Technology for preventing natural ignition and gas explosion of goaf coal seam by adopting isolation method

A technology of natural ignition and gas explosion, which is applied in fire prevention, dust prevention, mining equipment, etc. It can solve the problems that the actual effect cannot meet the requirements, the air leakage in the goaf increases, and the prevention cannot be achieved, so as to avoid the natural ignition of the coal seam, The effect of preventing gas explosion and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These exemplary embodiments are provided so that those of ordinary skill in the art can clearly understand the present invention and implement the present invention from the description herein. The drawings and specific examples are not intended to limit the invention, the scope of which is defined by the appended claims.

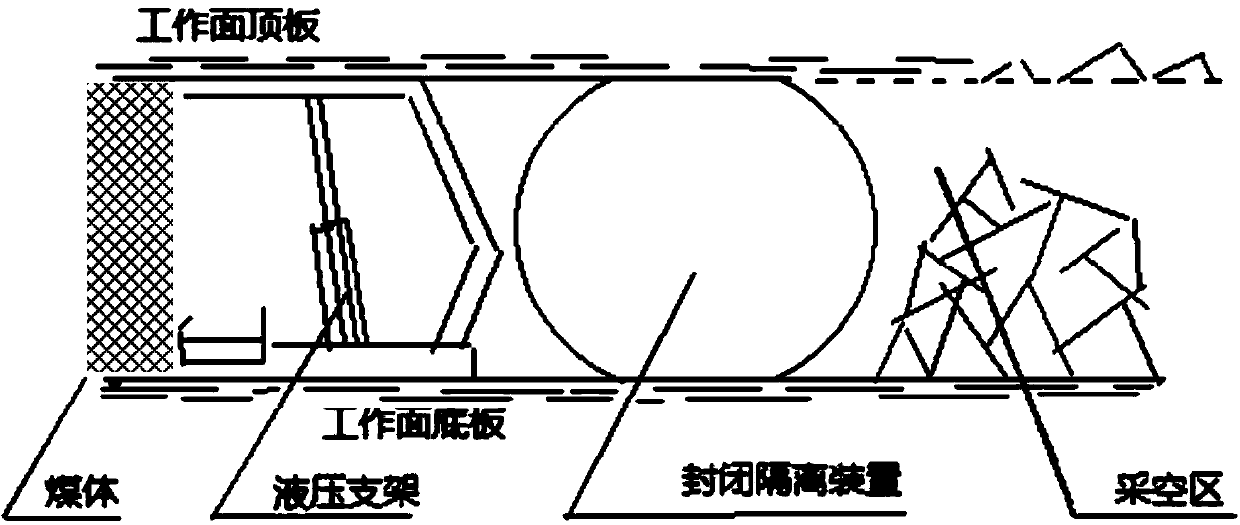

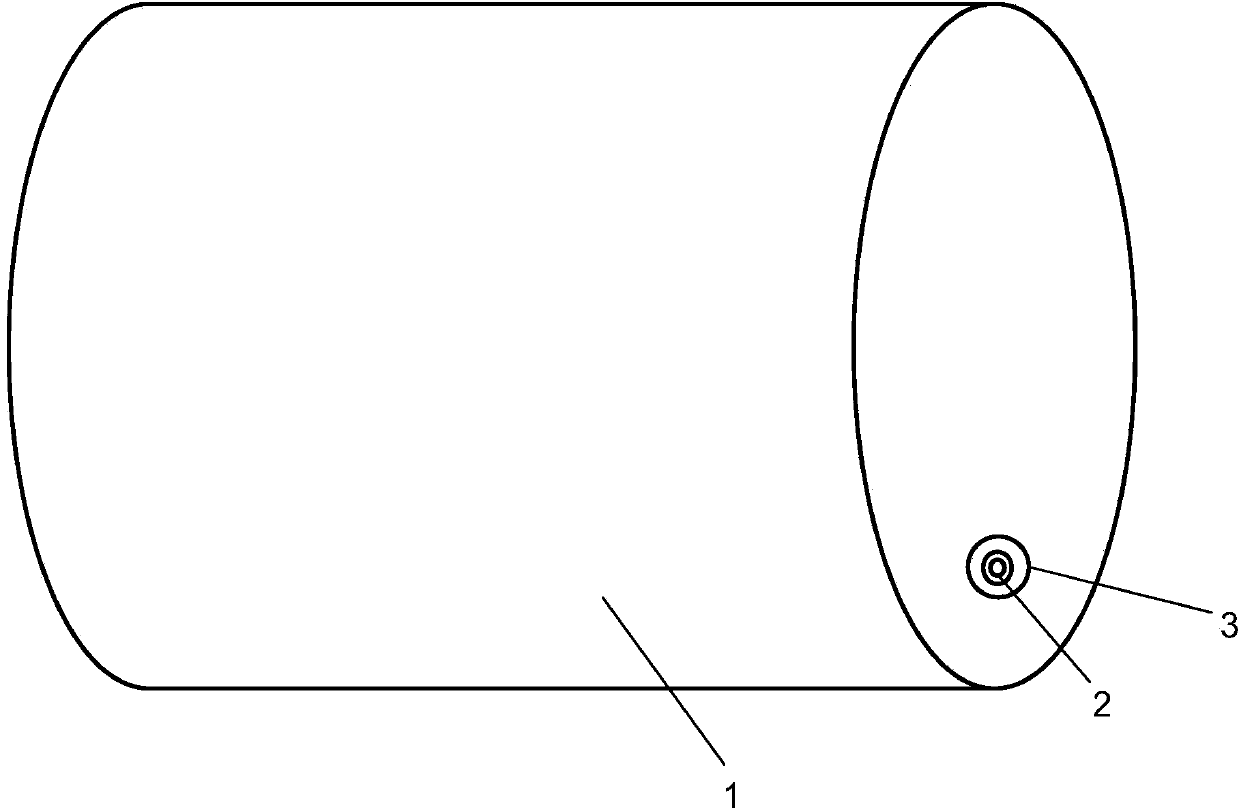

[0022] figure 1 A schematic diagram showing the use and positional relationship of the inflated and inflated isolation device used in the isolation method provided by the embodiment of the present invention to prevent coal seam spontaneous combustion and gas explosion technology in goafs. refer to figure 1 , the present invention provides a kind of isolation method to prevent goaf coal seam spontaneous combustion and gas explosion technology, this technology has used a kind of inflatable isolation device, comprises the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com