Reservation and replacement of cast-in-place curb stones on asphalt concrete pavement and its construction method

A technology of asphalt concrete and cast-in-place curb, which is applied in the direction of gutter/curb, roads, roads, etc., can solve the problems such as the inability to accurately locate the curb in the separation belt, the inability to reuse the asphalt concrete, and the inability to guarantee the rolling quality, etc. Achieve the effect of smooth and beautiful line shape, reliable technical support, and high overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment: In this embodiment, the manufacturing process requirements of the indwelling groove mold, the technical requirements for asphalt concrete pavement paving and rolling construction, and the construction process requirements for cast-in-place curb stones will not be described in detail, and the asphalt concrete pavement curb stones involved in the present invention will be focused on Implementation of reserved substitution structures.

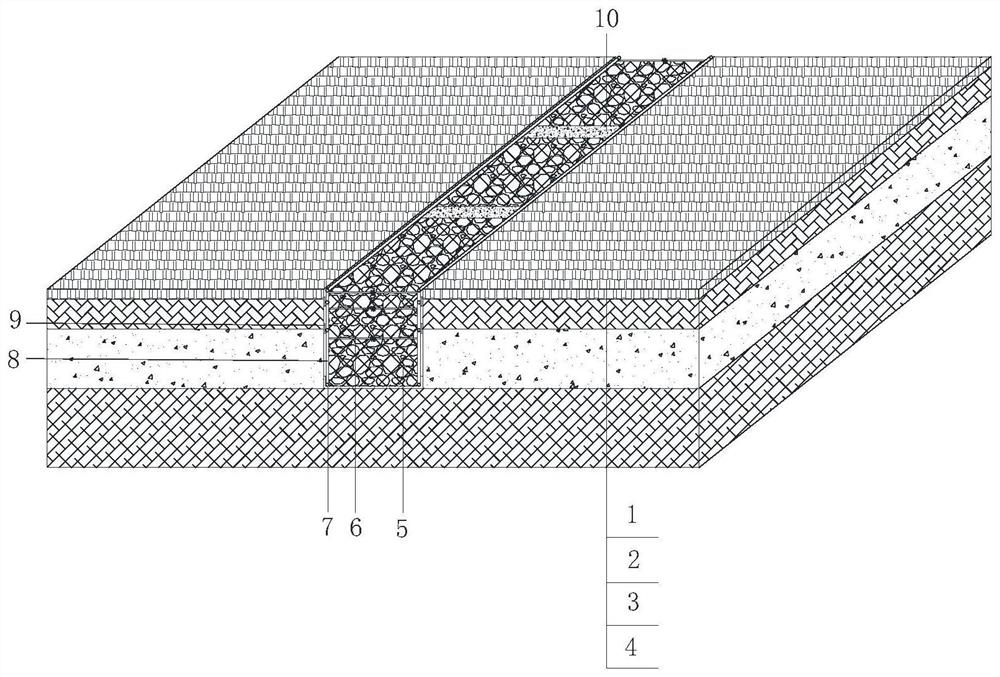

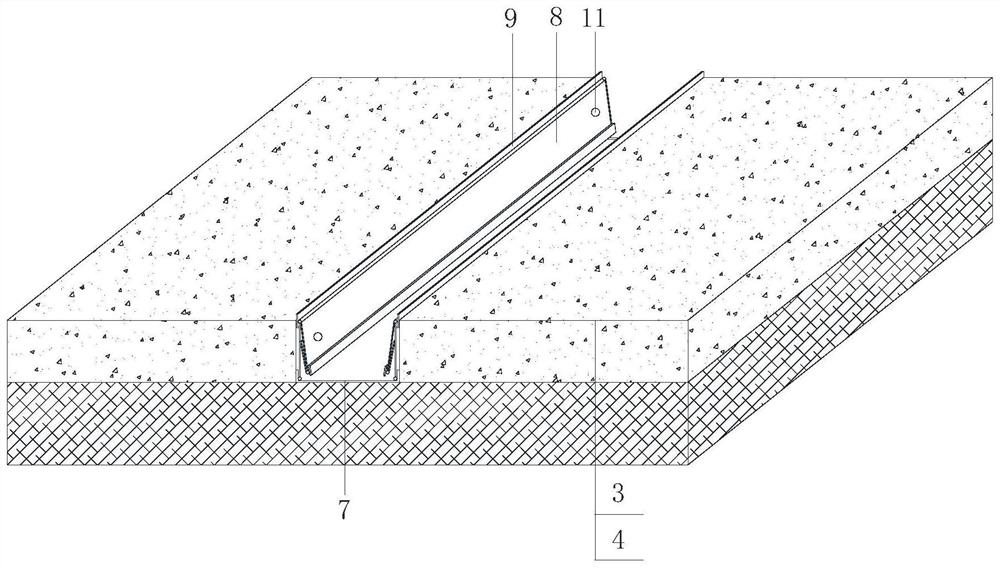

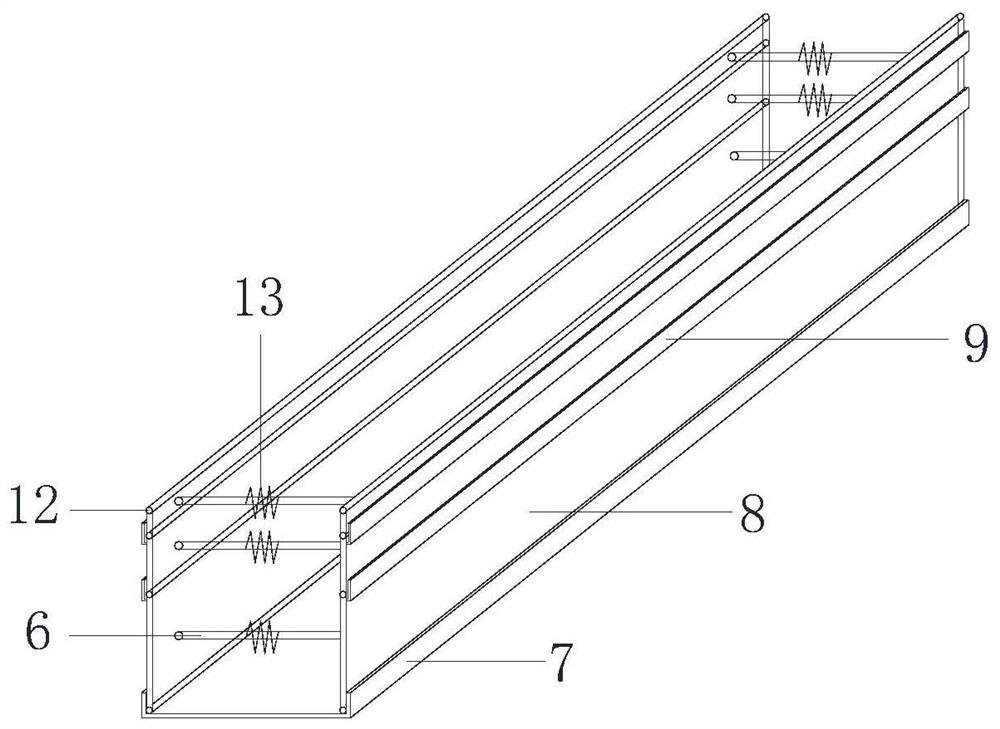

[0047] refer to Figure 1-9 As shown, the asphalt concrete pavement reserves and replaces cast-in-place curbstones, including retention trough moulds, crushed stone dense mesh bags 5, lightweight ribs 10, cast-in-place slipform systems, cast-in-place curbstones 18 and asphalt concrete pavement; Cement-stabilized gravel base 3 is set on the subbase 4, and the curb retention groove is excavated through the separation belt curb stone mold 16 on the cement-stabilized gravel base 3, and the retention groove mold is set in the curb re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com