High-molecular material foaming device and application method thereof

A polymer material and foaming device technology, which is applied in the field of polymer material foaming, can solve the problems of limiting radio frequency heating, etc., and achieve the effects of rapid and efficient foaming, good working conditions and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

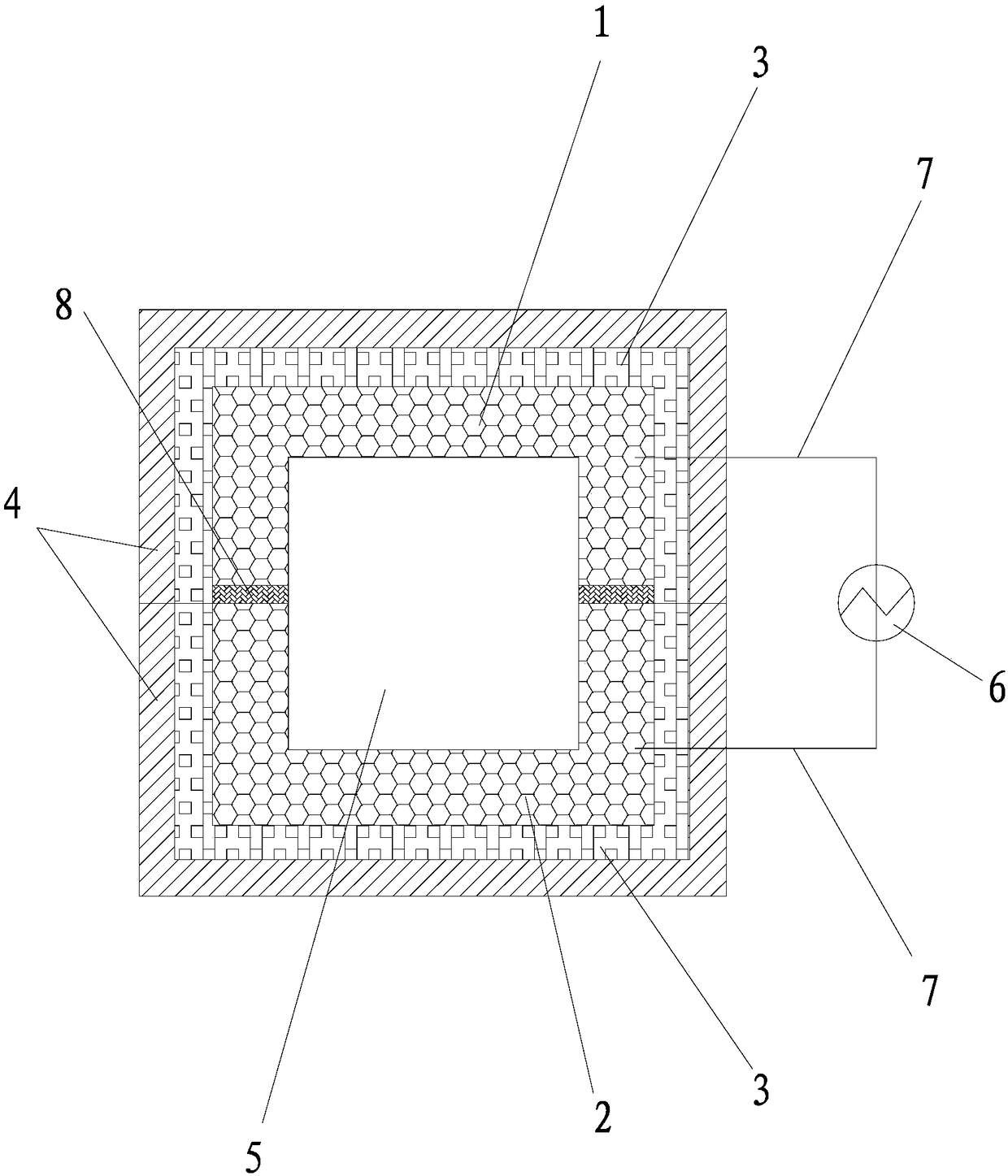

[0024] A foaming device for polymer materials, suitable for foaming PU, TPU, EVA, PE, PP, PU, SEBS and other elastomer materials or blended materials. Even for non-polar or low-polar polymer materials that do not absorb radio frequency, they can also be used as radio frequency absorbers by blending highly polar materials, such as -OH, -NH in the molecular structure 2 , -COOH and other highly polar functional groups, or macromolecules that can form intramolecular or intermolecular hydrogen bonds in the molecular structure; and non-macromolecular chemical substances such as water molecules, alcohols, glycerin, graphite, salt, etc. Both can be used as radio frequency absorbers to realize radio frequency heating of polymer materials. Such as figure 1 As shown, including foaming mold and high frequency power supply 6. The high-frequency power supply 6 is a known technology. The above-mentioned foaming mold includes an upper mold 1 and a lower mold 2 , an insulating spacer is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com