Underpass superhighway tunnel trunk excavation static blasting construction method

A technology of static blasting and expressway, which is applied in the field of tunnel blasting and excavation, can solve problems such as unreasonable construction process, damage to tunnel initial support, and difficulty in controlling adverse effects of strata, so as to achieve safe production, reduce damage, and expand The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention is described in detail below with reference to accompanying drawing and embodiment:

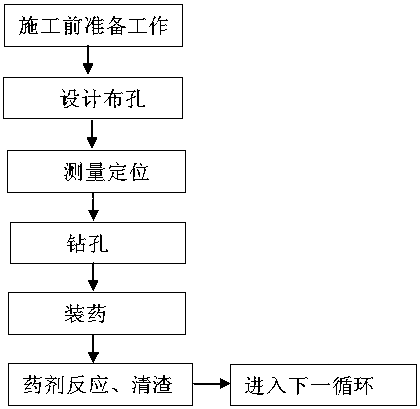

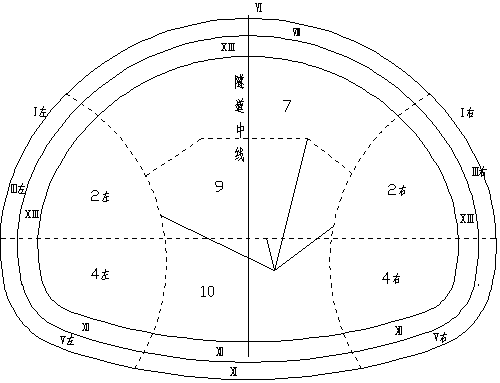

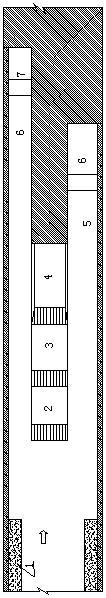

[0068] attached Figure 1-5 It can be seen that a static blasting construction method for tunnel body excavation passing through the expressway follows the principles of "short footage, weak blasting, less disturbance, early spraying and anchoring, frequent measurement, and tight sealing" in the excavation and support construction of the tunnel body. According to the principle, all the surrounding rocks of this tunnel are excavated by double-side-wall pilot pit method. The footage of each section of the Tangjin expressway tunnel is controlled within the range of 0.8-1.0m.

[0069] Excavation of Level Ⅴ Surrounding Rock of Tunnel

[0070] ① For the excavation sequence of V-level surrounding rock, see figure 1 .

[0071] ② The sequence of excavation and support is described as follows:

[0072] The excavation and support of the tunnel body include the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com