Large composite material product forming die

A composite material, forming mold technology, applied in the field of machinery, can solve the problems of large deformation, excessive accumulated error, affecting product forming accuracy, etc., to achieve the effect of simple forming mold, improving quality, and saving demoulding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

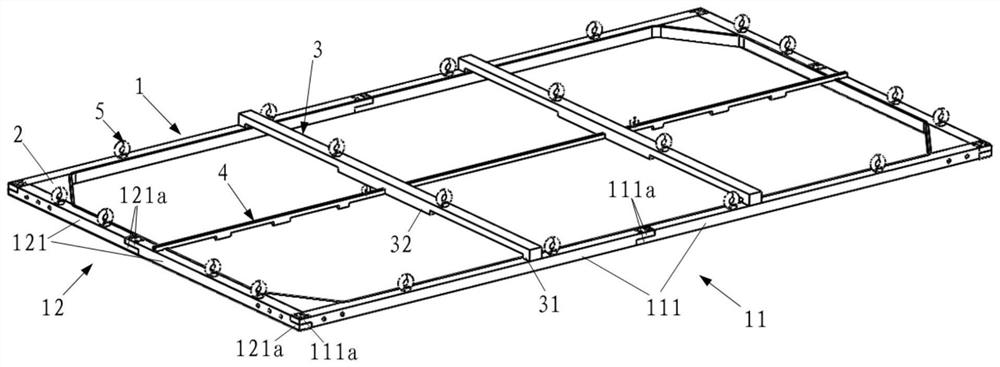

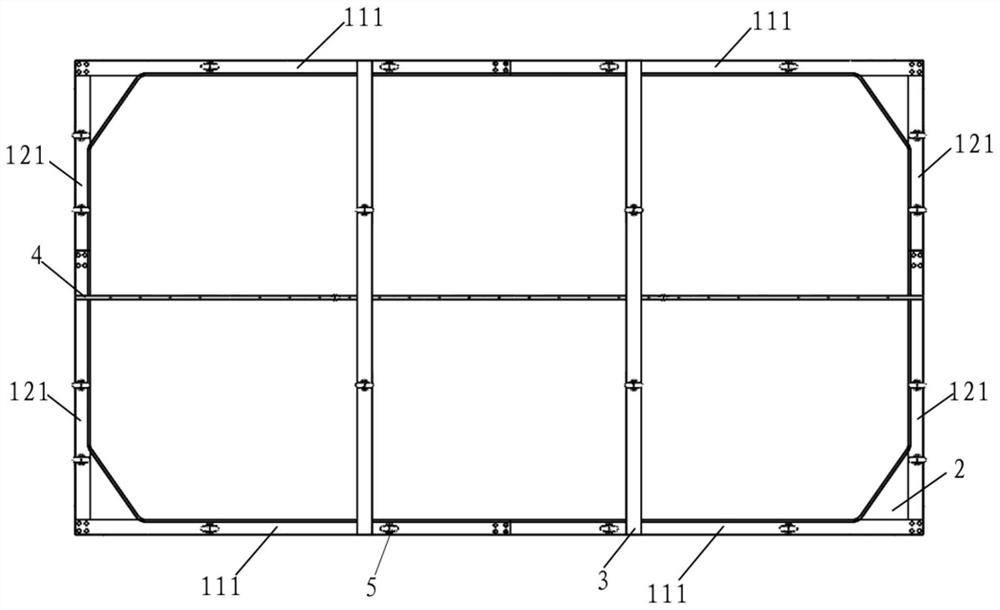

[0048] combine figure 1 and figure 2 As shown, according to one embodiment of the present invention, the long rod 11 includes: at least one long rod assembly 111 . In this embodiment, the opposite ends of the long rod assembly 111 are respectively provided with first end connectors 111a with a thickness smaller than the thickness of the long rod assembly 111; in this embodiment, the length of the long rod 11 is determined according to the shape and structure of the product , and can be obtained by splicing each other by setting a corresponding number of long rod assemblies 111 . Wherein, the adjacent long rod assemblies 111 are connected to each other by stacking the first end connecting pieces 111a provided at the ends. In this embodiment, the thickness of the first end connecting piece 111a can be set to be half of the thickness of the long rod assembly 111, and then when the first end connecting pieces 111a of adjacent long rod assemblies 111 are stacked and connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com