A processing method for stable heat treatment of titanium alloy parts

A processing method and technology of titanium alloy, applied in the field of stable heat treatment processing of titanium alloy parts, can solve problems such as residual stress and uneven structure, and achieve the effect of ensuring performance, ensuring geometric shape and dimensional accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A processing method for stable heat treatment of titanium alloy parts, comprising the steps of:

[0022] 1) Clean the titanium alloy part 6 with acetone,

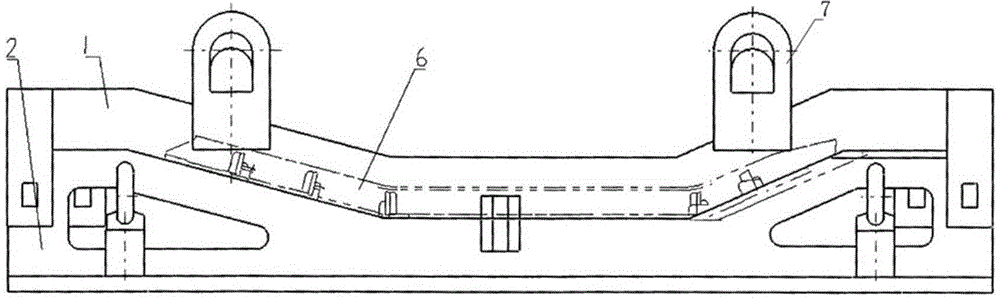

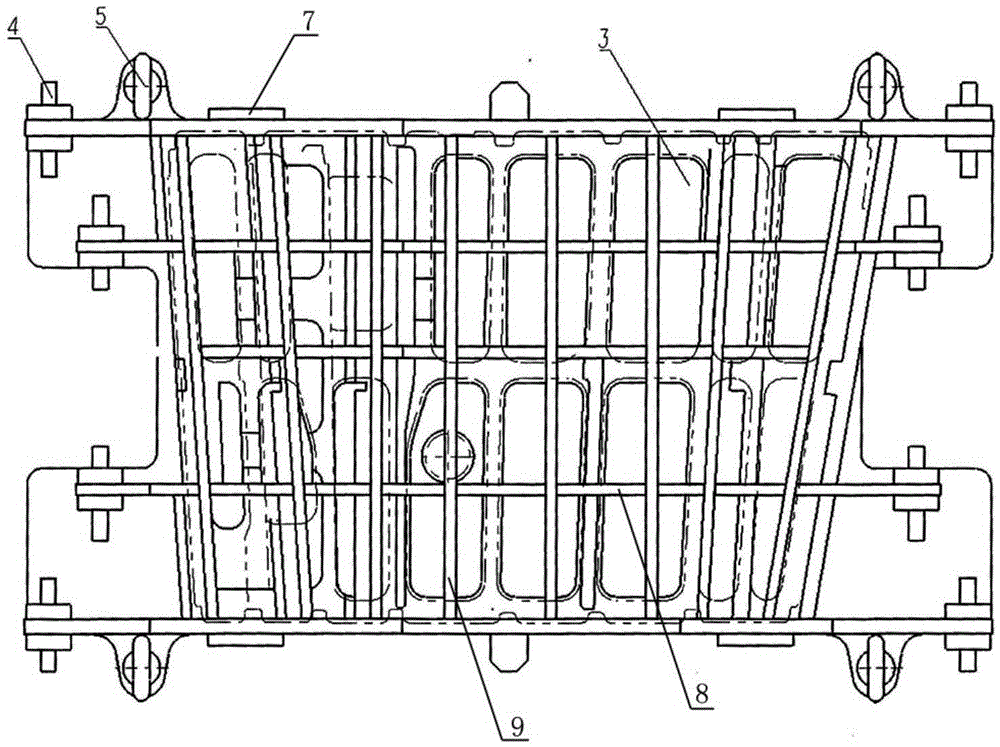

[0023] 2) Place the cleaned titanium alloy part 6 on the base 2 of the jig for positioning, position the pressing block assembly 3 and the pressing assembly 1 of the jig on the titanium alloy part 6 in sequence, and use the wedge 4 of the jig to press Tightening component 1, briquetting component 3, titanium alloy part 6 and base 2 are assembled and pressed,

[0024] 3) Put the clamp equipped with the titanium alloy part 6 into a vacuum heat treatment furnace to vacuumize,

[0025] 4) After vacuuming, raise the temperature of the vacuum heat treatment furnace to 290-310 degrees, and keep it for 30 minutes after the furnace temperature is stable.

[0026] 5) Then heat up to 650 degrees, and keep the furnace temperature for 90 minutes after it stabilizes.

[0027] 6) After the furnace is cooled to 280-200 degrees, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com