Method for underground chamber digging and laneway opening digging

A tunnel and tunnel technology, which is applied in the field of tunnel opening and tunnel tunneling with comprehensive mechanized tunneling equipment, can solve the problems of difficult support, high labor intensity of workers, and increased auxiliary processes, so as to improve the level of mechanized equipment and reduce the number of workers. Labor intensity, the effect of reducing mechanical handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

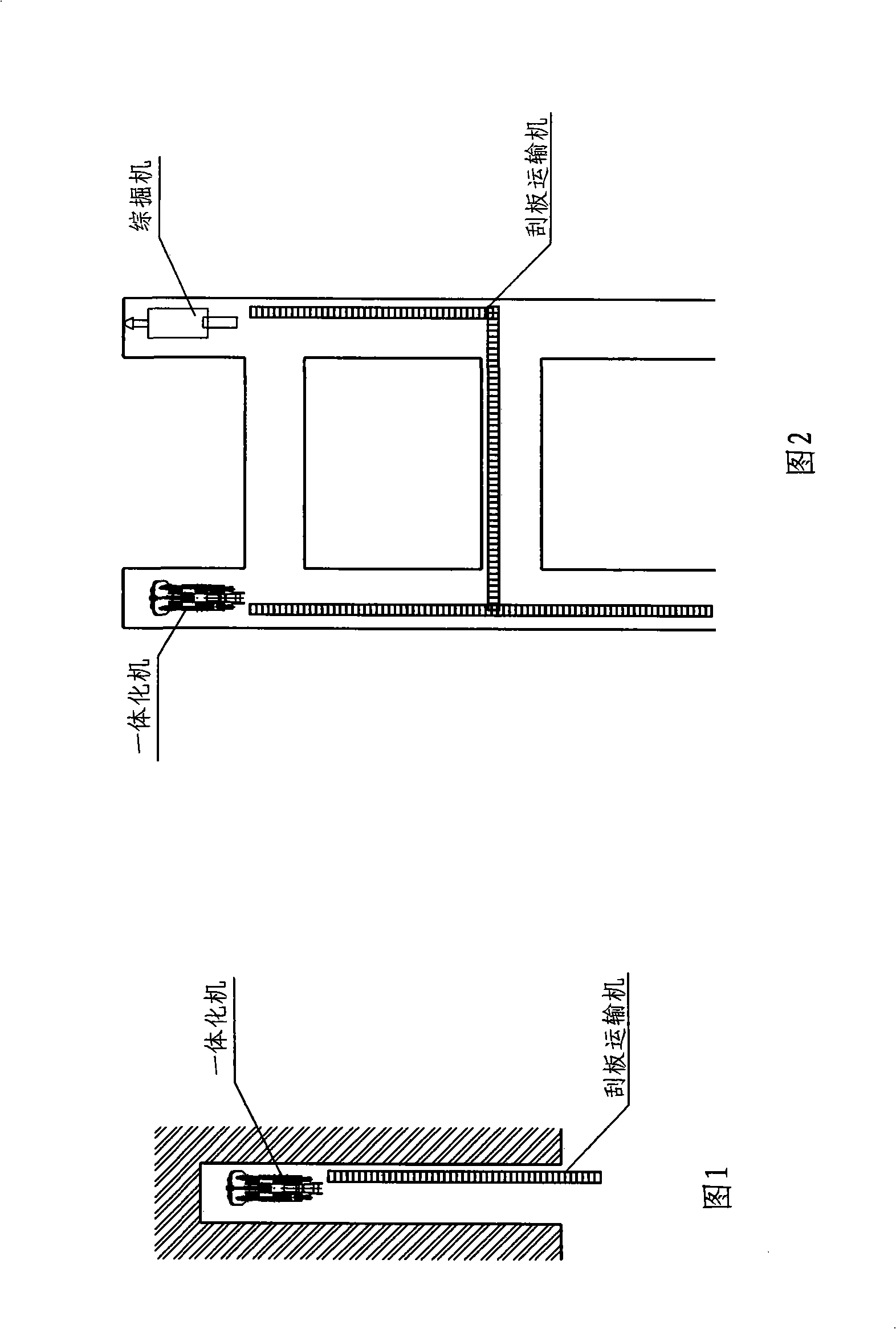

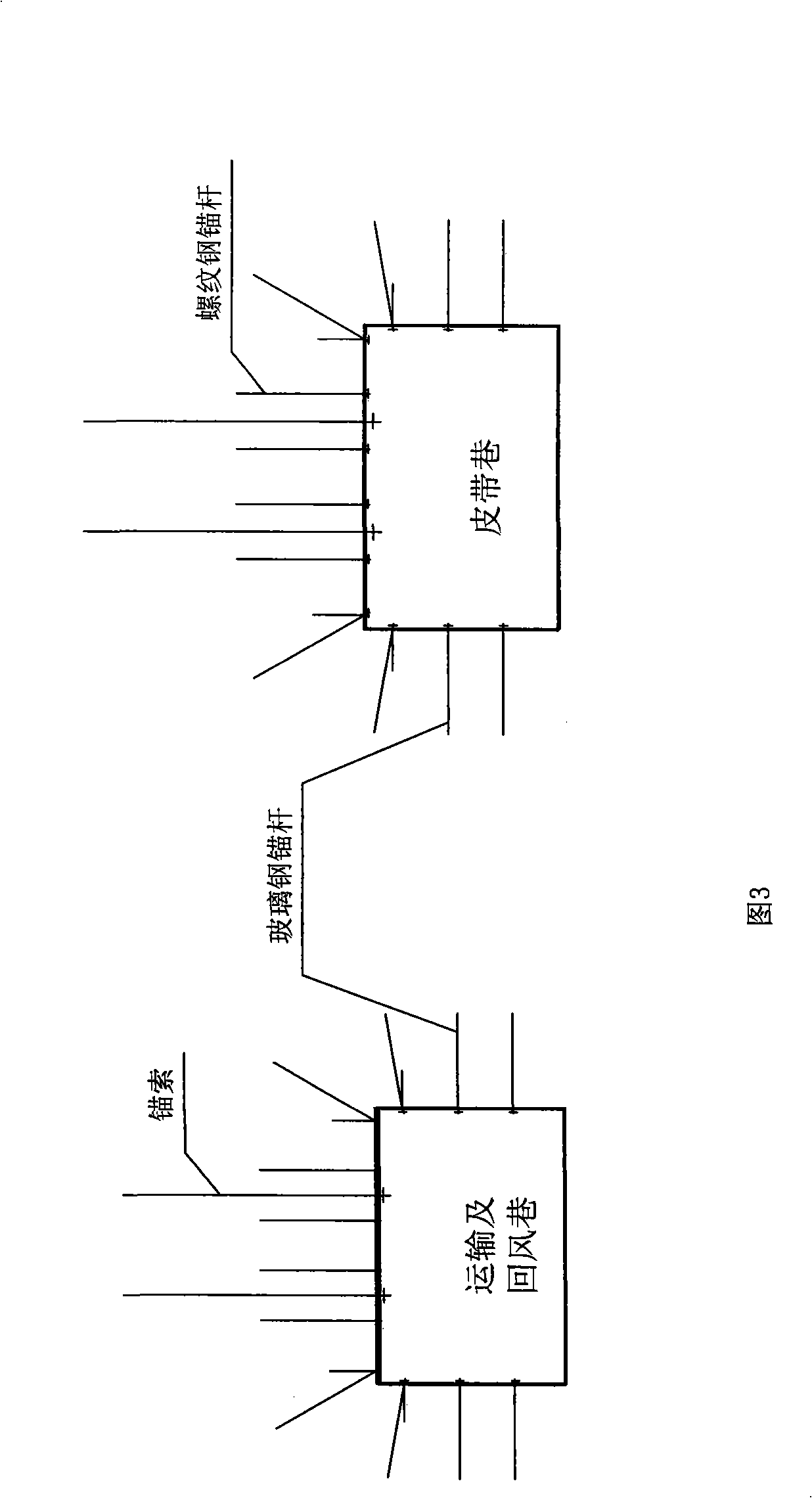

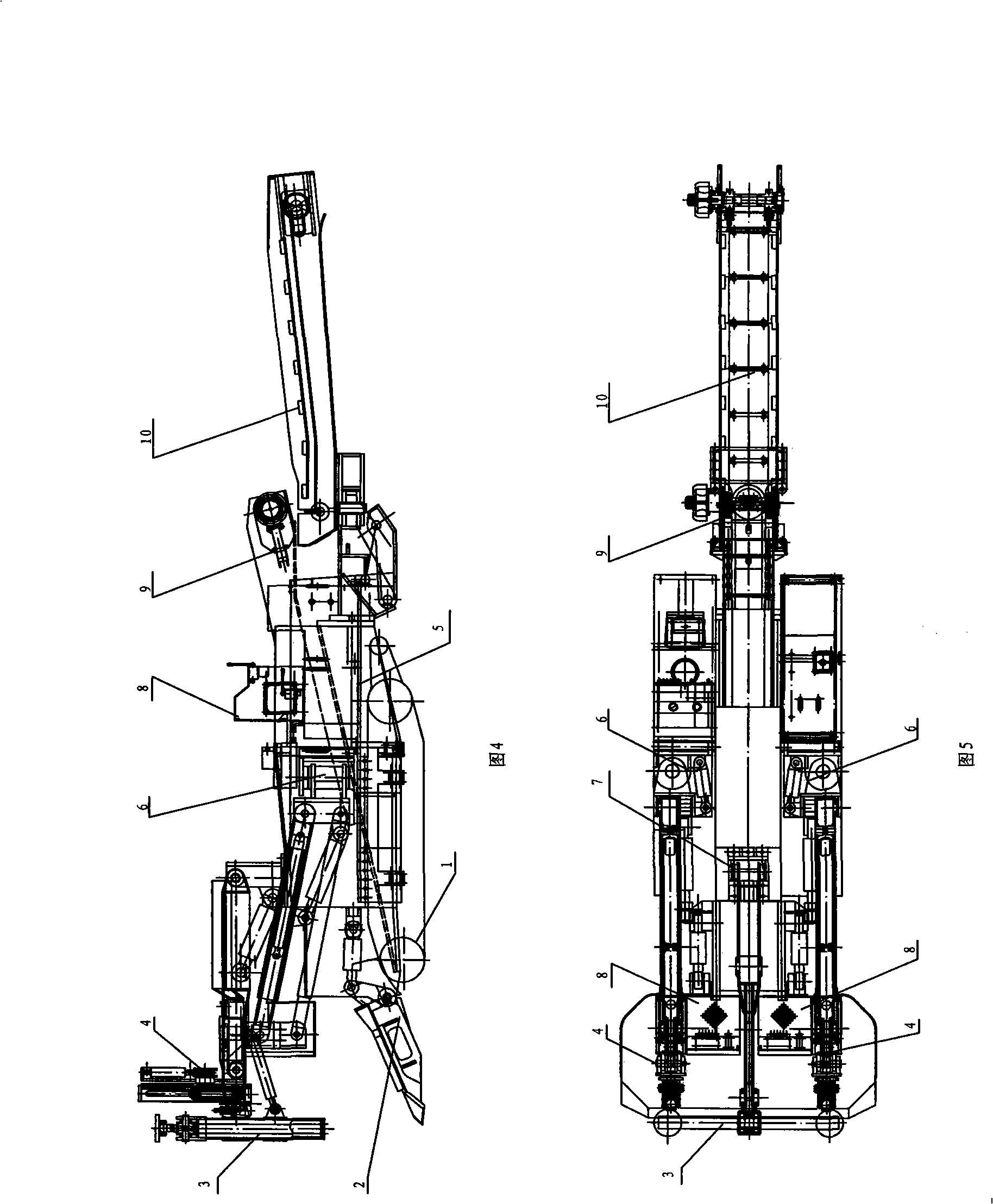

[0033] The roadway opening excavation and chamber excavation are carried out by drilling, blasting and dropping coal, smooth blasting, coal loading, coal transportation; drilling, mechanical support and other processes; as shown in Figure 1, it is a schematic diagram of the layout of the single-lane excavation integrated machine; The mechanical equipment used in the method of inventing roadway opening excavation and chamber excavation has integrated machine, fully mechanized excavator and scraper conveyor (belt slipper) system, and described concrete process is:

[0034] 1. Drilling: According to the requirements of the operation regulations and the blasting chart, the two hydraulic drilling rigs on the integrated machine will implement the blasting construction;

[0035] 2. Charging and blasting: manually charge and blast, implement smooth blasting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com