Device and method for continuously preparing small-particle reclaimed rubber with low Mooney rebound

A technology of reclaimed rubber and small particles, applied in the field of reclaimed rubber, can solve the problems of affecting the cooling, transportation and packaging of reclaimed particles, poor elongation at break of mechanical properties, aggravating the adhesion of reclaimed particles, etc., to improve the practicality. Value, the particles are easy to dissipate heat without sticking, and the effect of improving the temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

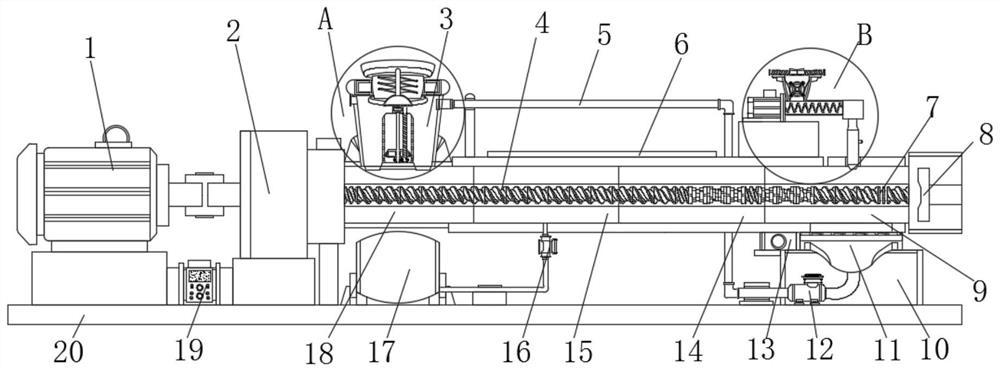

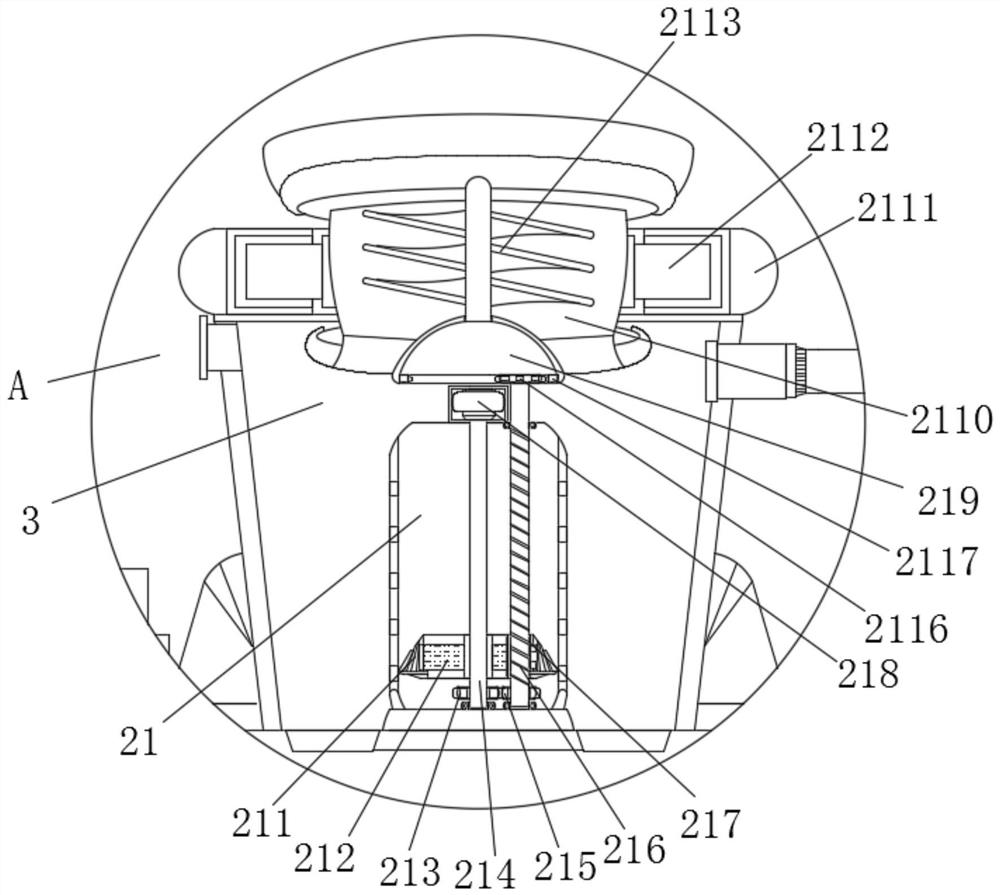

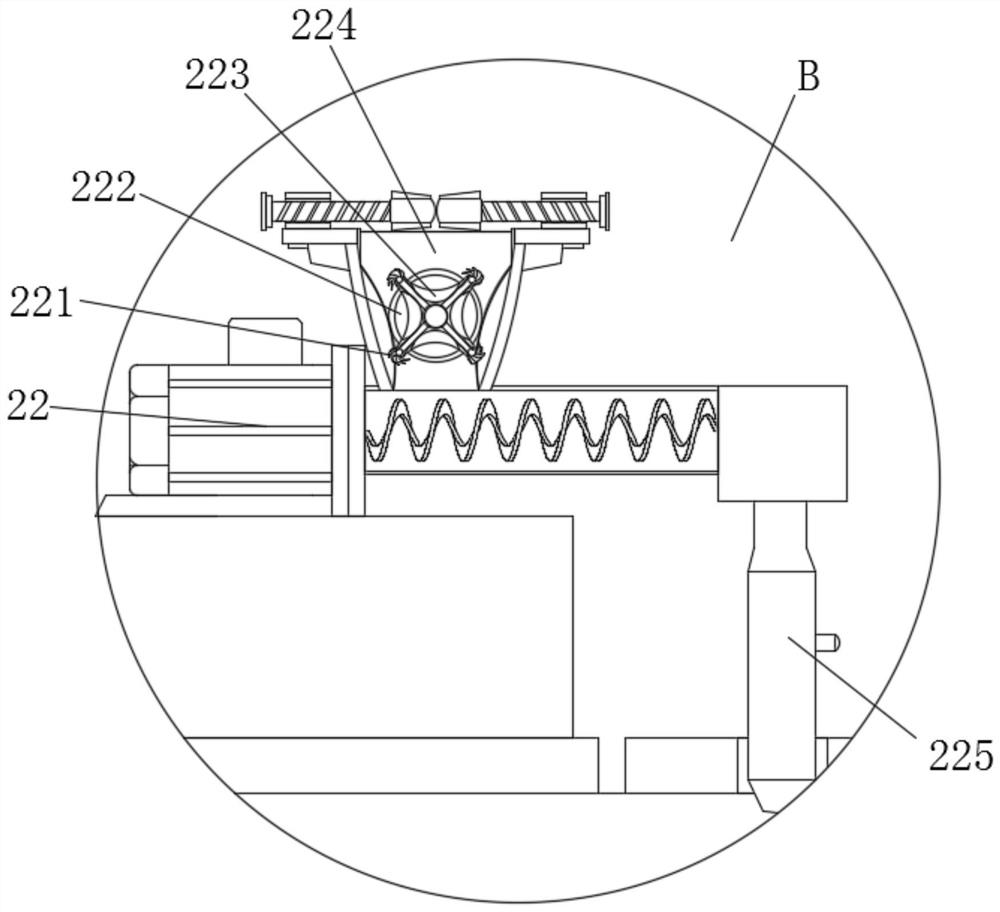

[0045]Example 1, the desulfurized rubber powder with a Mooney viscosity of 180 enters the fully meshing co-rotating twin-screw extrusion mechanism 4 through the feeding device, the temperature of the first extrusion conveying section 18 is controlled at 25°C, and the screw element is the conveying element and meshing The combination of the original parts, the depth of the screw groove is 20mm; the temperature of the compression and refining section 15 is controlled by a mold temperature meter to 100°C, the pressure is 8.0Mpa, the thread element is an engaging block, the depth of the screw groove is 10mm, and the temperature of the shearing and refining section 14 The temperature is 15°C, the pressure is 2.0Mpa, the temperature of the steady-flow cooling conveying section 9 is 10°C, the screw element is a combination of the conveying element and the toothed disk 7, the depth of the screw groove is 5mm, and the end is the toothed disk 7, by passing 0.05 The carbon dioxide fluid o...

Embodiment 2

[0047] Example 2, the desulfurized rubber powder with a Mooney viscosity of 200 enters the fully meshed co-rotating twin-screw extrusion mechanism 4 through the feeding device, and the temperature of the first extrusion conveying section 18 is controlled to be 20°C. The screw element is the conveying element. The groove depth is 15mm, the temperature of the compression and refining section 15 is controlled by a mold temperature instrument to be 120°C, and the pressure is 10.0Mpa. The threaded element is an engaging block, and the depth of the screw groove is 8mm. At 3.0Mpa, the temperature of the steady-flow cooling conveying section 9 is 8°C, the screw element is a combination of the conveying element and the toothed disk 7, the depth of the screw groove is 7mm, and the end is the toothed disk 7, by adding 1.5% carbon dioxide by mass The fluid is added in the compression refining section 15 of the extruder to make it in a state of supercritical carbon dioxide, and 0.5% calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com