Stratified blasting method for coal mine hard roof

A technology for hard roof and coal mine, which is applied in the field of blasting of coal mine roof, can solve the problems of imperfect hard roof blasting technology, and achieve the effect of operability, high efficiency and safe production of coal mine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

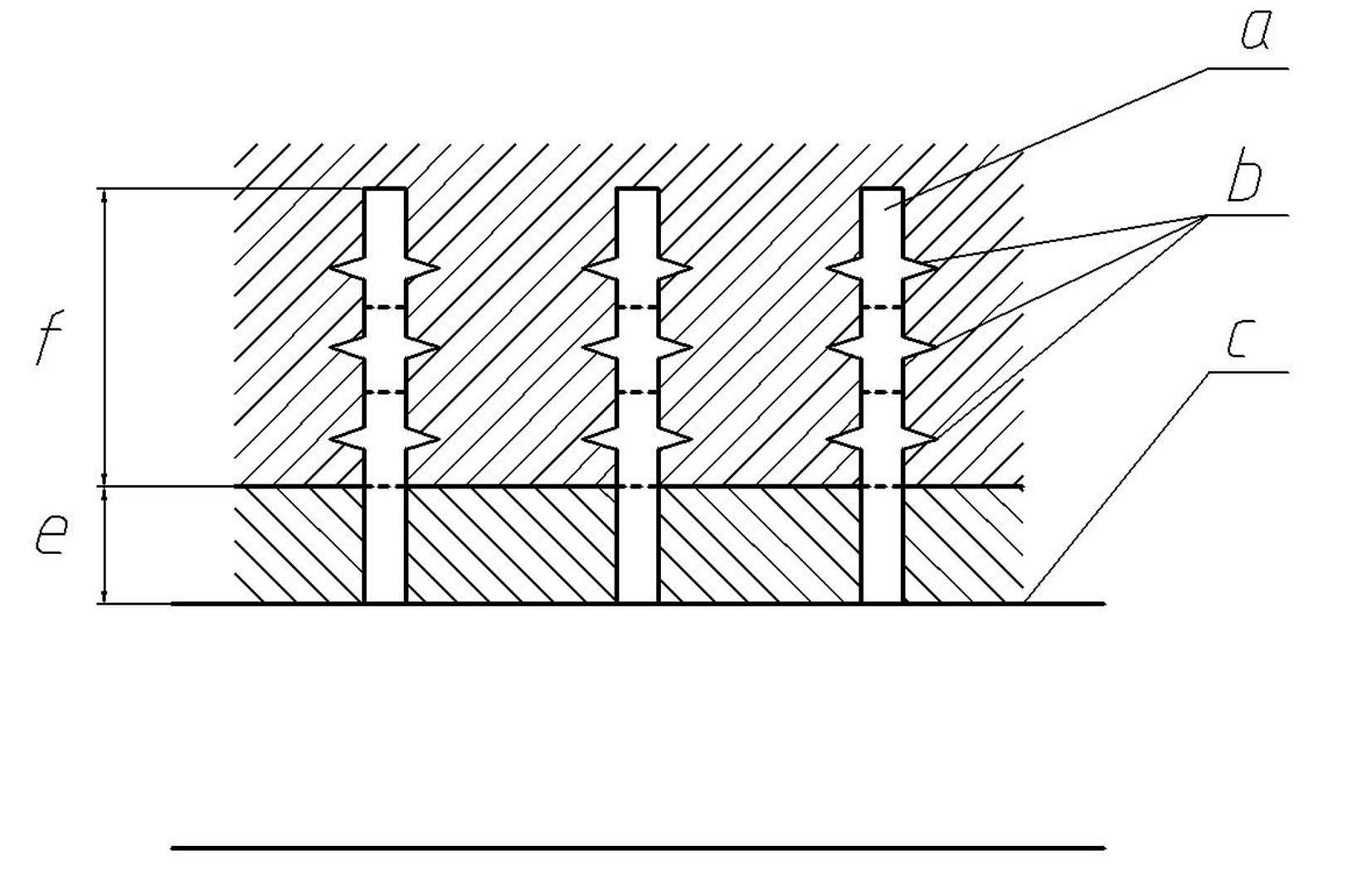

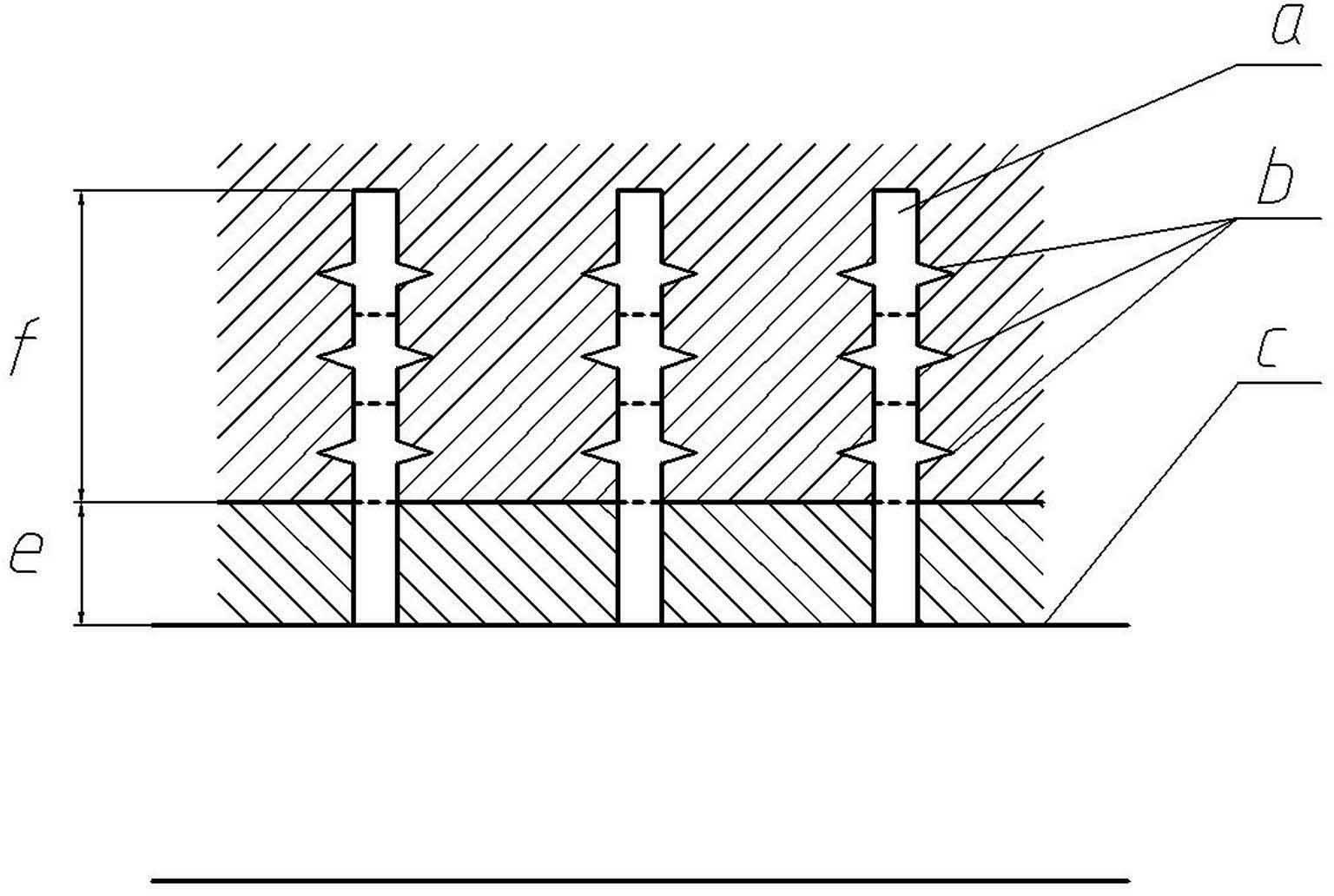

[0012] A layered blasting method for a hard roof in a coal mine, comprising the following steps,

[0013] (1) On the roof c of the mining face, use a drilling rig to drill a number of evenly distributed vertical boreholes a. The depth of each borehole a is the sum of the height e of the immediate roof and the height f required to break the old roof. Within the range of the height f of the old roof fracture, the borehole a has several wedge-shaped groove pre-cracks b along its depth;

[0014] (2) Each borehole a is charged, the number of charge layers is the same as the number of wedge-shaped groove pre-cracks b, the length of each layer of charge is the same as the distance between two adjacent wedge-shaped groove pre-cracks b, and the wedge-shaped groove pre-cracks are guaranteed b is located in the middle of each layer of charge. The charge step includes sending the priming charge, gun soil and wooden wedges into the borehole in sequence. The priming charge includes explosiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com