Down-hole tunnel suspended stepping self-moving advance timbering

A technology of self-moving and underground tunnels, which is applied to mine roof supports, mining equipment, earth-moving drilling, etc. Efficiency, increase labor productivity, achieve full utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

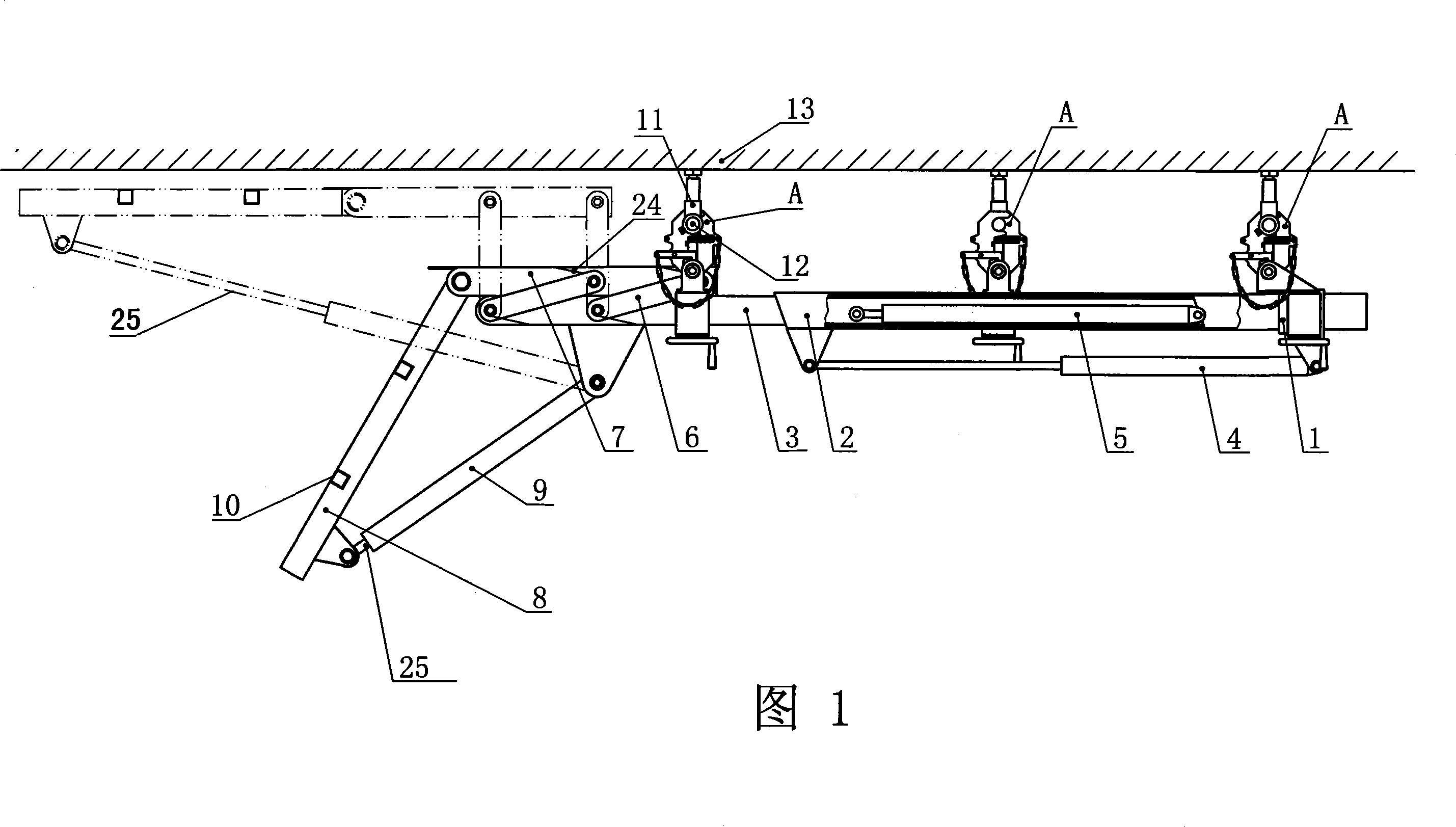

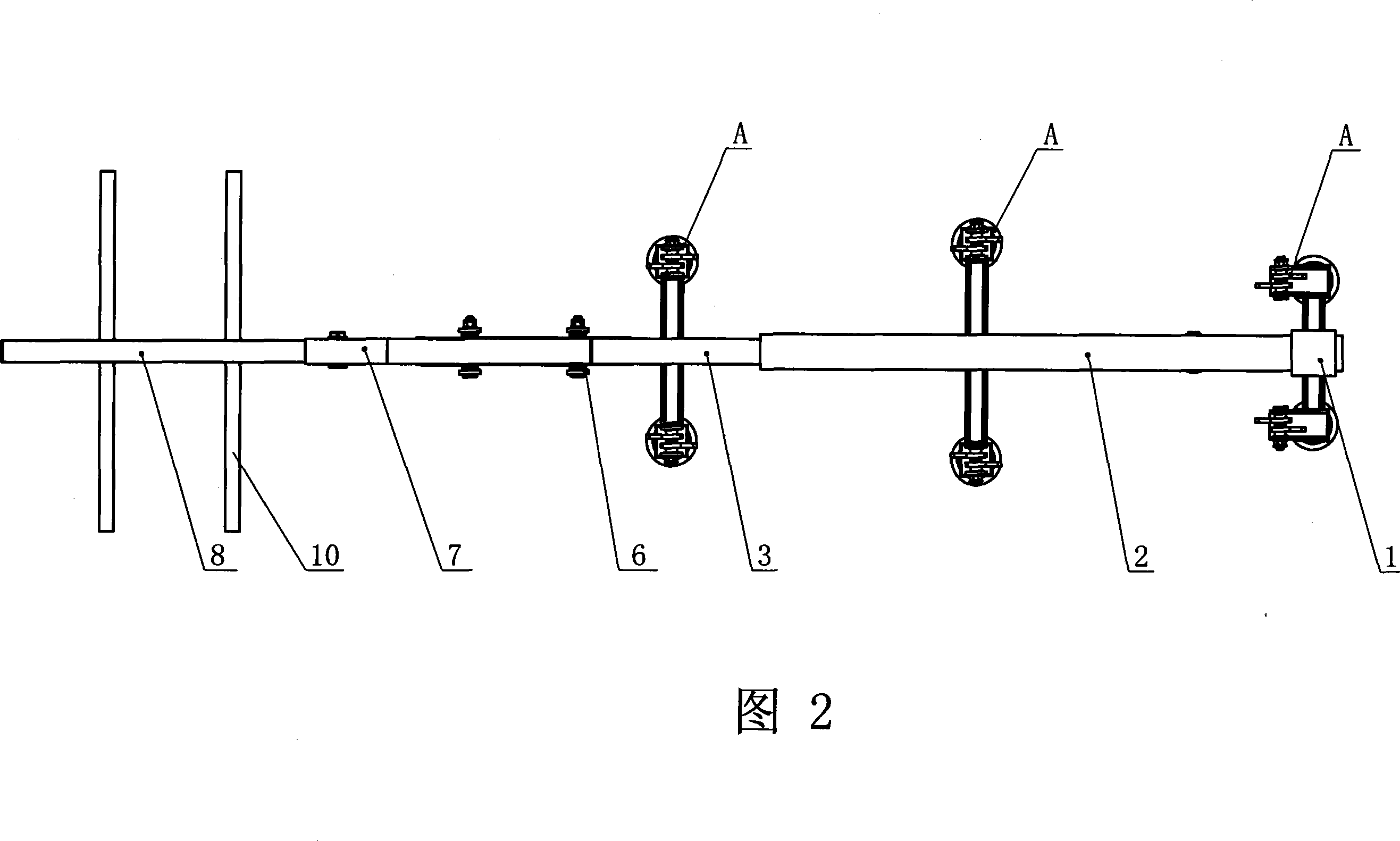

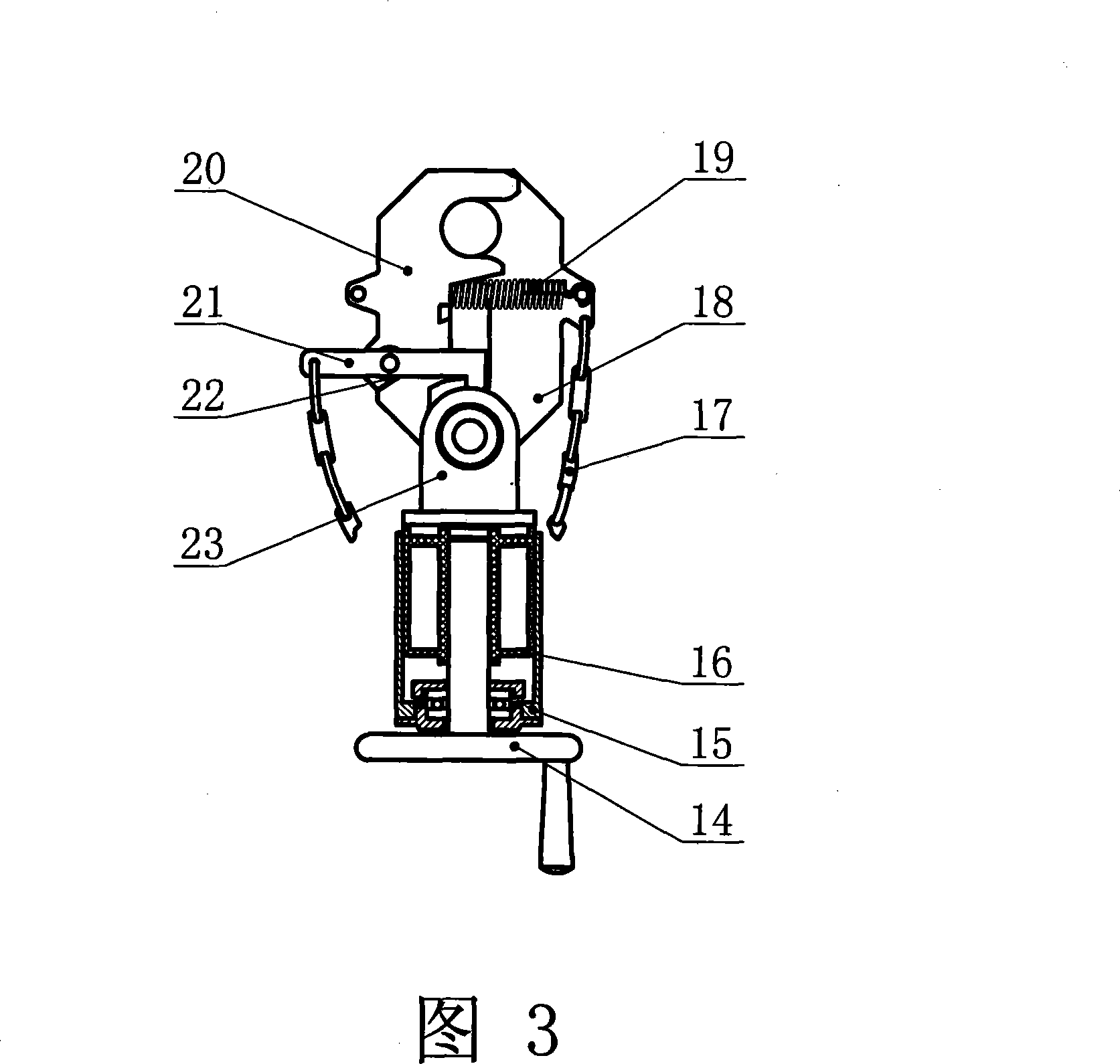

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] As shown in Fig. 1 and Fig. 2, it consists of a telescopic and variable degree of freedom hydraulic support mechanism, a walking and moving mechanism, a manipulator A and a cantilever beam 12 grasped by the manipulator A, the hydraulic support mechanism and the walking and moving mechanism Connected and move with the walking mechanism. The variable degree of freedom hydraulic support mechanism is located in the front section of the walking mechanism, and the temporary support for the roof of the roadway is realized by driving the hydraulic cylinder 9. The variable degree of freedom hydraulic support mechanism consists of a rocker four-bar mechanism and a parallelogram mechanism The rocker four-bar mechanism is composed of a drive hydraulic cylinder 9, a piston rod 25, a support arm 8 and a telescopic arm 3 that are sequentially hinged together, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com