Patents

Literature

39results about How to "Guaranteed product performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

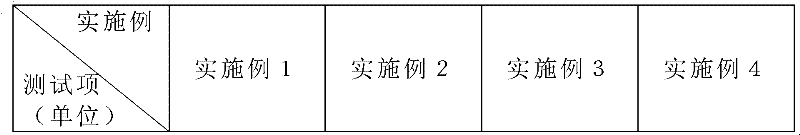

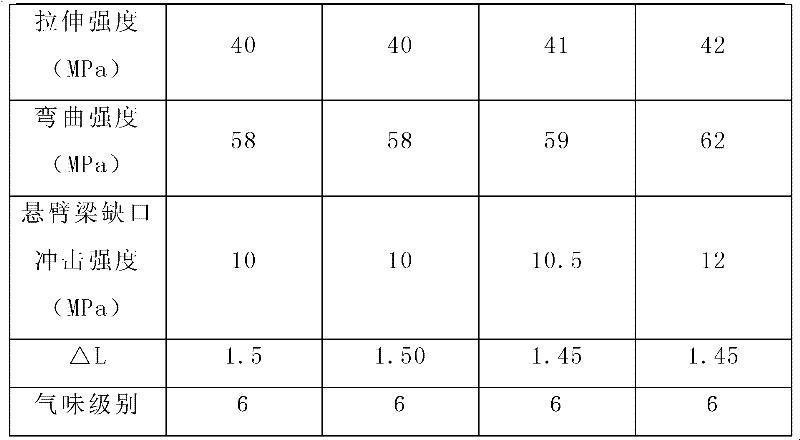

Low-odor scraping-resistant polypropylene material and preparation method thereof

The invention relates to a low-odor scraping-resistant polypropylene material and a preparation method of the low-odor scraping-resistant polypropylene material and belongs to the technical field of polypropylene materials. In order to solve the technical problems that the odor of the polypropylene material in the prior art is difficult to eliminate, the odor can be eliminated only through aiming at a certain single ingredient, the scraping resistance is poor, and the production cost is high when fluorine-containing polymers are adopted for production. The invention provides the low-odor scraping-resistant polypropylene material and also provides the preparation method of the polypropylene material, wherein the polypropylene material comprises acrylic resin, nanometer silicon dioxide, ultra-fine talcum powder, odor eliminating agents, disperse lubricating agents, antioxidants and hindered amine light stabilizers, the method comprises material mixing and squeezing granulation steps, and the low-odor scraping-resistant polypropylene material is obtained. The polypropylene material provided by the invention has the advantages of low odor and scraping resistance. The product obtained from the material has the advantage that the performance such as tensile strength, bending strength, cantilever beam notch impact strength and delta L is high. The method has the advantages that the process is simple, the operation is easy, raw materials are easy to obtain, and the industrial production is favorably realized.

Owner:浙江明江新材料科技股份有限公司

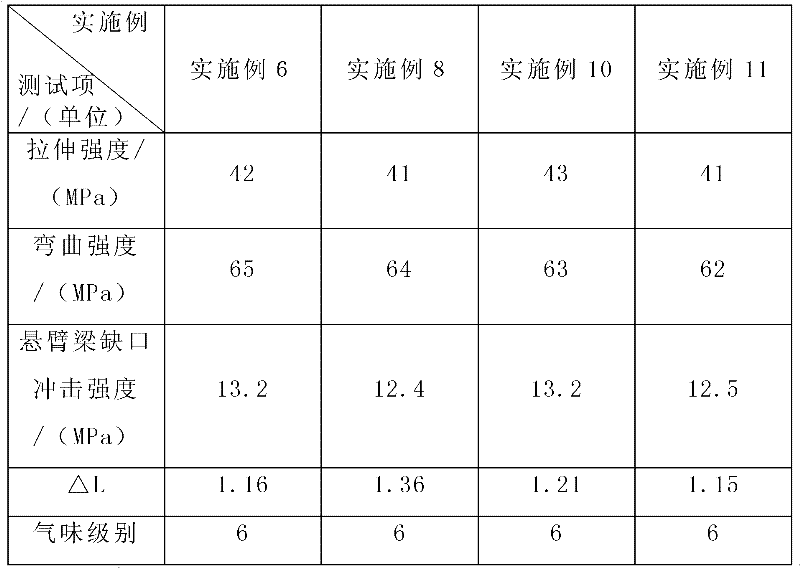

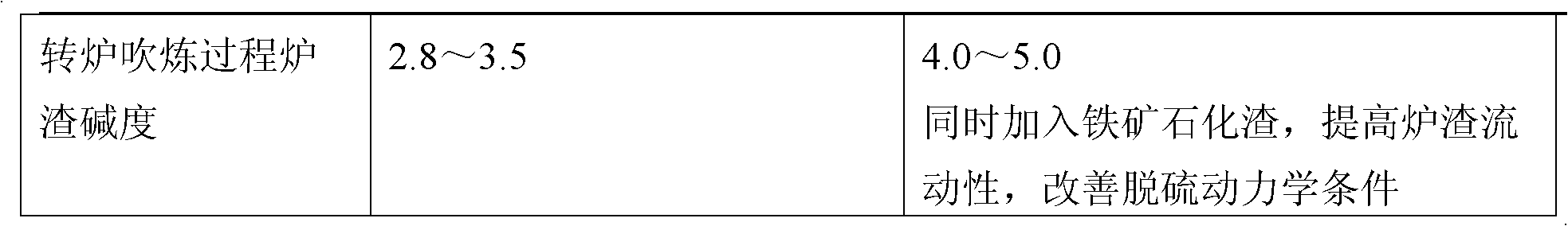

Method for realizing deep desulfurization during converter steelmaking through singly-blowing magnesium grain molten iron pretreatment

InactiveCN102094108AGuaranteed product performanceOptimizing deep desulfurization processManufacturing convertersAlkalinitySteelmaking

The invention relates to the metallurgical steelmaking field, in particular to a method for realizing deep desulfurization during converter steelmaking through the singly-blowing magnesium grain molten iron pretreatment. The method comprises the following steps: performing molten iron pretreatment, performing skimming of iron slag and smelting in a converter, wherein in the molten iron pretreatment, the temperature of molten iron is 1280-1350 DEG C, iron slag modifier is added in a ladle before molten iron is pouring in the ladle; the purity of singly-blowing magnesium grains is not less than 97%; slag conglomeration agent is added after the desulfurization of granulated magnesium, then the skimming of iron slag is performed; and the basicity of slag is 4.0-5.0 in the converting process of the converter. By adopting the method of the invention, the deep desulfurization qualification rate of molten iron pretreatment is more than 98%, the sulfur content of the treated molten iron remains stable, the recovered sulfur of molten iron is no more than 0.003% in the converting process, the average sulfur content of steel discharged by the converter is less than 0.005% and stable and ideal deep desulfurization effect can be realized.

Owner:通化市通关达环保技术设备有限公司

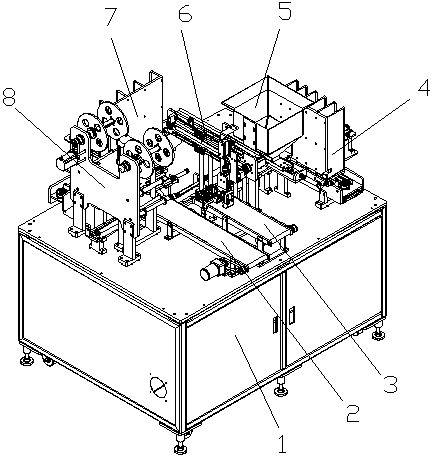

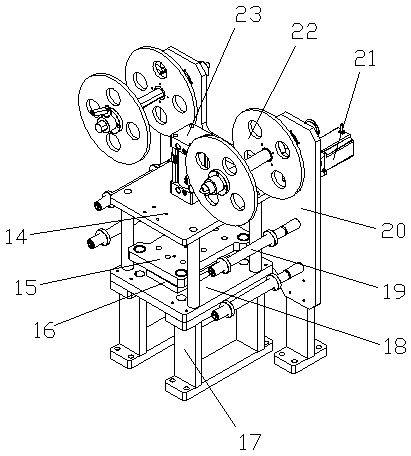

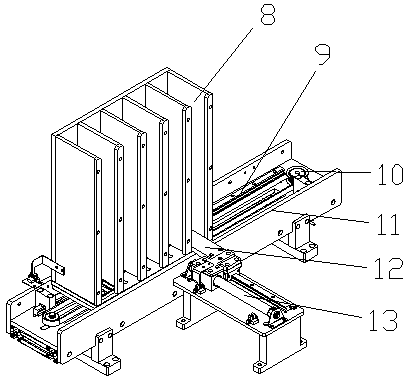

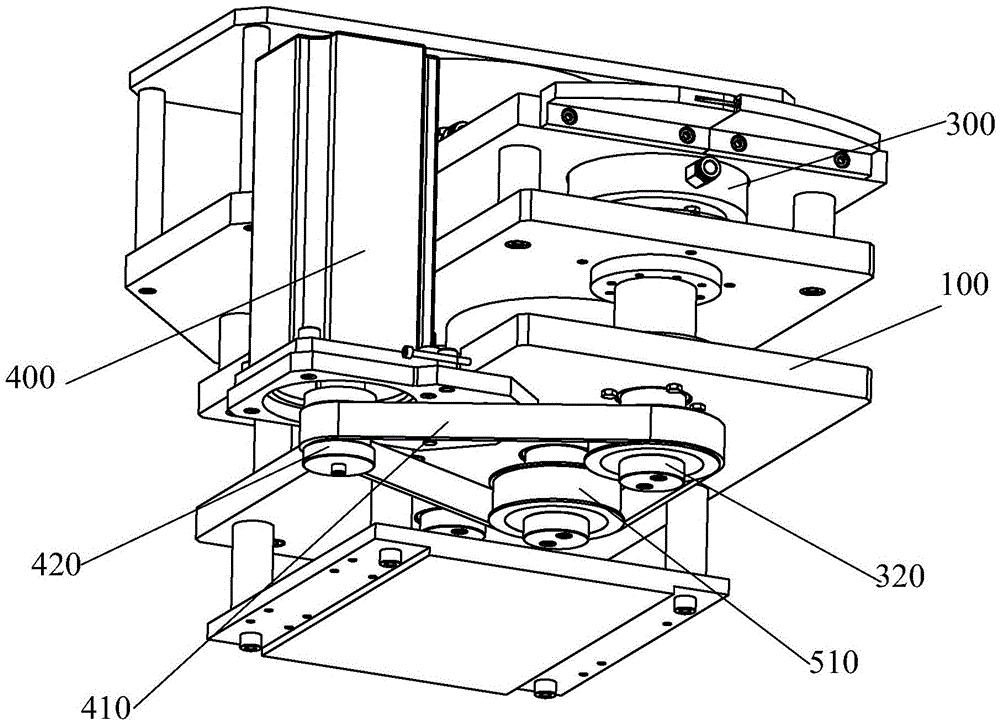

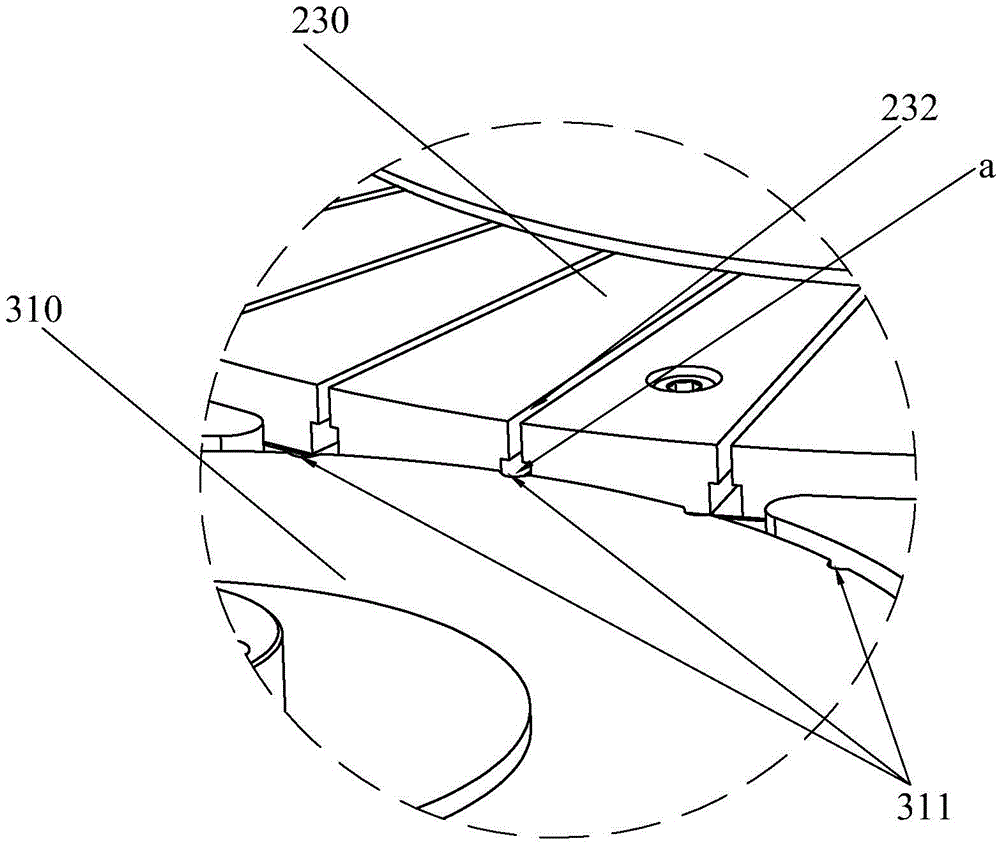

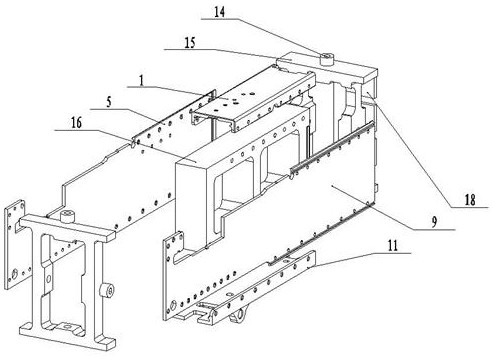

Granular material dividing boxing machine

InactiveCN108357720AGuarantee the quality of distributionGuaranteed product performancePackaging automatic controlEngineeringMechanical engineering

The invention relates to a granular material dividing boxing machine. The granular material dividing boxing machine comprises a rack and a control box. A box feeding device, a material boxing device,a carrying device, a cover feeding device and a foam cutting device are sequentially arranged on the rack. A finished product discharging rail is arranged below the foam cutting device; the box feeding device and the cover feeding device each comprise a storage box, a belt wheel, a feeding rail, a pushing plate and a pushing air cylinder; the pushing air cylinders are arranged on the rack, and sliding blocks are slidably arranged on the pushing air cylinders in a sleeving mode; the pushing plates are arranged on the sliding blocks, the feeding rails are arranged on the positions, on the lowerportions of the pushing plates, of the rack, and the belt wheels are arranged on the feeding rails and matched with the storage boxes; and the bottoms of the storage boxes are in sliding fit with thefeeding rails, and the pushing plates and box outlet holes formed in the back portions of the storage boxes are in alternating fit. According to the main operation steps of the granular material dividing boxing machine, upper covers and lower covers of products are automatically fed, foam is automatically punched into a product box, automatic boxing packaging of the products is achieved so as to ensure the dividing quality of granular materials, and accordingly the product effect is guaranteed.

Owner:邓君

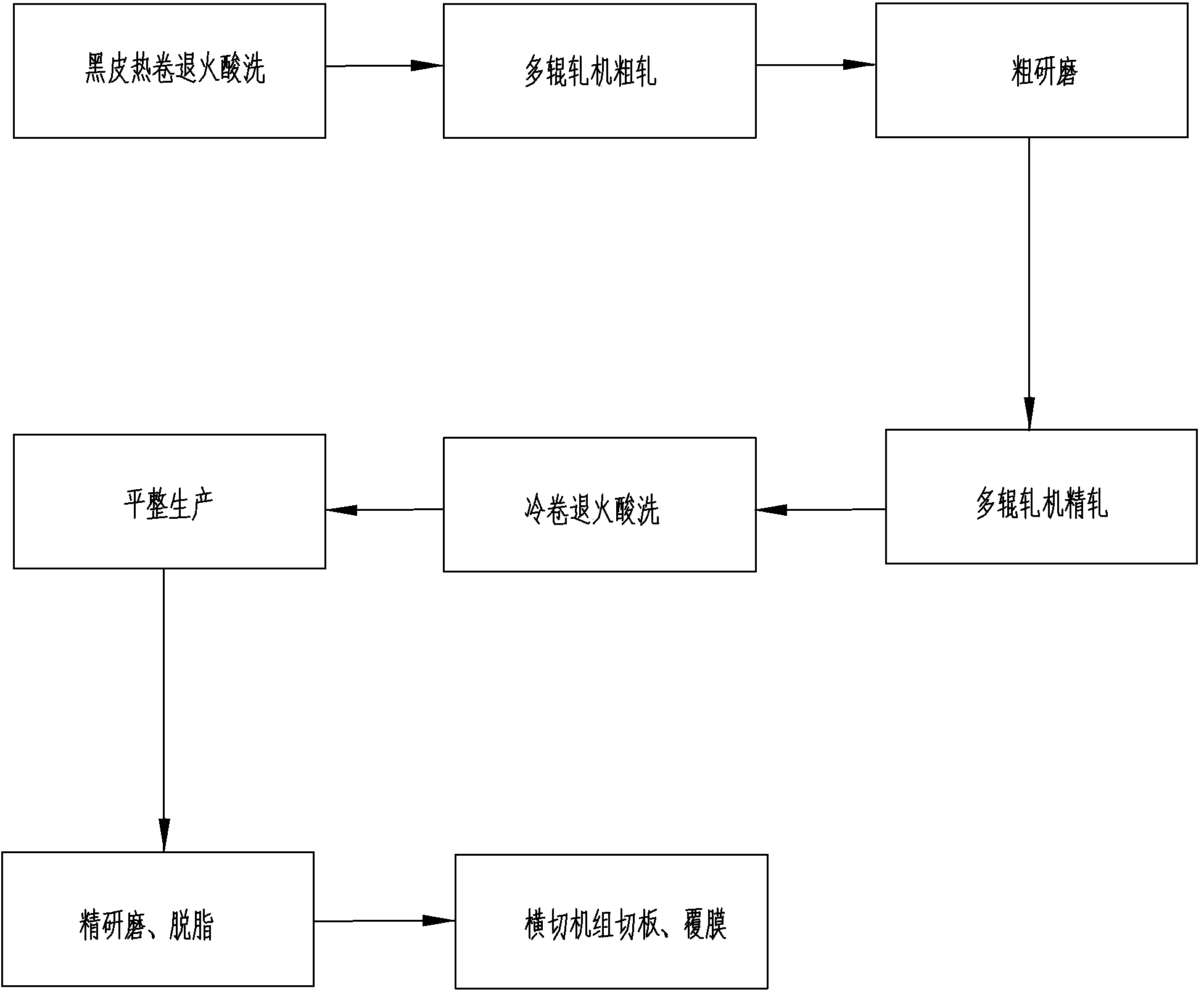

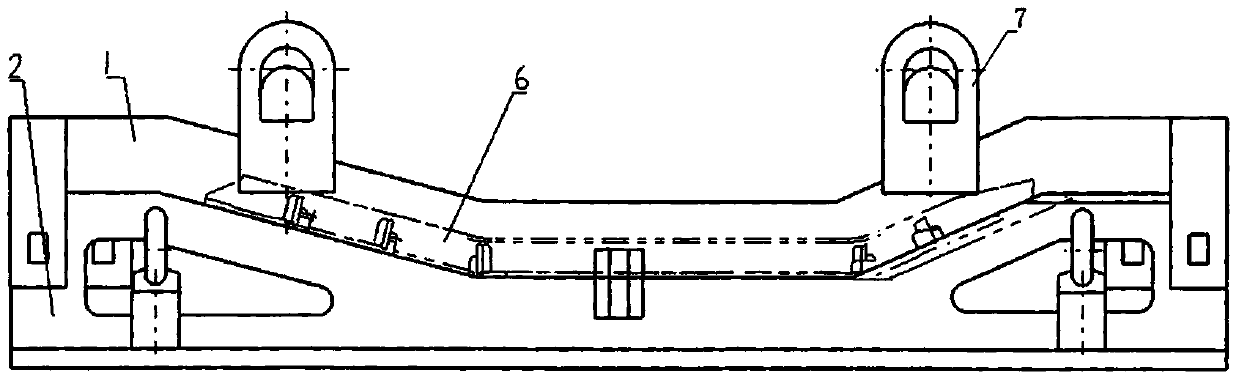

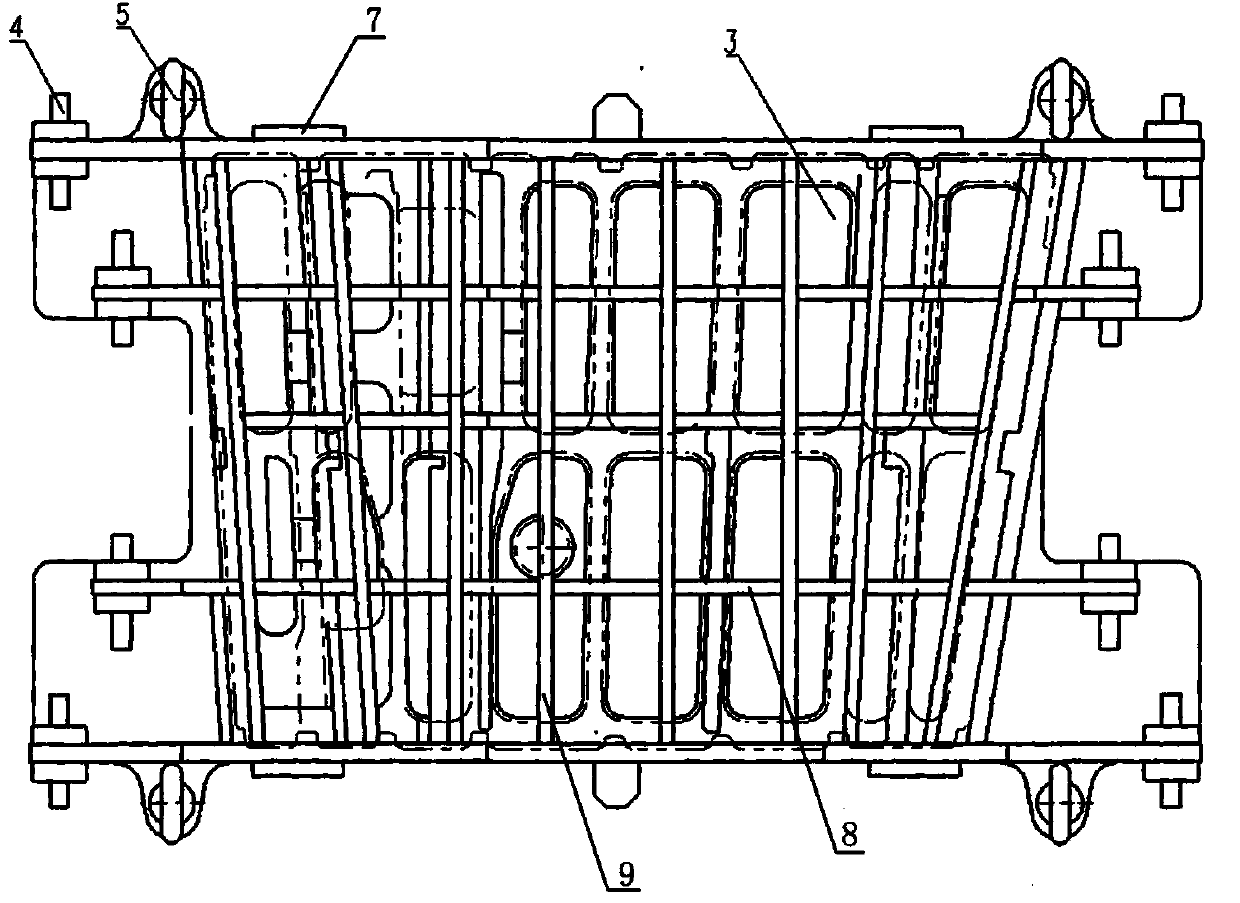

Manufacture method of stainless steel external wall panel for rail vehicle

ActiveCN103433319AGuaranteed product performanceGuaranteed surface qualityMaterials scienceRolling mill

The invention discloses a manufacture method of a stainless steel external wall panel for rail vehicle. The method sequentially comprises the following steps: firstly, annealing and pickling of a black hot coil, secondly, rough rolling by using a multi-roll mill, thirdly, rough grinding, fourthly, finish rolling by using the multi-roll mill, fifthly, annealing and pickling of a cold coil, sixthly, leveling production, seventhly, finish grinding, and eighthly, cutting plates by a transverse cutting unit. The method has the advantages that the product performance and the surface quality are guaranteed through the reasonable arrangement and collocation of all production processes, the processes of rough rolling and rough grinding are adopted, so as to eliminate the surface defect of raw material and guarantee the surface quality of final products, specified yield strength, tensile strength and elongation are achieved through a leveling mode, and the grinding time of all racks is controlled during grinding, so that required surface requirements are achieved.

Owner:NINGBO BAOXIN STAINLESS STEEL

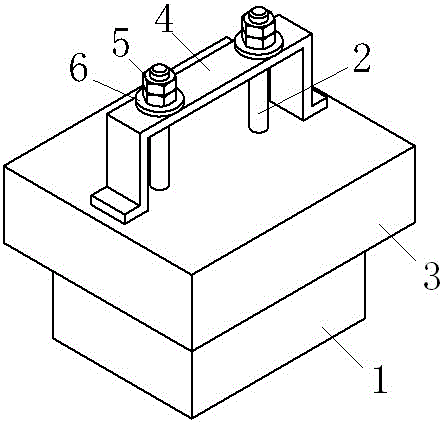

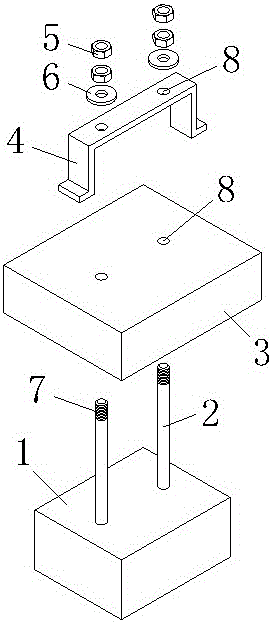

Stable heat processing method of titanium alloy part

ActiveCN104004982AGuaranteed structural sizeGuaranteed product performanceTitanium alloyHeat processing

The invention provides a stable heat processing method of a titanium alloy part. A stable heat processing clamp is used for processing the titanium alloy part, the problems that residual stress and a structure are not even in the processing process of the titanium alloy part are effectively resolved, and therefore the structural size and the product performance of the titanium alloy part are guaranteed.

Owner:吉林航空维修有限责任公司

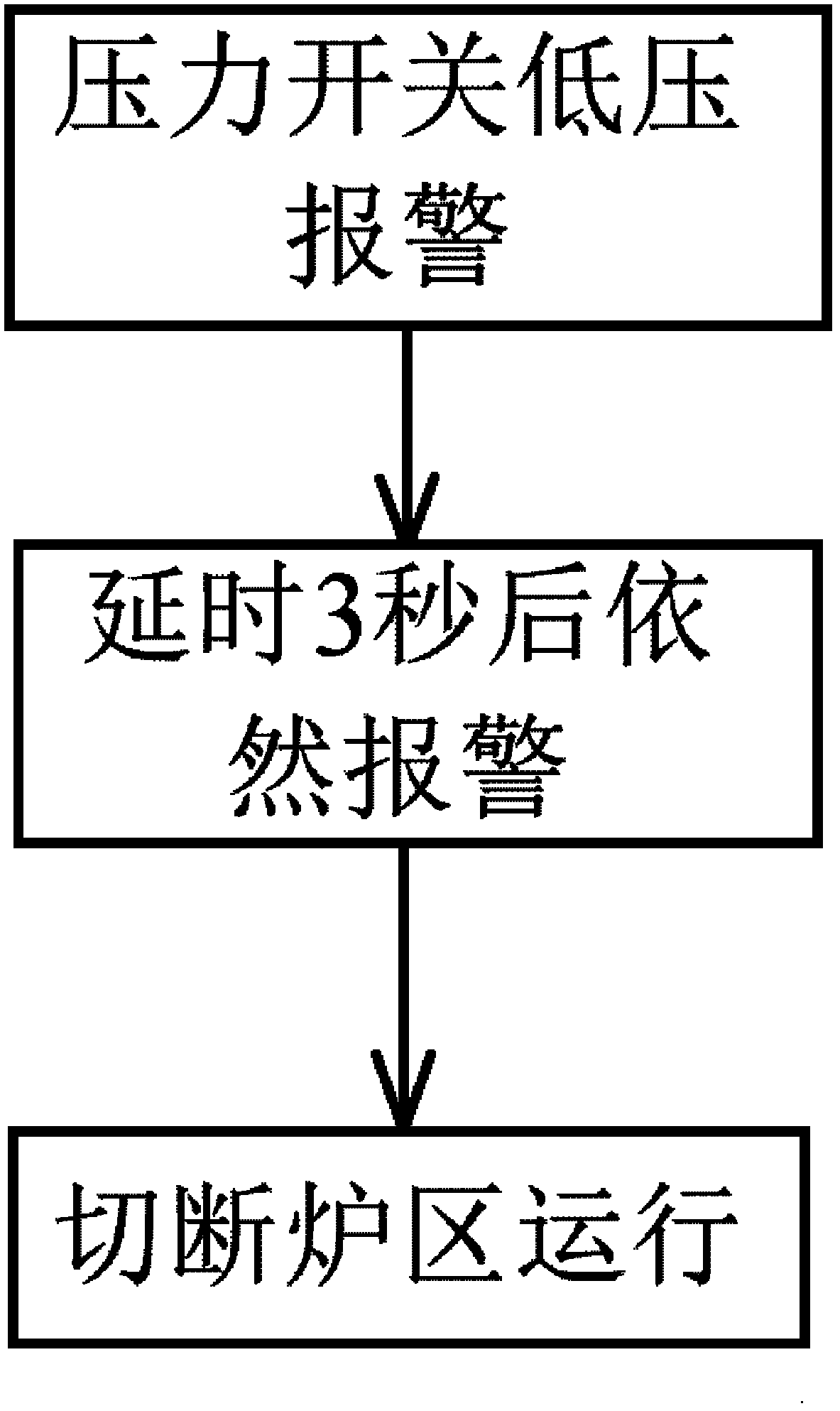

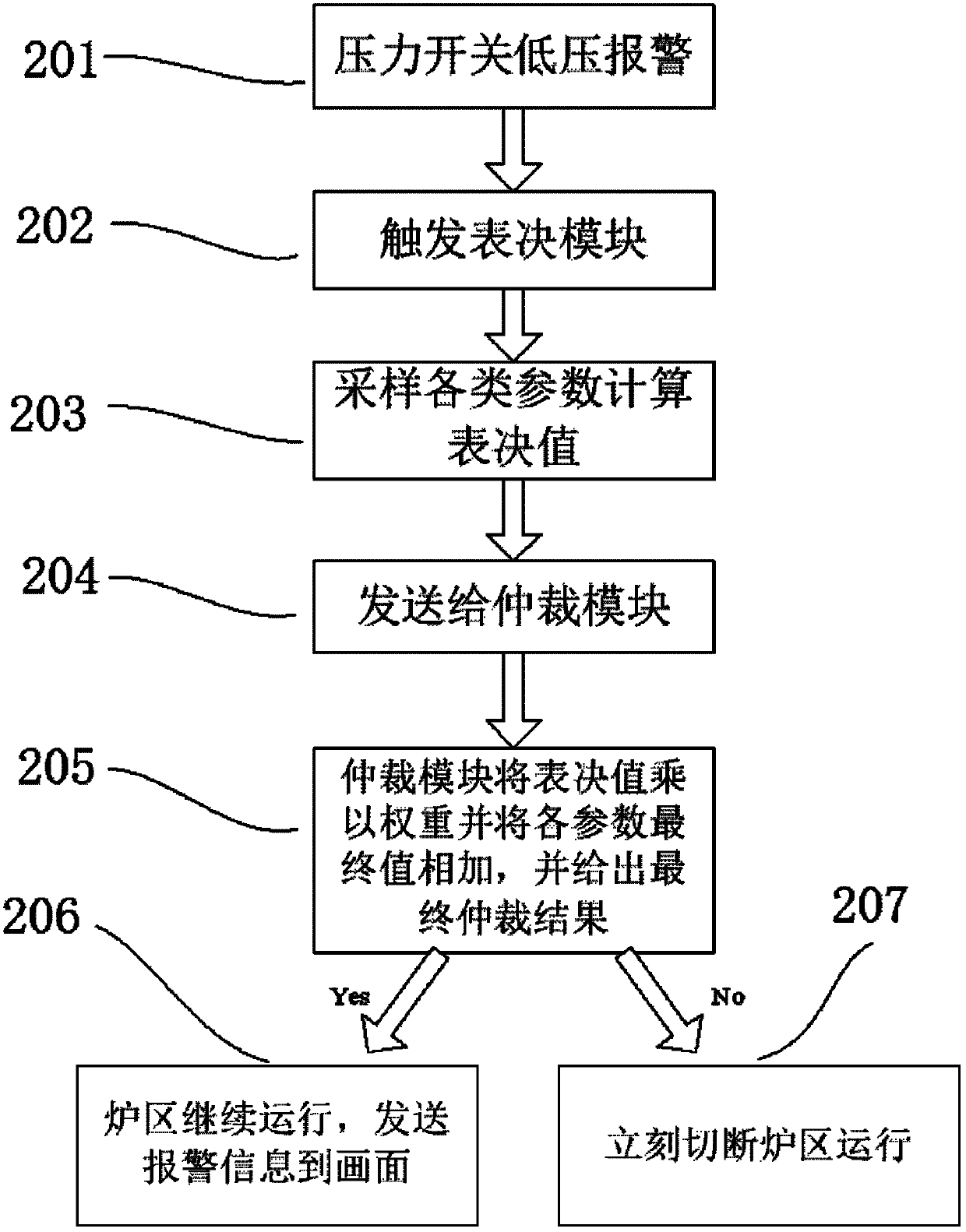

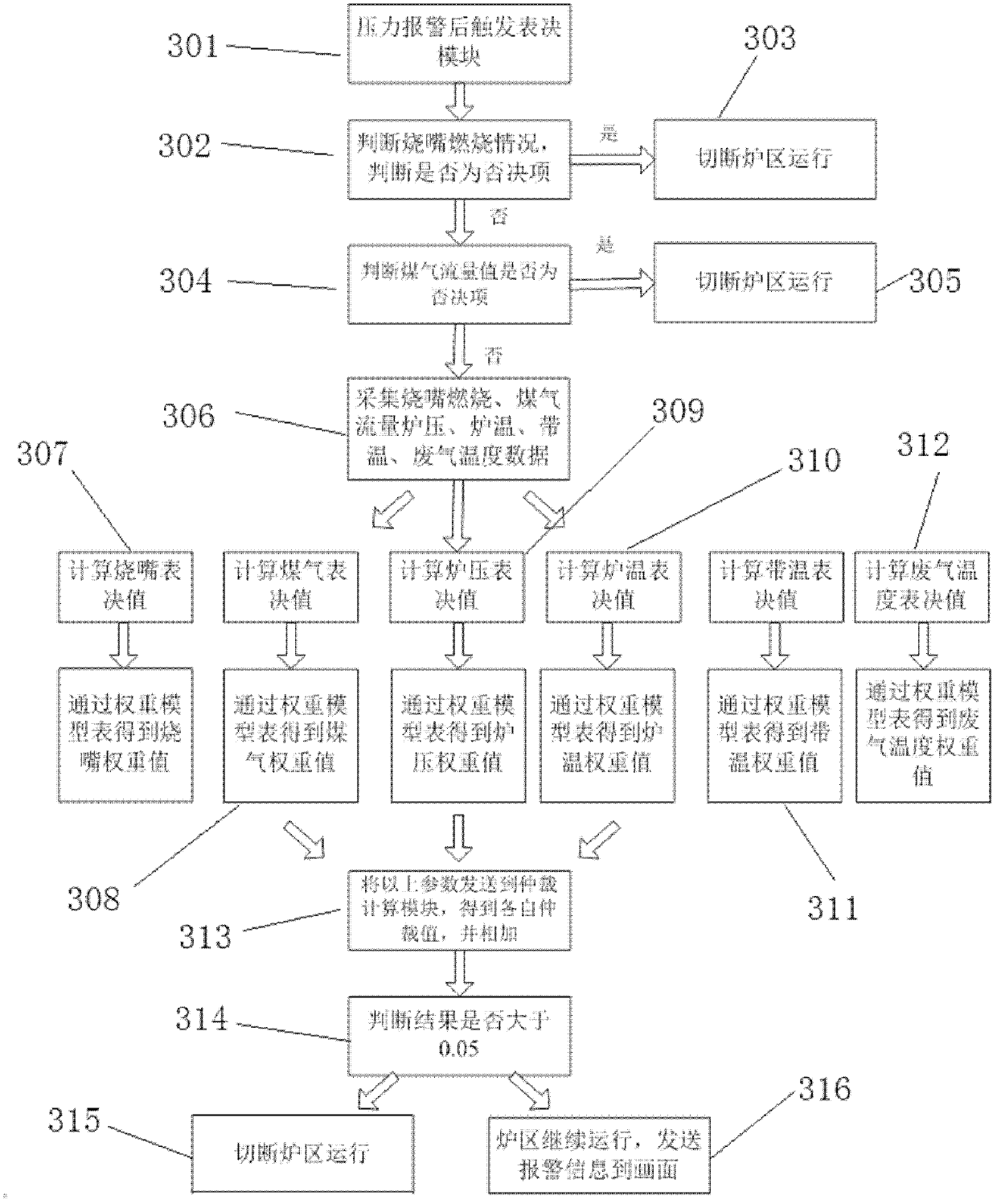

Control device of continuous annealing furnace pressure alarming and method thereof

ActiveCN103376739AGuaranteed outputGuaranteed product performanceFurnace typesAdaptive controlLogistics managementComputer module

The invention discloses a control device of continuous annealing furnace pressure alarming and a method thereof. The control device comprises a pressure switch low-pressure alarming module, a voting module and an arbitrating module. The pressure switch low-pressure alarming module triggers the voting module. The voting module samples a plurality of system states, allocates the corresponding voting values according to the system states, and sends the voting values to the arbitrating module. The voting values are respectively multiplied by weight through the arbitrating module, the voting values multiplied by the weight are added to obtain the arbitrating result, and the arbitrating result controls a furnace to continue to operate or to stop. By means of the technical scheme, when a pressure switch gives an alarm at the low pressure, the operation is not easily and directly cut off after the delay is carried out but a system parameter is judged for further controlling the operation or the non-operation of the annealing furnace according to the judgment result so that the annealing furnace can still keep working when small fluctuation is produced, normal operation of the annealing furnace is not easily interrupted, and the yield, product performance and unobstructed logistics can be guaranteed.

Owner:BAOSHAN IRON & STEEL CO LTD

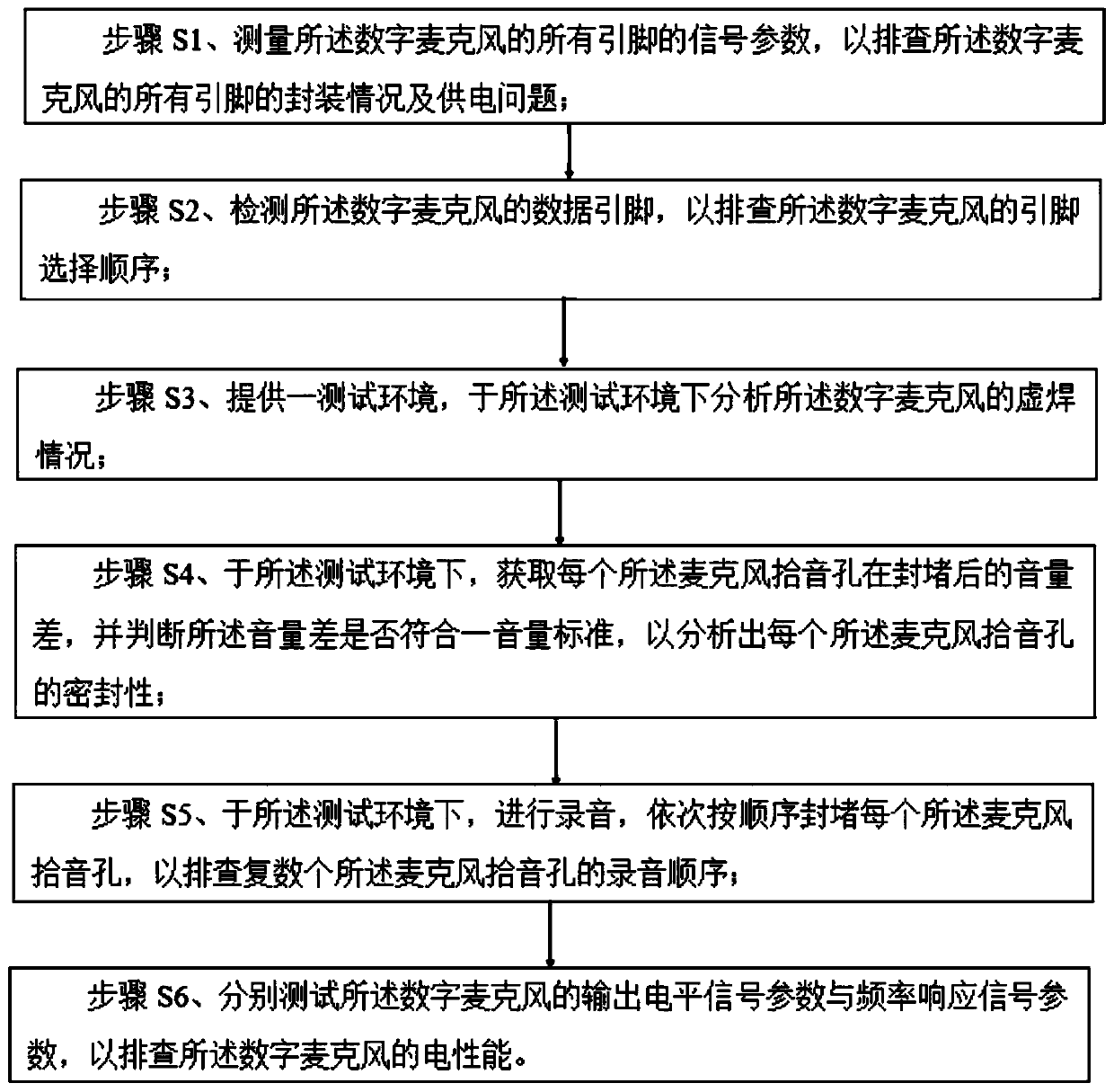

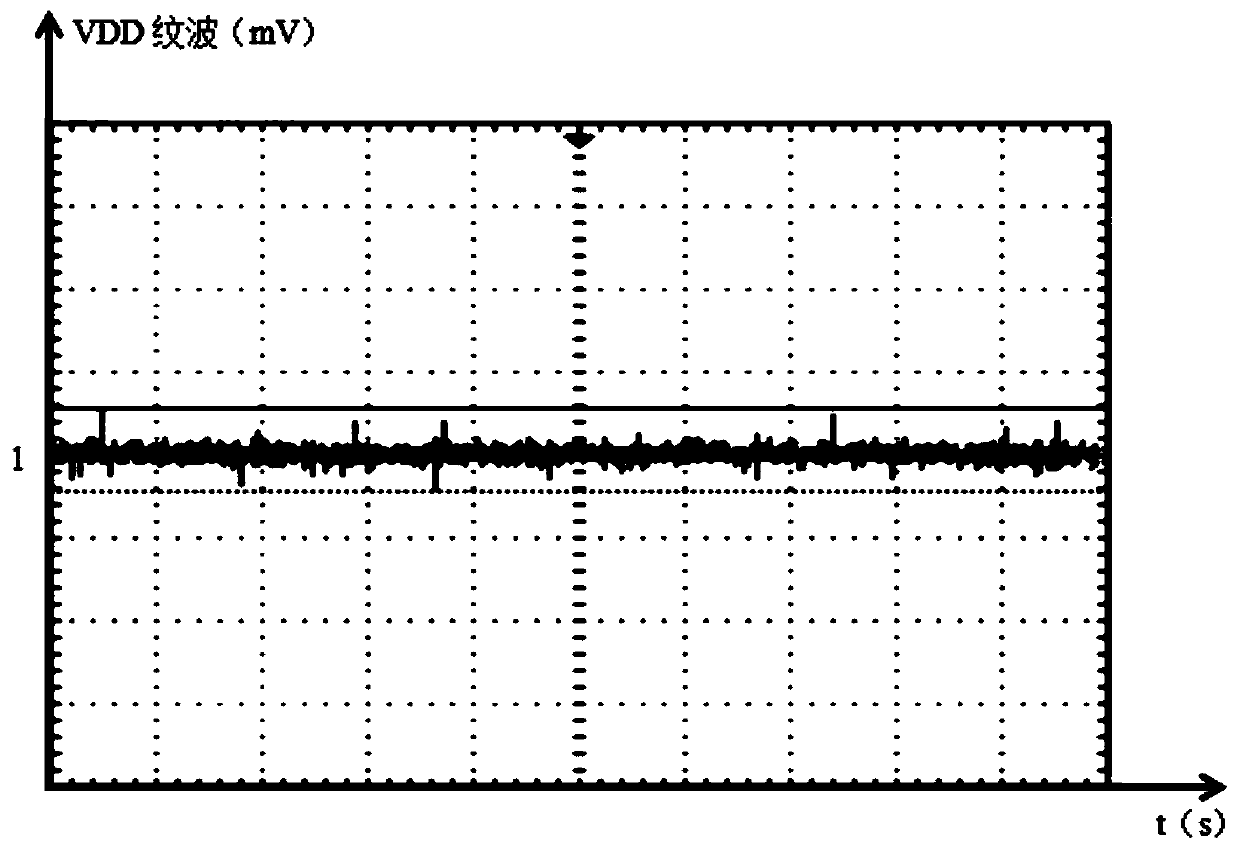

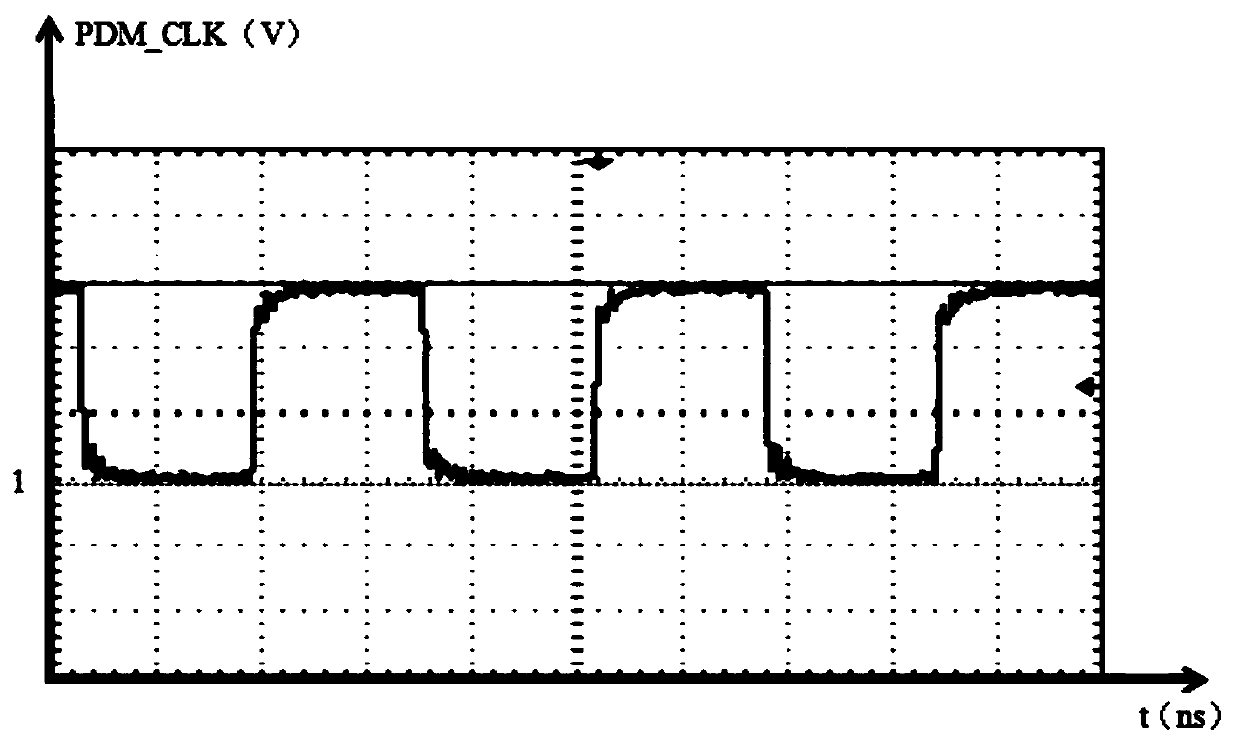

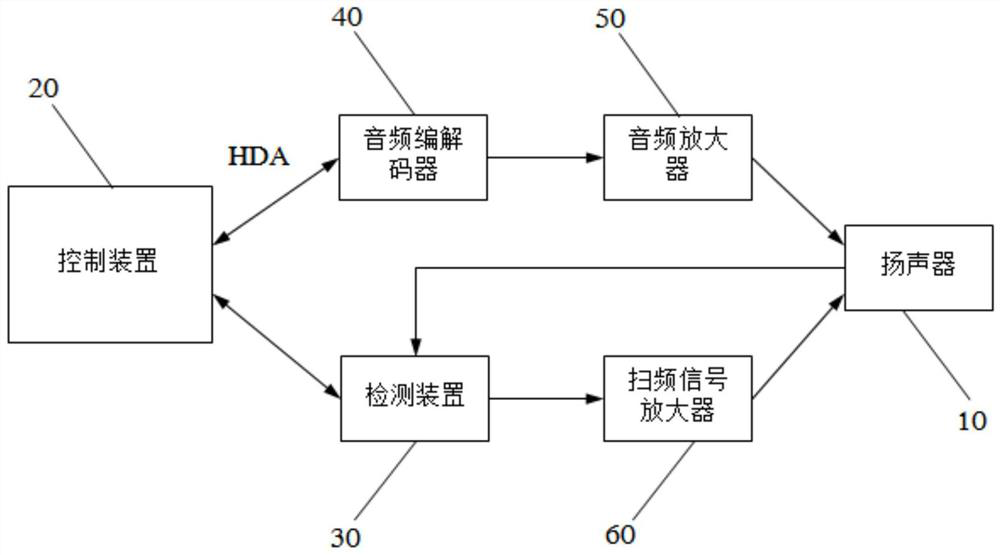

Hardware debugging method of digital microphone

ActiveCN110072166AReduce waste of resourcesGuaranteed product performanceMouthpiece/microphone attachmentsSolderingElectricity

The invention discloses a hardware debugging method of a digital microphone, wherein the method comprises the steps of S1, measuring the signal parameters of all pins of the digital microphone; s2, detecting a data pin of the digital microphone so as to check a pin selection sequence of the digital microphone; step S3, analyzing the pseudo soldering condition of the digital microphone in a test environment; s4, acquiring the volume difference of each microphone pickup hole after plugging, and judging whether the volume difference meets a volume standard or not, so as to analyze the sealing performance of each microphone pickup hole; step S5, recording in a test environment, and blocking each microphone pickup hole sequentially according to a sequence so as to check the recording sequence of the plurality of microphone pickup holes; and S6, respectively testing the output level signal parameter and the frequency response signal parameter of the digital microphone so as to check the electrical performance of the digital microphone. The method has the beneficial effects of being simple to operate, avoiding the repeated debugging, saving the time and cost and avoiding the resource waste.

Owner:AMOLOGIC (SHANGHAI) CO LTD

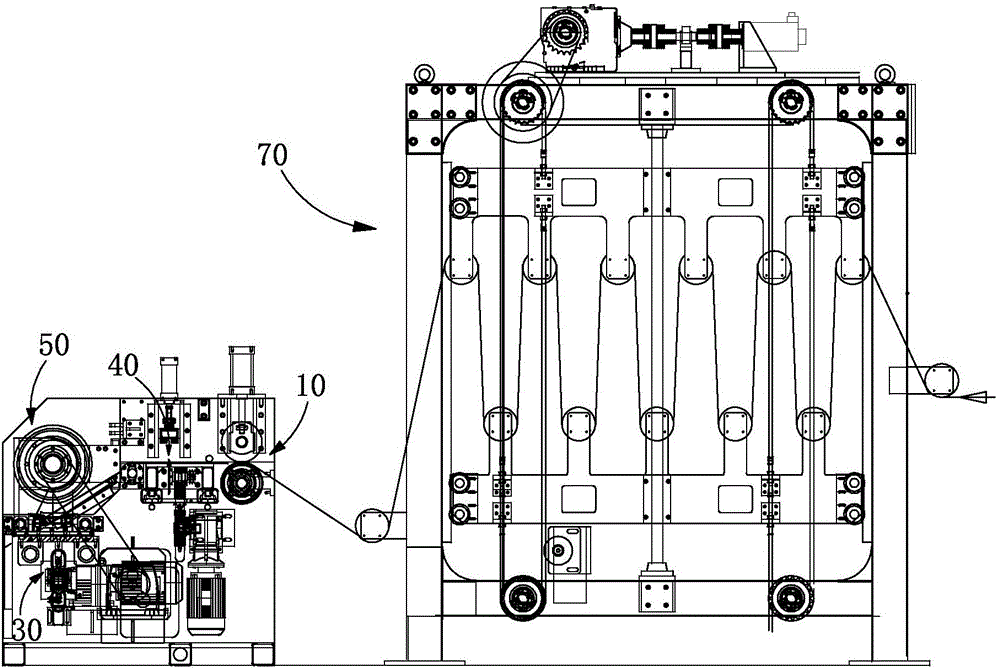

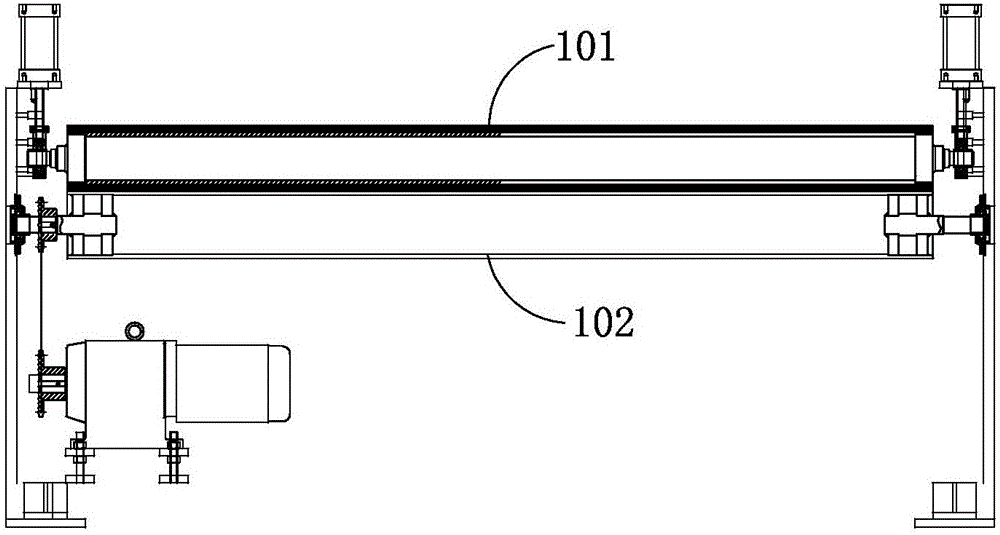

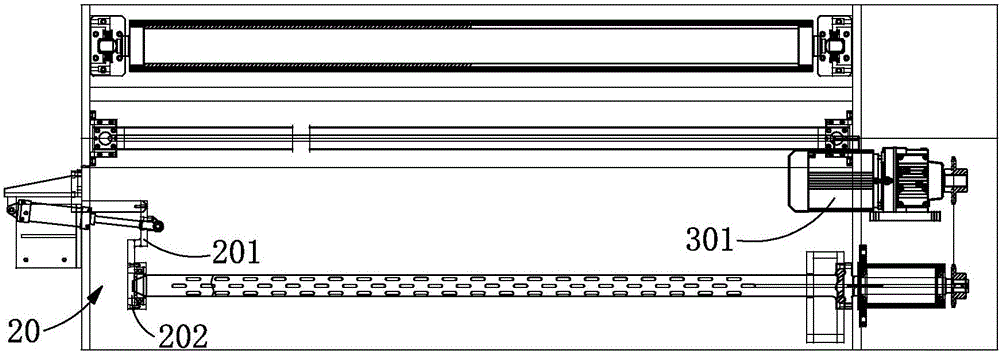

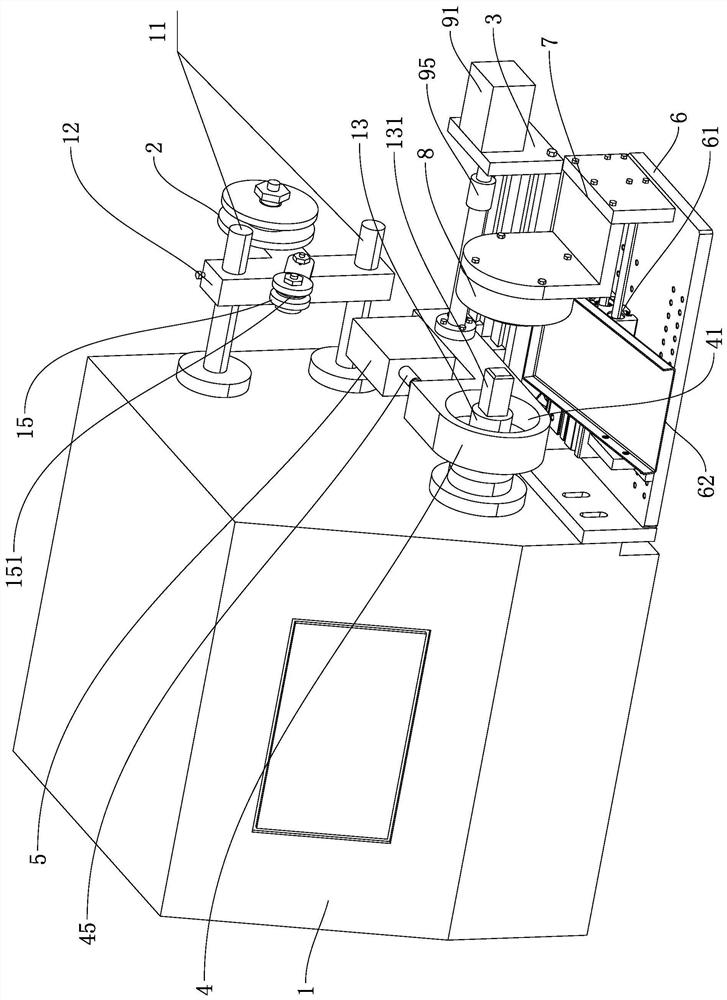

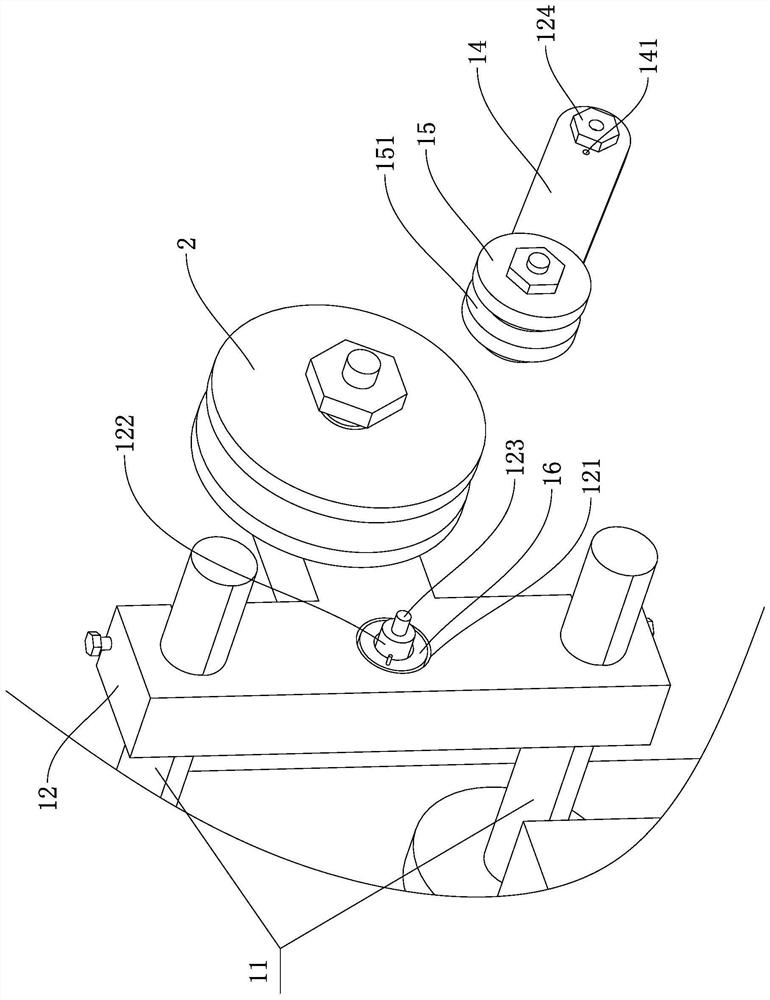

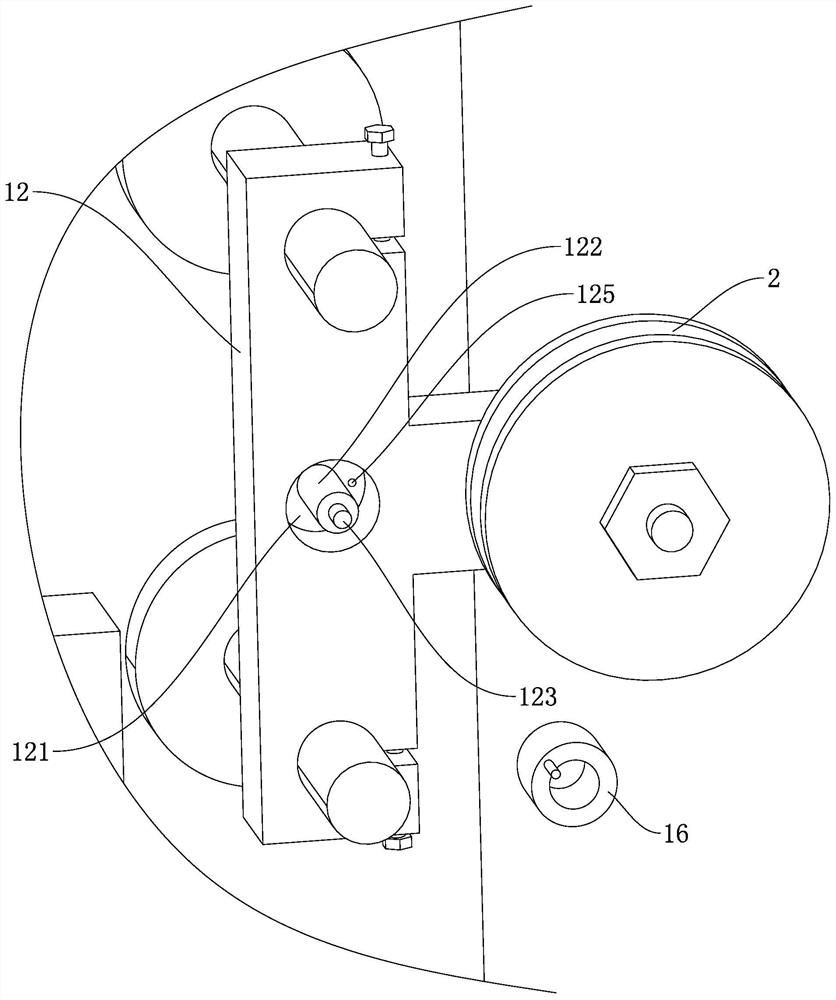

Small-rolling-diameter full-automatic winding device

ActiveCN106115322ANot easy to stretchGuaranteed product performanceWebs handlingEngineeringMaterial storage

The invention discloses a small-rolling-diameter full-automatic winding device. The small-rolling-diameter full-automatic winding device comprises a traction mechanism, a gas expansion shaft auxiliary tight jacking mechanism, a winding mechanism, an automatic cutting mechanism, an automatic unwinding mechanism, an automatic conveying and conveying mechanism and a material storage mechanism, wherein the traction mechanism, the gas expansion shaft auxiliary tight jacking mechanism, the winding mechanism, the automatic cutting mechanism, the automatic unwinding mechanism, the automatic conveying and conveying mechanism and the material storage mechanism are sequentially arranged on a rack. The winding, cutting, unwinding and weighing mechanisms of the small-rolling-diameter full-automatic winding device all achieve automation, by adjusting, controlling and feeding back the tensile force of a sheet, the winding tension degree is adjusted through a winding motor, the sheet winding tension is constant tension, and the product performance is guaranteed; and meanwhile, the unwinding mechanism is designed at the position of the center of a current winding shaft, the wound sheet can be fast unwound, in the unwinding process, the material storage mechanism stores the sheet at the same time, the material storage mechanism performs discharging on the sheet when winding is started, it is guaranteed that a product is not prone to stretching, the product performance is improved, and the wound sheet is weighed and subjected to labeling. The whole device structure effectively improves the production line efficiency, time is saved, operation is convenient, the effect is remarkable, and the labor cost is greatly saved.

Owner:SUZHOU JWELL MACHINERY

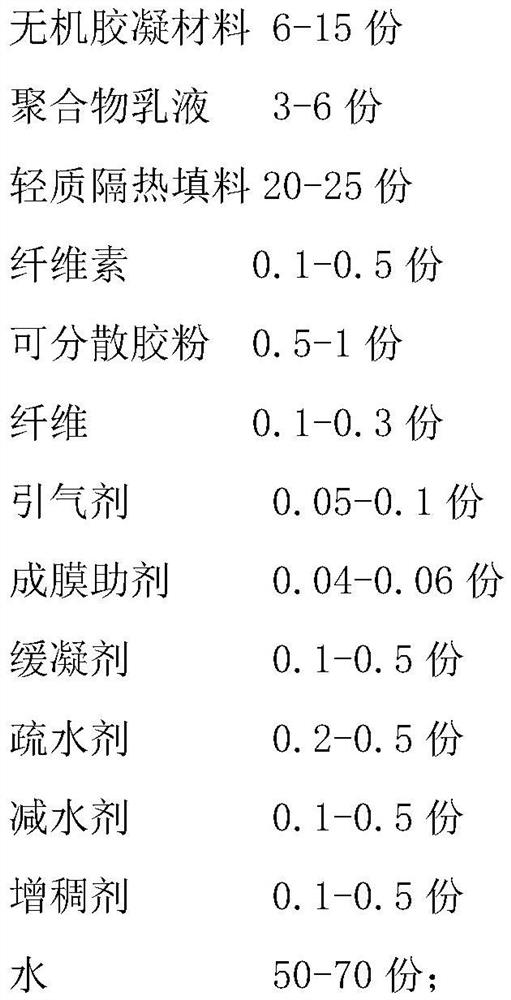

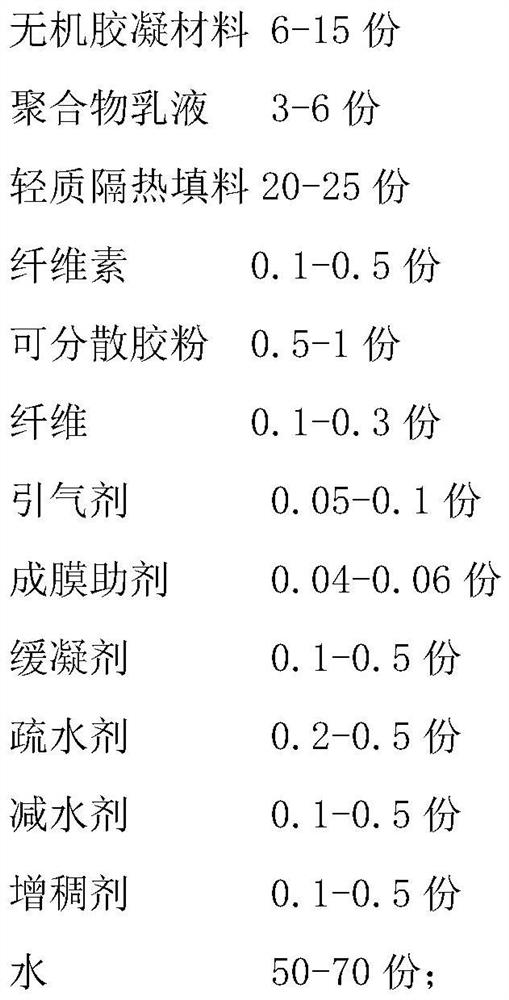

Inorganic paste for internal thermal insulation of buildings and preparation method thereof

The invention relates to inorganic paste for internal thermal insulation of buildings and a preparation method thereof. The inorganic paste is mainly prepared from the following components in parts by weight: 6-15 parts of inorganic cementing material, 3-6 parts of a polymer emulsion, 20-25 parts of a light heat-insulating material, 0.1-0.5 part of cellulose, 0.5-1 part of dispersible adhesive powder, 0.1-0.3 part of fibers, 0.0-0.1 part of an air entraining agent, 0.04-0.06 part of a film-forming agent, 0.1-0.5 part of a retarder, 0.2-0.5 part of a hydrophobic agent, 0.1-0.5 part of a water reducing agent, 0.1-0.5 part of a thickening agent and 50-70 parts of water. According to the invention, the inorganic paste overcomes the following problems: a plate joint exists after existing internal thermal insulation materials for buildings are spliced; after putty finish paint is painted on the plate joint, cracking is easy to occur, and fireproof performance is poor; and water needs to be added on site for stirring during construction, which leads to inconvenient construction, dust pollution and environmental pollution. The single-component inorganic paste material is prepared by selecting the light heat-insulating filler, the inorganic cementing material and the polymer emulsion and matching the above substances with other components in the system, can be subjected to integral batch scraping, and is free of cracking risk; and the inorganic paste is prefabricated, and construction can be carried out without adding water and stirring on site.

Owner:北京三棵树新材料科技有限公司

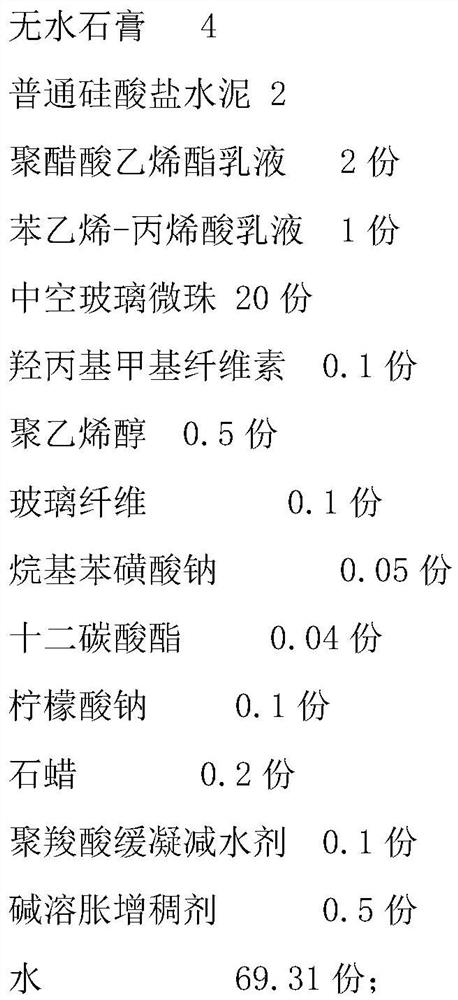

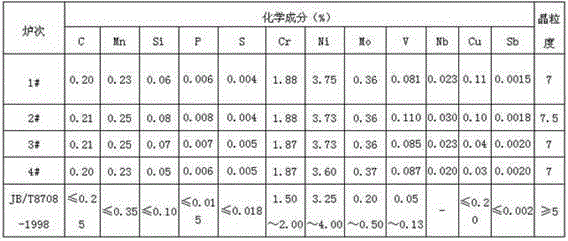

Process for melting 25Cr2Ni4MoV rotor steel

The invention discloses a process for melting a 25Cr2Ni4MoV rotor steel. The process particularly comprises the following steps: (1) selecting the raw materials; (2) performing primary smelting in an electric-arc furnace; (3) refining by an LF furnace; (4) performing carbon deoxidization; (5) pouring. When preparing the materials, the high-quality steel scrap and the stub bar are selected, the harmful residual element contents As, Sn, Sb, Cu, Al in the steel solution are strictly controlled to met the process requirement; the operation of dominant slag and steel is processed during electric furnace tapping so that the rephosphorization is effectively prevented; the deoxidization method is a vacuum carbon deoxidization process, so that the molten steel non-metallic inclusion and the gas content are effectively reduced and the purity of the molten steel is greatly increased.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Pig feed additive capable of replacing antibiotics, and preparation method and application thereof

ActiveCN103005210BAcid resistantGuaranteed Oxygen DensityAnimal feeding stuffPhosphoric acidAntibiotic Y

The invention relates to a pig feed additive capable of replacing antibiotics, and a preparation method and an application thereof. Components and weight part ratio thereof in a formula are as follows: 1-5 parts of medicated leaven, 1-5 parts of angelica sinensis, 1-5 parts of radix astragali, 1-5 parts of hawthorn, 1-5 parts of radix codonopsis, 10-20 parts of citric acid, 10-20 parts of lactic acid, 20-30 parts of coated phosphoric acid, 5-10 parts of a micro-ecological preparation, 5-10 parts of yeast cell wall polysaccharide, 1-5 parts of a composite plant essential oil and 5-10 parts of a carrier. The pig feed additive carries out combination collocation of traditional Chinese herbs and functional polysaccharide, the micro-ecological preparation, acidifying agents, plant essential oil and the like, so that synergic effect of the traditional Chinese herbs and other components are maximized; the pig feed additive can replace the antibiotics completely; problems of drug resistance, drug residues, overcommitment and the like of the antibiotics which trouble animal husbandry for a long time is reduced; and at the same time, the pig feed additive plays effects of improving culture environment, reducing feed safety hidden dangers, increasing culture benefits and the like.

Owner:LUOGANG BRANCH GUANGDONG WANGDA GRP

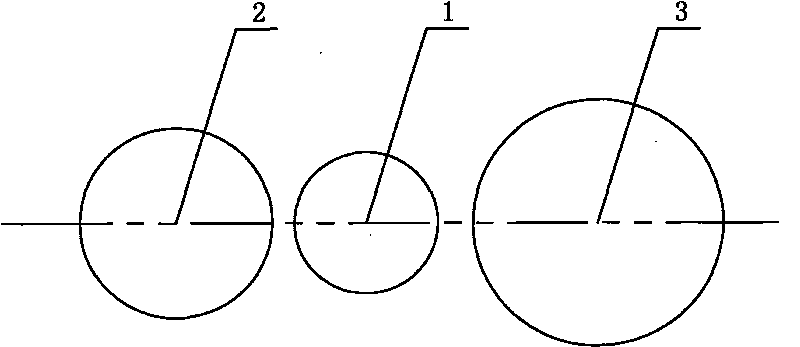

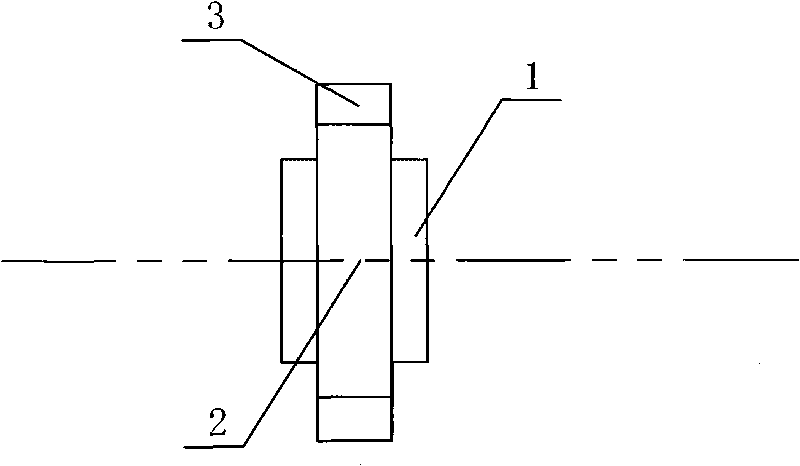

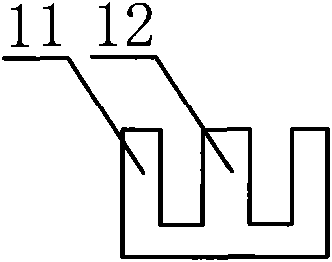

Dual air gap grinding head through grinding machine for grinding magnetic core

InactiveCN101704205AGuaranteed product performanceShorten the timeInductances/transformers/magnets manufacturePlane surface grinding machinesEngineeringGrinding wheel

The invention provides a dual air gap grinding head through grinding machine for grinding a magnetic core, which comprises a main shaft grinding wheel and a first air gap grinding wheel arranged in front of the main shaft grinding wheel, wherein a second air gap grinding wheel is arranged at the back of the main shaft grinding wheel. The dual air gap grinding head through grinding machine can finish processing the E-shaped magnetic core through once passing so as to save the time and cost and ensure the product performance of the E-shaped magnetic core.

Owner:HAINING SANHONG ELECTRONICS TECH

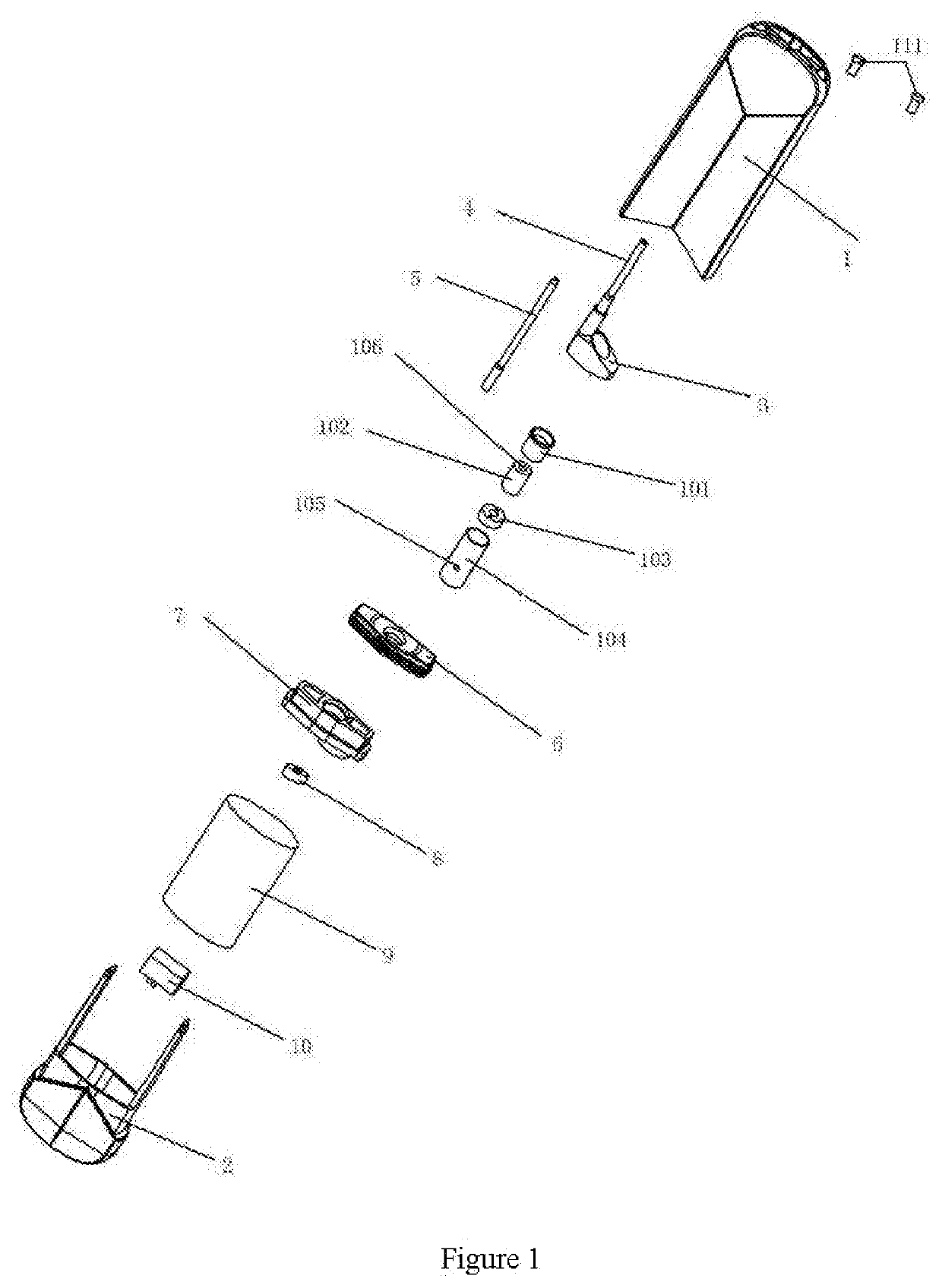

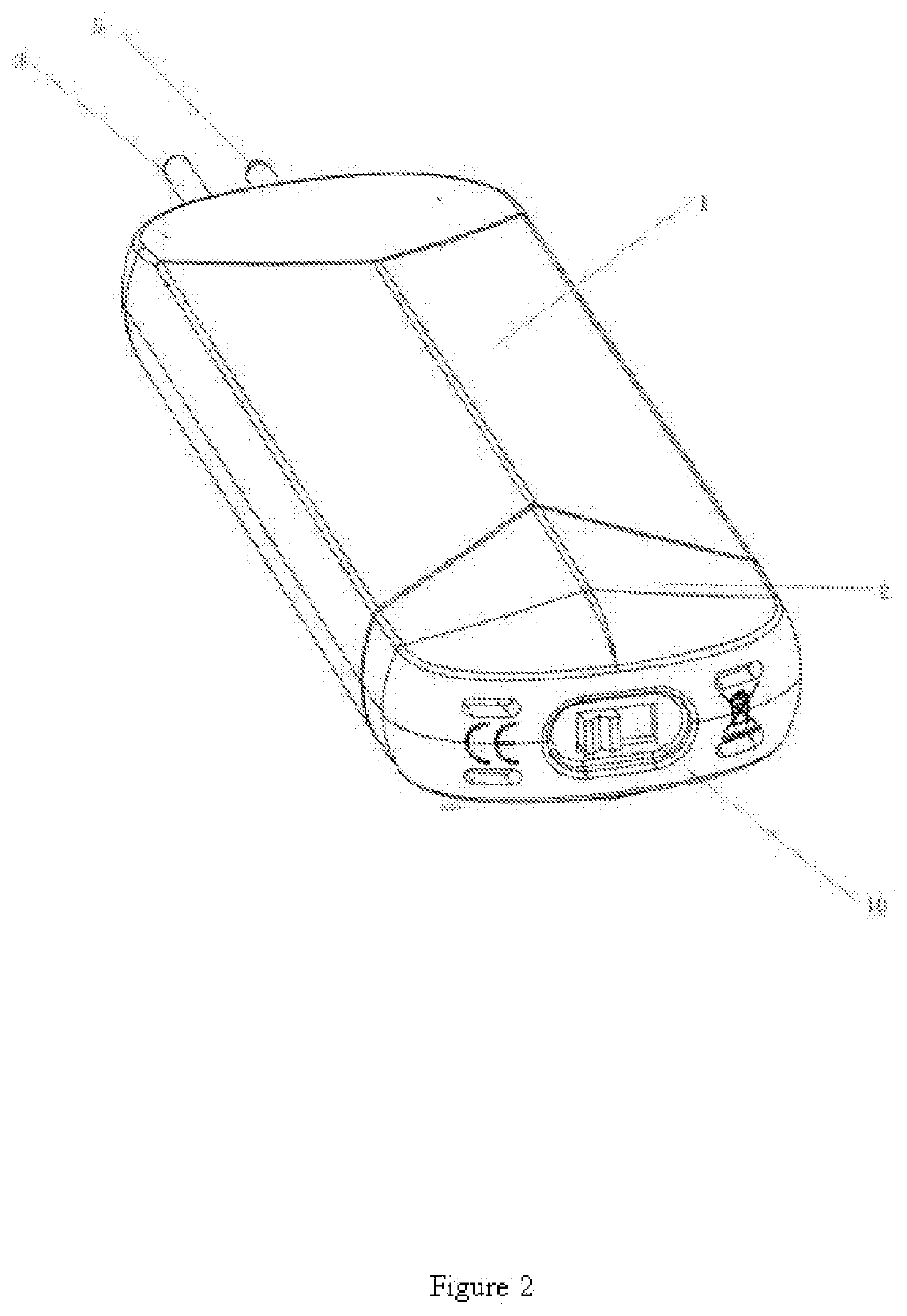

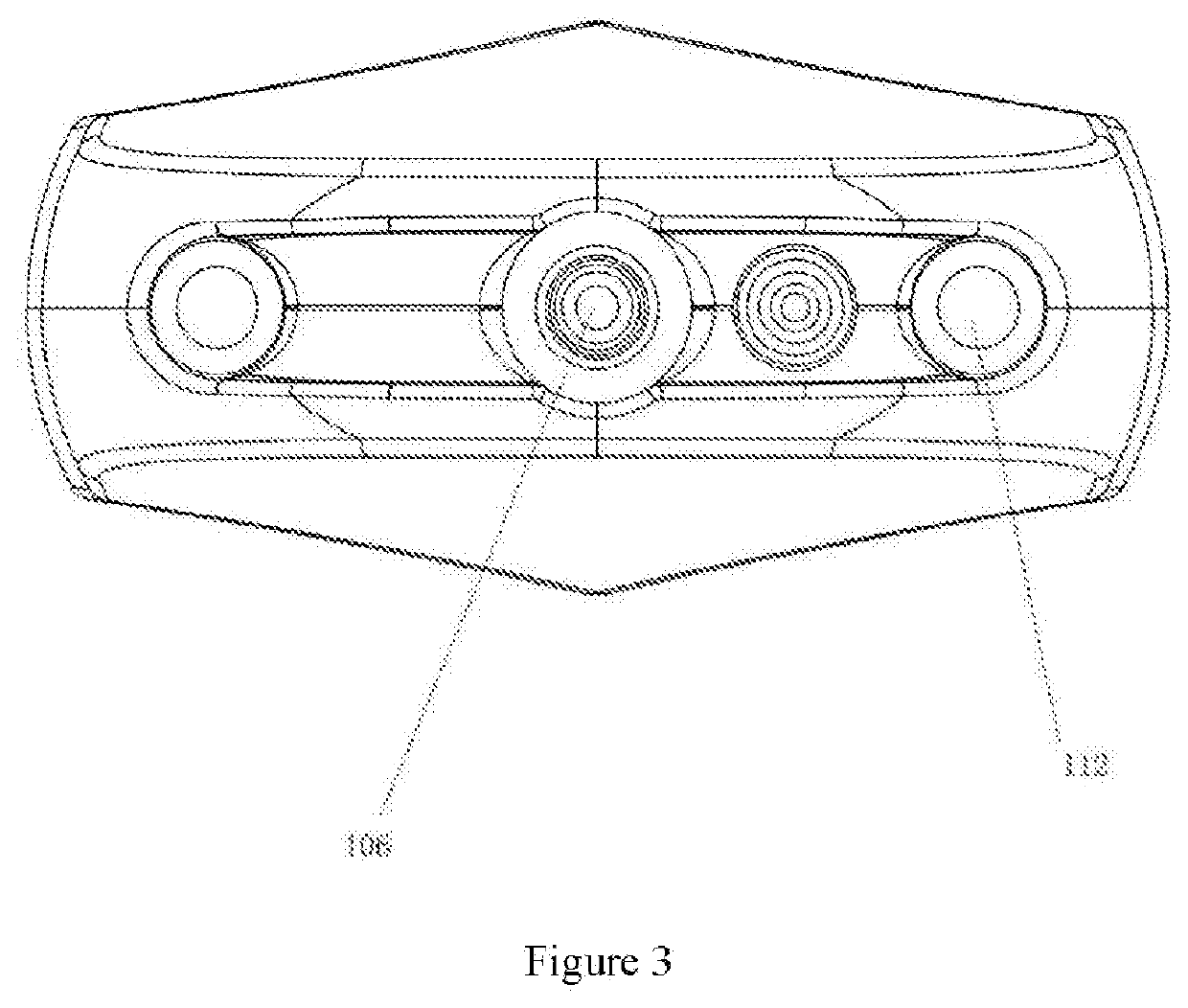

Disposable Electronic Cigarette

InactiveUS20200359702A1Good experience of high performanceGuarantee product qualityTobacco devicesHeating element materialsEngineeringElectronic cigarette

The present disclosure relates to a disposable electronic cigarette, including: a casing, a bottom cover is arranged at the bottom of the casing; an atomizer is accommodated in the casing, and the atomizer passes through a sealing ring of fixing member to arrange on the fixing member. The fixing member is further provided with a microphone, and the fixing member divides the electronic cigarette into a top chamber and a bottom chamber. The bottom chamber is provided with a battery, and the top chamber opens an atomizing tube shell and a tobacco tar chamber. The atomizing tube shell is connected to the atomizer and is not in communication with the tobacco tar chamber; the bottom chamber is further provided with a battery switch, the battery switch is connected to the battery to control on and off of the battery.

Owner:SHENZHEN ACEVAPE TECH CO LTD

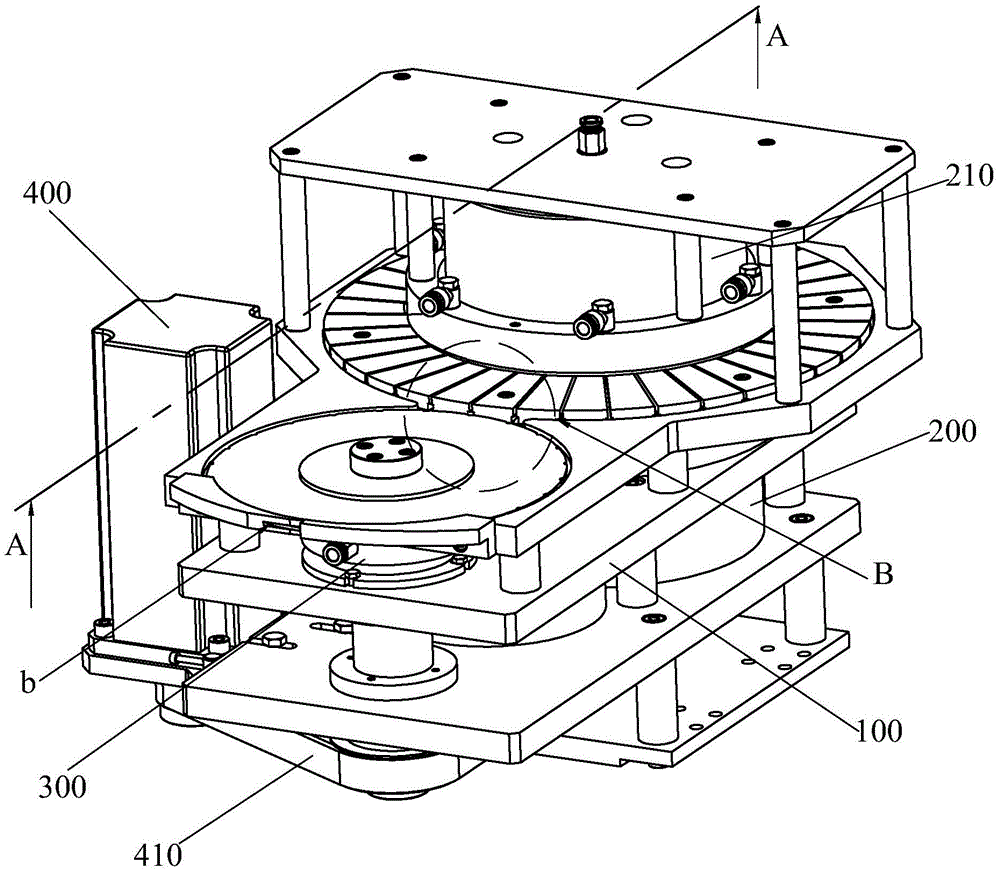

Particle material separation device

ActiveCN105540169AGuaranteed distribution effectGuaranteed qualityLoading/unloadingRotary conveyorsEngineeringHeight difference

Owner:GUANGDONG ZHONGDAO CREATIVE TECH CO LTD

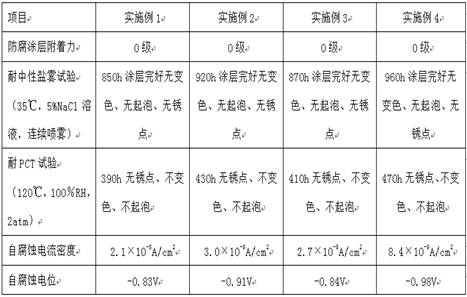

Preparation method and application of subsphaeroidal metal powder for anticorrosion repair spraying

ActiveCN112301304ABalanced performanceGood corrosion resistanceMolten spray coatingTransportation and packagingCorrosion preventionNickel

The invention provides application of subsphaeroidal metal powder for anticorrosion repair spraying. The subsphaeroidal metal powder for anticorrosion repair spraying is used for anticorrosion and repair of the surface of a component, and comprises the following steps of surface treatment, spraying and cladding. The preparation method of the subsphaeroidal metal powder for anticorrosion repair spraying comprises the following steps of material preparation, smelting, tundish preheating, atomization and powder collection, wherein in material preparation, the raw materials in mixing ratios comprise 93 to 96 percent by weight of pure iron, 2 to 3 percent by weight of high-carbon ferrochrome, 1 to 2 percent by weight of electrolytic manganese and 1 to 2 percent by weight of forged coal. When the subsphaeroidal metal powder for anticorrosion repair spraying provided by the invention is applied to corrosion prevention of a component, the hardness after spraying reaches 45 to 50 HRC, the surface strength of the component is effectively enhanced, and an anticorrosion effect is achieved; and the use amount of alloy is greatly reduced, particularly the use amount of precious metal molybdenum,chromium and nickel is reduced, so that precious metal consumption and environmental pollution are greatly reduced.

Owner:山东鲁银新材料科技有限公司

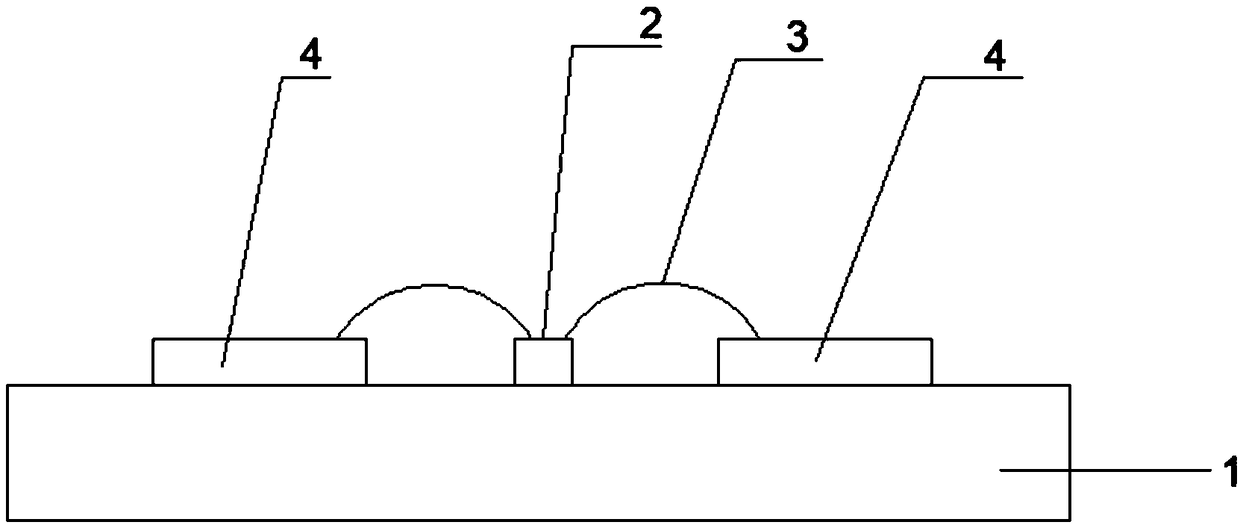

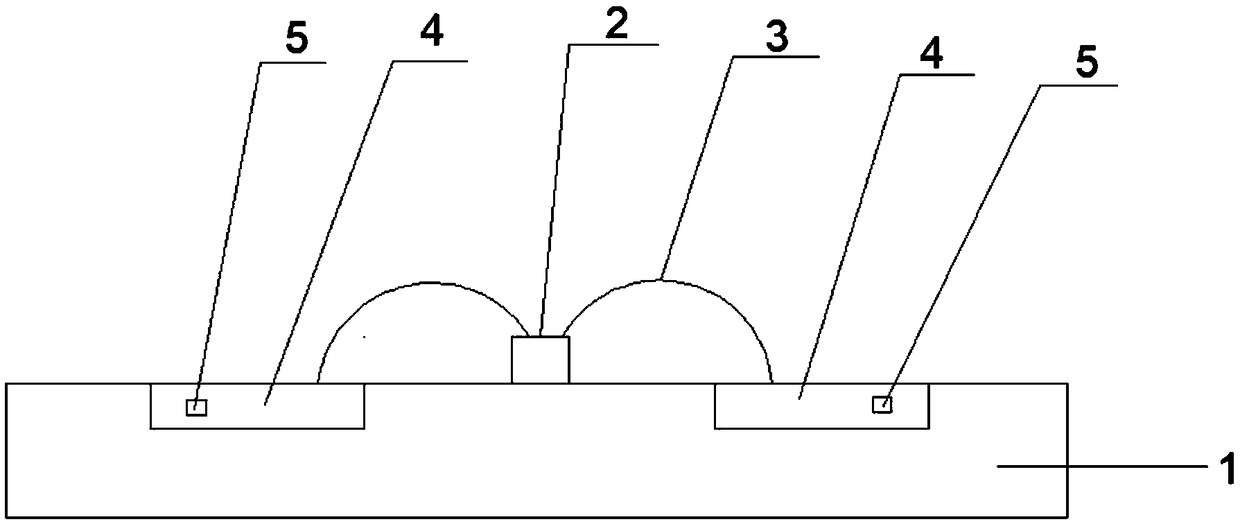

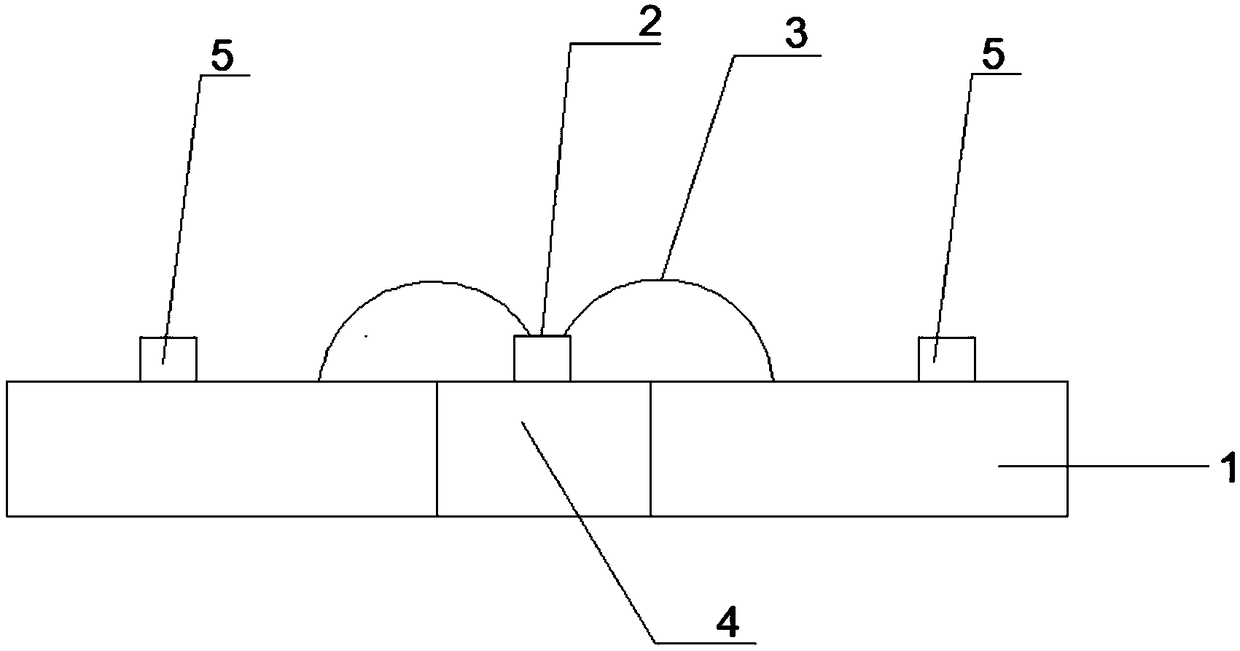

Packing structure for RF microwave power amplifier

PendingCN108807293AImprove cooling effectImprove performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceInductor

The invention relates to a packaging structure for an RF microwave power amplifier. The packaging structure comprises an RF power amplification chip, a circuit substrate, a metal substrate and a passive device, the RF power amplification chip is arranged on the metal substrate, the passive device is arranged on the circuit substrate, the metal substation is combined with the circuit substrate in asplicing manner, and the metal power amplification chip is connected to the circuit substrate via a metal connecting line. A high-heat-conduction metal material serves as the metal substrate, so thatthe heat radiation effect of the RF power amplification chip is improved; the RF power amplification chip and the passive device are arranged on the metal substrate and the circuit substrate respectively, the metal substation is combined with the circuit substrate in the splicing manner, thus, a resistor, inductor, capacitor or microstrip line with a relatively high Q value in the market can be used more conveniently, the research and development period is shortened, the cost is lower, and performance and reliability of a product are ensured; and design requirement can be reached via parameter adjustment of products as the resistor, inductor, capacitor and microstrip line, and the flexibility is high.

Owner:苏州本然微电子有限公司

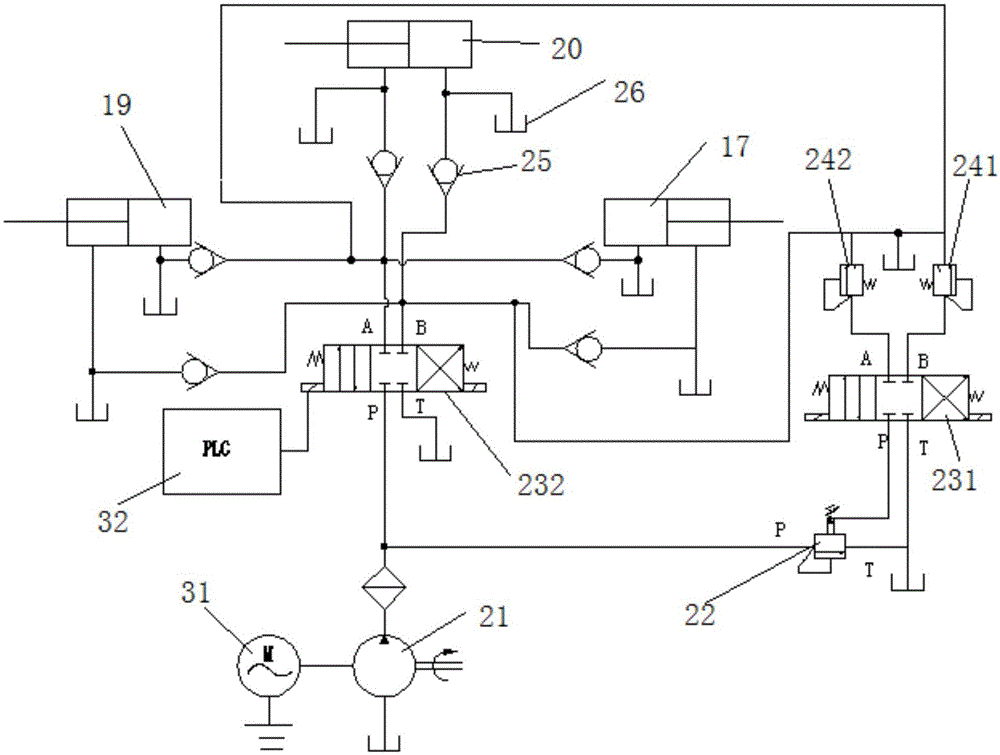

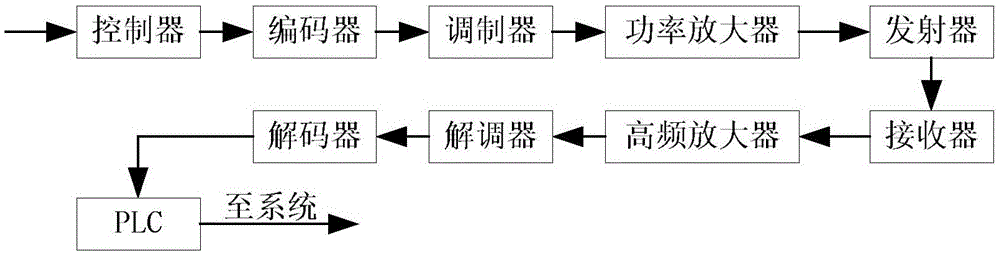

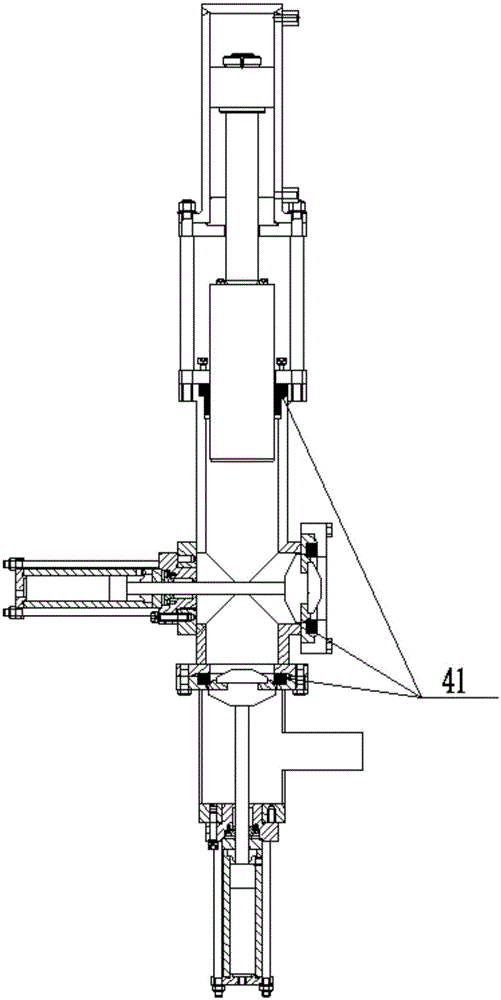

High-pressure long-range conveying device for magnetic material slurry and using method of high-pressure long-range conveying device

ActiveCN105084003APrevent leakageImprove product qualityMixersBulk conveyorsElectrical controlEngineering

The invention discloses a high-pressure long-range conveying device for magnetic material slurry and a using method of the high-pressure long-range conveying device, and belongs to the field of magnetic material slurry conveying equipment. The high-pressure long-range conveying device comprises a stirring part, an electrical system and a hydraulic system, and further comprises a double helix feeding system, an electrical remote control system and a press; the stirring part comprises a thick stirring part and a thin stirring part, and the slurry is conveyed to the double helix feeding system through the thick stirring part; the slurry is conveyed to the thin stirring part through the double helix feeding system, the thin stirring part conveys the slurry to the press, and the press is connected with an electrical cabinet of a touch screen; and the press is electrically controlled through the electrical cabinet of the touch screen to conduct operation, and therefore the slurry is pressed and molded. The electrical remote control system comprises a remote control transmitting system and a remote control receiving system, the remote control transmitting system transmits signals to the remote control receiving system, the remote control receiving system is connected with the electrical system which is connected with the hydraulic system, and a hydraulic cylinder of the hydraulic system is arranged in the double helix feeding system. By means of the high-pressure long-range conveying device, long-range conveying of the slurry can be achieved, sealing is achieved, and pollution is avoided.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Winding machine with hot air self-adhesion wire tensioning structure

InactiveCN113363072AAchieving circumferential heatingGood rotation effectInductances/transformers/magnets manufactureWinding machineHot blast

The invention discloses a winding machine with a hot air self-adhesion wire tensioning structure, and the winding machine comprises a winding machine body, a tier pole group is arranged at the rear part of the right side of the winding machine body, a pay-off rack is fixed on the tier pole group, a pay-off wheel is rotationally connected to the pay-off rack, a hot air self-adhesion wire is wound on the pay-off wheel, a winding shaft is arranged at the front part of the right side of the winding machine body, a winding part is arranged at the right end of the winding shaft, a rotating arm is rotationally connected to the pay-off rack, a tensioning wheel is rotationally connected to the end, away from the pay-off rack, of the rotating arm, and an annular groove used for clamping a hot air supply self-adhesion wire is formed in the peripheral wall of the tensioning wheel; a blind hole is formed in the side, facing the rotating arm, of the pay-off rack, a torsional spring sleeving the supporting shaft is arranged in the blind hole, and the torsional spring is used for driving the end, away from the pay-off rack, of the rotating arm to rotate upwards. According to the invention, the phenomenon that each strand of hot air self-adhesion wire in the self-adhesion coil wound on the winding shaft is inconsistent in tightness can be avoided.

Owner:李夏君

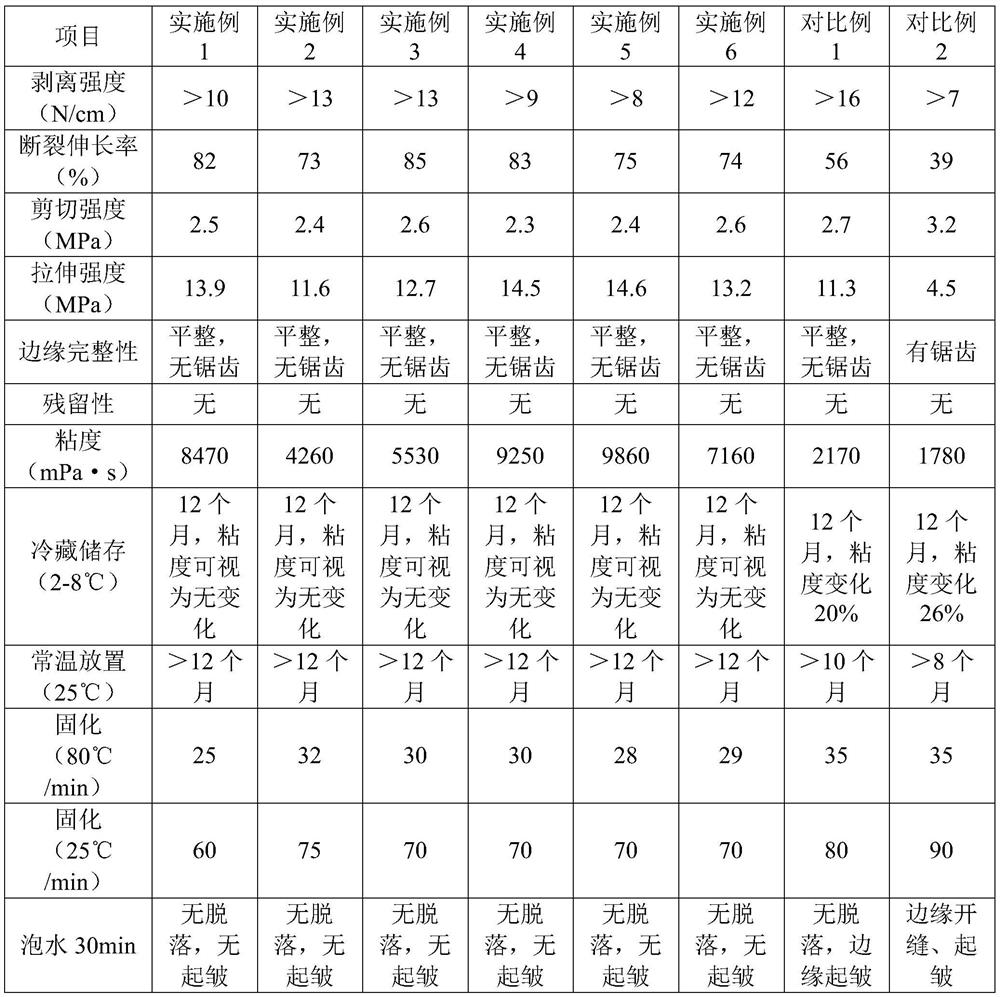

Low-temperature thermosetting waterborne peelable adhesive and preparation method thereof

PendingCN113621337AEasy to peelIncrease brightnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides a low-temperature thermosetting waterborne peelable adhesive and a preparation method thereof. The peelable adhesive comprises the following components: 50-70 parts of waterborne polyurethane resin, 3-7 parts of a silane coupling agent, 3-7 parts of nano graphene, 1-2 parts of a dispersing agent, 1-5 parts of a film-forming agent, 0.1-1 part of a wetting agent, 1-1.5 parts of a defoaming agent, 0.5-2 parts of a thickening agent, 0.3-0.5 part of color paste and 20-40 parts of filler. The preparation method comprises the following steps: weighing the raw materials; diluting the thickening agent and preparing a nano graphene dispersion liquid; uniformly mixing the nano graphene dispersion liquid and the waterborne polyurethane for three times, sequentially adding the silane coupling agent, the film-forming agent, the wetting agent, the defoaming agent, the color paste, the thickening agent and the filler, and uniformly stirring to obtain the low-temperature thermosetting waterborne peelable adhesive. The low-temperature thermosetting waterborne peelable adhesive is curable at low temperature, good in flexibility, good in adhesive force, peelable and capable of adapting to CNC operation, and the preparation method is simple and environmentally friendly.

Owner:广州亦盛环保科技有限公司

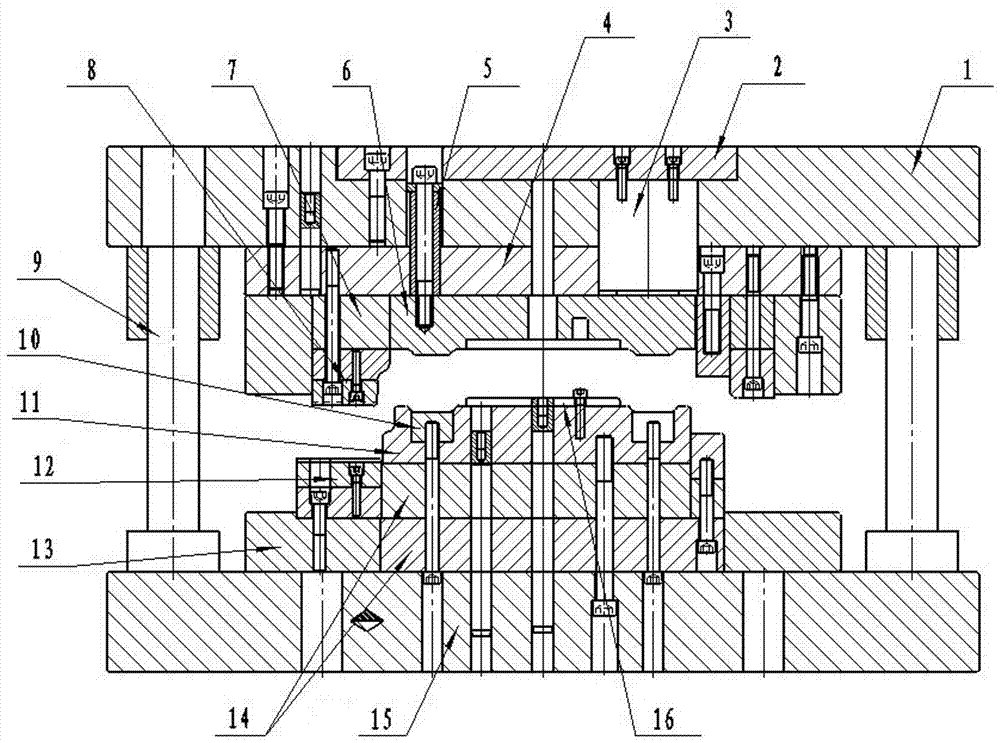

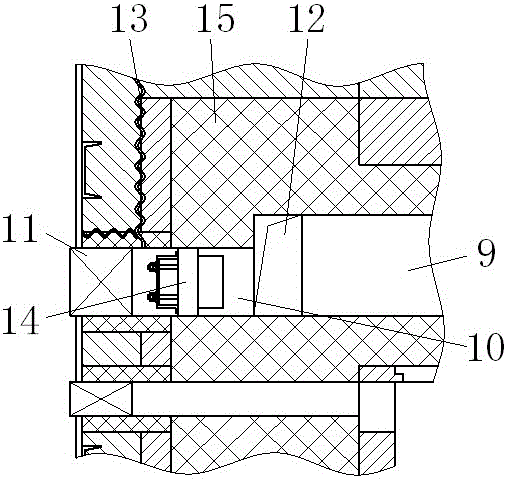

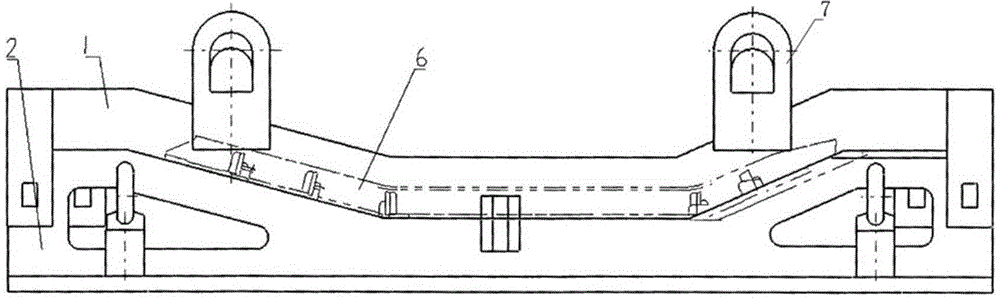

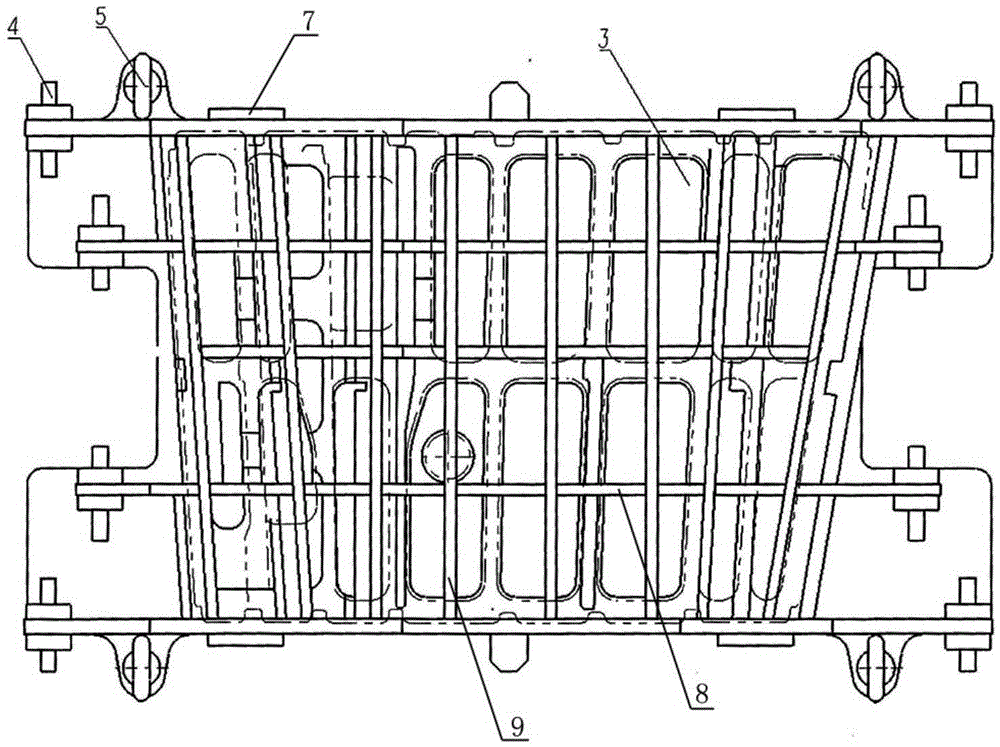

Automobile clutch cover forming coining die

InactiveCN107138616AImprove flatness and surface roughness accuracyGuaranteed product performanceShaping toolsVehicle componentsClutchSurface grinding

An automobile clutch cover forming and pressing die, comprising an upper die base, a nitrogen gas spring, an upper backing plate, an upper die core, an upper pressing block, a lower die core, a lower pressing block, a lower discharge plate and a lower die holder, and is characterized by: : Also includes: a nitrogen gas spring cover, which is detachably connected to the upper die base, and the nitrogen gas spring is arranged between the upper die base and the nitrogen spring cover; an equal-height sleeve, the equal-height sleeve and the upper die core Connected, the upper mold core moves up and down through the nitrogen gas spring, and the upper mold core is controlled to maintain a vertical state when it goes down through the equal-height sleeve; the lower mold core insert is detachably connected to the lower mold core; The unloading plate is locked with the lower pressing block, and the up and down movement is realized by the hydraulic ejector rod to return the material. The advantage of the present invention is that: the upper die seat is equipped with a nitrogen spring cover, which can be directly twisted and taken out. In the lower core, the supporting ring surface is used as a separate insert, and it is smoothed by plane grinding to improve the flatness and surface roughness accuracy, and effectively ensure product performance.

Owner:桂林福达重工锻造有限公司

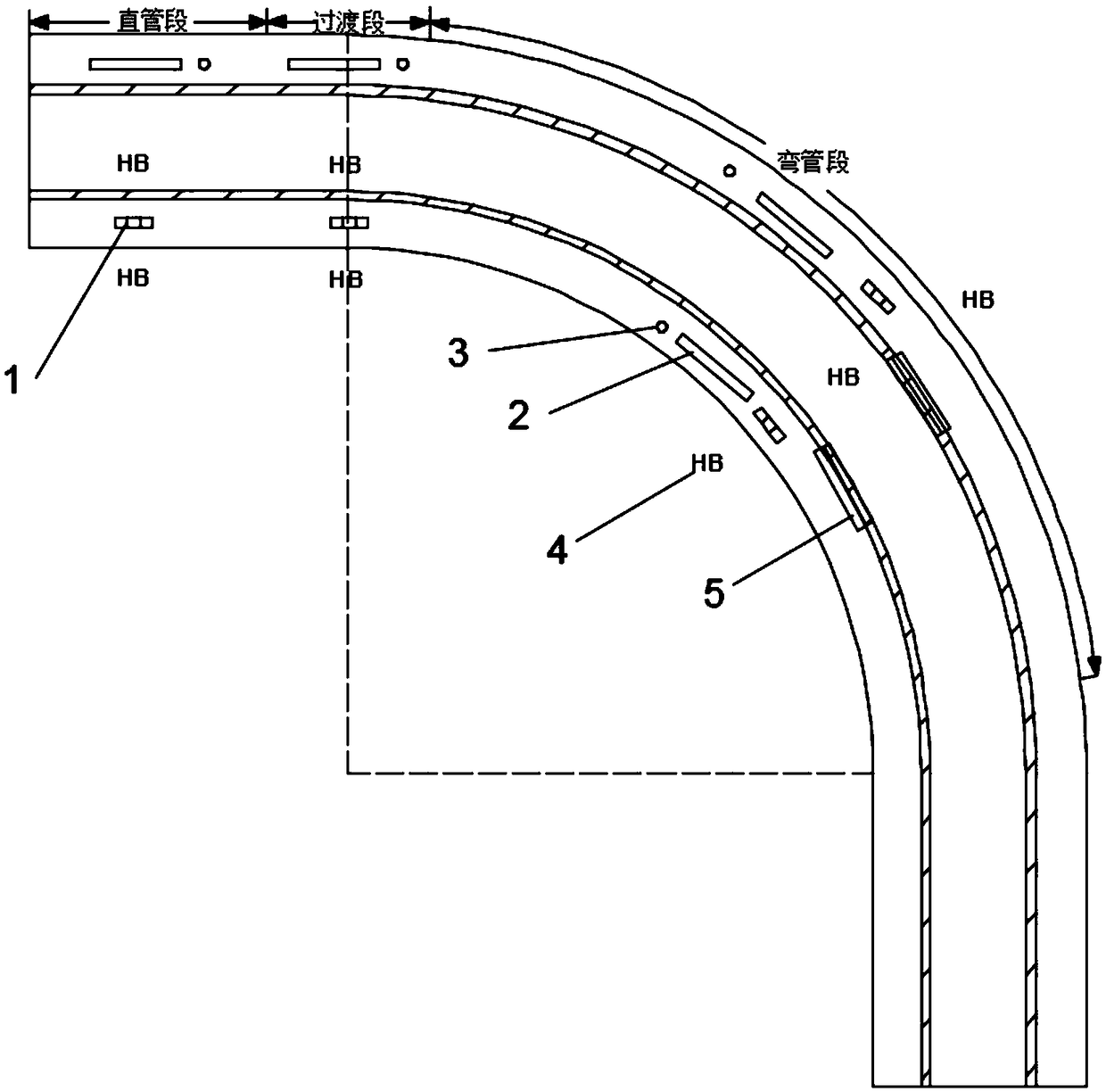

Bimetal metallurgy composite bent pipe heat treatment technology

InactiveCN108642258AGuaranteed corrosion resistanceElimination of heat affected zoneFurnace typesHeat treatment furnacesHeat-affected zoneHardness

The invention relates to the technical field of heat treatment, in particular to a bimetal metallurgy composite bent pipe heat treatment technology. The bimetal metallurgy composite bent pipe heat treatment technology comprises the following steps that firstly, base pipe surfacing is conducted, a bimetal metallurgy composite pipe is taken, welding slopes are formed at the two ends of the bimetal metallurgy composite pipe through machining, metal is arranged on the machined welding slopes in a surfacing manner, and then a surfacing layer is formed through turning of a machine tool, wherein themetal and the bimetal metallurgy composite pipe are the same in material; secondly, bending pretreatment is conducted, one end of the bimetal metallurgy composite pipe is blocked, and a medium with the temperature ranging from 140 DEG C to 160 DEG C is poured into the bimetal metallurgy composite pipe; and thirdly, bending is conducted, and when the temperature of the medium in the second step isreduced to 80-90 DEG C through cooling, a pipe bending machine is adopted for bending, and a bimetal metallurgy composite bent pipe is manufactured. The bimetal metallurgy composite bent pipe heat treatment technology has the beneficial effects that the heat affected zone generated during heat induction bending can be eliminated, and the product performance and corrosion resisting performance of acomposite layer are guaranteed; the size precision is high, and the inner wall is smoother; and the hardness and toughness are good, and the service life is long.

Owner:苏州罗克莱科技有限公司

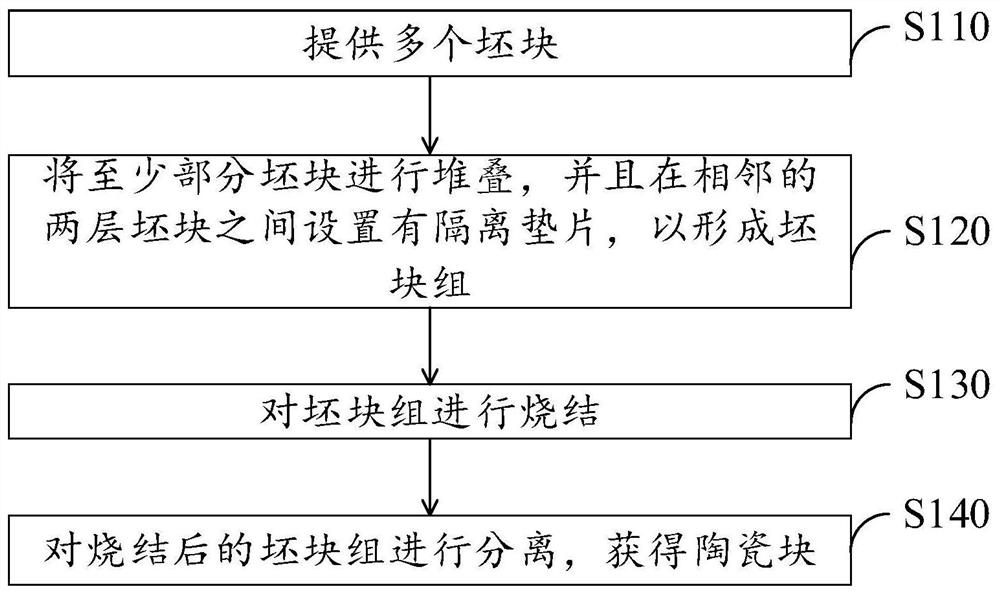

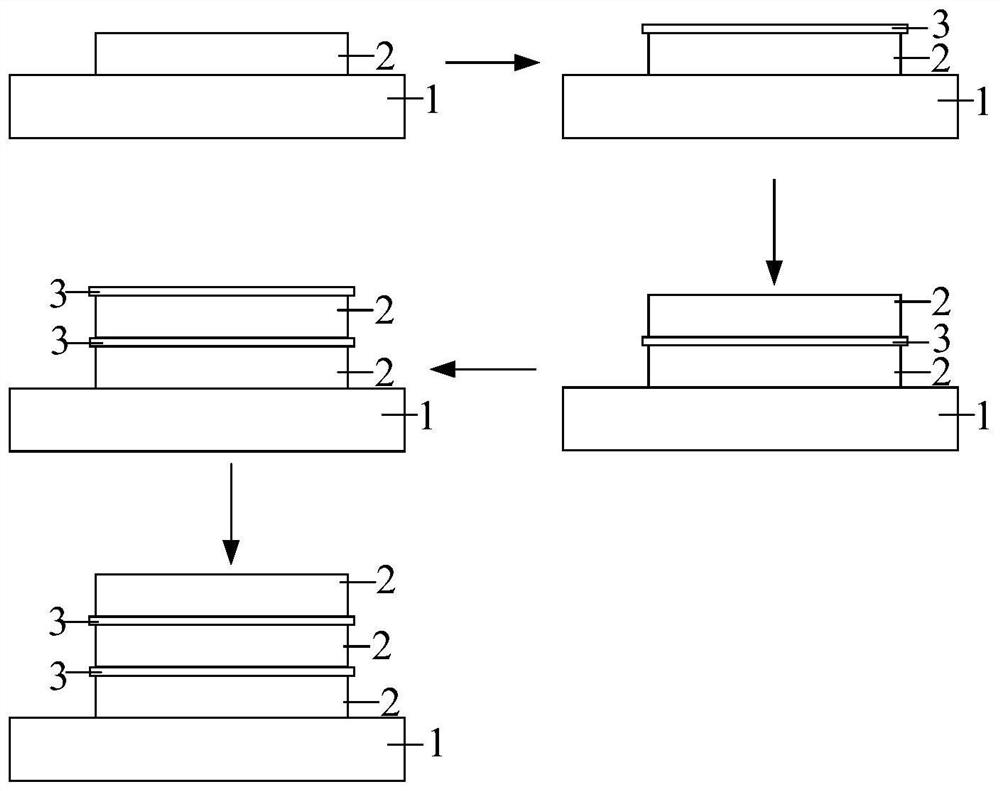

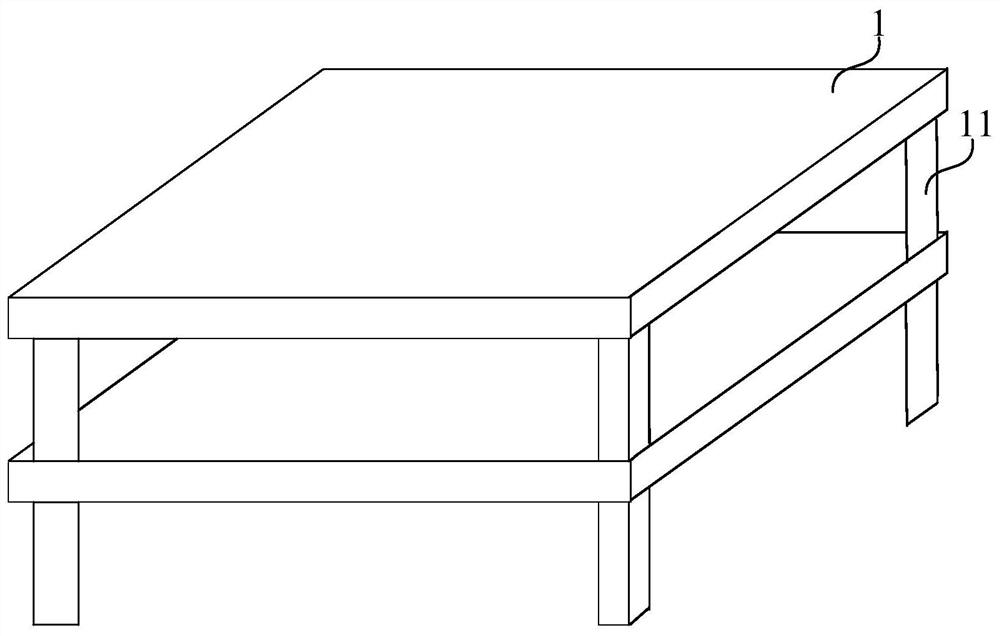

Sintering method of ceramic block

The invention provides a sintering method of a ceramic block. The method comprises the following steps: providing a plurality of briquettes; stacking at least part of the briquettes, and arranging an isolation gasket between two adjacent layers of briquettes to form a briquette group; sintering the blank block group; separating the sintered blank block group to obtain a ceramic block; wherein the isolation gasket does not deform at the sintering temperature of the blank block group. According to the sintering furnace, the number of blank blocks capable of being contained in the sintering furnace can be increased, so that the ceramic block sintering capacity is improved.

Owner:南京以太通信技术有限公司

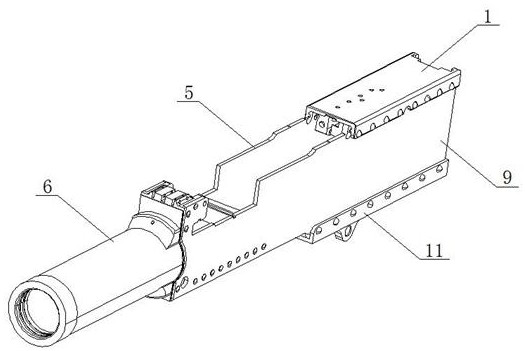

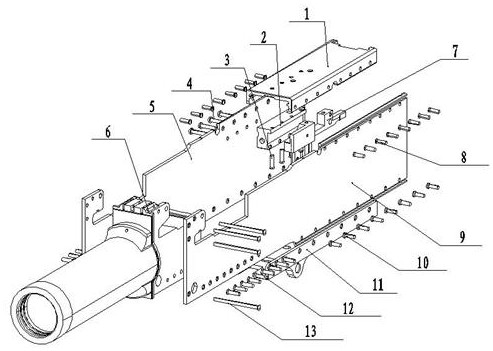

Assembly method of combined cartridge receiver

ActiveCN112475196AImprove accuracy and reliabilityGuaranteed assembly qualityWeapon componentsStructural engineeringReliability engineering

The invention relates to the technical field of firearm assembly, and discloses an assembly method of a combined cartridge receiver. The assembly quality of the cartridge receiver and the performanceof a formed product are ensured by improving the assembly method of the combined cartridge receiver, and finally the precision and reliability of firearm shooting are improved.

Owner:CHONGQING JIANSHE IND GRP

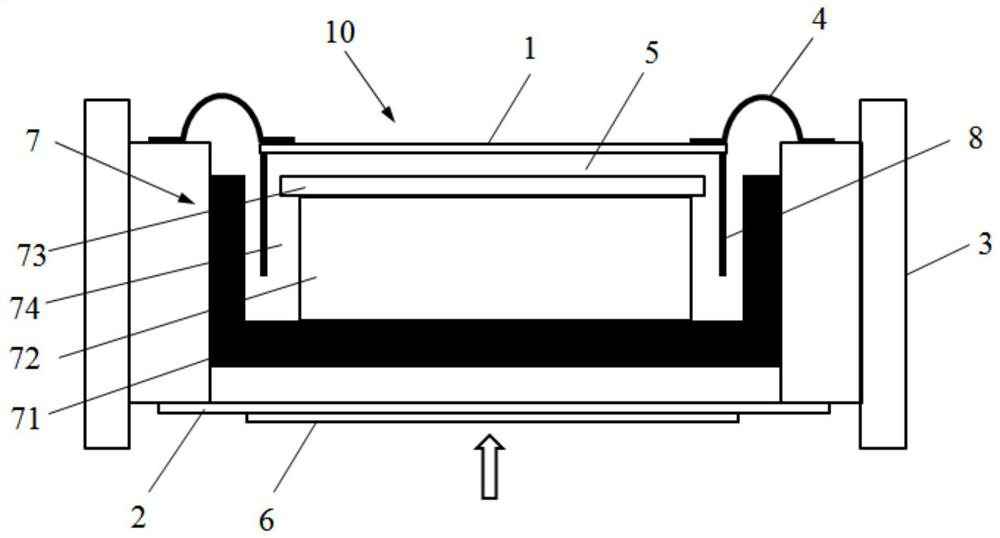

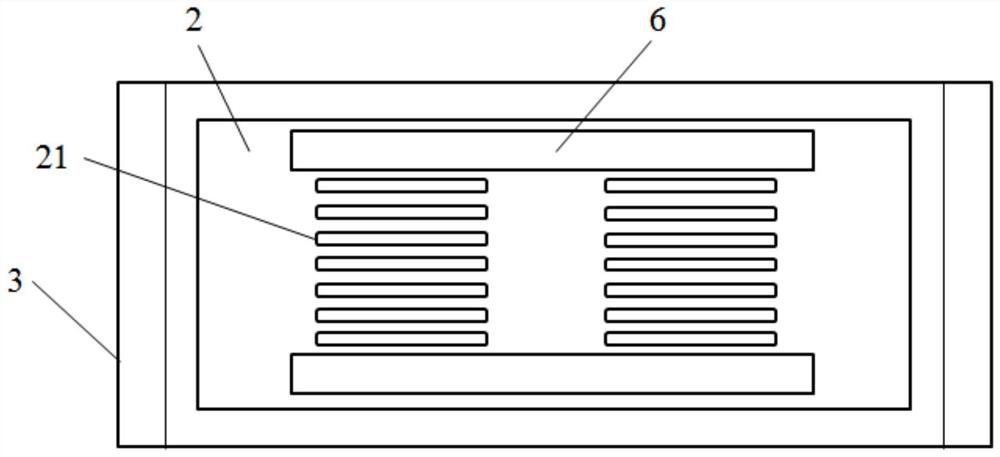

Loudspeaker, electronic equipment and control method of electronic equipment

ActiveCN112954553AGuaranteed product performanceGuaranteed sound effectDiaphragm dampingLoudspeakerEngineering

The invention relates to a loudspeaker, an electronic device and a control method of the electronic device, the loudspeaker comprises a loudspeaker diaphragm and a vibration damping diaphragm, the vibration damping diaphragm and the loudspeaker diaphragm are oppositely arranged, the vibration damping diaphragm and the loudspeaker diaphragm can form anti-phase vibration, therefore, the vibration caused by the vibration of the loudspeaker diaphragm is counteracted. According to the embodiment of the invention, the damping diaphragm capable of forming anti-phase vibration with the loudspeaker diaphragm is arranged at the position opposite to the loudspeaker diaphragm, so that the vibration of the loudspeaker and the like caused by the vibration of the loudspeaker diaphragm can be directly counteracted, and the vibration reduction is realized; meanwhile, a better vibration reduction effect can be always kept, and the product performance of the loudspeaker is ensured; in addition, the vibration of the damping diaphragm does not affect the sound production of the loudspeaker, and the sound production effect is ensured. And the thickness of the damping diaphragm is relatively thin, so that the size of the loudspeaker is relatively small, and the light and thin design requirements of the electronic equipment with the loudspeaker can be met.

Owner:LENOVO (BEIJING) CO LTD

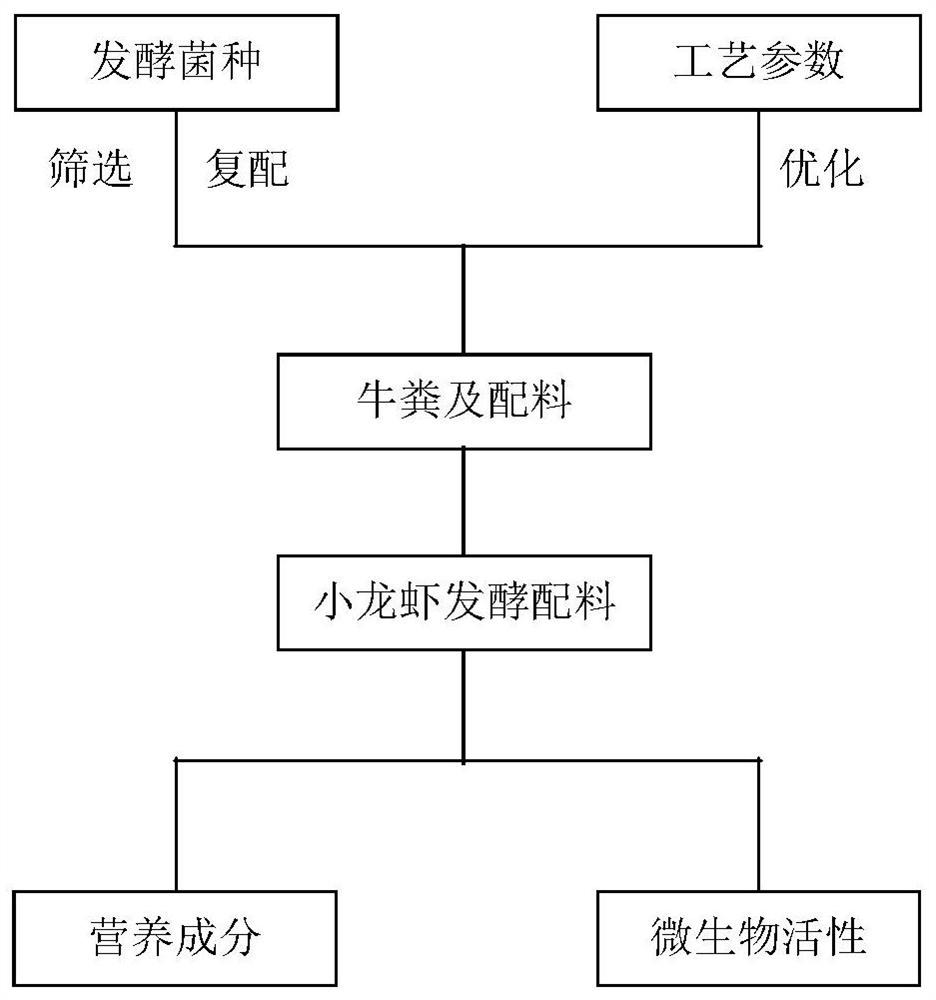

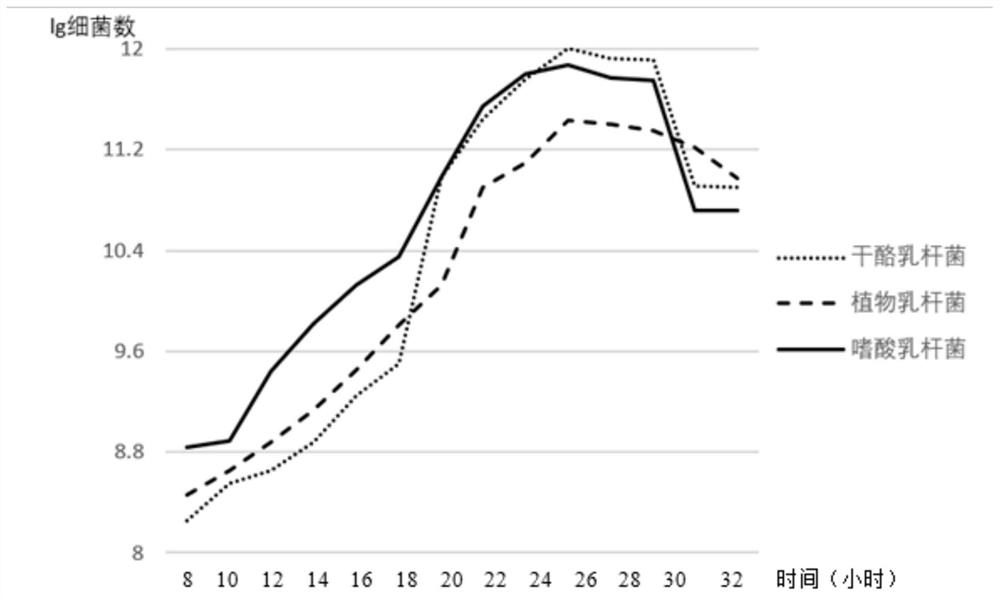

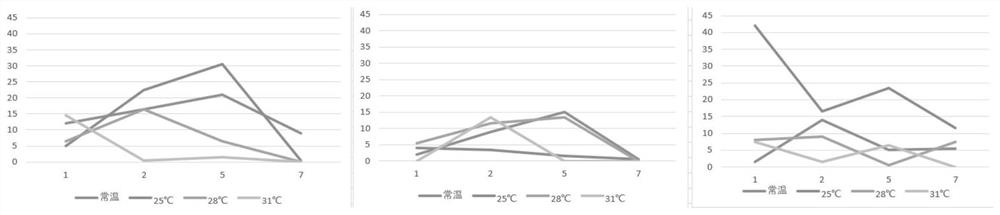

Crayfish feed and preparation method

PendingCN112674238AProcess parameter optimizationDetermine feasibilityBacteriaFood processingBiotechnologyNutrition

The invention belongs to the technical field of biochemistry, and discloses a crayfish feed and a preparation method. Process parameters of the crayfish feed taking fermented cow dung as a main component are determined, and the process parameters are optimized by controlling important variables in the fermentation process so as to guide the actual production. According to the crayfish feed, following two-stage combined fermentation is carried out: step 1, mixed fermentation is carried out in a microbial ex-situ fermentation bed; and step 2, anaerobic fermentation is carried out by selecting lactobacillus casei, lactobacillus plantarum and lactobacillus acidophilus as fermentation strains. Agricultural waste cow dung and other ingredients are fermented to prepare the crayfish fermented feed, so that the problem of cow dung pollution is solved, rich nutrition can be provided for crayfishes, the breeding input cost is reduced, and the economic benefit is very high. Meanwhile, a crayfish fermented feed process taking the fermented cow dung as the main component is systematically researched, and therefore, the fermentation process and the production stability are determined and the product effect is ensured.

Owner:WUHAN ACADEMY OF AGRI SCI

Sand blasting process of aviation fire-extinguishing bottle dome

The present invention discloses a sand blasting process of an aviation fire-extinguishing bottle dome. The sand blasting process comprises: a, a pretreatment, wherein a sand blasting machine, an air compressor and a sand blasting nozzle are tested, and compressed air is introduced into the air compressor; b, sand blasting, wherein sand blasting is performed on a fire-extinguishing bottle dome, both sides of the sand blasting nozzle are respectively provided with a baffle, and during a sand blasting process, the sand blasting nozzle move slowly and the fire-extinguishing bottle rotates at a uniform speed; c, cleaning, wherein sand and lime sand on the fire-extinguishing bottle dome surface are cleaned; and d, testing, wherein roughness of the fire-extinguishing bottle dome surface is tested. According to the manner, with the sand blasting process, wall thickness uniformity during a dome molding process can be effectively controlled, and the product weight can be reduced on the basis of assurance of the product performance.

Owner:常州蓝翼飞机装备制造有限公司

Sealing method and internal sealing device used for volatile matter main channel of tank furnace

ActiveCN103727229BSolve the problem of burning out of controlSimple structureEngine sealsCombustionBrick

The invention discloses a method for sealing the main channel of volatile matter in a pot furnace and an internal sealing device used therefor. The wall body of the pot furnace targeted by the method is composed of multiple layers of refractory material layers, and the top of the pot furnace is provided with a volatile matter The main road, the main road of volatiles is equipped with a main road cleaning hole that goes over the entire tank furnace wall. An inner sealing device is added at the innermost refractory layer of the tank furnace wall at the main road cleaning hole to isolate the outer layer of the furnace. The passage between the cracks in the body and the main volatile channel prevents the air infiltrated from the cracks from combining with the volatiles in the main volatile channel. The invention perfectly solves the cracks between the layers caused by the inconsistency of the thermal expansion rates of different refractory material layers inside the tank furnace wall, so that the air enters the volatile matter main channel from the cracks and combusts with the volatile matter to cause the furnace top to catch fire. Or the volatile matter escapes downward from the crack into the observation hole under the negative pressure in the furnace, and burns together with the air leaking in from the outside of the furnace, causing the insulation brick layer to burn and deform, and the furnace burns out of control.

Owner:GUIYANG AL-MG DESIGN & RES INST

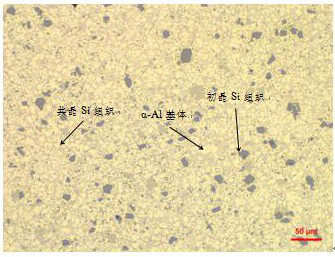

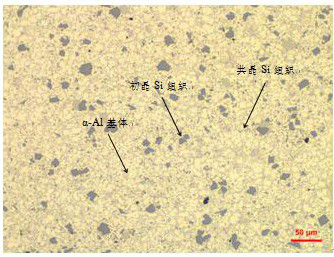

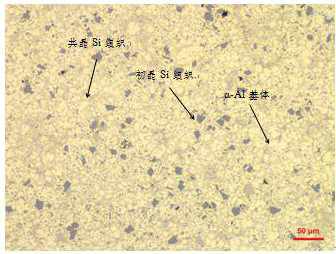

High-hardness wear-resistant aluminum alloy material and preparation method thereof

PendingCN114752825AAccurate and reliable heat treatment processGuaranteed product performanceAlloy elementHardness

The high-hardness wear-resistant aluminum alloy material comprises the following elements in percentage by mass: 3.5%-5.5% of Cu, 13.5%-18.5% of Si, 0.35%-0.55% of Mn, 0.55%-0.95% of Mg, less than or equal to 0.75% of Fe, less than or equal to 1.3% of Zn, less than or equal to 30 ppm of Ca, less than or equal to 20 ppm of P, 0.060%-0.15% of Ti, 0.0065%-0.013% of P, 0.075%-0.15% of Cr, 0.015%-0.035% of La + Ce and the balance of Al and impurities, and the total content of the impurities is less than or equal to 0.15%. The method has the advantages that after the aluminum alloy is fully modified and refined, effective alloy elements Ti, P and Cr do not have burning loss and specific gravity segregation, the long-acting and stable effect is achieved, meanwhile, the heat treatment process is accurate, reliable and efficient, the product performance is effectively guaranteed, and the excellent characteristics of being efficient and rapid are achieved.

Owner:南通鸿劲金属铝业有限公司

A processing method for stable heat treatment of titanium alloy parts

ActiveCN104004982BGuaranteed structural sizeGuaranteed product performanceEffective solutionTitanium

The invention provides a stable heat treatment processing method for titanium alloy parts, which uses a stable heat treatment fixture to process titanium alloy parts, which effectively solves the problems of residual stress and uneven structure in titanium alloy parts after processing, thereby ensuring the structural size of titanium alloy parts and product performance.

Owner:吉林航空维修有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com