Carbon monoxide composite inhibition absorbent for coal mine and preparation method thereof

A carbon monoxide and absorbent technology, used in chemical instruments and methods, separation methods, gas treatment and other directions, can solve problems such as endangering the physical and mental health of operators, changing the limit of underground explosive gas, and exceeding the concentration of CO, and achieves inhibition of oxygen-containing functional groups. output, the realization of large-scale industrial production, the effect of reducing coal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

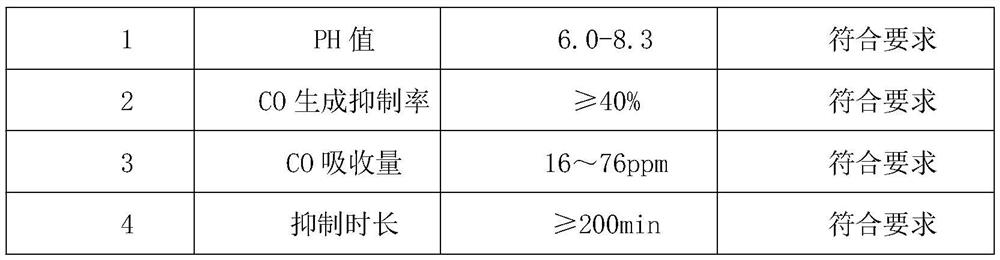

Image

Examples

Embodiment 1

[0024] A carbon monoxide composite suppression absorbent for coal mines, consisting of the following components in weight percent: 3.5% CO absorbent, 17.54% CO absorbent solubilizer, 8.7% CO generation inhibitor, 0.14% deoxygenation agent, 0.42% stabilizer and 69.7% water.

[0025] The CO absorbents are all cuprous chloride.

[0026] The CO absorbent solubilizer is a mixture of ammonium chloride, tartaric acid, and citric acid, and the weight ratio of the three is 48:1:1.

[0027] All of the CO production inhibitors are urea.

[0028] The oxygen scavenger is acetone oxime.

[0029] The stabilizer is hydroxypropyl methylcellulose.

[0030] A preparation method of a carbon monoxide composite suppression absorbent for coal mines, comprising the following steps:

[0031] (1) prepare each raw material by above-mentioned proportioning;

[0032] (2) Add an oxygen scavenger in water, and let it stand for 2 hours to react;

[0033] (3) Take half of the water in step (2), add the ...

Embodiment 2

[0041] A composition ratio of a carbon monoxide composite suppression absorbent for coal mines:

[0042] CO absorbent 100kg;

[0043] CO absorbent solubilizer 499.3kg;

[0044] CO generation inhibitor 210kg;

[0046] Stabilizer 2kg;

[0047] 2000kg of water.

[0048] The CO absorbent is cuprous chloride.

[0049] The CO absorbent solubilizer is ammonium chloride;

[0050] The CO generation inhibitor is a mixture of urea and calcium chloride, wherein urea is 200kg and calcium chloride is 10kg.

[0051] The oxygen scavenger is acetone oxime;

[0052] Described stabilizing agent is hydroxypropyl methylcellulose;

[0053] A preparation method of a carbon monoxide composite suppression absorbent for coal mines, comprising the following steps:

[0054] (1) Prepare 2000kg of water according to the above-mentioned composition ratio, 4kg of oxygen scavenger (acetone oxime), 100kg of CO absorbent (cuprous chloride), 500kg of CO absorbent solubiliz...

Embodiment 3

[0064] A composition ratio of a carbon monoxide composite suppression absorbent for coal mines:

[0065] CO absorbent 50kg;

[0066] CO absorbent solubilizer 250kg;

[0067] CO generation inhibitor 803kg;

[0068] Oxygen scavenger 4kg;

[0069] Stabilizer 1.55kg;

[0070] 2000kg of water.

[0071] The CO absorbent is cuprous chloride.

[0072] The CO absorbent solubilizer is a mixture of ammonium chloride and citric acid;

[0073] The CO formation inhibitor is a mixture of urea, calcium chloride, sodium chloride and magnesium chloride, wherein 600kg of urea, 50kg of calcium chloride, 50kg of sodium chloride and 100kg of magnesium chloride.

[0074] The oxygen scavenger is acetone oxime;

[0075] The stabilizer is hydroxypropyl methylcellulose.

[0076] A preparation method of a carbon monoxide composite suppression absorbent for coal mines, comprising the following steps:

[0077] (1) Prepare 2000kg of water, 4kg of oxygen scavenger (acetone oxime), 50kg of CO absorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com