Gob-side entry retaining side support method of coal bed fully mechanized caving face

A technology of fully mechanized caving face and support method, applied in pillars/supports, mining equipment, earth-moving drilling, etc., to reduce equipment investment, ensure integrity, and reduce bending effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

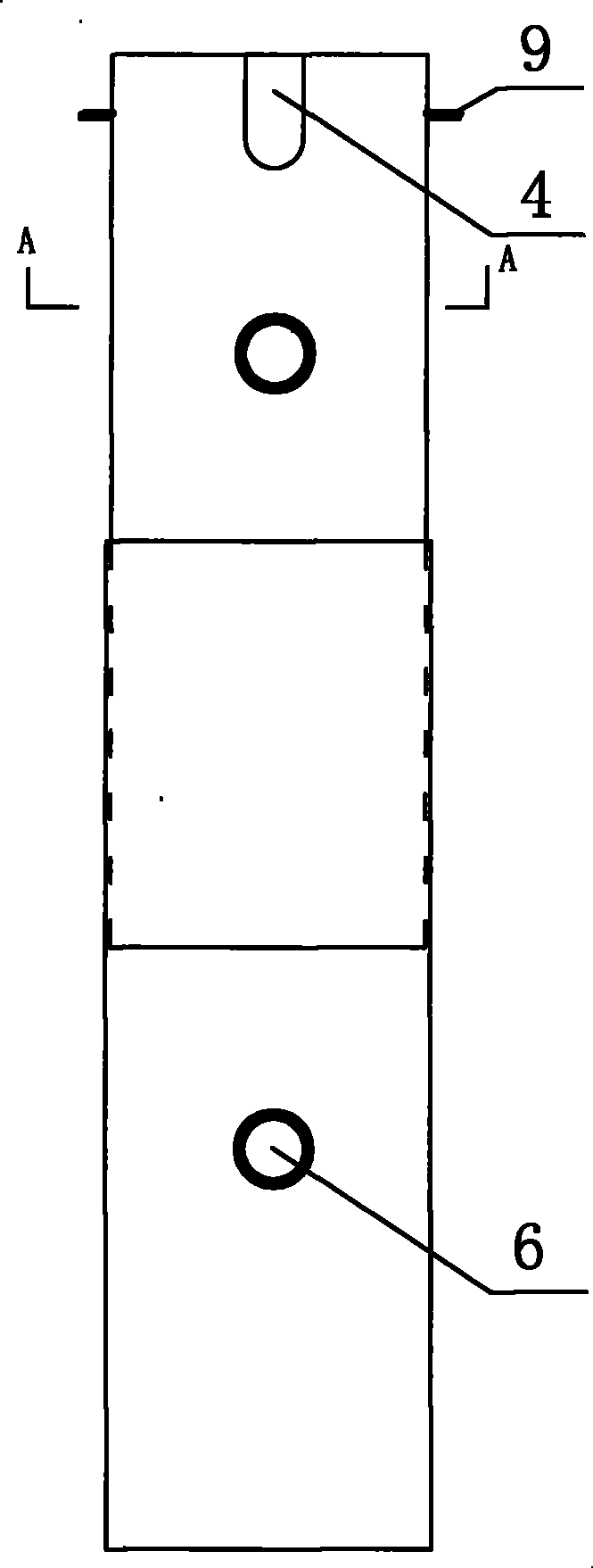

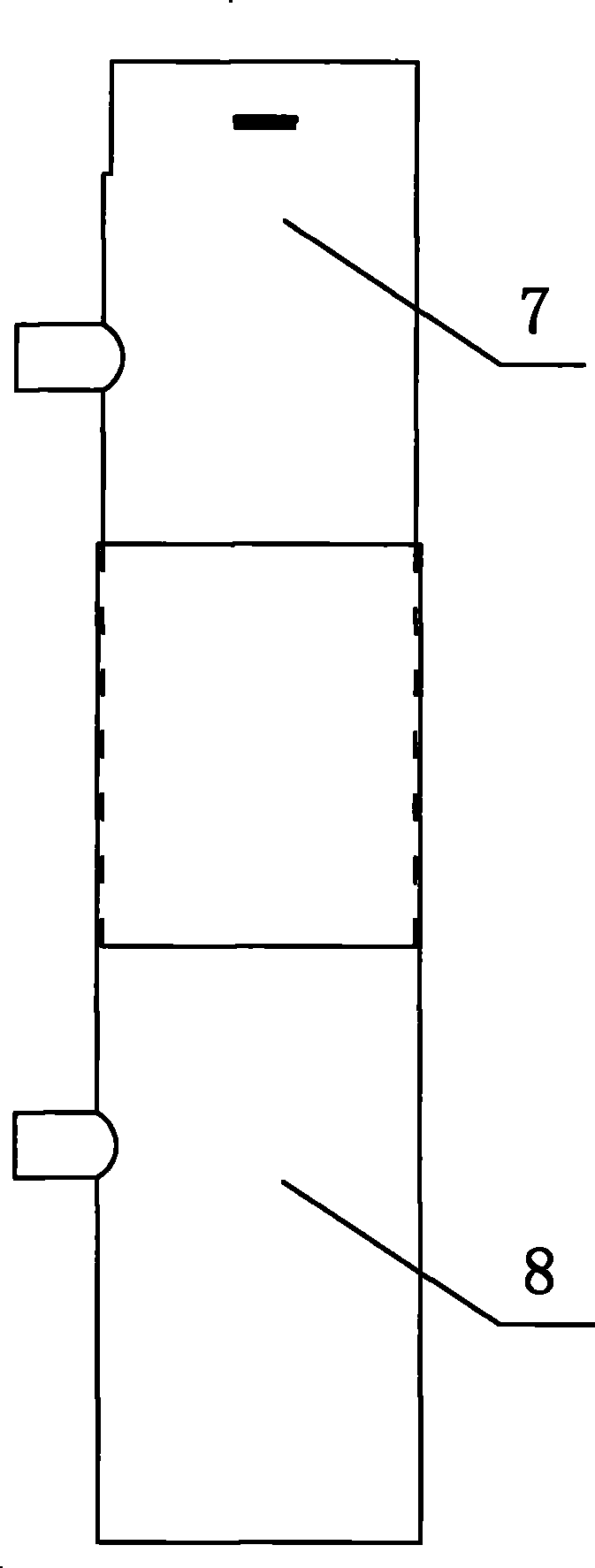

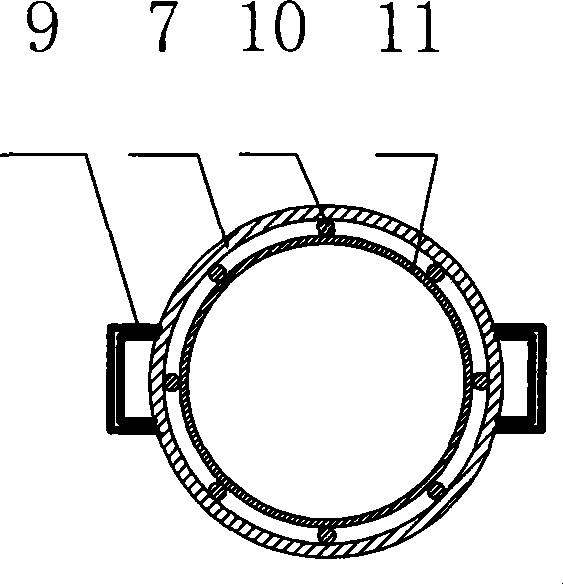

[0025] ①. Every time the working face is pushed forward by 1.4 meters, dig a 300mm column socket on the bottom plate near the gob 5 side behind the head support 2 of the working face. A barrel body is erected in the column socket. The barrel body is a cylinder made of iron plates. The cylinder is divided into inner and outer sections. The inner section can be stretched up and down in the outer section. , the interior of the inner section 7 and the outer section 8 are welded with 3 to 10 vertical steel bars 10, and steel bars 11 are used to weld and fix the vertical steel bars 10 at intervals of 1.2m along the length direction. There is a concrete pouring observation port 6; barrel body handles 9 are arranged on both sides of the barrel body section 7, and a single hydraulic prop is provided under the barrel body handle 9 to pull out the barrel inner section 7 to contact the top plate, and the barrel body The body is placed vertically on the bottom plate, and is in close contac...

Embodiment 2

[0033] ①. Every time the working face is pushed forward by 1.5 meters, a 310mm column socket is dug on the bottom plate near the goaf 5 side behind the head support 2 of the working face. A barrel body is erected in the column socket. The barrel body is a cylinder made of iron plates. The cylinder is divided into inner and outer sections. Both the inner section 7 and the outer section 8 are welded with 3 to 10 vertical steel bars 10, and the vertical steel bars 10 are welded and fixed together with steel rings 11 every 1m along the length direction. Concrete pouring observation port 6; barrel body handles 9 are arranged on both sides of the barrel inner section, and a single hydraulic prop is provided under the barrel body handle 9 to pull the barrel inner section 7 out to contact the top plate, and the barrel body is vertical to the bottom plate Put it in close contact with the roof and floor of the roadway, the upper end of the inner section is provided with a pouring port, ...

Embodiment 3

[0041] ①. Every time the working face is pushed forward by 1.8 meters, a 300mm column nest shall be dug on the floor near the side of the goaf after the end support 2 of the working face. A barrel body is erected in the nest, and the barrel body is a cylinder made of iron plates. The cylinder is divided into inner and outer sections. The inner section 7 can be stretched up and down in the outer section 8. There are 8 vertical steel bars 10 welded inside the section 7 and the outer section 8, and the vertical steel bars 10 are welded and fixed together with steel rings 11 every 0.7m along the length direction, and there is a concrete pouring on the inner and outer sections of the barrel. Observation port 6; barrel body handles 9 are arranged on both sides of the barrel inner section, and a single hydraulic prop is provided under the barrel body handle 9 to pull out the barrel inner section 7 to contact the top plate, and the barrel body is placed vertically on the bottom plate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com