A combined regional grouting method for up and down wells

A regional and grouting technology, applied in earthwork drilling, safety devices, mining equipment, etc., can solve the problems affecting the progress of the project, the amount of grouting can not be effectively controlled, insufficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

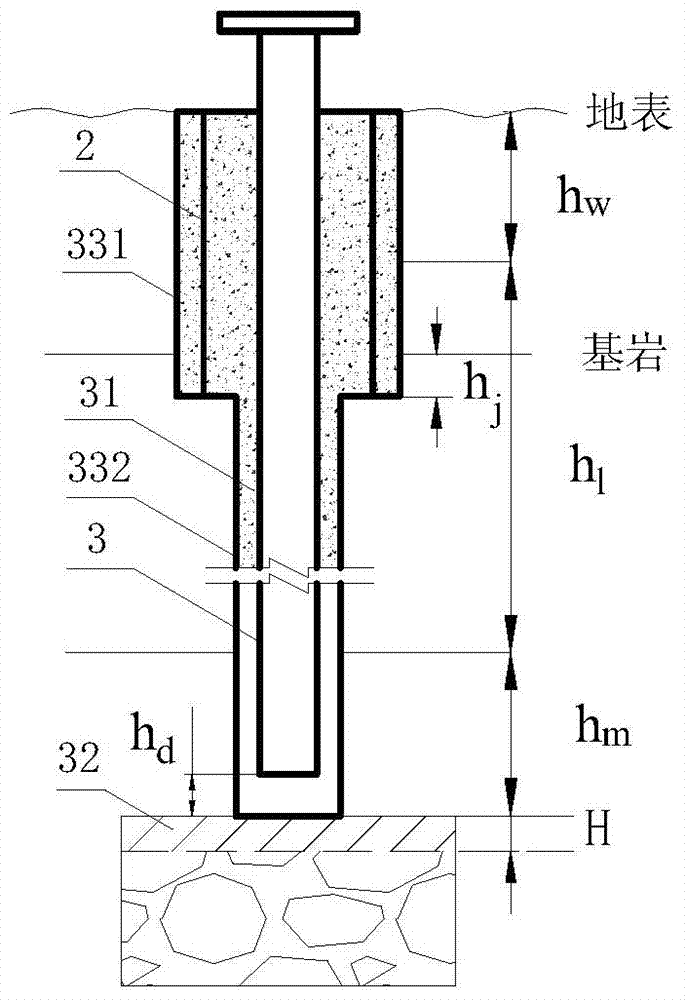

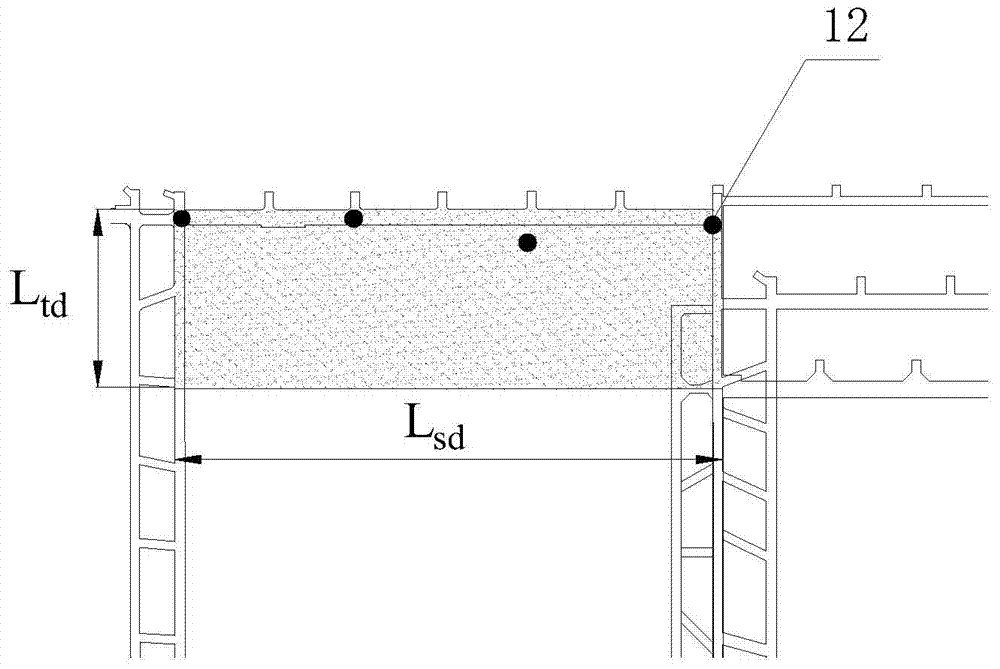

[0105] see figure 1 , image 3 , Figure 4 , Figure 5 , a combined regional grouting method for upper and lower wells, including ① First, obtain the strike length L of the grouting area of the overlying goaf td m, is the distance between the position of the cutting eye on the working face and the end of the height adjustment of the working face, generally 20-100 meters, take L td = 100 meters, the inclination length L of the overlying gob opening grouting area sd =300.8 meters, characterized in that: the amount of grouting is calculated according to the following formula:

[0106] Calculation of soil requirement:

[0107]

[0108] In the formula: Q 土 ——Amount of soil required, m 3 , Q 土 = 56722 meters 3 ;

[0109] K m ——The surplus coefficient, considering the comprehensive influence of the connection with the adjacent mined-out area and the mud shrinkage coefficient, this coefficient should be determined according to the actual situation of each mine working ...

Embodiment 2

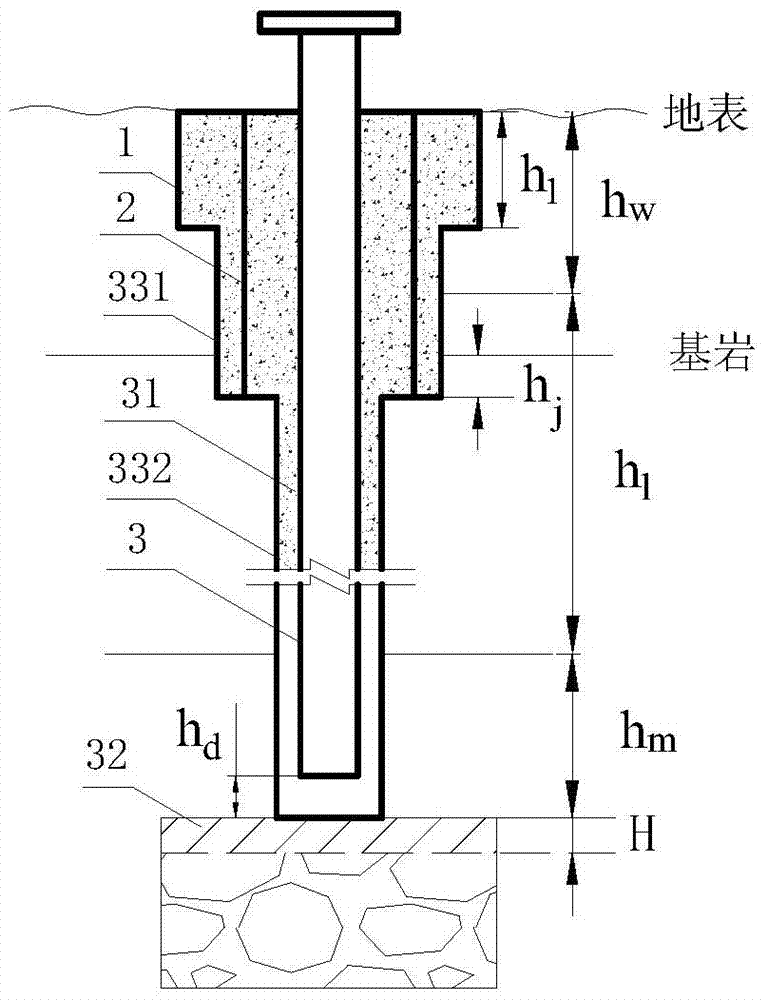

[0192] see figure 2 , image 3 , Figure 4 , Figure 5 , a combined regional grouting method for upper and lower wells, including ① First, obtain the strike length L of the grouting area of the overlying goaf td m, is the distance between the position of the cutting eye on the working face and the end of the height adjustment of the working face, generally 20-100 meters, take L td = 100 meters, the inclination length L of the overlying gob opening grouting area sd =300.8 meters, characterized in that: the amount of grouting is calculated according to the following formula:

[0193] Calculation of soil requirement:

[0194]

[0195] In the formula: Q 土 ——Amount of soil required, m 3 , Q 土 = 56722 meters 3 ;

[0196] K m ——The surplus coefficient, considering the comprehensive influence of the connection with the adjacent mined-out area and the mud shrinkage coefficient, this coefficient should be determined according to the actual situation of each mine working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com