Goaf waste rock filling coal mining method of flexible shield support in half-edge coal seam

A flexible shielding support and backfill coal mining technology, which is applied in backfill, ground mining, mining equipment and other directions to protect the ecological environment, promote harmonious development, and avoid transportation tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

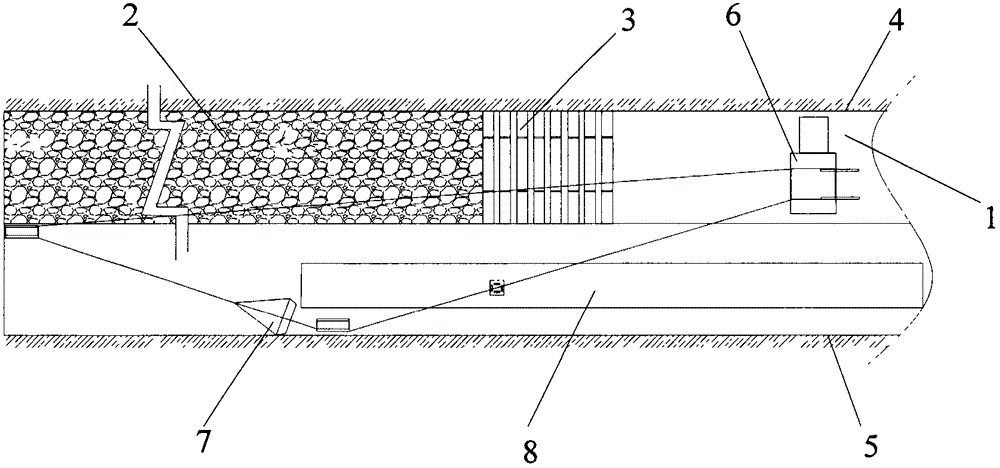

[0041] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] (1) Roadway layout and construction sequence

[0043] According to the actual geological situation and engineering layout, the working face is arranged into 5 warehouses: advancing from west to east, the slope roadway 1 is arranged at an angle of 23° to 25° along the false surface.

[0044] Construction sequence: follow the trend from top to bottom, mining from west to east along the trend, mining 2# bins first, and then connecting with bins 3#, 4#, 5#, and 1# to form multi-bin mining.

[0045] (2) Coal mining method and coal mining process

[0046] ① Coal mining method: According to the coal seam occurrence conditions and the actual exposed coal seam conditions, the flexible cover support coal mining method is adopted. The specific steps and parameters are as follows:

[0047] The height of the sill is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com