Safety monitoring system

A technology of safety monitoring system and controller, which is applied in the direction of closed-circuit television system, instrument, alarm, etc., can solve the personal safety hazards of staff and other problems, and achieve the effect of realizing safe production and avoiding the hazards of toxic and harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

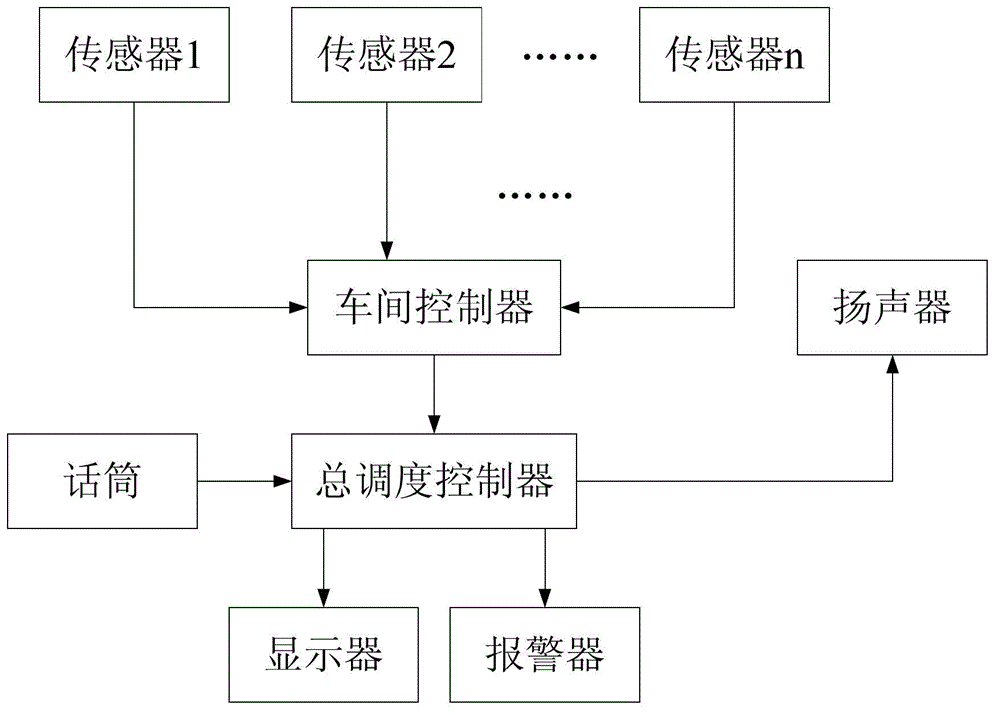

[0019] The safety monitoring system provided in this embodiment is suitable for chemical production workshops, and is mainly used for monitoring toxic and harmful gases and production and installation status in chemical production workshops. figure 1 shows the structural block diagram of the safety monitoring system of this embodiment, refer to figure 1 As shown, the safety monitoring system includes sensors installed at multiple monitoring points in the chemical production workshop, such as figure 1 Sensor 1, sensor 2 ... sensor n shown in the figure, a plurality of said sensors are connected to the workshop controller, each production workshop will set up a safety contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com