Automatic formwork release and assembly device

A mold clamping device and automatic demoulding technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of cumbersome operation process, hidden safety hazards, manpower consumption, etc., and achieve the effects of easy operation, safe production and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

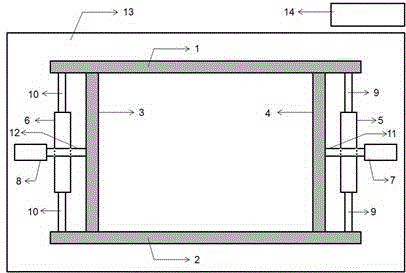

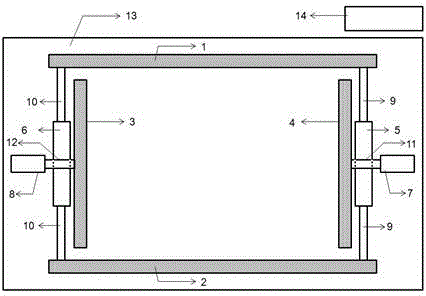

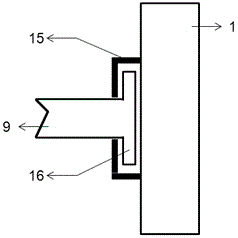

[0012] Embodiment: After the prefabricated reinforced concrete wallboard is prepared in the mold, in the control system 14, the working time of each hydraulic cylinder and the displacement of each connecting rod are set by adjusting the buttons 22, 23, 24, and 25. Operate the handles 17, 18, 19, 20 again, so that the four frames 1, 2, 3, and 4 of the mold are all displaced by 100 mm to the outside, so that the wallboard is automatically separated from the mold. Subsequently, the four frames 1, 2, 3, and 4 of the mold all generate a displacement of 100mm to the inside, and thus the automatic mold closing of the mold is completed.

[0013] The invention is simple in structure, easy to operate, realizes the automatic demoulding and mold closing of prefabricated reinforced concrete wall panels, meets the requirements of the automatic production line of standardized assembled houses for the preparation and release of prefabricated reinforced concrete wall panels, and saves a lot of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com