All surface grinding and shaping automation processing center for hard and crisp particle's products

A hard and brittle material, machining center technology, applied in polishing machine tools and grinding fields, can solve problems such as low production efficiency and inability to automate production, and achieve the effects of fast processing speed, high work efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

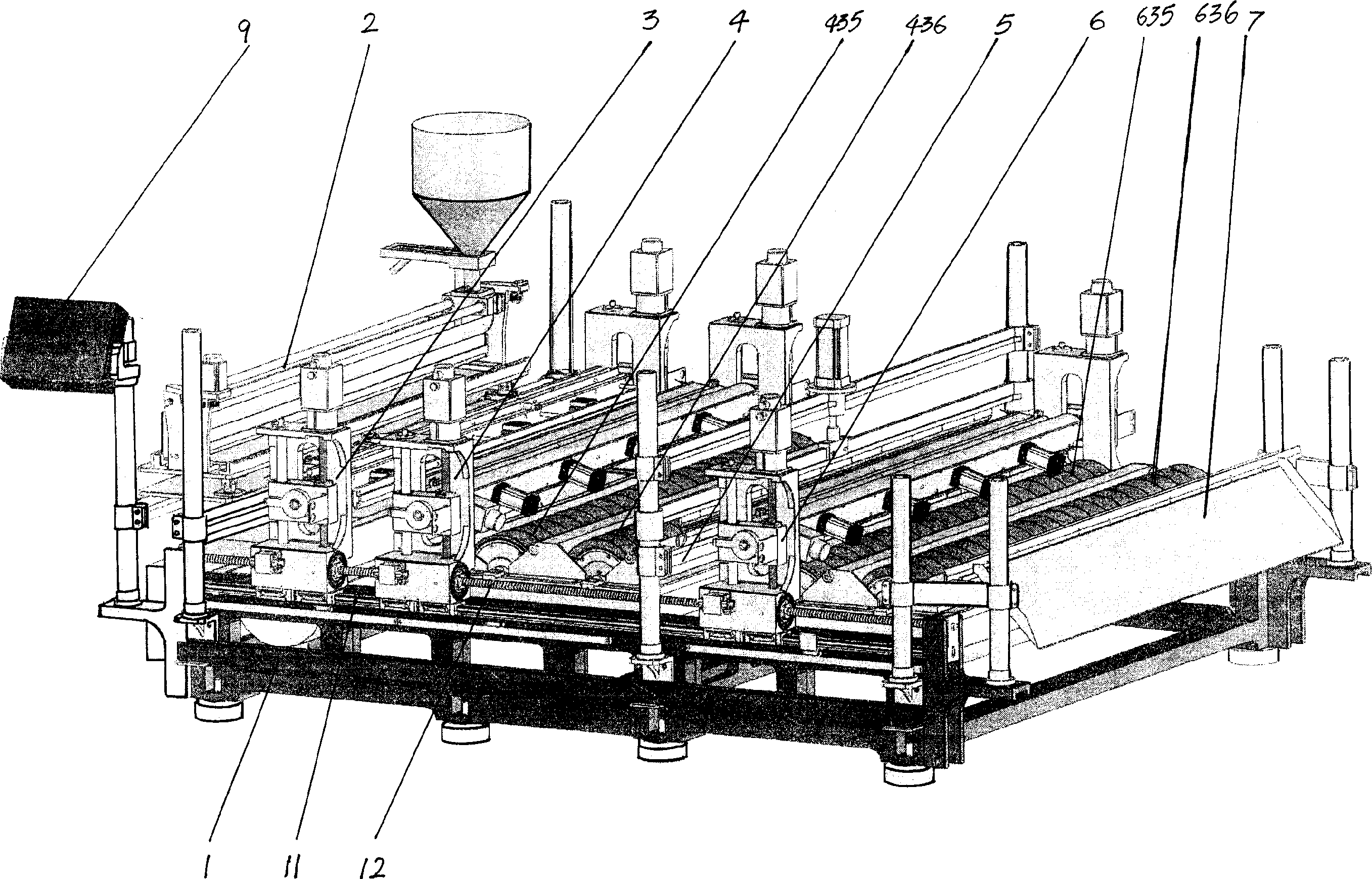

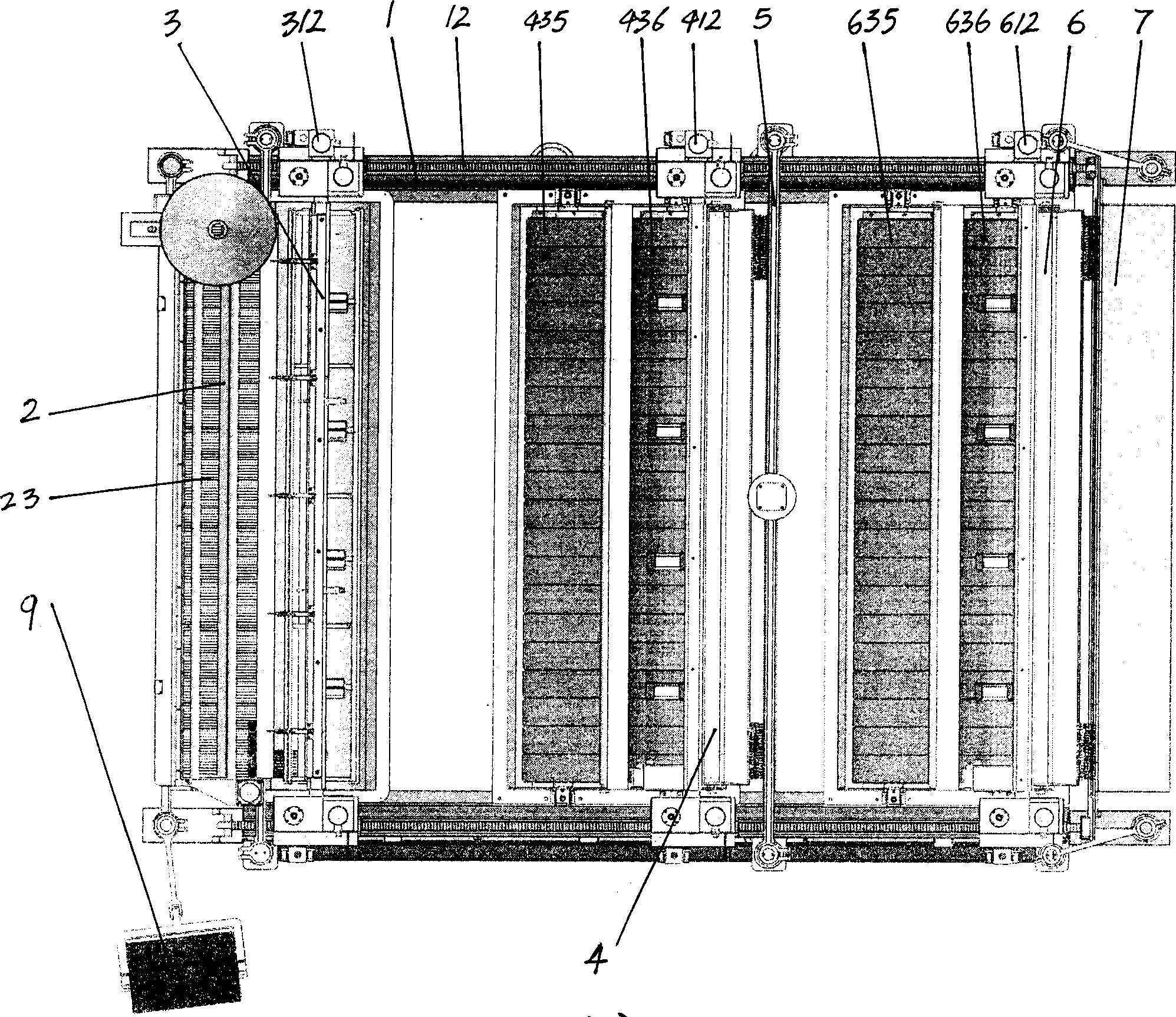

[0047] Depend on Figure 1-26 Represented is an embodiment of the present invention, the full-surface grinding and forming automatic machining center of hard and brittle material particle products, which includes an automatic control circuit device 9, a gantry bed 1, and the beginning of the gantry bed 1 is provided with an automatic arrangement of feeding materials. Device 2, the gantry bed 1 is sequentially provided with a receiving and feeding device 3, a workpiece front surface grinding and polishing device 4, a workpiece transfer device 5, a workpiece rear surface grinding and polishing device 6, a workpiece unloading device 7, and a gantry bed Track rail 11 and screw mandrel 12 are housed on body 1.

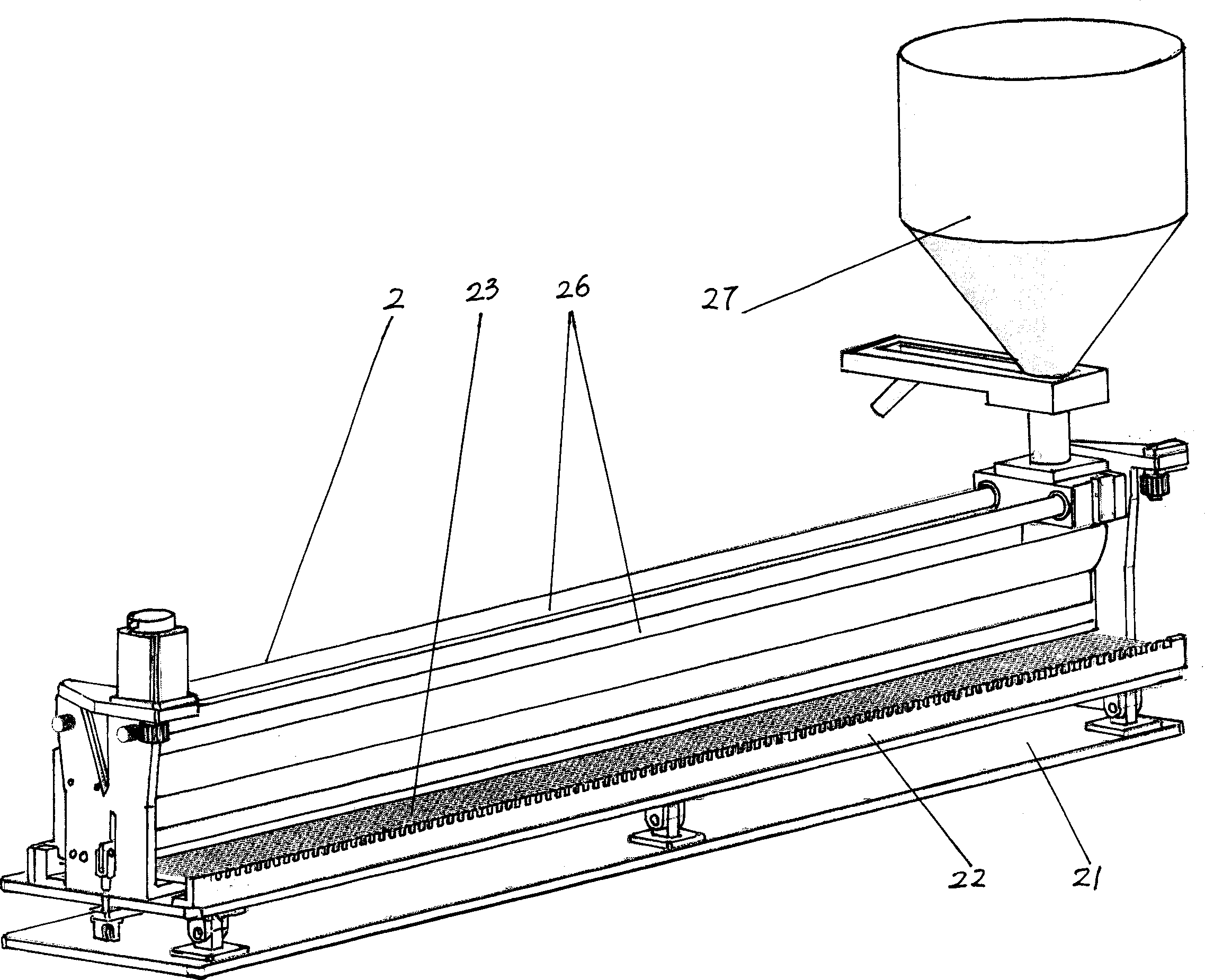

[0048] The automatic arrangement feeding device is that the support 21 is equipped with a frame 22 that can adjust the horizontal inclination in the X-axis direction, that is, along the direction of the track 11. The frame 22 is equipped with 200 threaded rollers 23 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com