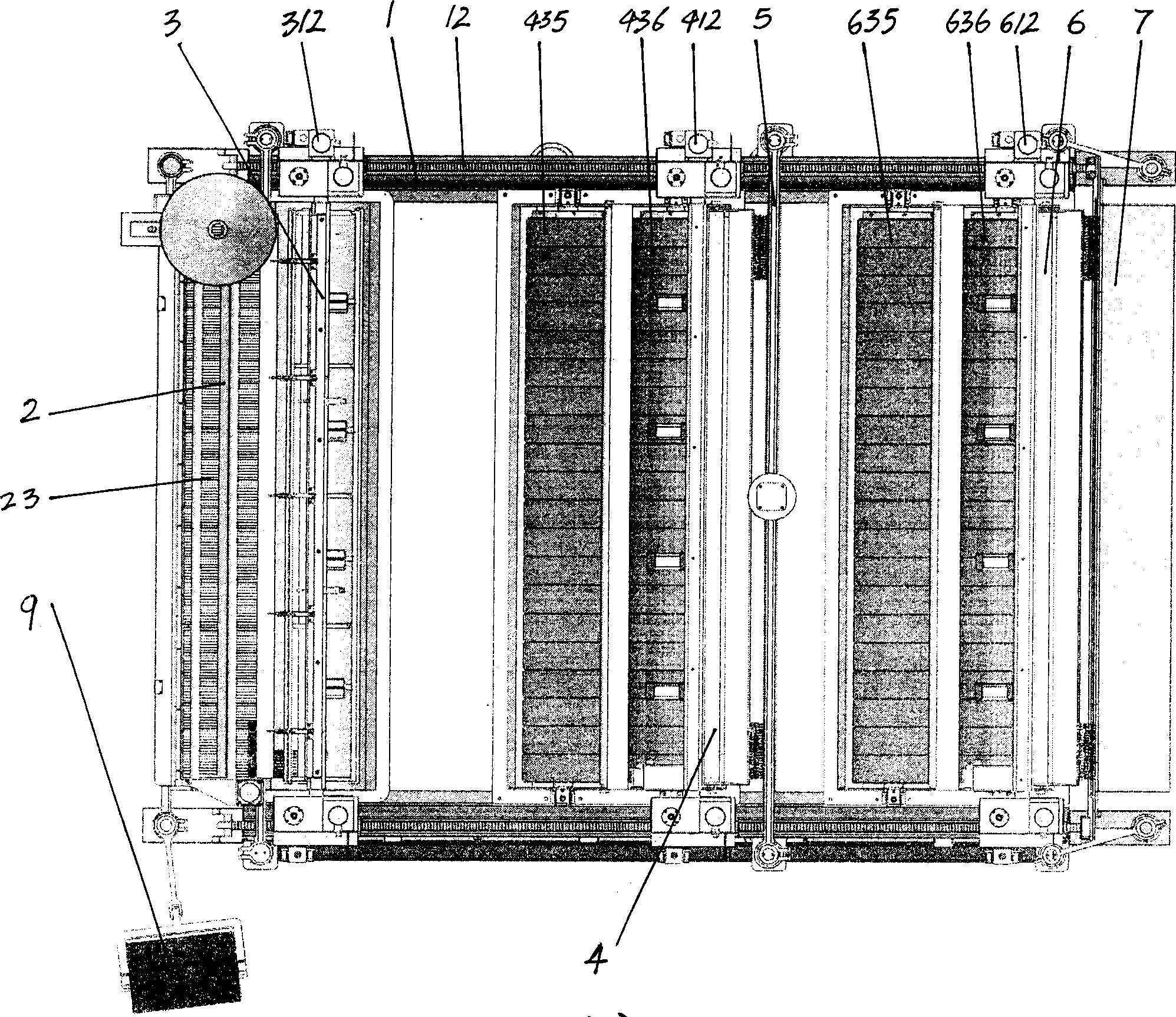

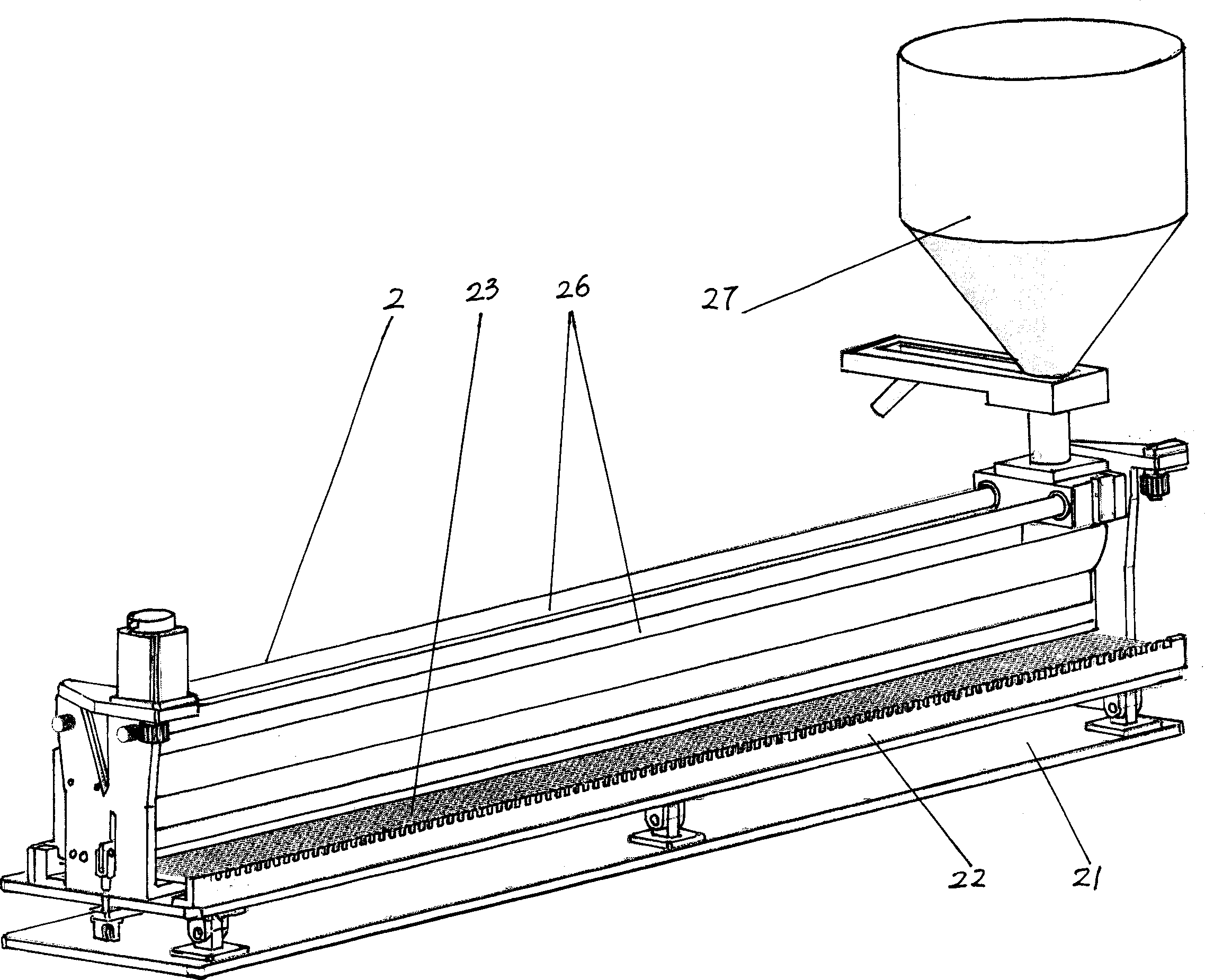

All surface grinding and shaping automation processing center for hard and crisp particle's products

InactiveCN1833819AAchieve civilizationRealize safe productionEdge grinding machinesAutomatic controlEngineering

A machine for grinding and polishing the polygonal or elliptical surface of the particle made of hard and crisp material, such as glass bead, has an automatic control circuit, a gantry body with particle receiving and feeding unit, the grinding and polishing units for the front and back surfaces of particles, particle turning over unit and particles discharging unit. It has high automation level.

Owner:柯明月

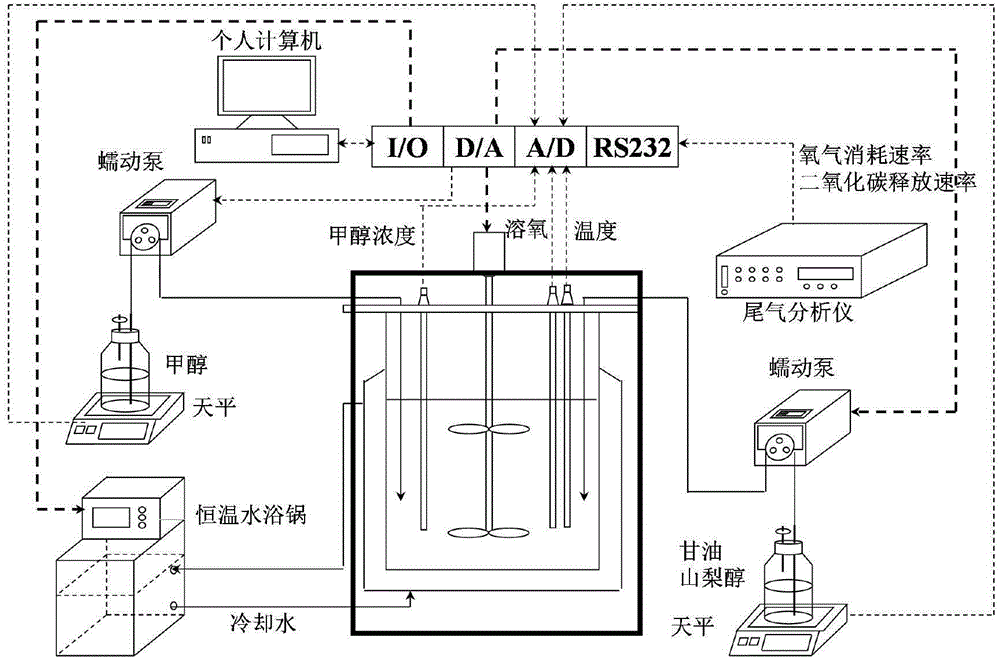

Expert control system for process of expressing foreign protein by recombinant pichia pastoris

ActiveCN104531522AIncrease stream accelerationAvoid dropping NADH levelsBioreactor/fermenter combinationsBiological substance pretreatmentsPichia pastorisProtein target

The invention discloses an expert control system for a process of expressing a foreign protein by recombinant pichia pastoris and belongs to the biotechnical field. When pichia pastoris expresses the foreign protein, several important control variables such as temperature, DO, sorbitol feeding speed (blend induction) and the like have a very complicated relationship with physiological statuses of cells. Aiming at the complicated process that the control variables are mutually interfered, the quantitative relation between the control variables and the controlled variables is not clear and the performance indexes are hard to be independently controlled, the invention provides an expert control strategy. The expert control system is an intelligent computer control system which internally contains expert knowledge and experience. The expert control system is used for solving related problems in a compound optimized control process by constructing, implementing and adjusting expert commands and rules. The control system controls the fermenting temperature, the sorbitol feeding speed and dissolved oxygen online in the optimum level simultaneously by an energy-saving way, so that the activity and concentration of a target protein are improved and the operating cost and energy consumption are lowered.

Owner:JIANGNAN UNIV

Method for extracting sodium lignin sulfonate from papermaking black liquor employing sulphur treatment

InactiveCN103665390ANo personal injuryQuick responseRegeneration of alkali lyeSulfite saltPrecipitation

The invention discloses a method for extracting sodium lignin sulfonate from a papermaking black liquor employing sulphur treatment. The method is characterized by comprising the following steps: 1, injecting a black liquor into a reaction circulating tank, pumping the black liquor to the top of a reaction absorption tower by using a pump, and spraying down from a solution distribution sieve at the top; 2, feeding an SO2 acid gas generated by a burner into the bottom of a reaction tower by using an exhaust fan through a pipeline, and generating reverse gas-liquid reaction by a gas inside the tower and the black liquor sprayed down from the top; 3, absorbing SO2 in a cycle to carry out sulfuration reaction, so as to control the pH value to 3.5-4.0; 4, sulfonating lignin and finishing winterization to sink into the bottom of the tank after foam of reaction liquid disappears in a precipitation tank, and discharging upper brown liquid to obtain lignin pulp; 5, pumping the pulp into a filter press to filter the liquid by a pump, baking and packaging after crushing a filter cake, so as to obtain the product. The method is low in cost, safety production is achieved, the liquid after reaction is a sodium sulfite solution, and a pulping material, and the solution after lignin is filtered and pressed can be prepared into an alkaline pulp. Thus, cyclic utilization of resources is achieved.

Owner:潘增强

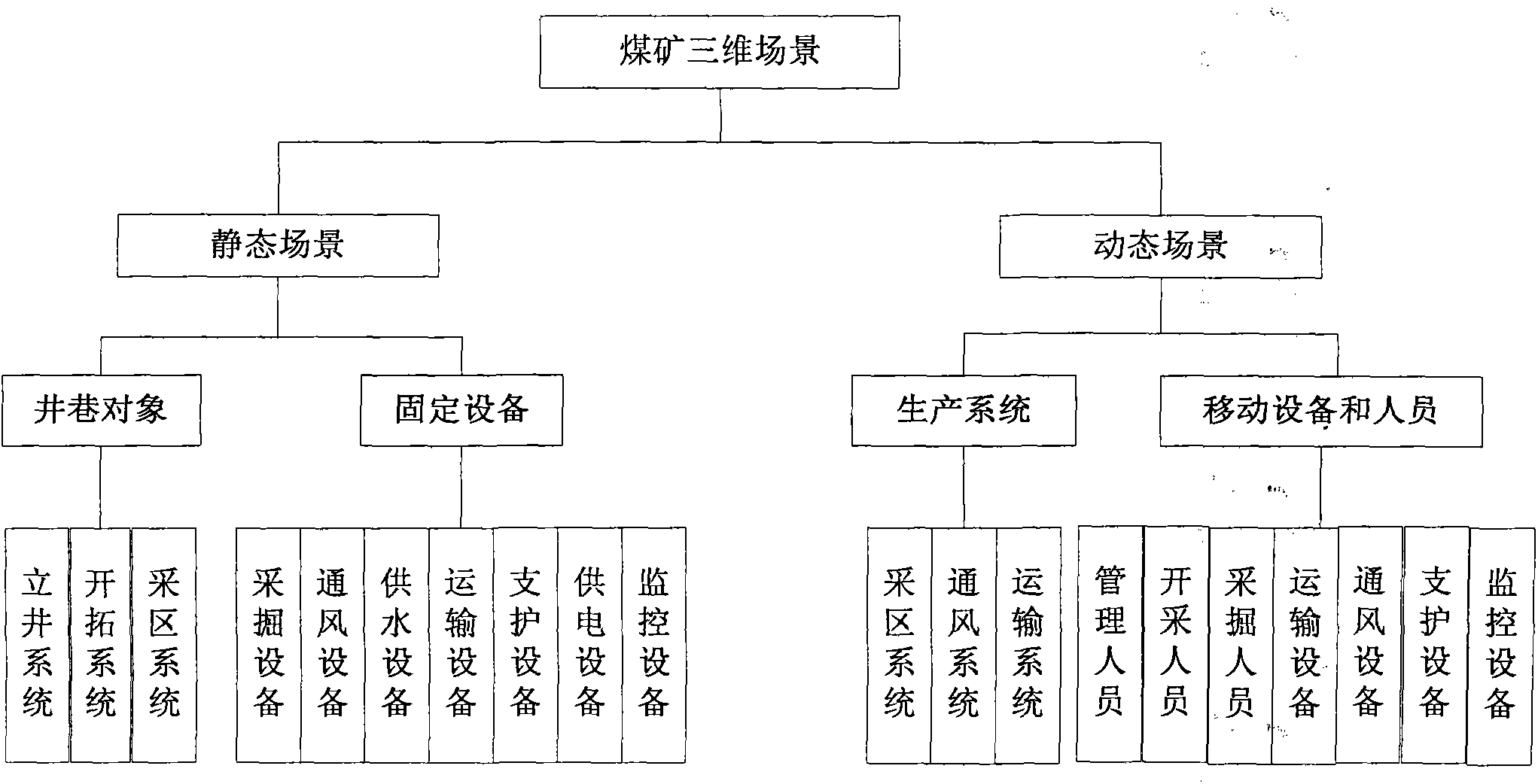

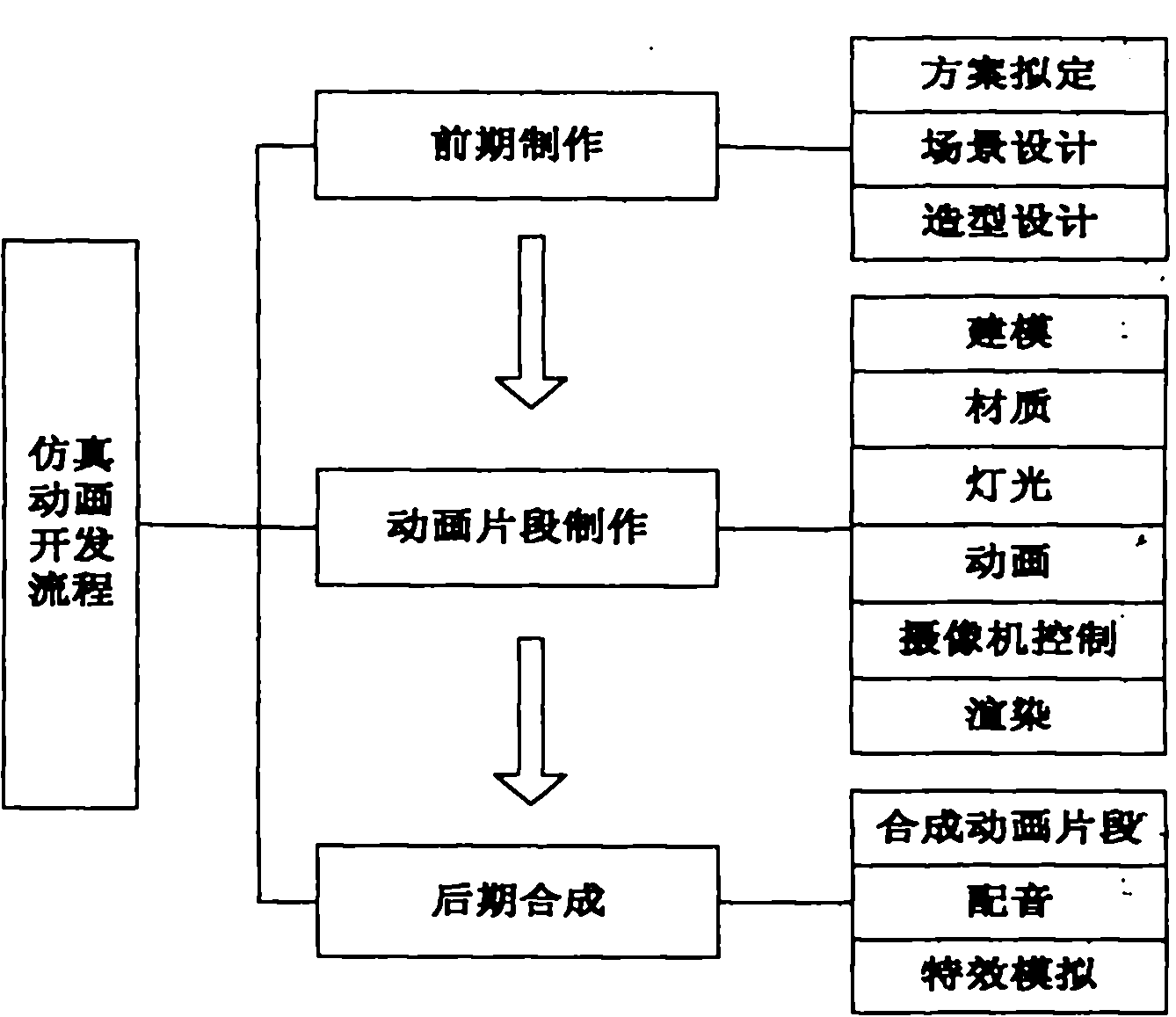

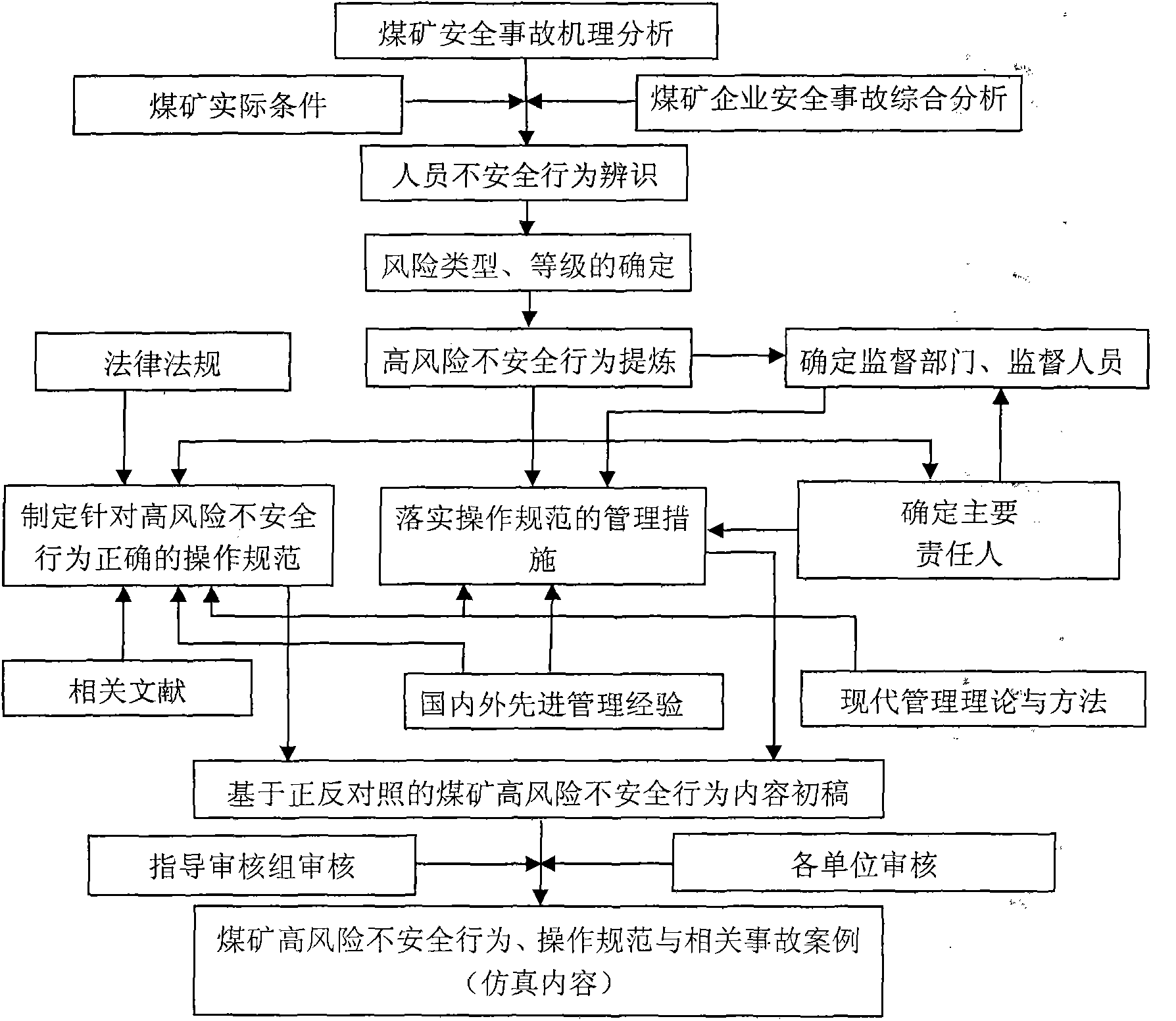

Warning simulation method for unsafe acts in coal mines

ActiveCN103886132AThe purpose of reducing the three violationsReduce coal mine accidentsData processing applicationsAnimationAnimationCoal

The invention discloses a method for warning unsafe acts in coal mines by utilizing the three-dimensional virtual simulation technology. The method includes the following steps: 1, identifying common unsafe acts in the coal mines and assessing consequences; 2, planning and designing three-dimensional animations, and designing potentially existing elements and scenes both needed in a simulation system; 3, creating a basic model; 4, performing static and dynamic simulation; 5, performing post-synthesis on virtual simulated animations to form a complete virtual simulation system for the unsafe acts in the coal mines. In established virtual scenes, the unsafe acts are vividly and visually expressed through the three-dimensional animations, so that safety awareness of underground workers is improved, and quality of coal mine safety training is also improved.

Owner:JIANGSU BITEDA INFORMATION TECH CO LTD +1

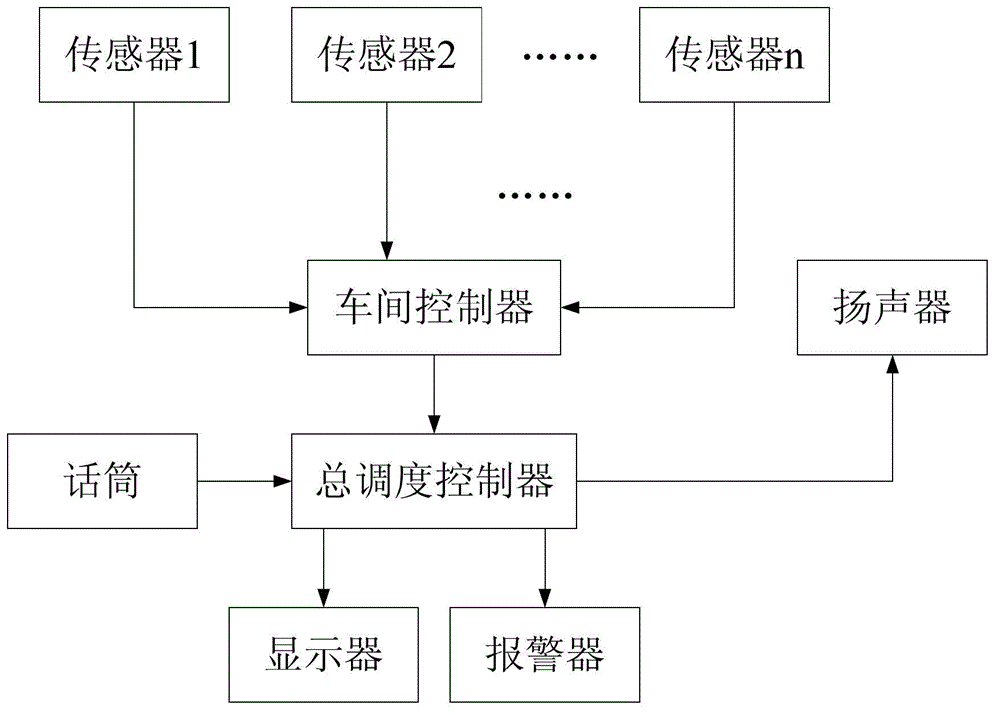

Safety monitoring system

InactiveCN102750805AAvoid harmRealize safe productionClosed circuit television systemsAlarmsLoudspeakerMicrophone

The invention relates to the safety monitoring technology and discloses a safety monitoring system. The safety monitoring system comprises sensors, wherein the sensors are arranged at a plurality of monitoring points in a chemical production workshop, a plurality of sensors are connected with a workshop controller, the workshop controllers of a plurality of different chemical production workshops are respectively connected with a general scheduling controller, and the general scheduling controller is connected with a display, a warner, a microphone and loudspeakers arranged in each chemical production workshop. The safety monitoring system has the advantages that various types of sensors are arranged in workshop work fields, in addition, collected information is transmitted to a remote controller, the real-time monitoring on the audio / video state of the workshop work fields and the real-time monitoring on whether poisonous and harmful gas leakage conditions exist or not are realized, corresponding warning information is given, the safety handling of the workshop work fields is carried out in real time, the poisonous and harmful gas harm to workers is avoided, and the safe production is realized.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

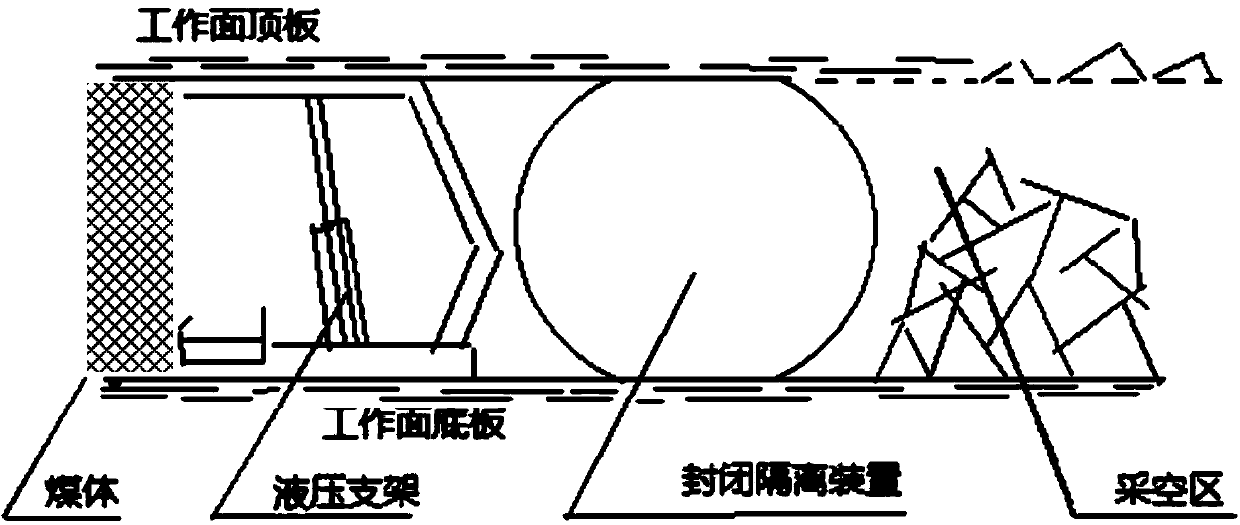

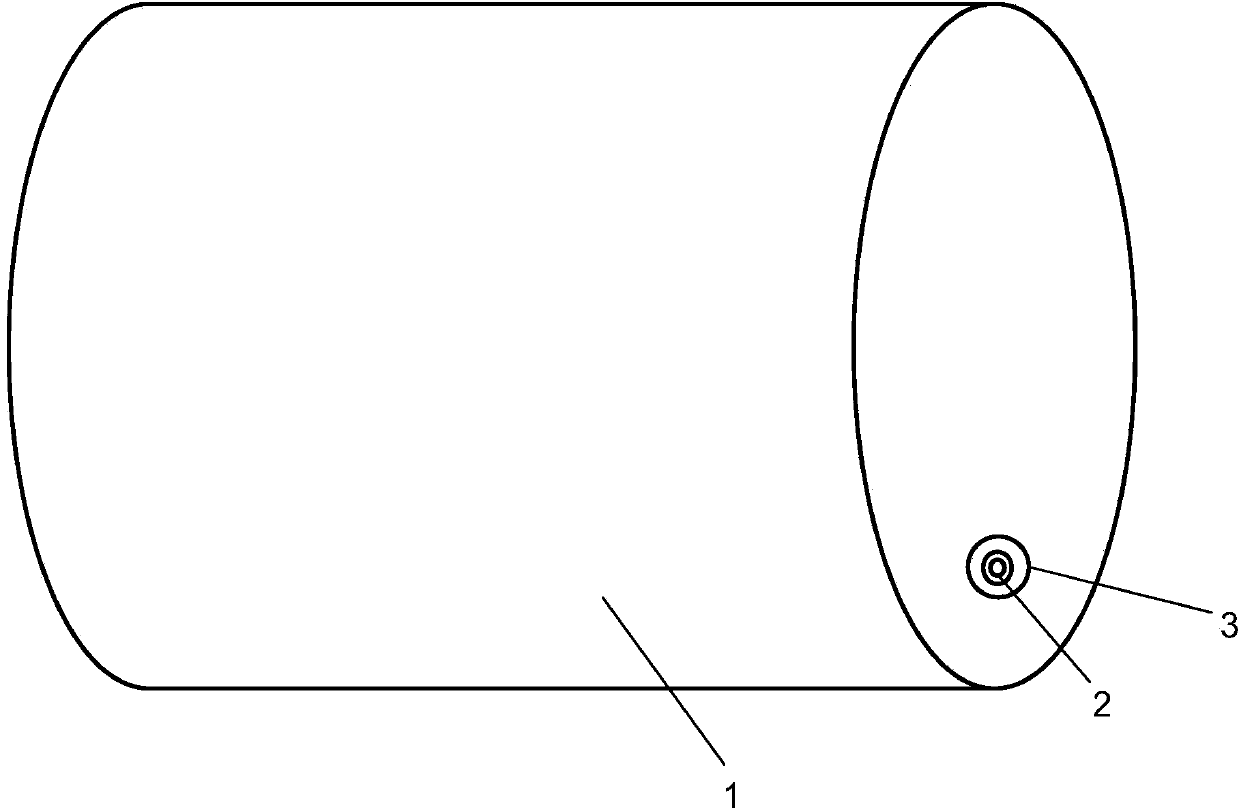

Technology for preventing natural ignition and gas explosion of goaf coal seam by adopting isolation method

InactiveCN104047628APrevent spontaneous ignitionAvoid explosionDust removalFire preventionEngineeringGas explosion

The invention provides a technology for preventing natural ignition and gas explosion of a goaf coal seam by adopting an isolation method. The technology for preventing natural ignition and gas explosion of the goaf coal seam by adopting the isolation method uses an isolation device capable of expanding through air inflation, so that the inflated and expanded isolation device is in tight contact with collapsed or incompletely collapsed top and base plates in a goaf to isolate the goaf. By adopting the technology for preventing natural ignition and gas explosion of the goaf coal seam by adopting the isolation method, the goaf can be effectively isolated, the oxygen content in the goaf can be lower than a critical value, the natural ignition of the coal seam can be avoided, the gas explosion of the goaf can be prevented, and meanwhile the gas leakage in the goaf can be alse prevented.

Owner:李继水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com