High-hardness wear-resistant aluminum alloy material and preparation method thereof

A technology of aluminum alloy materials and high hardness, which is applied in the field of material manufacturing, can solve problems such as difficult to find materials, and achieve the effects of product performance assurance and accurate and reliable heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

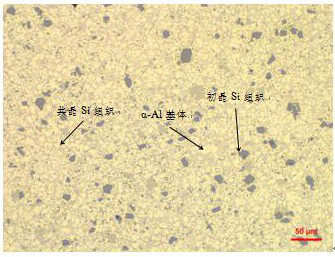

Embodiment 1

[0038]Embodiment 1: The present invention relates to a high-hardness wear-resistant aluminum alloy material, including the elements in mass percentage: Cu3.5%, Si13.5.%, Mn0.35%, Mg0.55%, Fe≤0.75%, Zn ≤1.3%, Ca≤30ppm, P≤20ppm, Ti0.060%, P0.0065%, Cr0.075%, La+Ce 0.015%, the balance is Al and impurities, of which the total content of impurities is not more than 0.15%.

[0039] A method for preparing a high-hardness wear-resistant aluminum alloy material, comprising the following steps:

[0040] S1. Prepare raw materials according to the percentage of each element in the formula of the aluminum alloy material;

[0041] S2, melting;

[0042] S3, the first slag and degassing;

[0043] S4, remove the scum, and deal with the deterioration;

[0044] S5, the second deslagging and degassing;

[0045] S6, remove the scum, close the furnace door, and carry out a standing treatment, and the standing time is controlled at 20min;

[0046] S7, refinement treatment to form aluminum alloy...

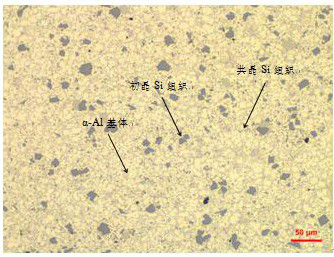

Embodiment 2

[0059] Embodiment 2: a high-hardness wear-resistant aluminum alloy material, including mass percentage of each element: the Cu4.5%, Si15.5%, Mn0.45%, Mg0.75%, Fe≤0.75%, Zn≤ 1.3%, Ca≤30ppm, P≤20ppm, Ti0.1%, P0.01%, Cr0.1%, La+Ce 0.025%, the balance is Al and impurities, of which the total content of impurities is not more than 0.15%.

[0060] The present invention also relates to a method for preparing a high-hardness wear-resistant aluminum alloy material, comprising the following steps:

[0061] S1. Prepare raw materials according to the percentage of each element in the formula of the aluminum alloy material;

[0062] S2, melting;

[0063] S3, the first slag and degassing;

[0064] S4, remove the scum, and deal with the deterioration;

[0065] S5, the second deslagging and degassing;

[0066] S6, remove the scum, close the furnace door, and carry out a standing treatment, and the standing time is controlled at 30min;

[0067] S7, refinement treatment to form aluminum al...

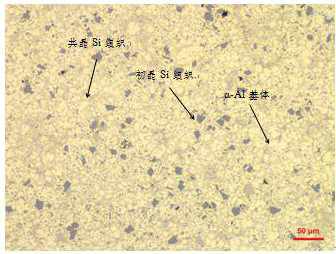

Embodiment 3

[0080] Embodiment 3: a high-hardness wear-resistant aluminum alloy material, including mass percentage of each element: Cu5.5%, Si18.5%, Mn0.55%, Mg0.95%, Fe≤0.75%, Zn≤1.3%, Ca≤30ppm, P≤20ppm, Ti0.15%, P0.013%, Cr0.15%, La+Ce 0.035%, the balance is Al and impurities, and the total content of impurities is not more than 0.15%.

[0081] The present invention also relates to a method for preparing a high-hardness wear-resistant aluminum alloy material, comprising the following steps:

[0082] S1. Prepare raw materials according to the percentage of each element in the formula of the aluminum alloy material;

[0083] S2, melting;

[0084] S3, the first slag and degassing;

[0085] S4, remove the scum, and deal with the deterioration;

[0086] S5, the second deslagging and degassing;

[0087] S6, remove the scum, close the furnace door, and carry out a standing treatment, and the standing time is controlled at 40min;

[0088] S7, refinement treatment to form aluminum alloy liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com