Patents

Literature

40results about How to "Guaranteed structural size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

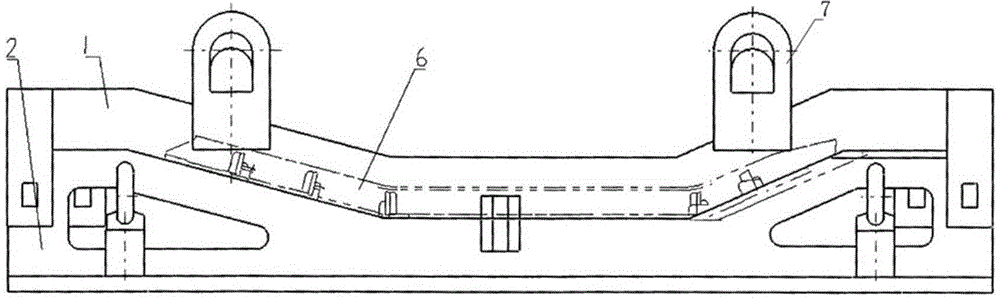

Stable heat processing method of titanium alloy part

ActiveCN104004982AGuaranteed structural sizeGuaranteed product performanceTitanium alloyHeat processing

The invention provides a stable heat processing method of a titanium alloy part. A stable heat processing clamp is used for processing the titanium alloy part, the problems that residual stress and a structure are not even in the processing process of the titanium alloy part are effectively resolved, and therefore the structural size and the product performance of the titanium alloy part are guaranteed.

Owner:吉林航空维修有限责任公司

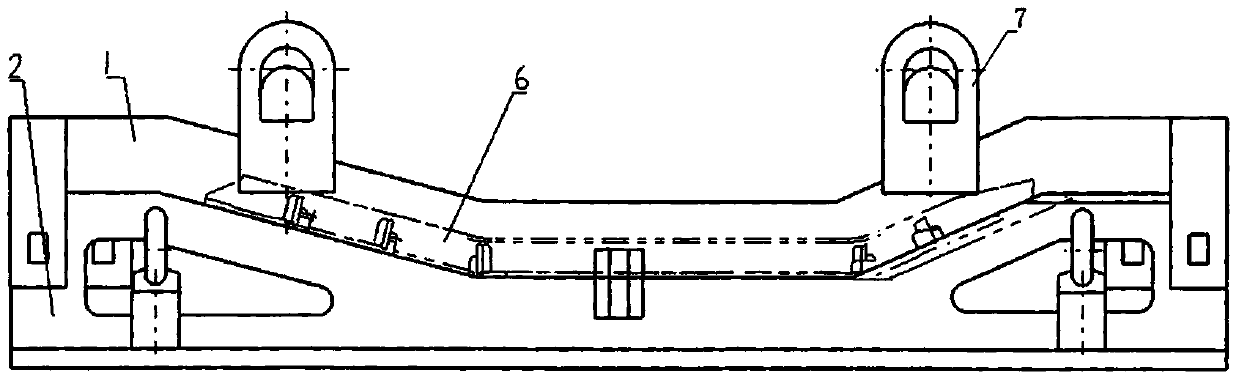

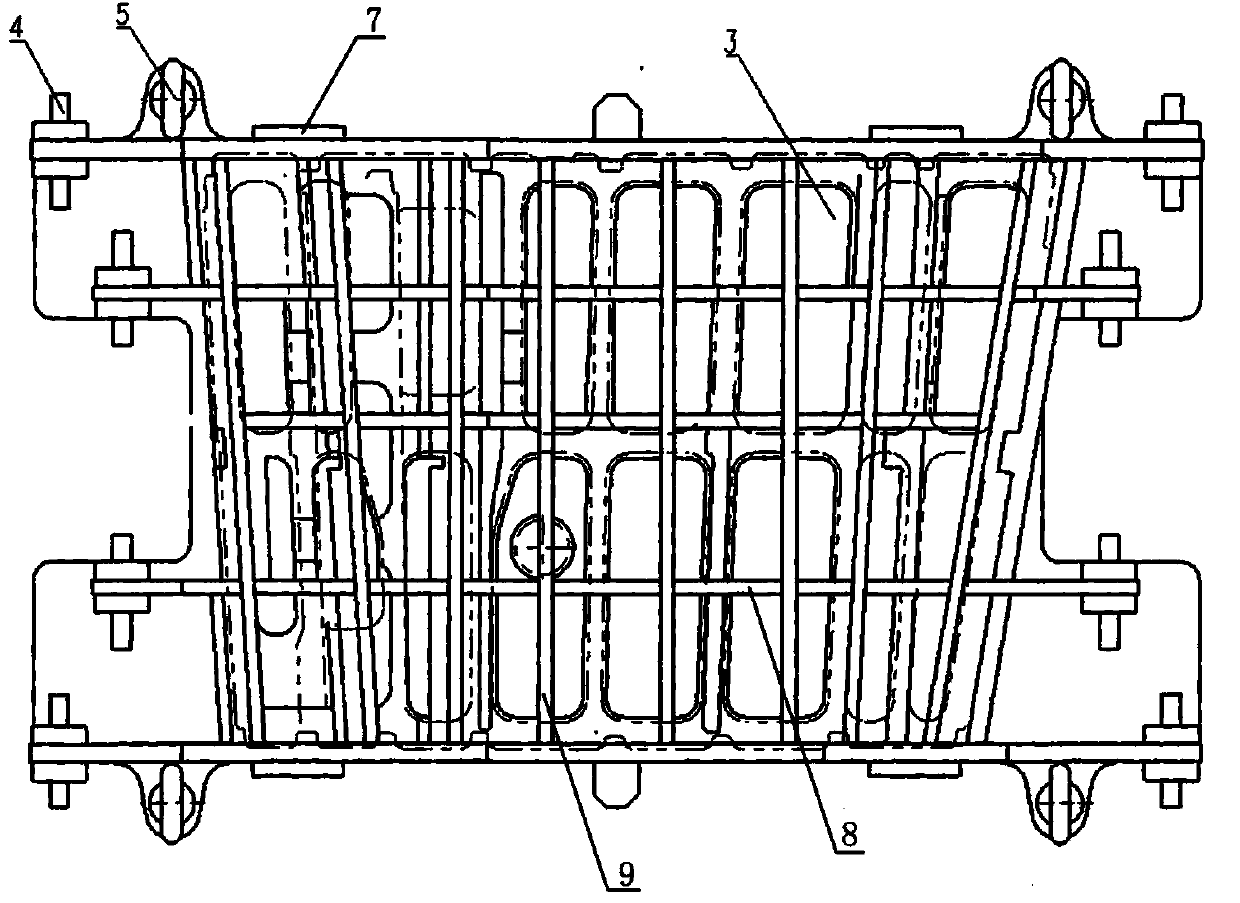

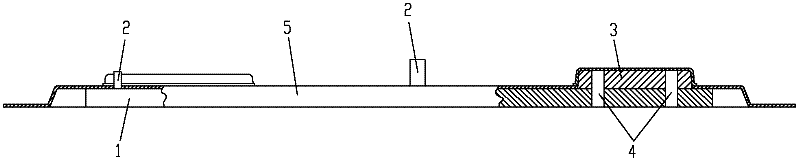

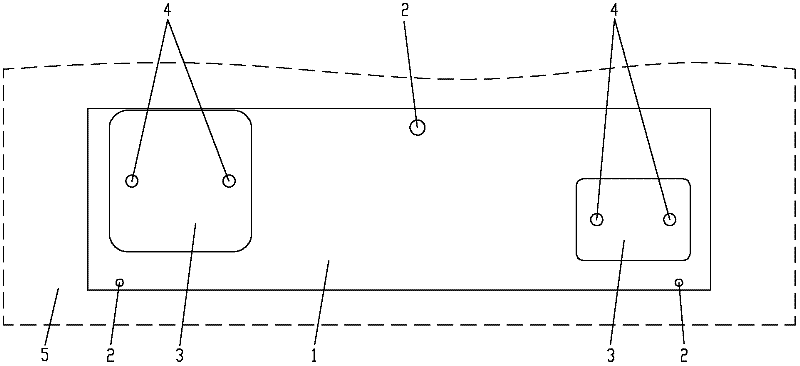

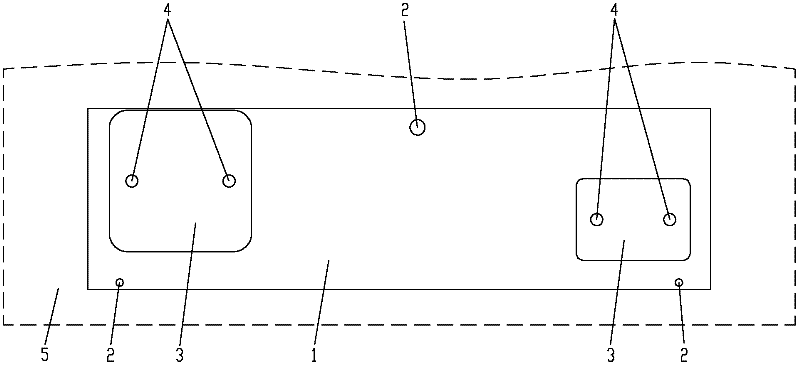

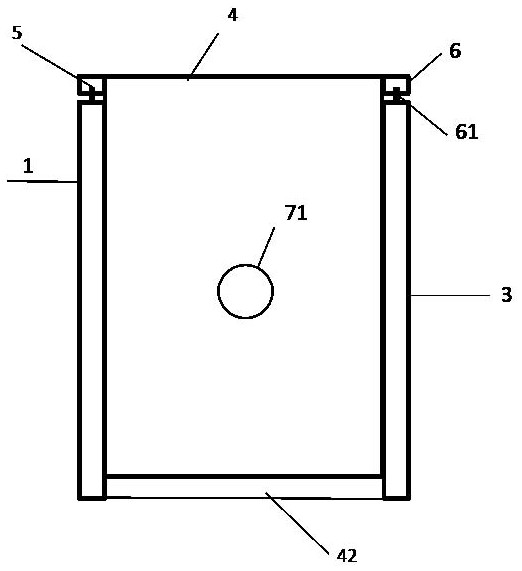

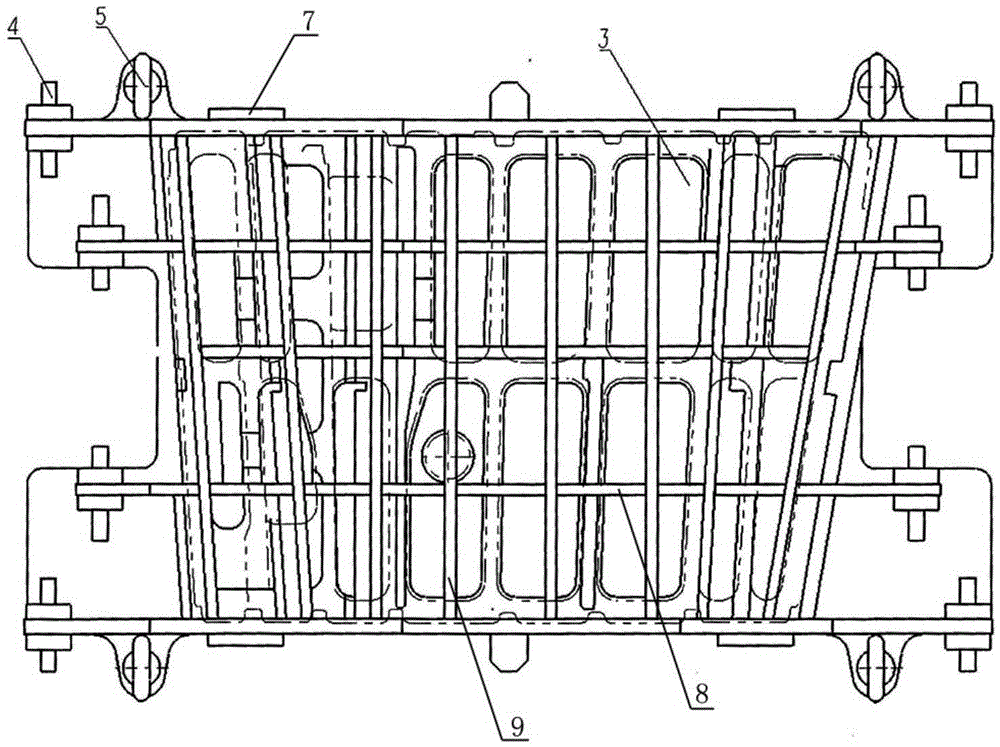

Wiring panel welding tooling

InactiveCN102328169AGuaranteed structural sizeAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesDirect currentStructural dimension

The invention discloses a wiring panel welding tooling, which comprises a bottom plate, at least two positioning pins and a positioning block, wherein the positioning pins are vertically and fixedly arranged on the bottom plate, the positioning pins are used for positioning a panel body in the horizontal direction through being matched with holes on the panel body, and the positioning block is arranged on the bottom plate corresponding to the position where a one-way socket box and a direct current wiring box need to be welded on the panel body and is used for positioning the internal outline of the one-way socket box and the direct current wiring box needing to be welded on the panel body. The wiring panel welding tooling can be used for precisely positioning the panel body as well as the one-way socket box and the direct current wiring box needing to be welded on the panel body, in addition, the deformation of each welding element in the welding process caused by high-temperature effect is prevented, the structural dimension of a wiring panel after the welding is ensured, and the defective percentage is reduced.

Owner:CHONGQING BEIBEI DISTRICT FENGHUO MACHINERY MFG

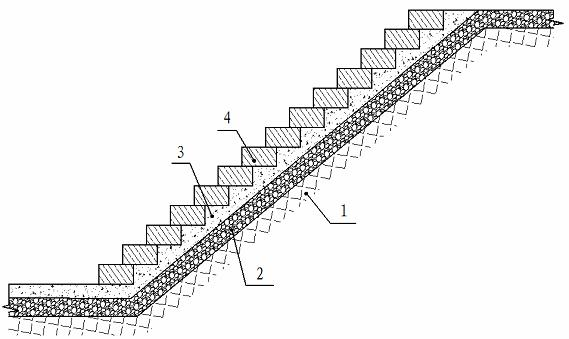

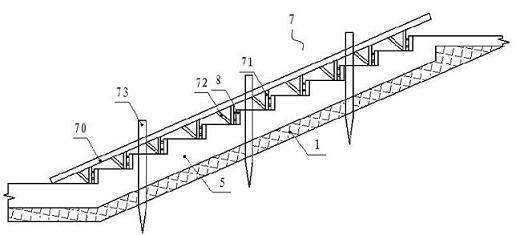

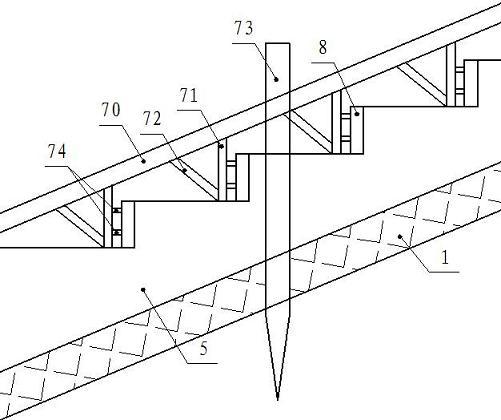

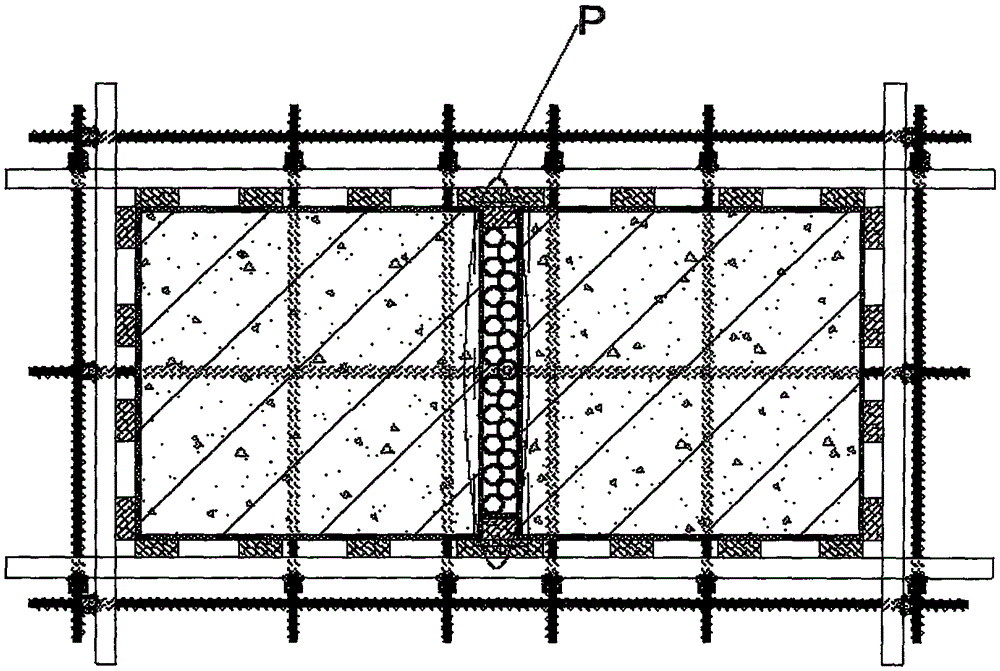

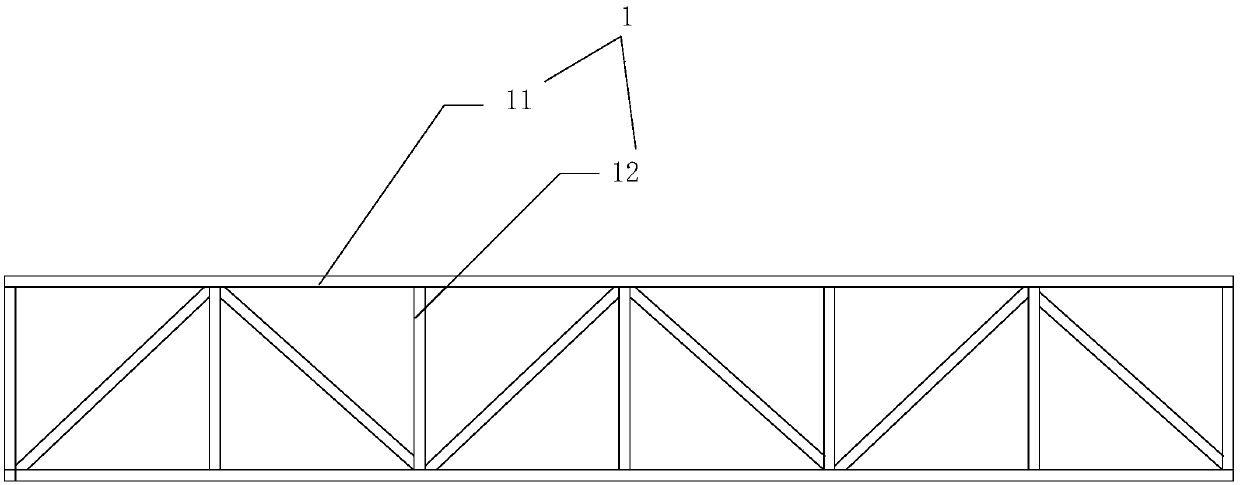

Suspended formwork pouring method for concrete foundation steps

ActiveCN102677895AEasy to assemblePrecise positioningForms/shuttering/falseworksBuilding material handlingStructural engineeringUltimate tensile strength

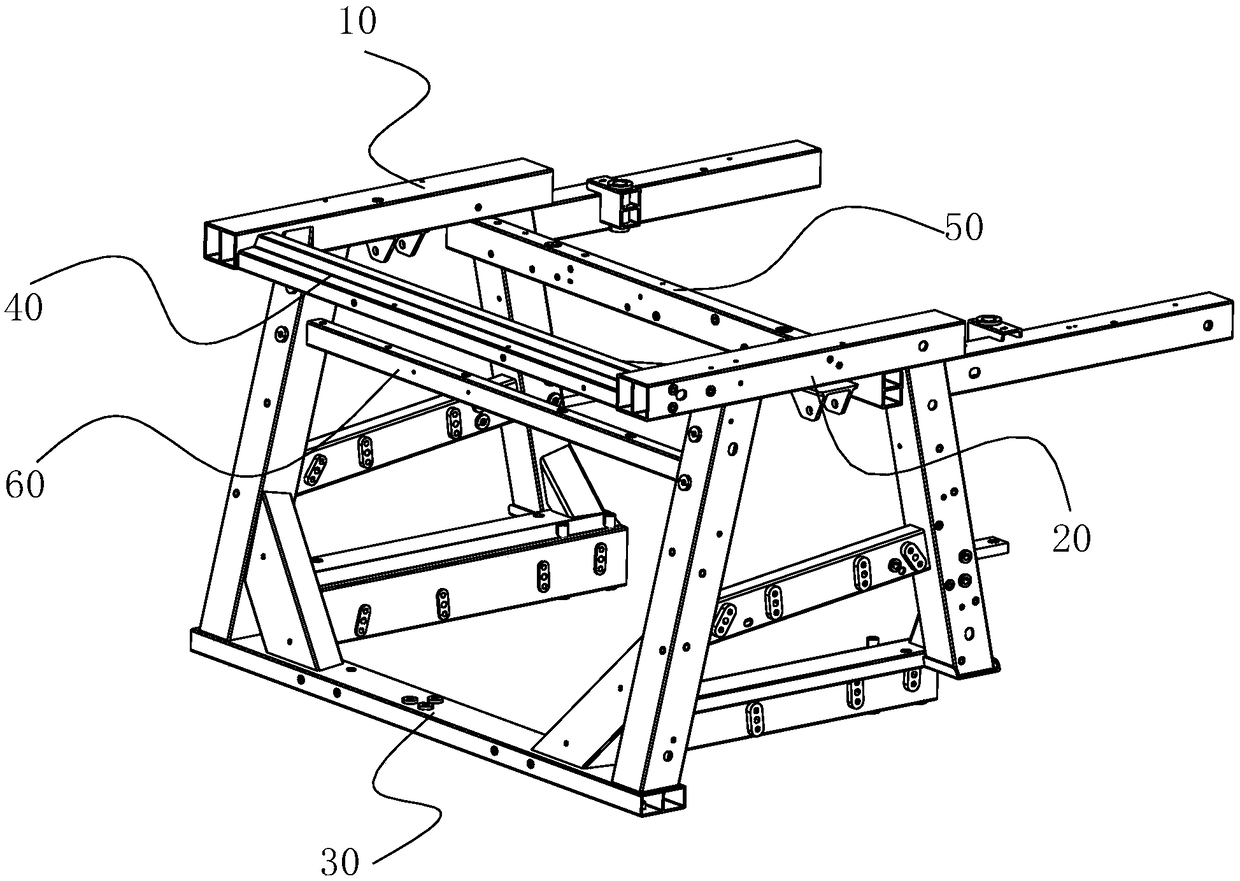

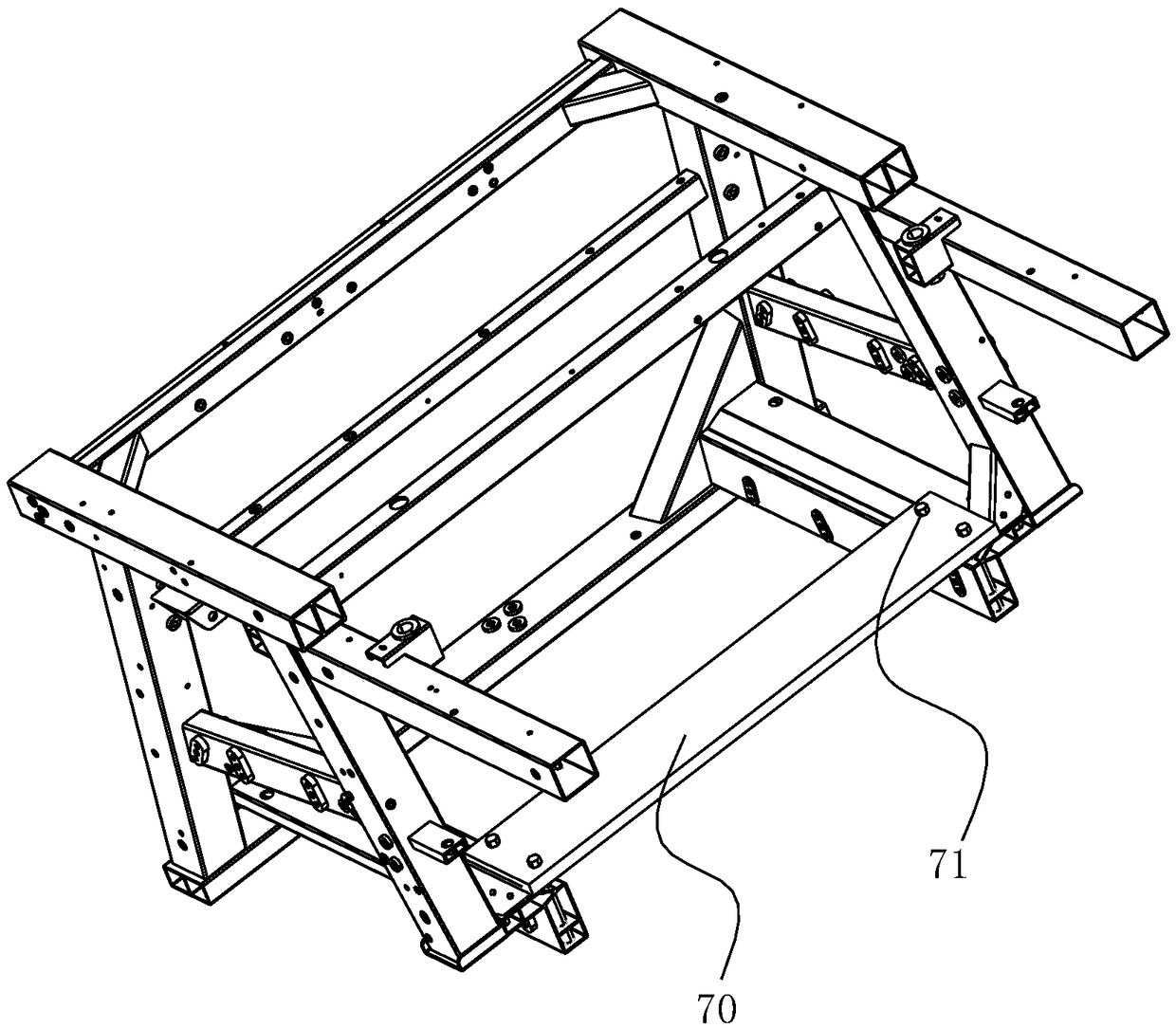

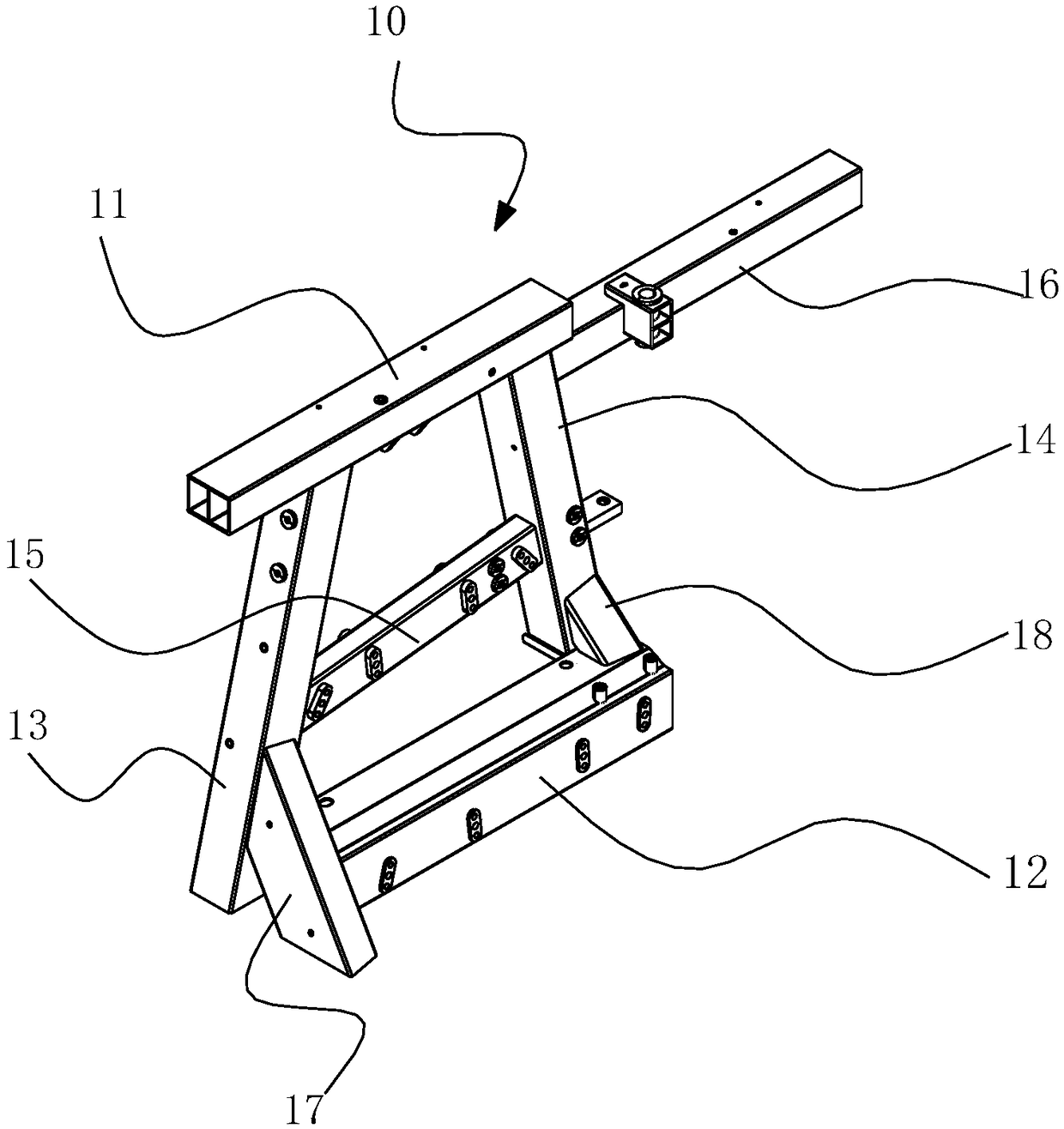

The invention relates to a suspended formwork for concrete foundation steps and a suspended formwork pouring method for pouring concrete foundation steps by using the suspended formwork. The suspended formwork comprises one or a plurality of formwork racks, each formwork rack comprises at least one longitudinal beam and a plurality of structural units distributed along the longitudinal beams in turn, each structural unit comprises a vertical formwork rack for mounting a vertical formwork and an inclined strengthening rib for fixing the vertical formwork rack, one end of the vertical formwork rack is fixedly connected with the longitudinal beam, and the two ends of the inclined strengthening rib are fixedly connected with the longitudinal beam and the vertical formwork rack respectively to form a steady triangular structure. The method comprises the following steps: (1) leveling up and tamping a foundation; (2) mounting a suspended formwork; and (3) pouring concrete foundation steps by use of the suspended formwork fabricated in step (2). The suspended formwork provided by the invention has the advantages of simple structure, accurate positioning and easiness in operation, and can be repeatedly used. The steps constructed using the method provided by the invention have the advantages of regular structure, esthetic appearance, high strength, and greatly improved quality.

Owner:北京正和恒基滨水生态环境治理股份有限公司

Frame-type car body rear compartment structure and welding method

ActiveCN109501867AControl welding deformationGuarantee welding qualityWelding/cutting auxillary devicesSuperstructure subunitsEngineeringWeld seam

The invention relates to a frame-type car body rear compartment structure and a welding method. The structure comprises a first side assembly at the rear portion of a car body, a second side assemblyat the rear portion of the car body, a first cross beam assembly at the rear portion, a second cross beam assembly at the rear portion, a battery box frame fixing assisting beam, a storage battery cross beam and a process beam, wherein the process beam is mounted between the bottom of the first side assembly at the rear portion of the car body and the bottom of the second side assembly at the rearportion of the car body. According to the structure and the welding method, the welding quality of a rear compartment of the car body and a welding process for welding deformation can be effectivelycontrolled, the repair quantity and size adjustment of welding seams are reduced, the welding seam quality and structural size of the rear compartment of the car body are ensured, the production efficiency is improved, and the qualification rate of products is increased.

Owner:CH AUTO TECH CORP CO LTD

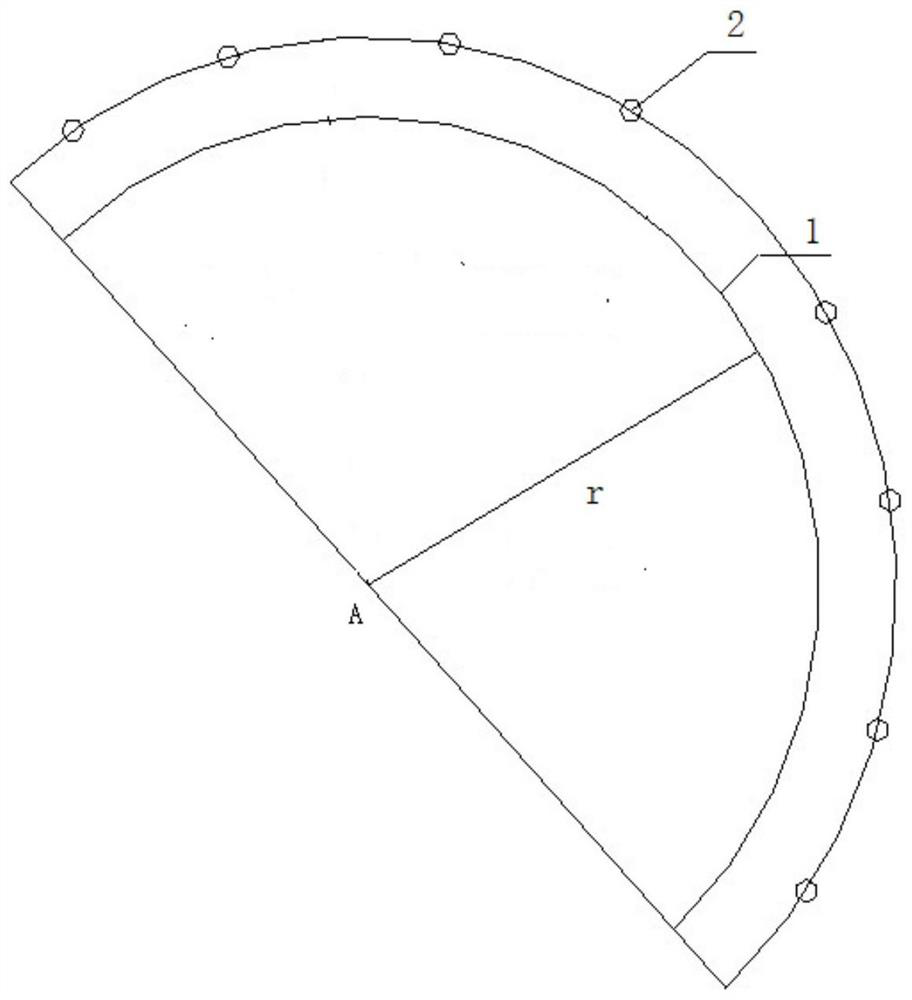

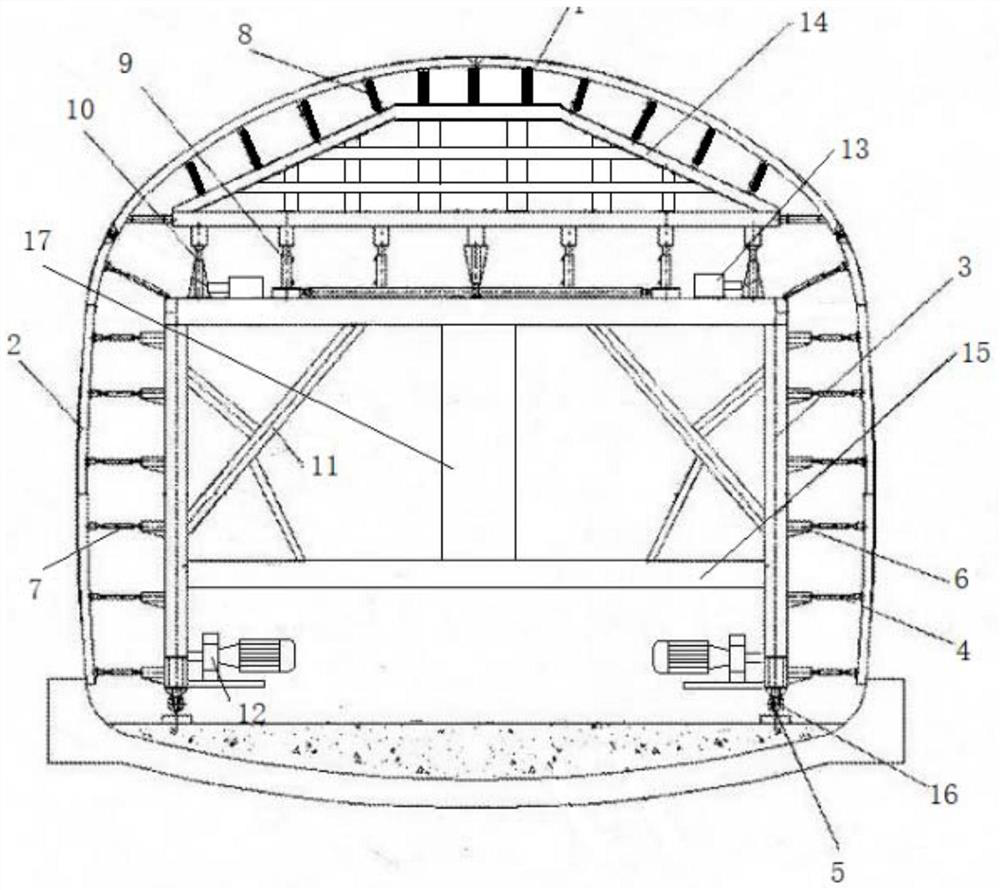

Arc rolling machine

PendingCN112139313AGuaranteed structural sizeAvoid actionVehicle componentsControl systemControl engineering

The invention provides an arc rolling machine. The arc rolling machine comprises a support, a workbench is arranged on the support, a power roller is rotationally installed on the workbench, and the axis of the power roller is perpendicular to the workbench; a power mechanism is in transmission connection with the power roller; an extrusion roller opposite to the power roller is arranged on the workbench, a machining channel allowing a workpiece to penetrate through is formed between the extrusion roller and the power roller, a position adjusting mechanism is fixedly arranged on the support, and the output end of the position adjusting mechanism is in transmission connection with the extrusion roller or the power roller so as to drive one of the extrusion roller and the power roller to move towards or away from the other one; and a limiting switch is arranged on the workbench in a relatively-fixed mode, a limiting piece is fixedly arranged relative to the output end of the position adjusting mechanism, the limiting switch can be triggered by the limiting piece, the limiting switch is in signal connection with a control system, and the control system is controllably connected to theposition adjusting mechanism and controls the position adjusting mechanism to stop acting when receiving a signal that the limiting switch is triggered. Therefore, the position adjusting mechanism isprevented from continuing to act, and the size precision of a formed product is guaranteed.

Owner:HENAN SENYUAN HEAVY IND

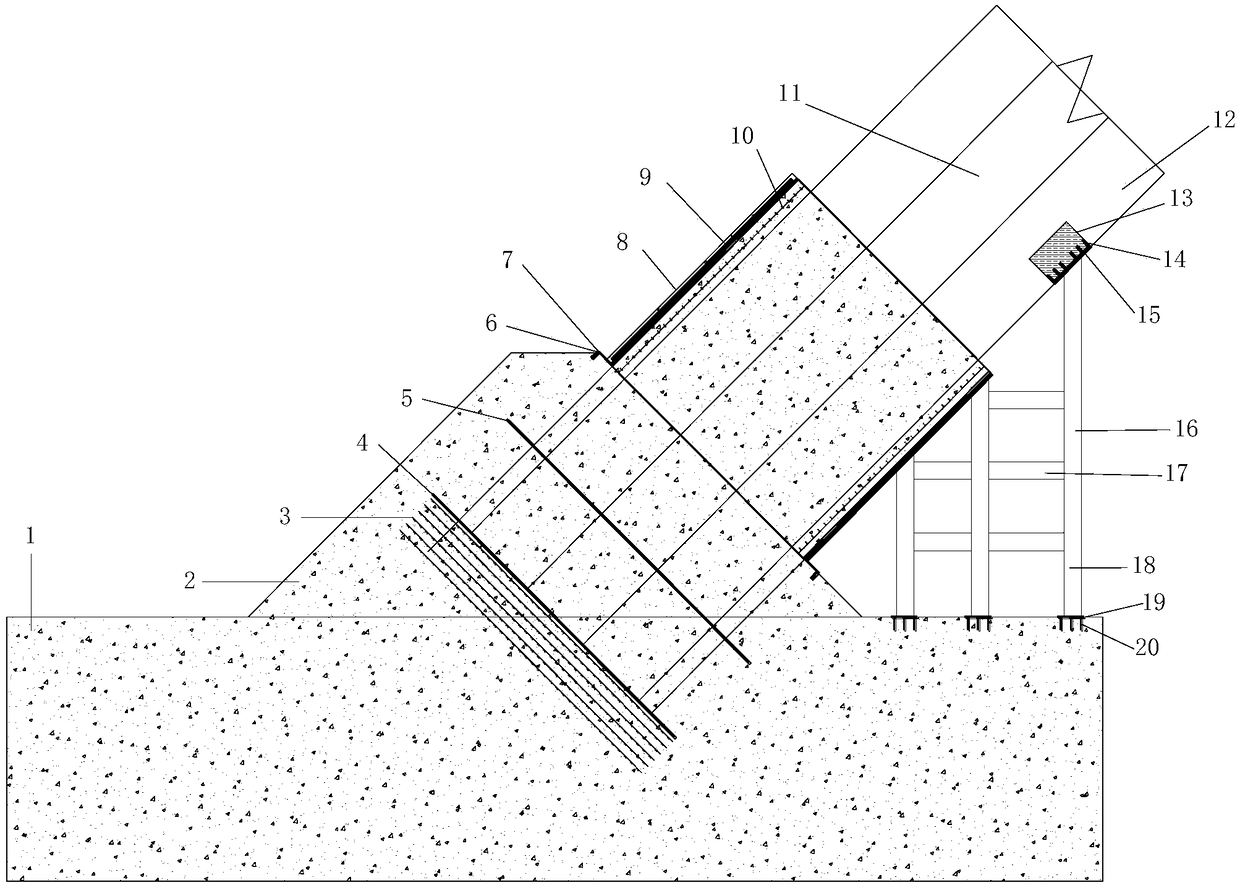

Steel tube concrete arch bridge body outer wrapped concrete arch springing structure and construction method

InactiveCN108611958AFast installation and constructionGuaranteed structural sizeBridge erection/assemblyArch-type bridgeHigh strength concreteSheet steel

The invention discloses a steel tube concrete arch bridge body outer wrapped concrete arch springing structure including a bearing platform, a support base, a pressure bearing rebar net, a skewback pressure bearing steel plate, an anti-shearing steel plate, a sleeve barrel with wires, an L-shaped limiting plate, a comb-shaped integral fixed bolt, an anti-cracking rebar net, a middle batten plate,a steel tube arch rib, an arc guard board, a weight bearing steel plate, an integral type fixed support, a pre-buried steel plate, self-compaction high-strength concrete, a skewback shearing force nail, a hinged open-and-close type steel mould and a shearing force nail welding locating frame; the bearing platform is connected with the support base, and a connection part of the bearing platform andthe steel tube arch rib is provided with the pressure bearing rebar net and the skewback pressure bearing steel plate to be enhanced; the connection part of the support base and the steel tube arch rib is provided with the anti-shearing steel plate to be enhanced; and the steel tube arch rib is provided with an anti-cracking rebar net to be enhanced and the outer portion of the steel tube arch rib is provided with the hinged open-and-close type steel mould. The steel tube concrete arch bridge body outer wrapped concrete arch springing structure and a construction method have the beneficial effects that the attaching and fixing canalization quick releasing hinged open-and-close type steel mould is arranged, the mounting and constructing speed of an arch springing template is improved, thesize of the structure is effectively guaranteed.

Owner:中国路桥集团西安实业发展有限公司

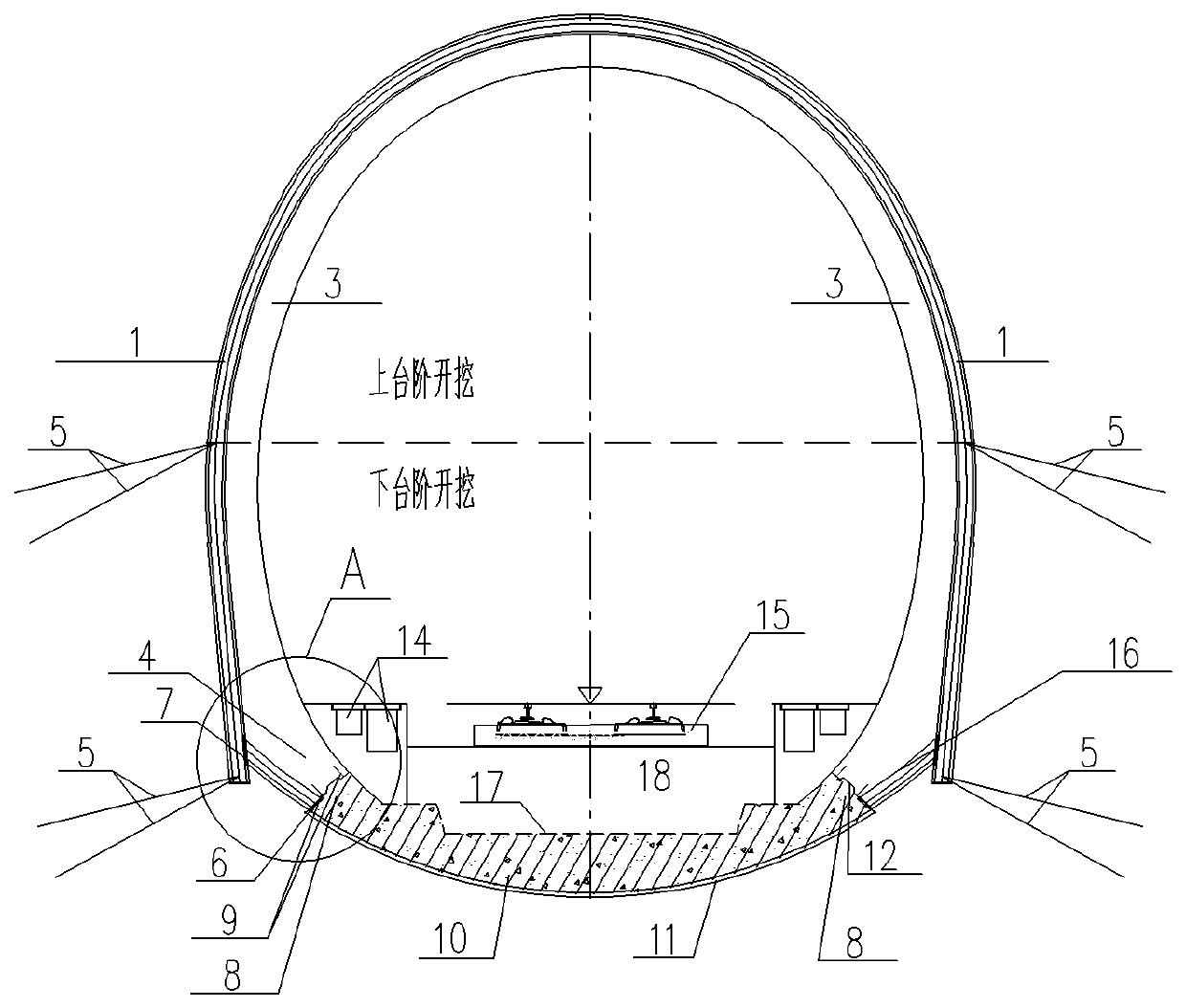

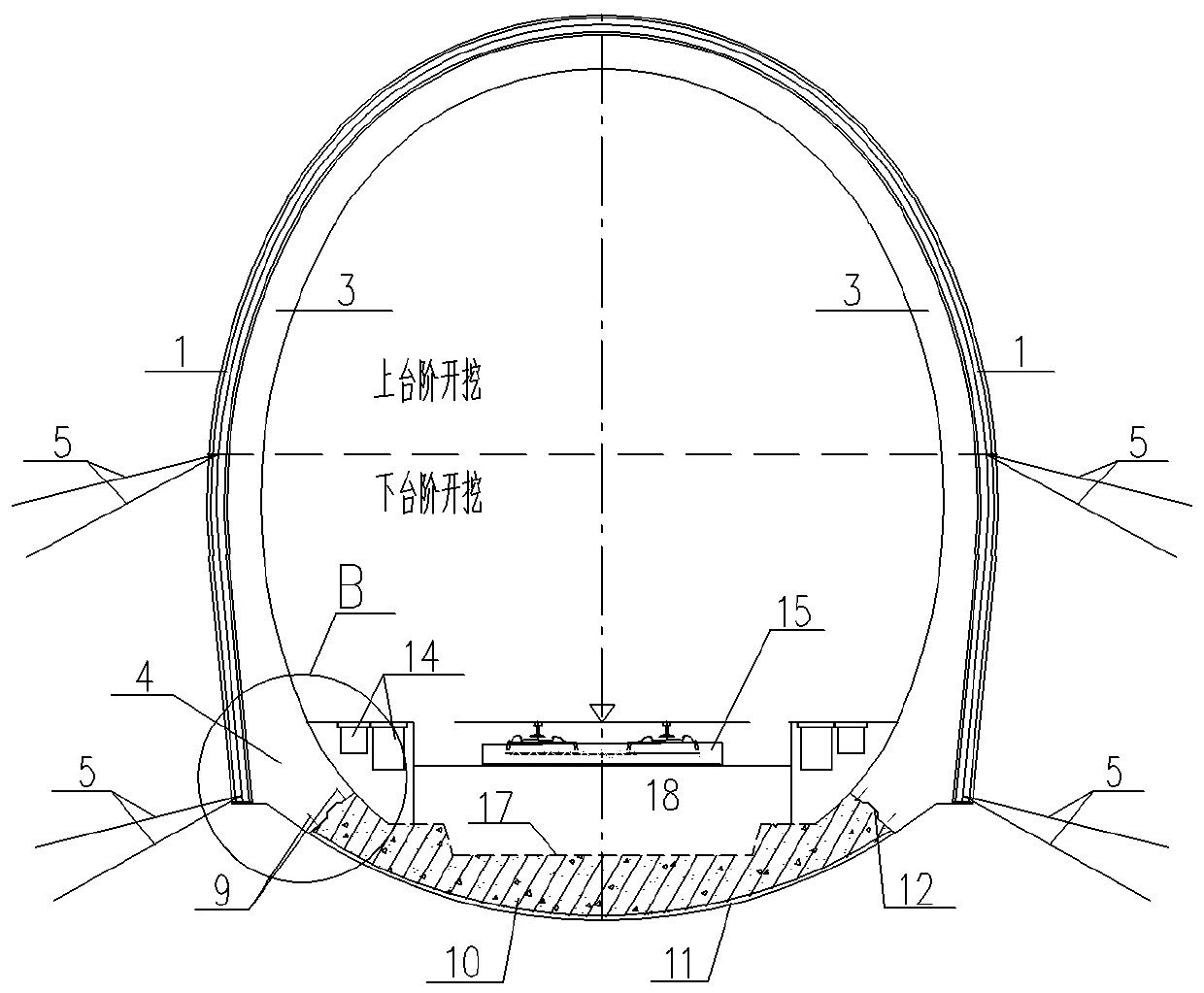

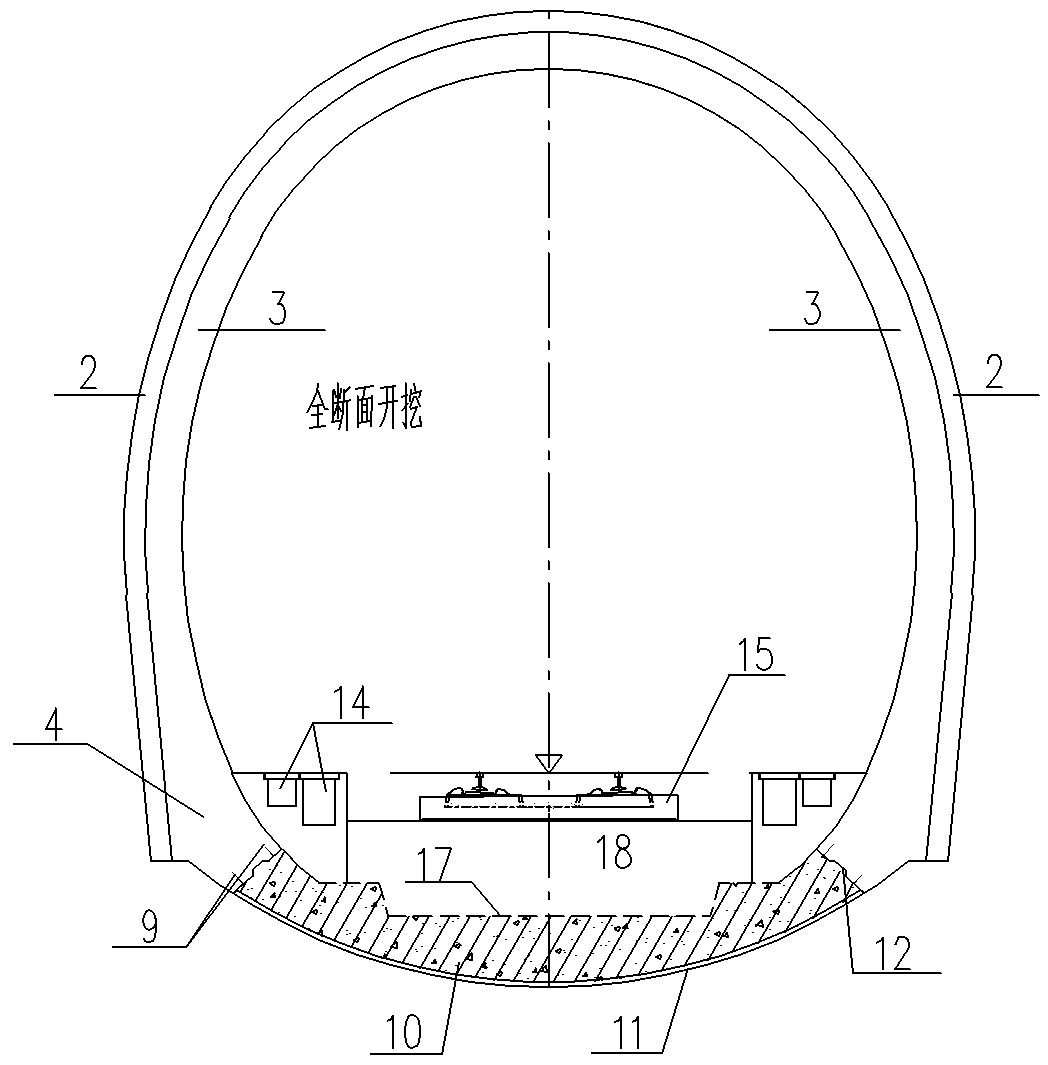

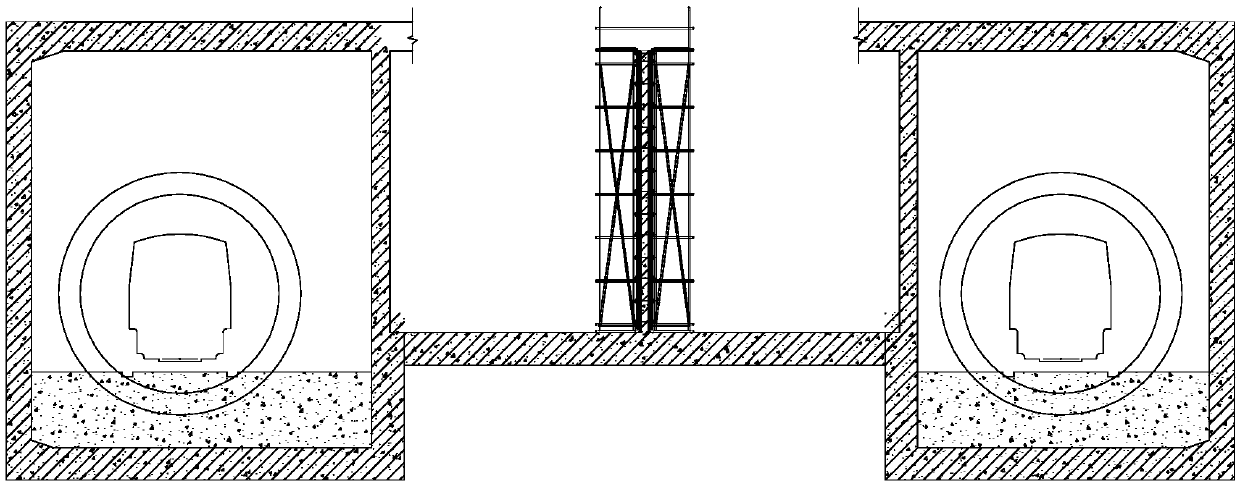

Drilling and blasting tunnel structure adopting prefabricated inverted arch

PendingCN109667587AQuality improvementHigh strengthUnderground chambersTunnel liningButt jointUltimate tensile strength

The invention relates to a drilling and blasting tunnel structure adopting a prefabricated inverted arch. An arch part is an initial support of a tunnel; a secondary lining of a cast-in-place arch wall is arranged in the initial support of the tunnel; the lower end of the secondary lining of the cast-in-place arch wall and a fabricated inverted arch prefabricated block at the bottom are connectedinto a ring through a cast-in-place inverted arch lining; the end parts of both sides of the fabricated inverted arch prefabricated block are provided with fabricated inverted arch block two-side expansion ends; and the end faces are provided with tenons which are in butt joint with blind mortises on the end faces of the cast-in-place inverted arch lining. The drilling and blasting tunnel structure meets the requirements for the basic structural form of the tunnel fabricated inverted arch, and the inverted arch structure is prefabricated in factory-like and standardization modes, so that the reliable quality is ensured, and the quality, strength and other properties of a prefabricated component are much better than those of a cast-in-place structure.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

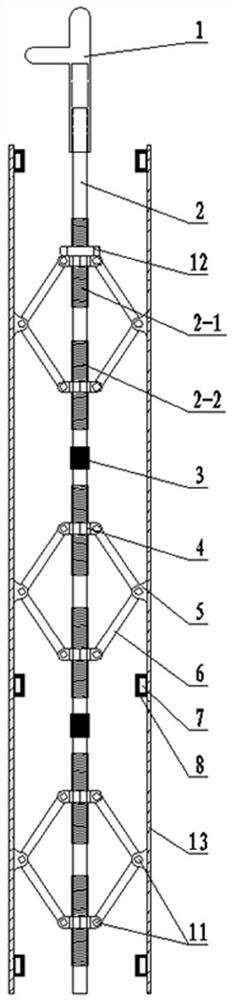

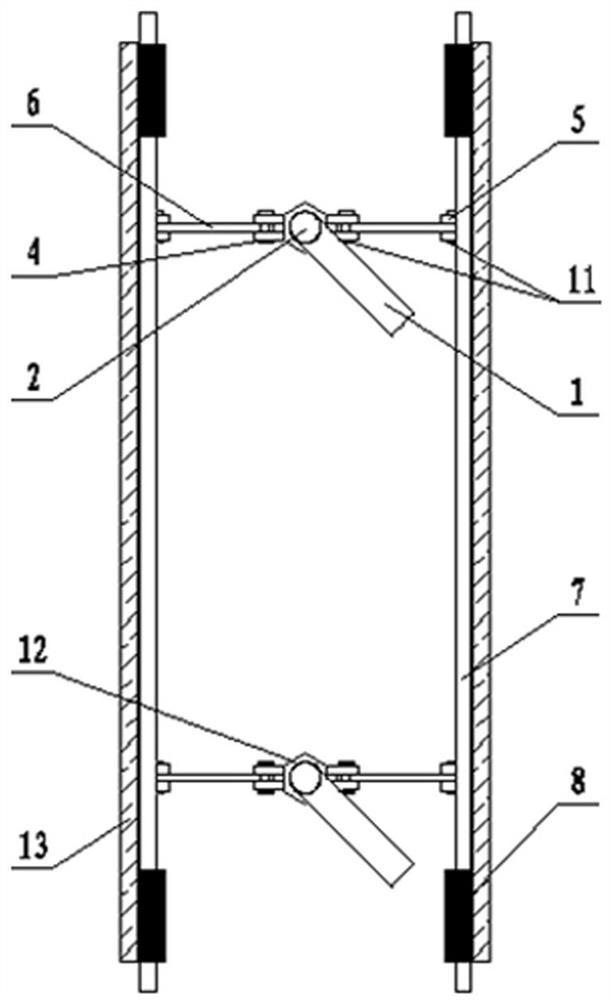

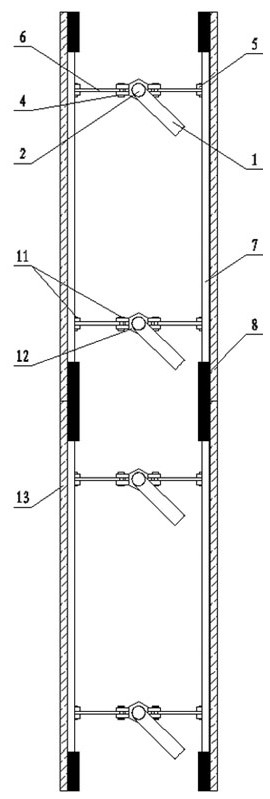

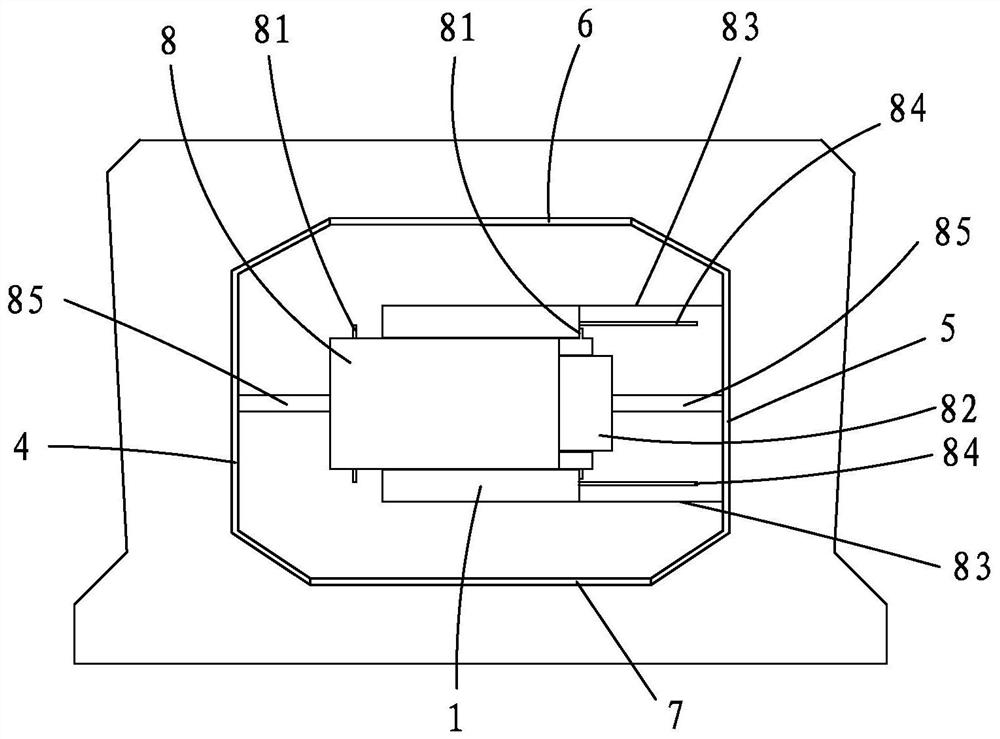

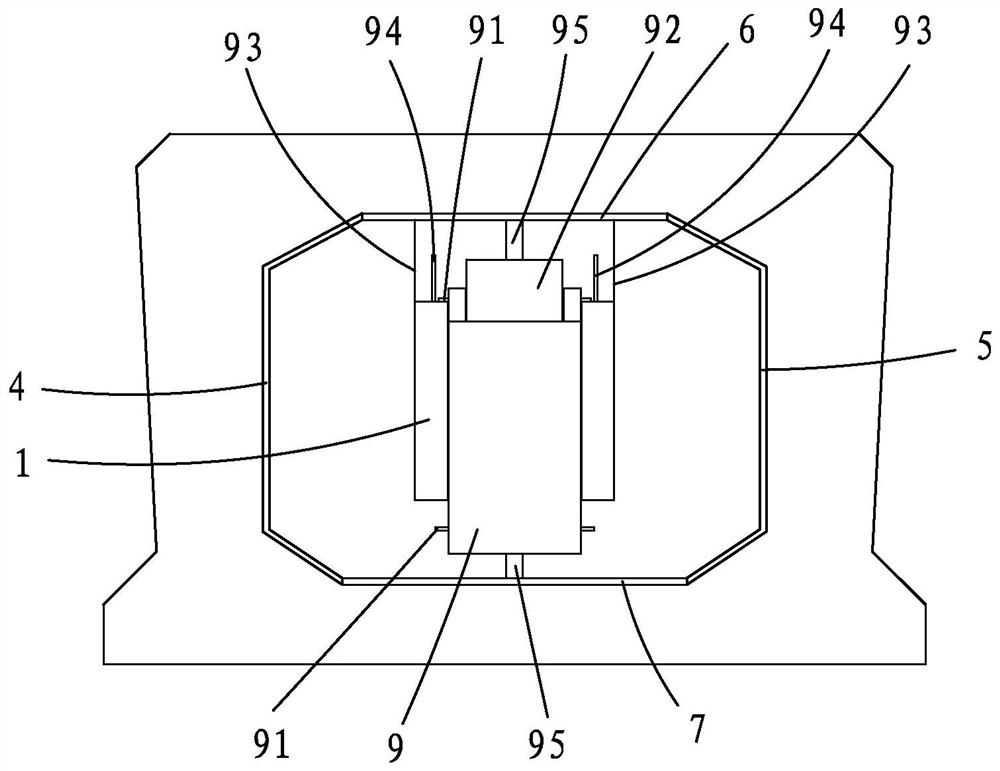

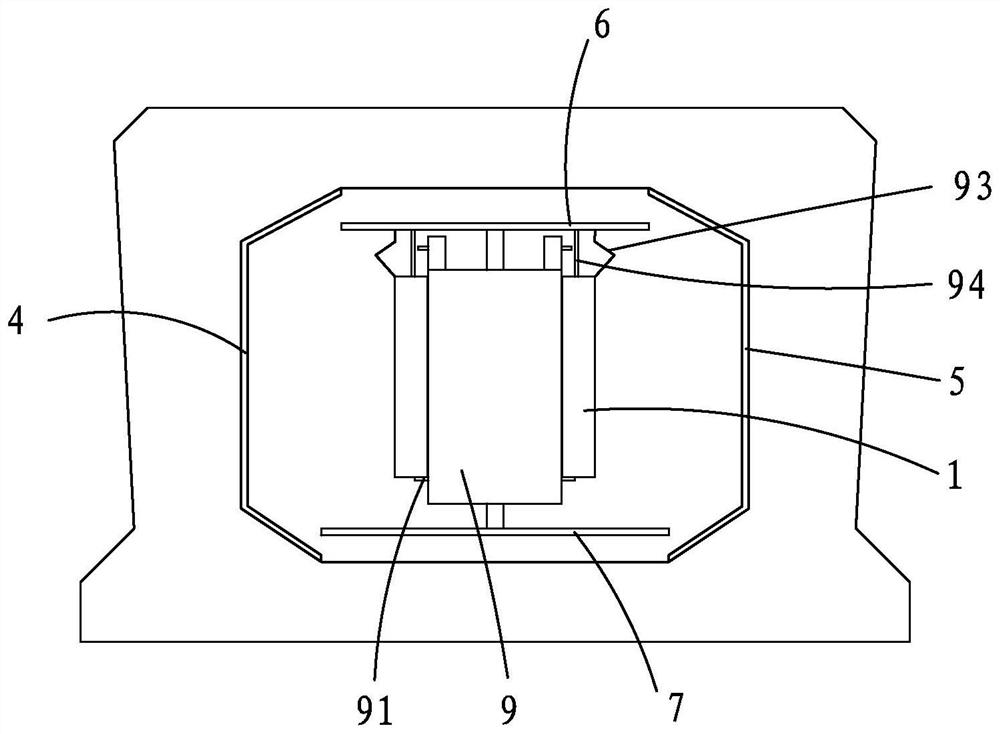

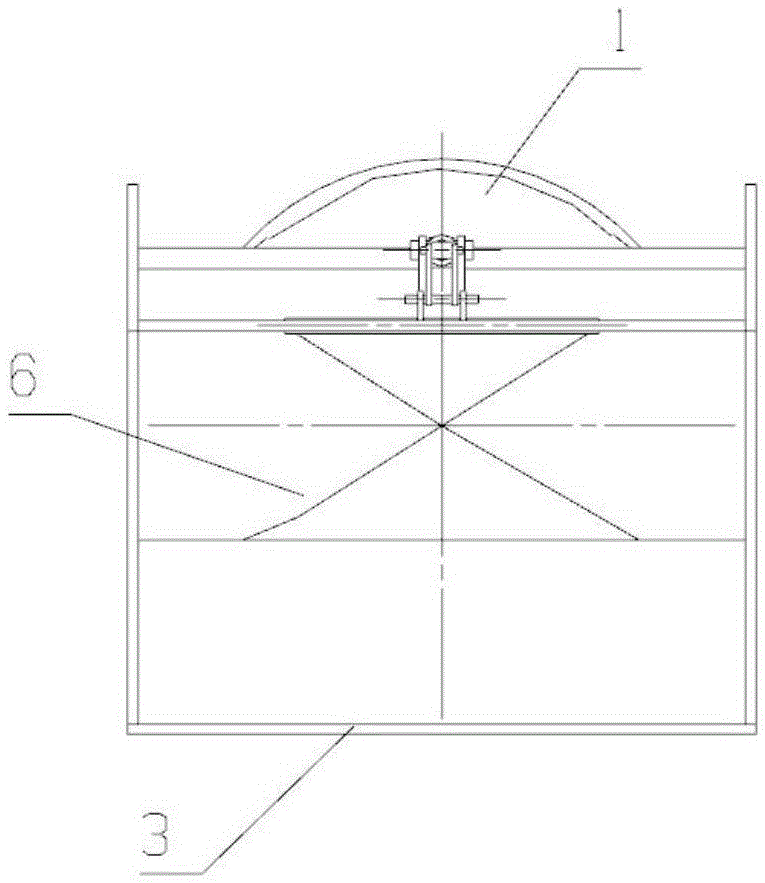

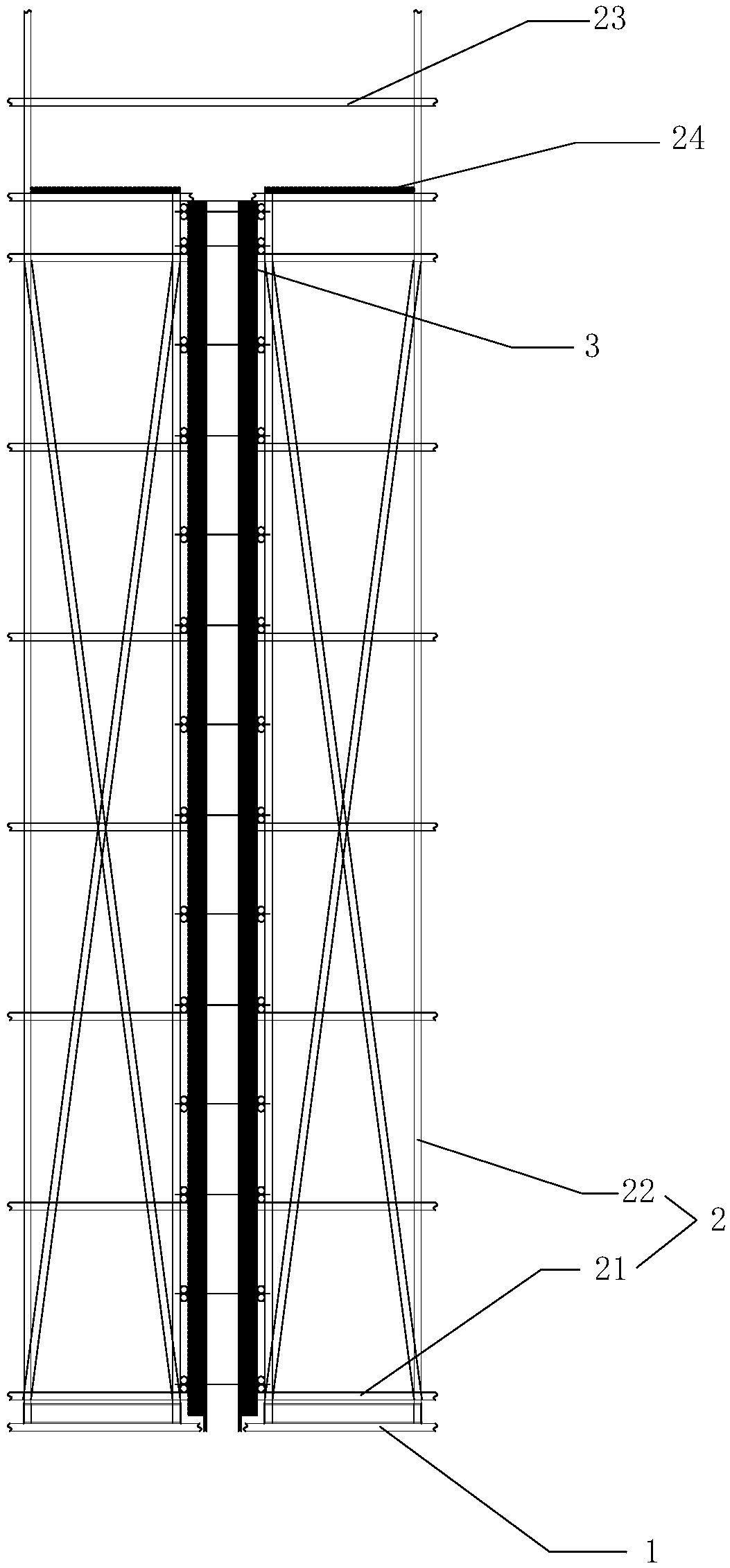

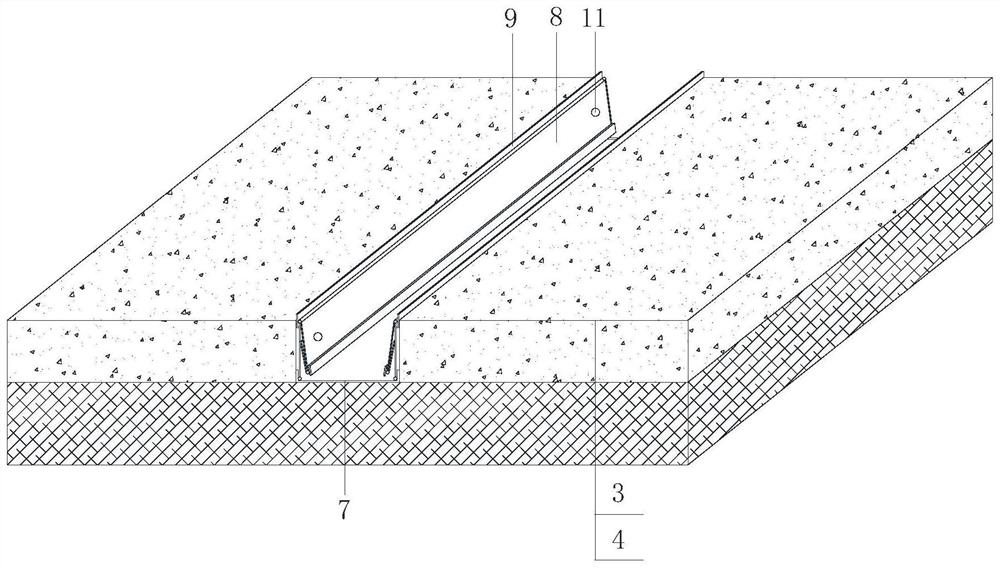

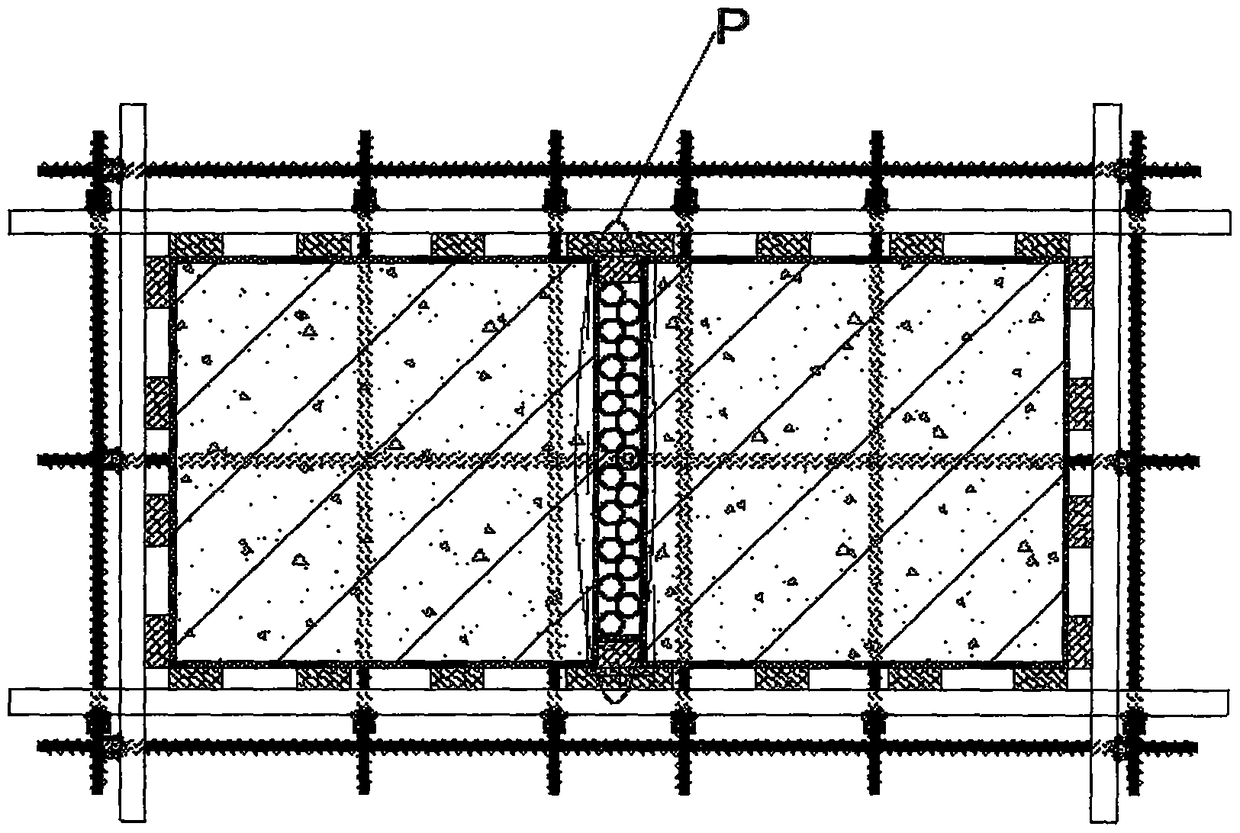

Adjustable formwork system for small-size deformation joint construction

PendingCN112412005AReduce spacingSolve the installationForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringScrew thread

The invention discloses a small-size deformation joint construction adjustable formwork system which is characterized in that forward thread sections and reverse thread sections are arranged on screwsat intervals in the axial direction, connecting sleeves are fixed to the vertically adjacent screws, and handles are arranged at the tops of the screws at the top ends. The nuts are respectively arranged on the forward thread section and the reverse thread section of the same screw and internally provided with corresponding threaded holes, the steel formworks are parallelly arranged on two sidesof the screw respectively, the lug plates are fixed on the steel formworks at intervals along the axial direction of the screw, and the nuts are hinged with one ends of the two pull plates on two sides corresponding to the steel formworks respectively. The other ends of the two pull plates hinged with the screw on the adjacent forward-rotating or reverse-rotating thread section of the screw rod are respectively hinged with the lug plates. The forward and reverse thread sections are arranged on the screw rods, so that the nuts, the lug plates and the pull plates form an openable shear type structure, the distance between the steel formworks can be conveniently adjusted, the problem that the formworks are difficult to mount and dismount in small-size deformation joint construction is solved,and the device has the advantages of being convenient to mount and dismount, flexible in adjustment, high in supporting strength and capable of being repeatedly used.

Owner:CCFED THE FIGTH CONSTR & ENG

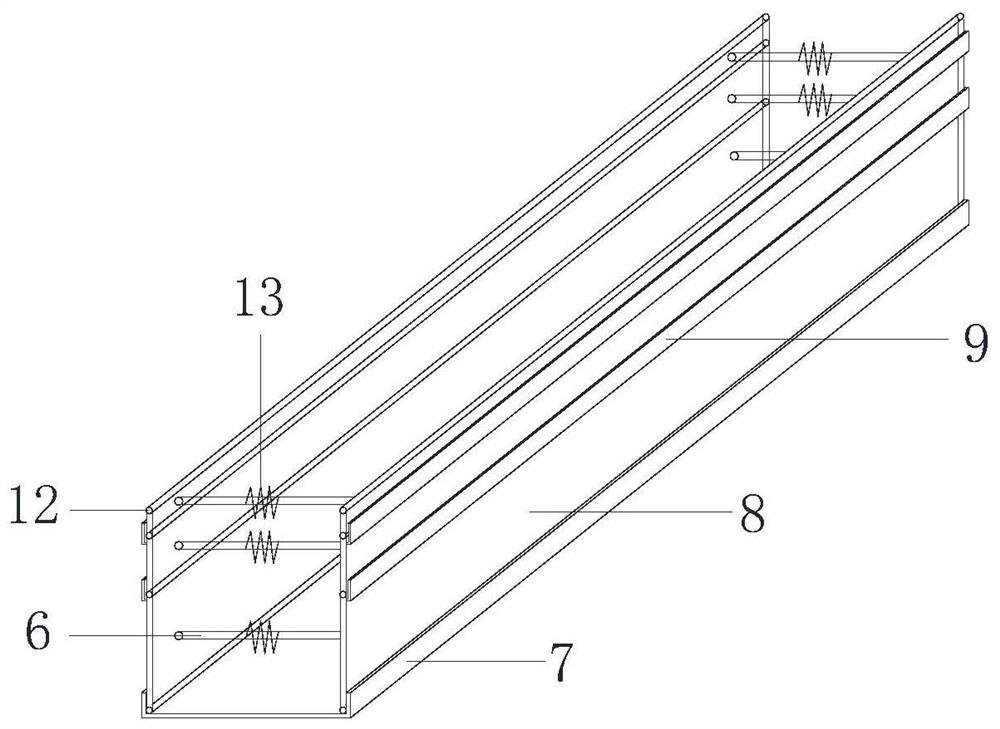

Mechanical demolding device for steel core mold of prefabricated hollow slab beam

PendingCN113681701ASurface integrityStrict and rigorous construction stepsDischarging arrangementMould auxillary partsHollow coreSheet steel

The invention provides a mechanical demolding device for a steel core mold of a prefabricated hollow slab beam, and relates to the technical field of highway engineering. The mechanical demolding device comprises a support frame, a first base, a first expansion device, a first limiting rope and a first limiting rod, wherein the first base is connected with the support frame in a sliding manner and is also fixedly connected with a sheet steel form; the first expansion device is provided with a first shell and a first movable rod, the first shell is fixedly connected with the first base, and the first movable rod is fixedly connected with another sheet steel form; the two ends of the first limiting rope are fixedly connected with another sheet steel form and the support frame respectively; and the first limiting rod is fixedly connected with the support frame and can abut against another sheet steel form. The mechanical demolding device has the advantages that the support frame is placed at the hollow position of the prefabricated hollow slab beam, the sheet steel forms are automatically installed and demolded through the expansion devices, the support frame is directly drawn after demolding, each expansion device correspondingly controls the movement of the two sheet steel forms, and the sheet steel forms are conveniently installed and dismantled.

Owner:福建建工基础设施建设集团有限公司 +1

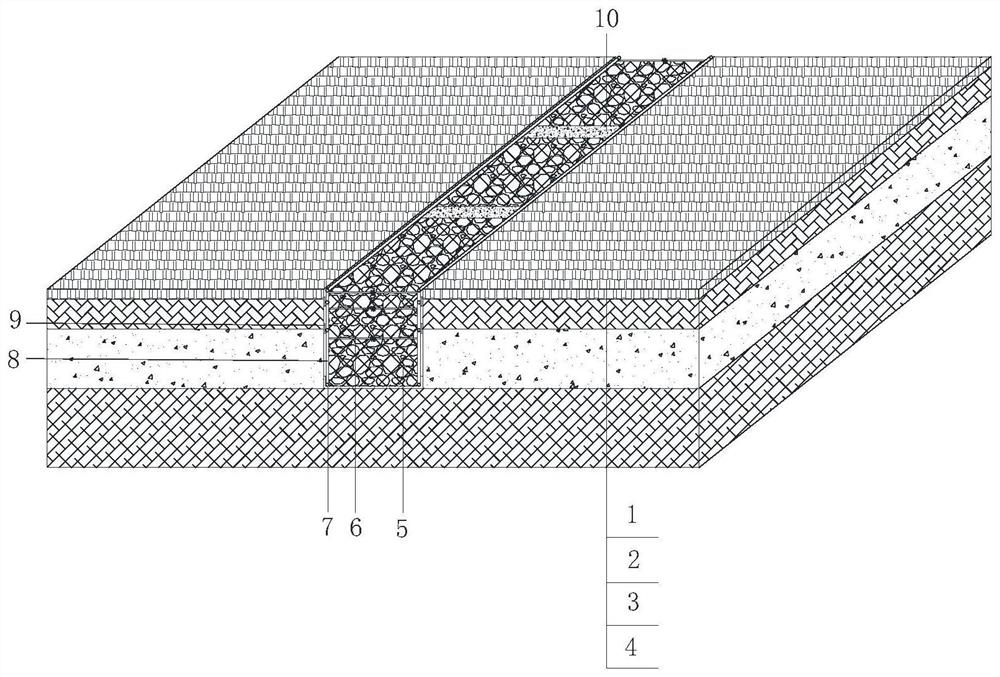

Cast-in-place kerbstone for reserved replacement of asphalt concrete pavement and construction method

ActiveCN108625249AImproving the construction quality of filling and rollingGuaranteed structural sizePaving gutters/kerbsRoads maintainenceCrushed stoneRoad surface

The invention relates to cast-in-place kerbstone for reserved replacement of an asphalt concrete pavement. The cast-in-place kerbstone comprises a reserved groove mold, a gravel dense screen bag, a lightweight rib separating block, a cast-in-place slip form system, the cast-in-place kerbstone and the asphalt concrete pavement. A cement stabilized macadam foundation is arranged on a subbase course,wherein a kerbstone indwelled groove is excavated on the cement stabilized macadam foundation by a separator kerbstone mould; in addition, a indwelled groove mold is arranged in the kerbstone indwelled groove; the lightweight rib separating block and the gravel dense screen bag are arranged in the indwelled groove mold; the cement stabilized macadam foundation is sequentially provided with a coarse-grained asphalt concrete layer and a fine-grained asphalt concrete layer from bottom to top. According to the cast-in-place kerbstone for the reserved replacement of the asphalt concrete pavement,disclosed by the invention, by adopting slip-form construction for the kerbstone, the construction method has the advantages of high construction speed, less required labor and no prefabricated site;the paved kerbstone has high integral structural strength and smooth and beautiful linetype.

Owner:HANGZHOU JIANGRUN TECH LIMITED

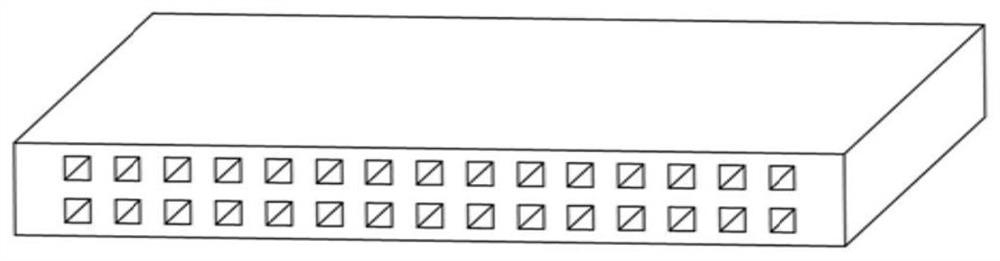

Micro-channel pipe forming die and method

ActiveCN114345971AGuaranteed structural sizeReduce stressExtrusion diesGlass productionEngineeringMechanical engineering

The invention provides a micro-channel pipe forming die and method, and relates to the field of die forming, the micro-channel pipe forming die comprises a die main body, the die main body is provided with a feeding channel, a welding chamber and a forming channel which are communicated in sequence, multiple stages of shunting channels which are communicated in sequence are formed in the feeding channel, and a die core neck is arranged in the welding chamber; one end of the mold core neck is connected with a mold core composed of a series of sub-mold cores distributed in an array mode, the mold core stretches into the forming channel, an inner wall channel communicated with gaps of the sub-mold cores and the flow dividing channel is formed in the mold core neck, and an outer wall channel communicated with the flow dividing channel and the forming channel is formed between the mold core neck and the welding chamber; aiming at the problem that the quality requirement is difficult to meet when the micro-channel pipe is extruded and formed through a die at present, a multi-stage shunting channel is adopted to promote blank flowing so as to reduce the die stress, and meanwhile, flow guide channels are correspondingly arranged on the outer wall and the inner wall of the micro-channel pipe so as to promote the flowing uniformity of a deformation material and reduce the distortion of a profile; and the structural size of the formed micro-channel pipe is ensured to meet the precision requirement.

Owner:SHANDONG UNIV

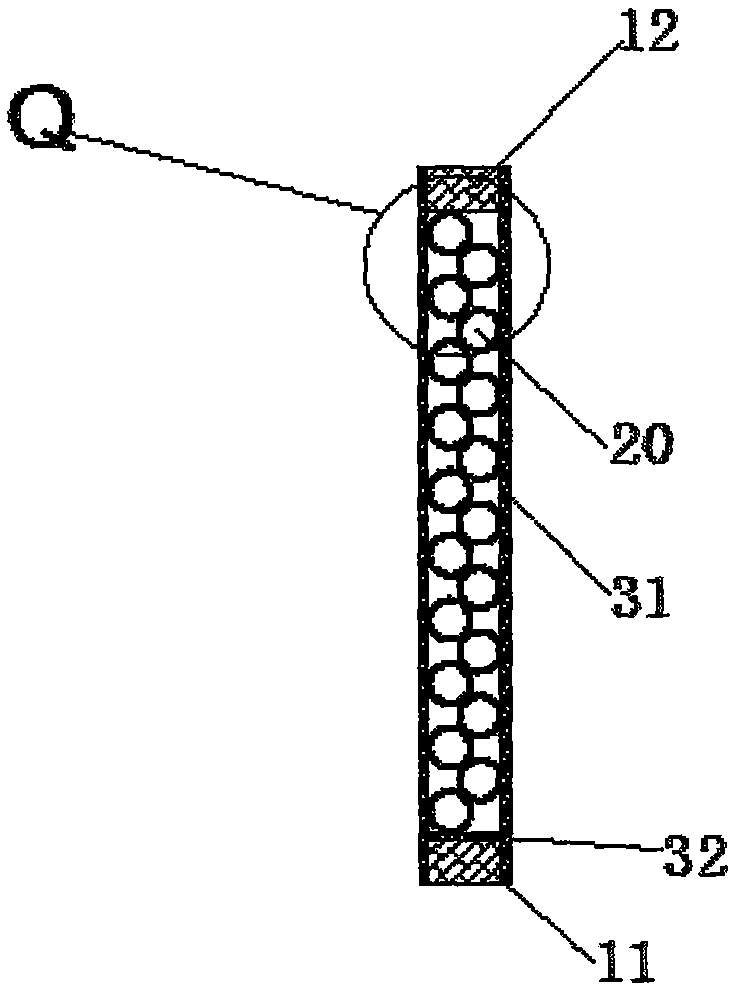

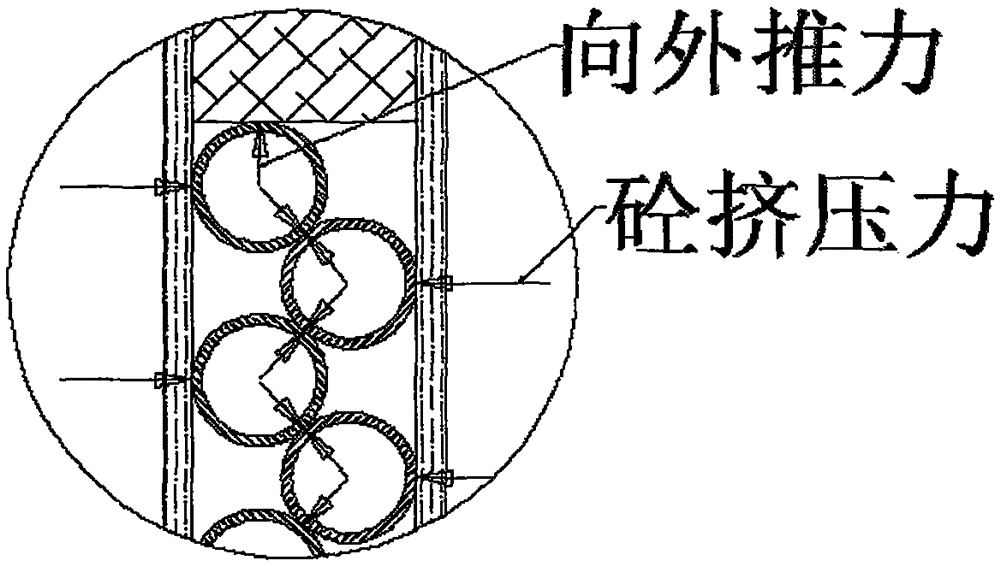

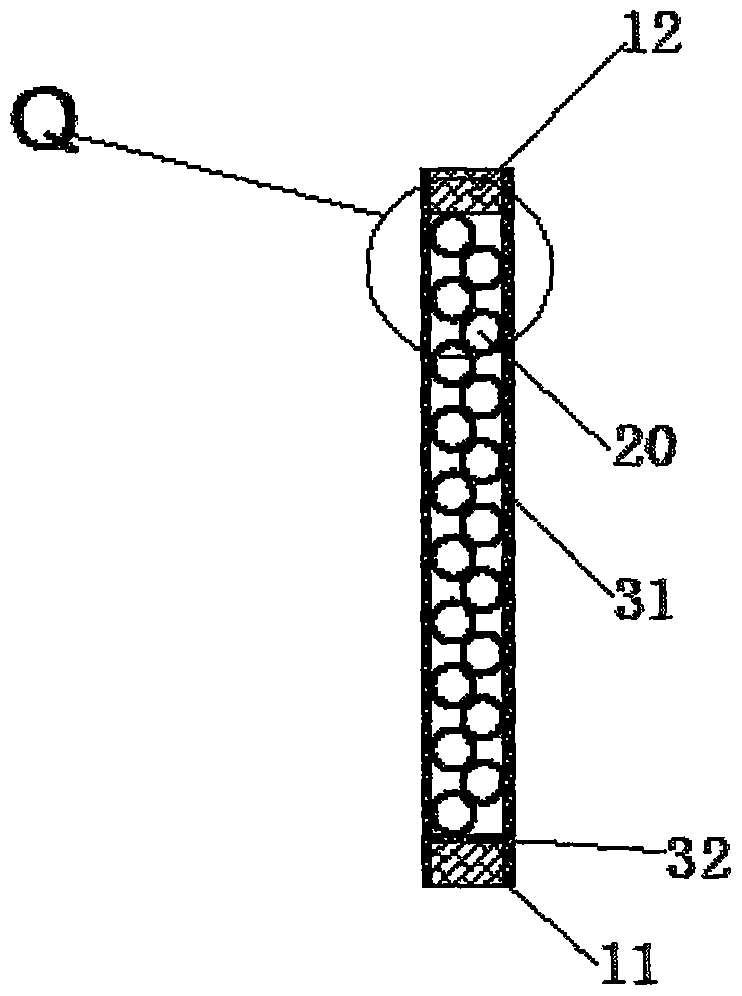

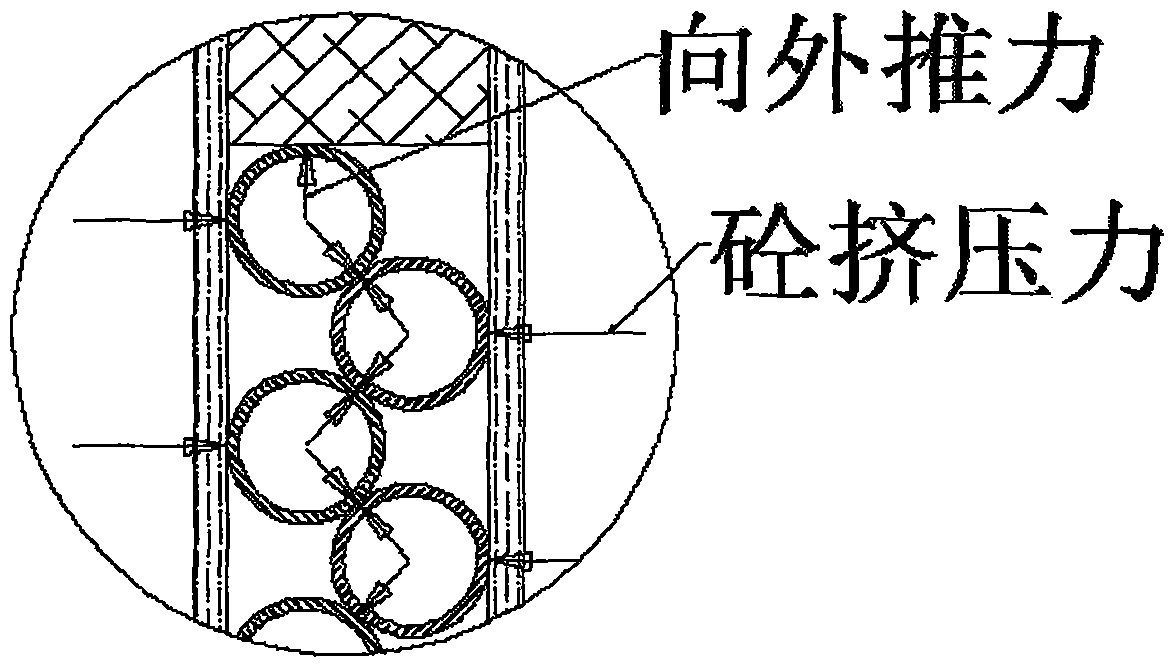

Easy-to-dismantle deformation joint form erecting method

ActiveCN106481075AEasy to removeGuaranteed structural sizeForms/shuttering/falseworksEngineeringStructural dimension

The invention relates to an easy-to-dismantle deformation joint form erecting method which comprises the following steps: (1) mounting first wood glue plates which are 1 to 12mm thick on the two sides of a deformation joint respectively; (2) laying a first batten which is 50mm thick at the bottom of the deformation joint; (3) sequentially placing scaffold tubes in the deformation joint until the distance between the scaffold tubes and the upper surface is smaller than 100mm; (4) arranging a second batten above the scaffold tubes. The easy-to-dismantle deformation joint form erecting method has the beneficial effects that (1) easiness for dismantling is achieved; (2) such a combination is stiff enough, and the structural dimensions on the two sides of the deformation joints can be ensured; (3) the adopted materials are common for construction, and can be recycled; (4) the two sides of the deformation joints are simultaneously constructed, so that the construction speed is increased.

Owner:NORTH CHINA METALLURGICAL CONSTR ENG CONSTR +1

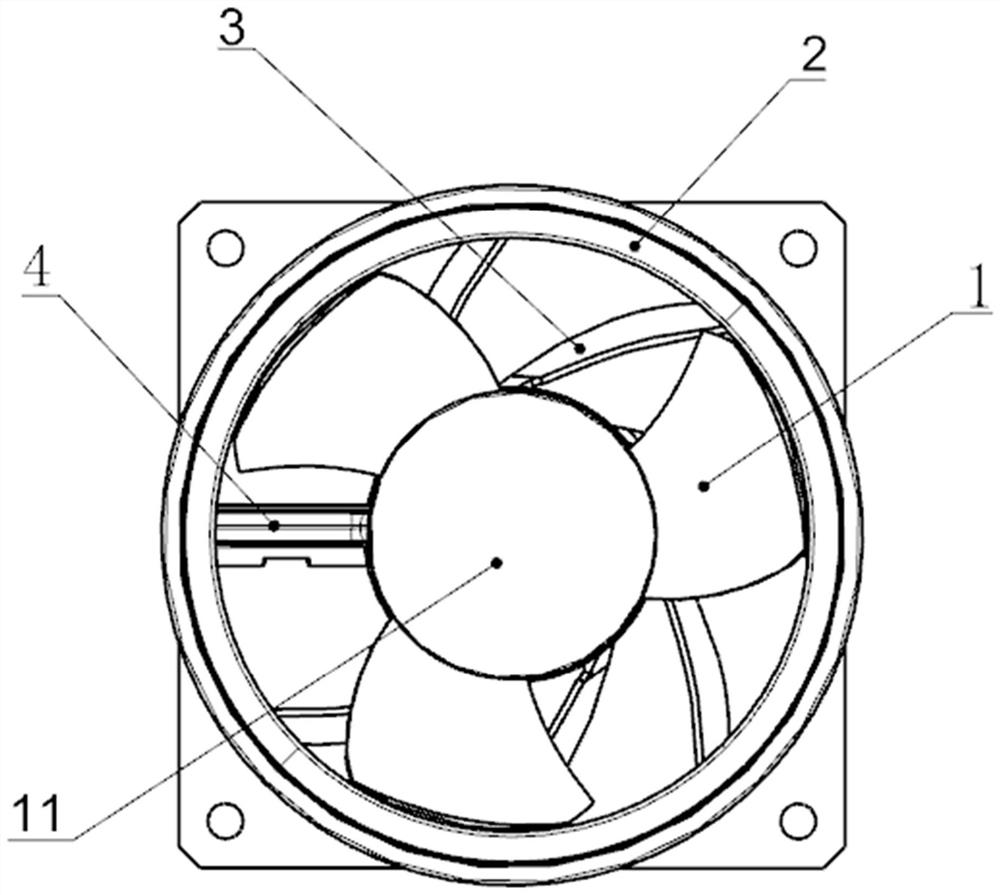

Air-cooled heat-dissipation axial flow cooling fan for electronic equipment

InactiveCN112128124AReduce the pressure gradientImprove aerodynamic performancePump componentsPump installationsImpellerAir volume

The invention discloses an air-cooled heat-dissipation axial flow cooling fan for electronic equipment, and aims to provide an axial flow fan which is high in efficiency, low in vibration, large in air volume, high in back pressure and low in noise. According to the technical scheme, a machine shell is a double-funnel-shaped inclination angle air duct machine shell in which a backward air draft air duct is wide in the front end, narrow in the middle and wide in the rear portion, an inclination angle inner wall is formed, and all middle sections change according to a linear rule; blades are offront bending edge types; axial flow sweeping type blades are formed by suction curved surfaces with upper inclination angles of at least -14 degrees and pressure curved surfaces with lower inclination angles of at least -11 degrees; spiral radian flow guide stationary blades matched with the air flow direction of the fan and the air duct convert kinetic energy generated by winding back airflow ofan impeller into pressure; the inclination angle inner wall of the machine shell prevents blade tops of the fan blades from leaking; and the pressure of the inner wall of the machine shell is cut toform forced air flow with the axial flow sweeping type blades, so that separation of boundary layers of the fan blades is prevented, and the air flow is sent out.

Owner:10TH RES INST OF CETC

Reinforcing device for tenon-mortise structures of cylindrical template and use method thereof

PendingCN109944438AEasy to installImprove work efficiencyForms/shuttering/falseworksReinforced concrete columnMortise and tenon

The invention relates to a reinforcing device for tenon-mortise structures of a cylindrical template and a use method thereof, and belongs to the field of construction devices and methods of reinforced concrete columns. The reinforcing device for the tenon-mortise structures of the cylindrical template is characterized by including main back bars, the main back bars made from wood are arranged onthe peripheral surface of the template from bottom to top, main back bars are segmented ring bodies connected in a mortise and tenon joint mode, each main back bar include back bar sections, each backbar section includes a back bar body, a mortise and a tenon, the mortises are formed in the right side faces of the back bar bodies, the tenons are arranged on the left side faces of the back bar bodies, and transition fit between the mortises and the tenons is achieved. The use method of the reinforcing device is characterized in that the annular main back bars are used for making the inner surfaces of the main back bars tightly attached to the template, and the template is reinforced by occlusion force of the tenon-mortise structures of the back bar sections. The use method includes the following steps of 1, preparation work, 2, preparation of the main back bars and 3, field installation. The device is safe and reliable to use, and the construction efficiency and the construction quality are improved.

Owner:CHINA MCC17 GRP

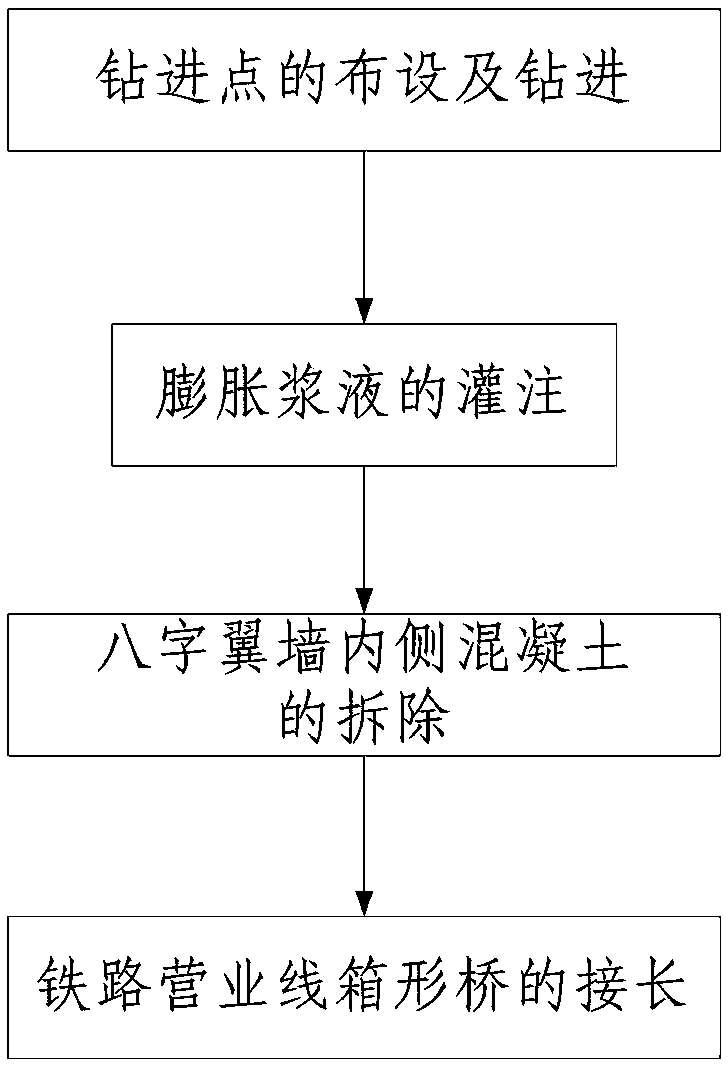

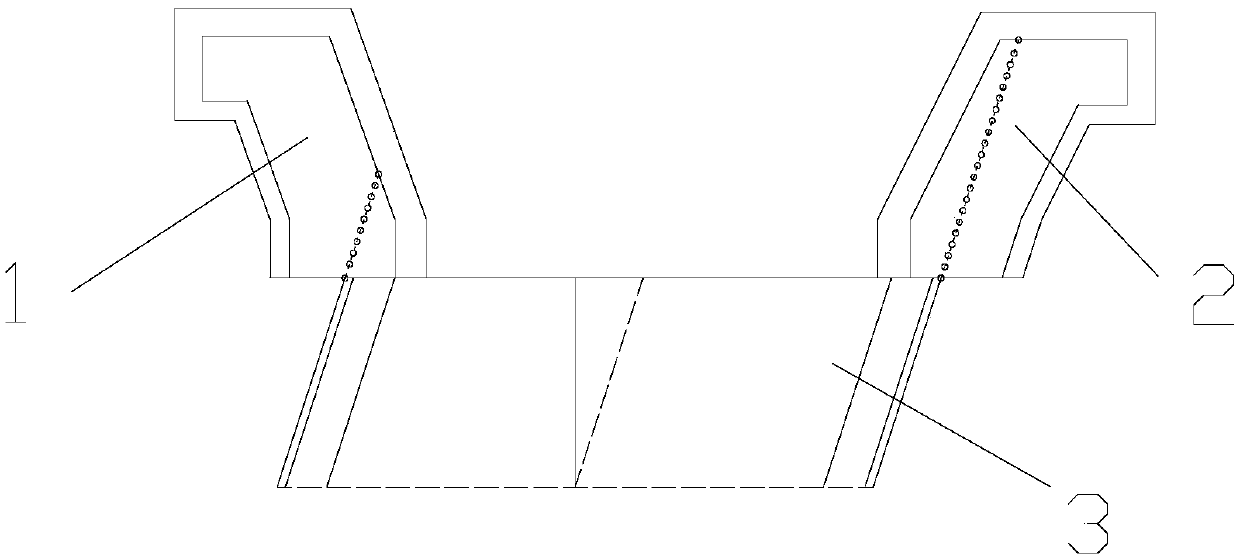

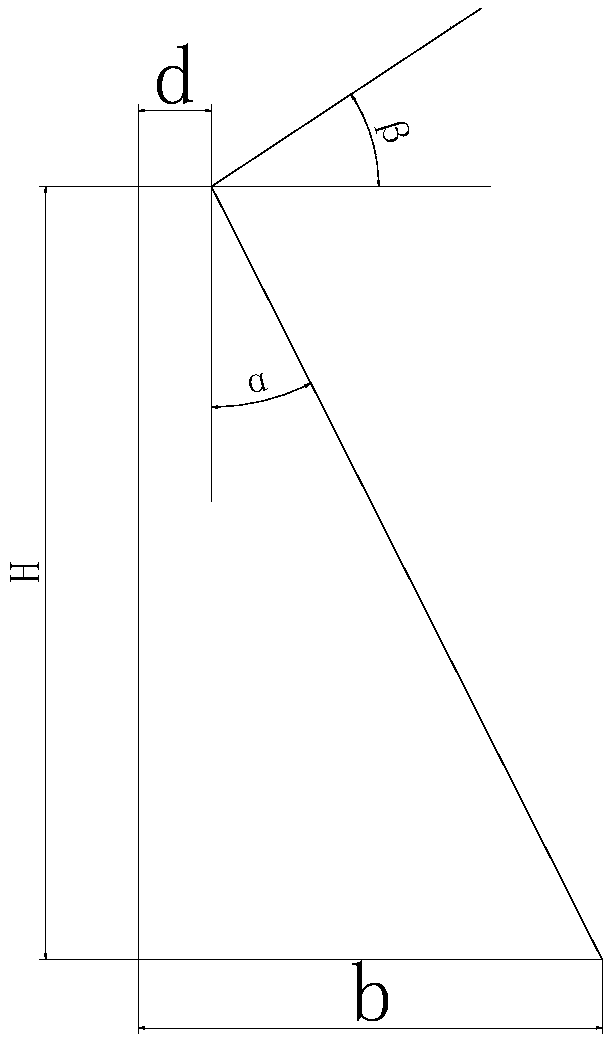

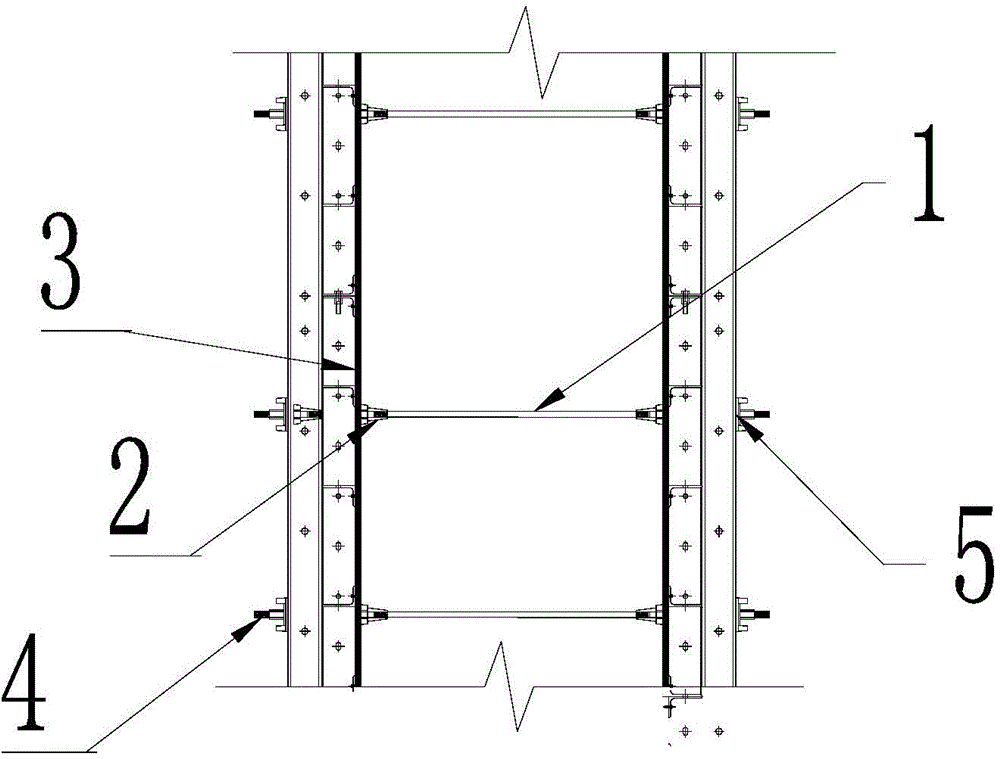

Railroad business line box bridge extension construction method

InactiveCN109537474AThe method steps are simpleEasy to implementRoadwaysBridge erection/assemblySlurryEngineering

The invention discloses a railroad business line box bridge extension construction method. The railroad business line box bridge extension construction method comprises the steps of 1, arrangement ofdrilling points and drilling; 2, expansion slurry injection; 3, removal of concrete on the inner side of a flare wing wall; 4, extension of a railroad business line box bridge. In the method, part ofthe flare wing wall of the box bridge is removed, the remaining part of the flare wing wall has a supporting effect on a roadbed behind the flare wing wall, the basic concrete structure of the flare wing wall can serve as the basis of a box bridge body which is about to be extended later, the construction period is short, the construction quality is ensured, the problem about the safety and protection of a business line is solved, the protection engineering quantity is greatly reduced, and the protection construction process is simplified.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Form board fastening device facilitating control on large-thickness concrete protecting layer

InactiveCN104631821AThe ills of improving qualityControl effective controlAuxillary members of forms/shuttering/falseworksEpoxyCircular disc

The invention relates to the technical field of civil engineering, in particular to a form board fastening device for facilitating control on a large-thickness concrete protecting layer. The form board fastening device for facilitating control on the large-thickness concrete protecting layer comprises an inner opposite-pull rod, an outer opposite-pull rod, a circular-truncated-cone-shaped nut and a disc-shaped nut, wherein the outer opposite-pull rod penetrates in a form board and is detachably connected with the inner opposite-pull rod through the circular-truncated-cone-shaped nut; and the length of the circular-truncated-cone-shaped nut is matched with the thickness of the concrete protecting layer so that thicknesses of different concrete protecting layers can be controlled effectively. When the form board is detached, the circular-truncated-cone-shaped nut is detached, a hole in the location of the circular-truncated-cone-shaped is chiseled and is filled with epoxy mortar, the inner opposite-pull rod does not need to be taken out, defects on the quality of concrete due to drawbacks of the traditional technology are greatly avoided, according to the structure with the inner opposite-pull rod, the outer opposite-pull rod and the circular-truncated-cone-shaped nut, the opposite-pull rods can be customized according to the thickness of thickness of a wall body, the mounting position of the form board can be limited well by the combination of the opposite-pull rods, and the structural size can be guaranteed.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

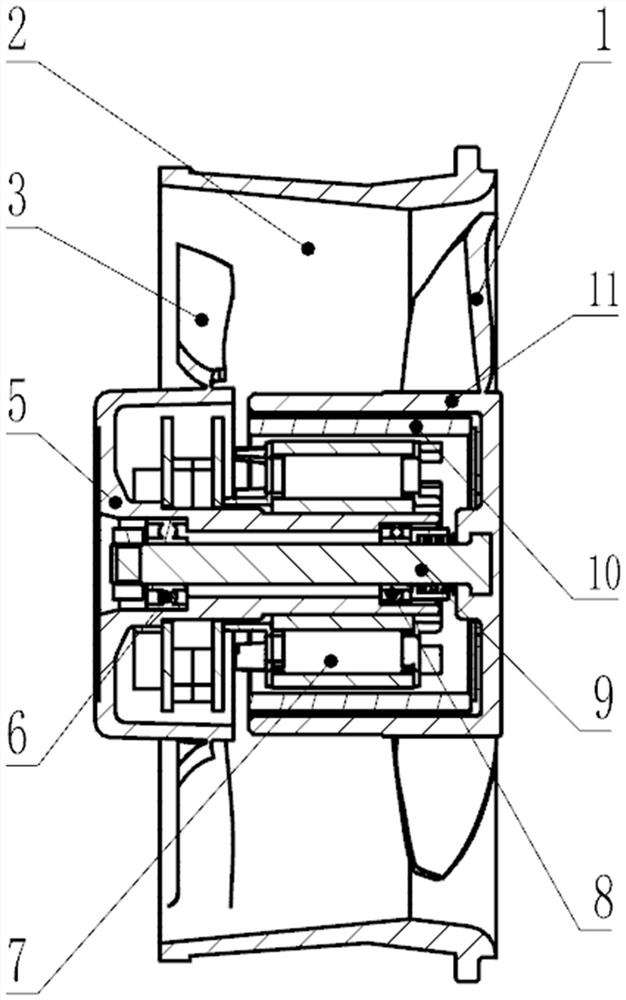

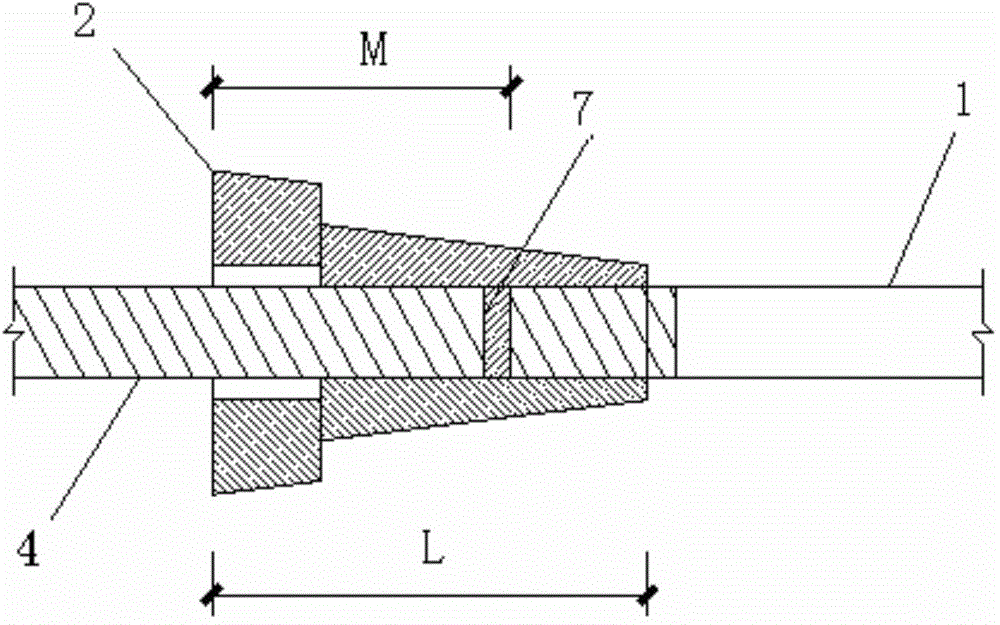

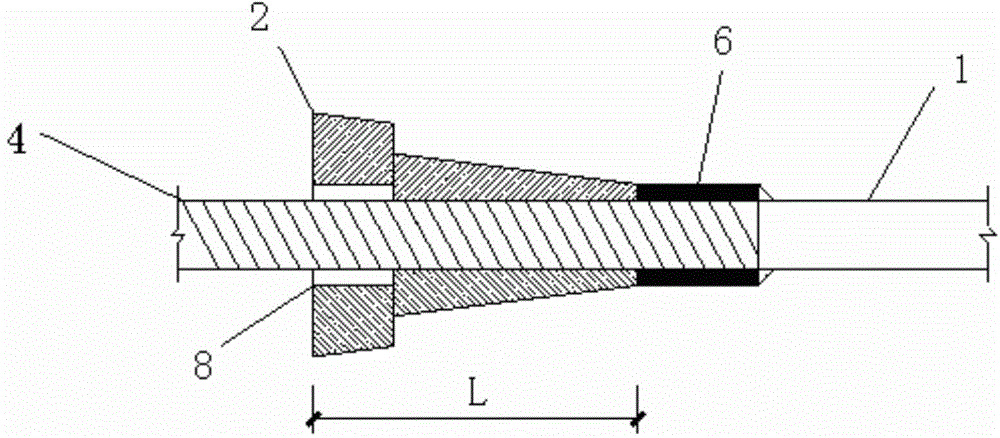

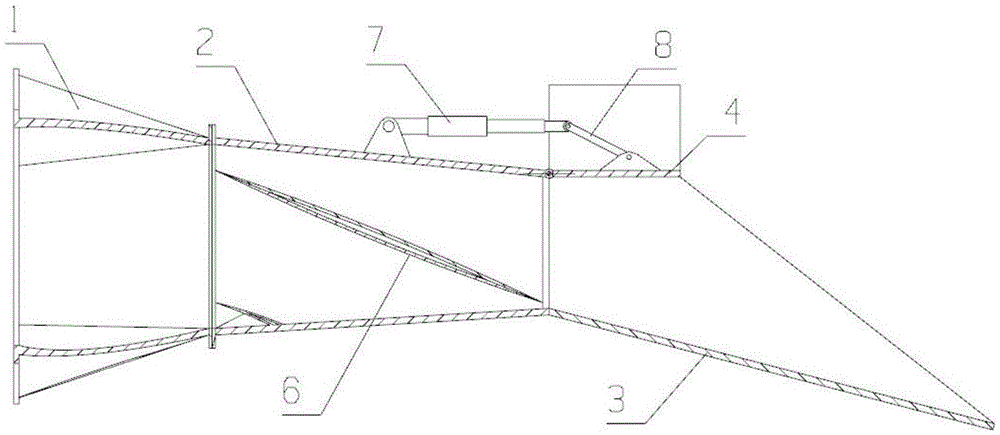

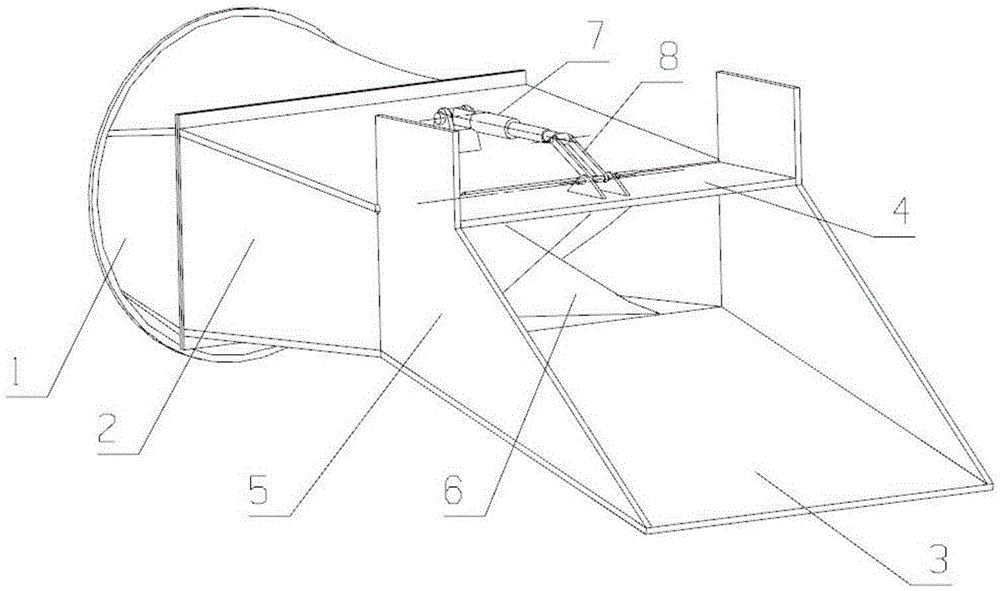

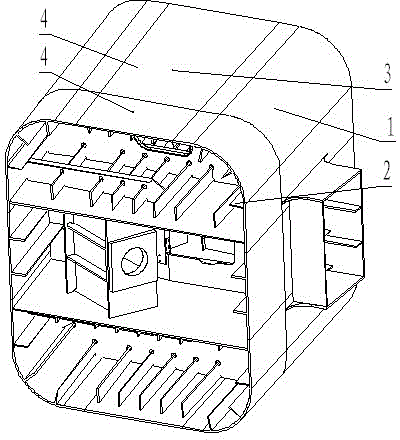

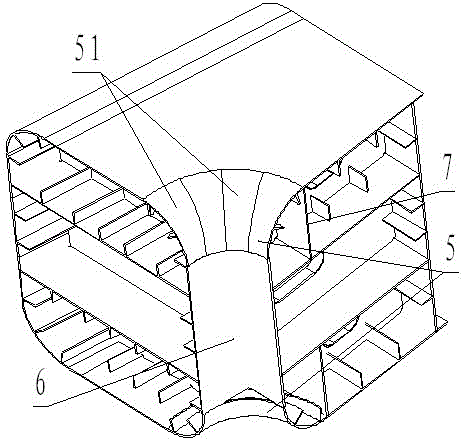

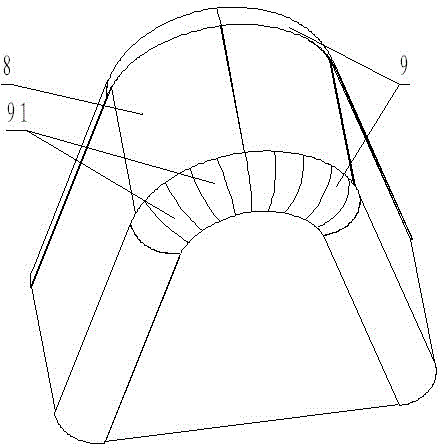

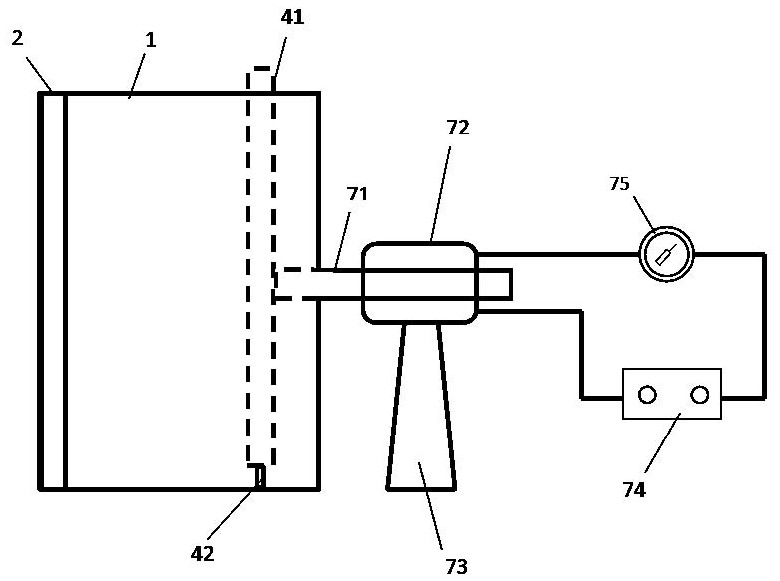

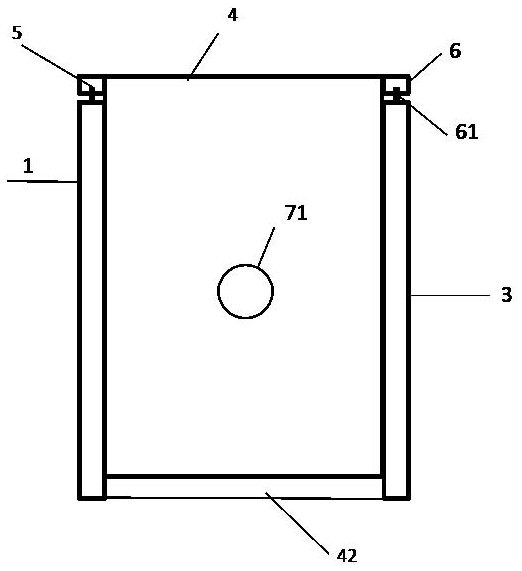

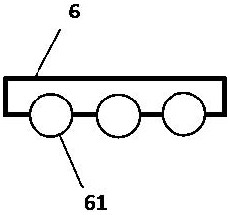

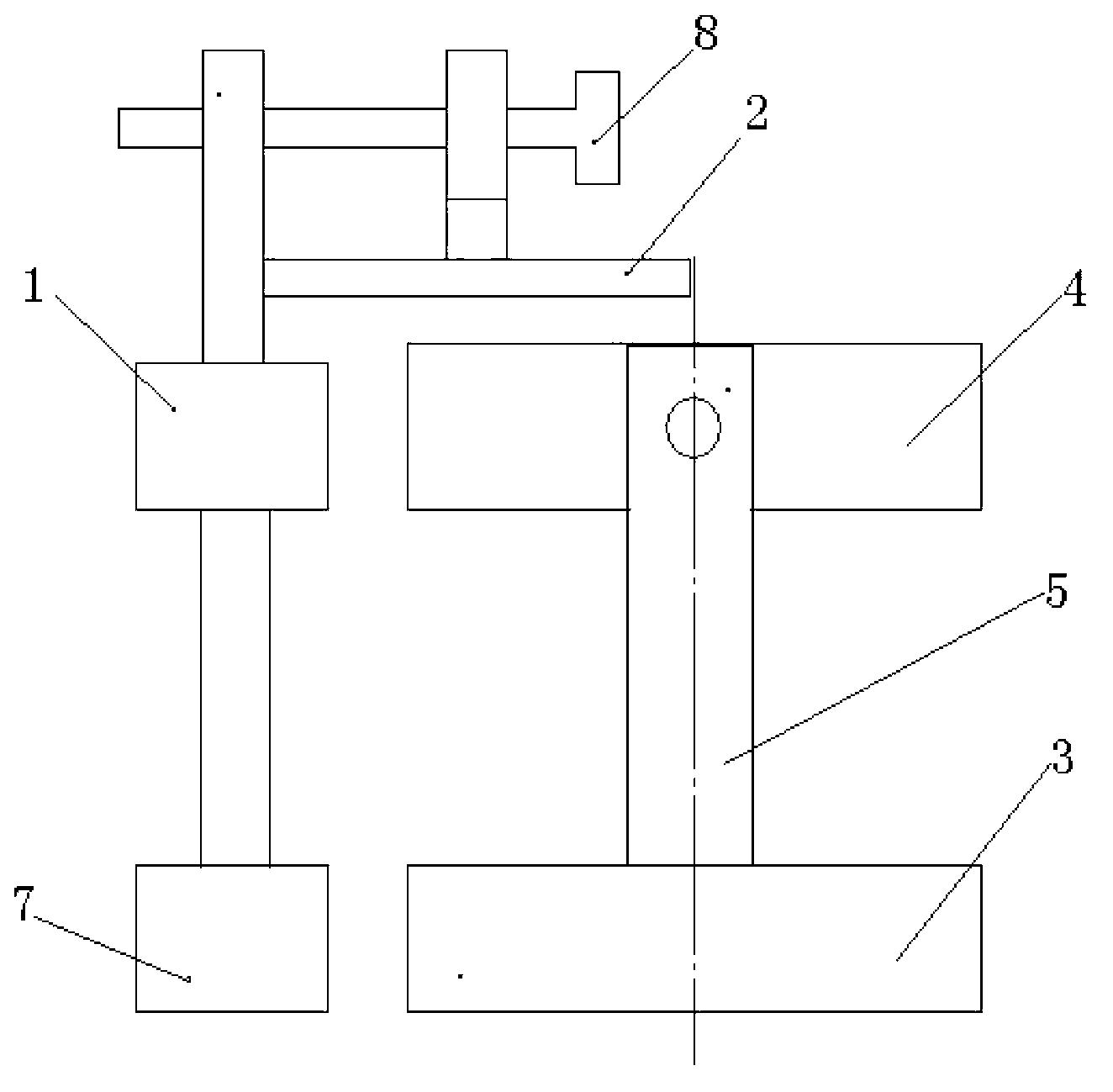

A Novel Two-Element Unilateral Expansion Nozzle

ActiveCN104033283BMake up for the stealth function defectGuaranteed structural sizeJet propulsion plantsEngineeringStructural engineering

The invention relates to a novel two-dimensional single-side expansion nozzle and belongs to the technical field of aero-engine nozzles. The nozzle comprises a round-to-square barrel (1), a single-side expansion wall (3), an adjustment plate (4), extension section side walls (5) and a shield swirling leaf-shaped structure (6) and is particularly characterized in that the front end of the round-to-square barrel (1) is connected with an engine and serves as a support member of the whole nozzle; the rear end of the round-to-square barrel (1) is connected with the single-side expansion wall (3), the adjustment plate (4) and the extension section side walls (5); and the shield swirling leaf-shaped structure (6) is fixedly mounted in the round-to-square barrel (1) and mainly used for shielding a hot end member at the front end of the nozzle to achieve a good invisibility function. The nozzle has the advantages that a structure size of the conventional two-dimensional single-side expansion nozzle is ensured, a defect of the poor invisibility function of the conventional two-dimensional single-side expansion nozzle is overcome, and the nozzle has the advantages of simple structure and high reliability at the same time.

Owner:AECC SHENYANG ENGINE RES INST

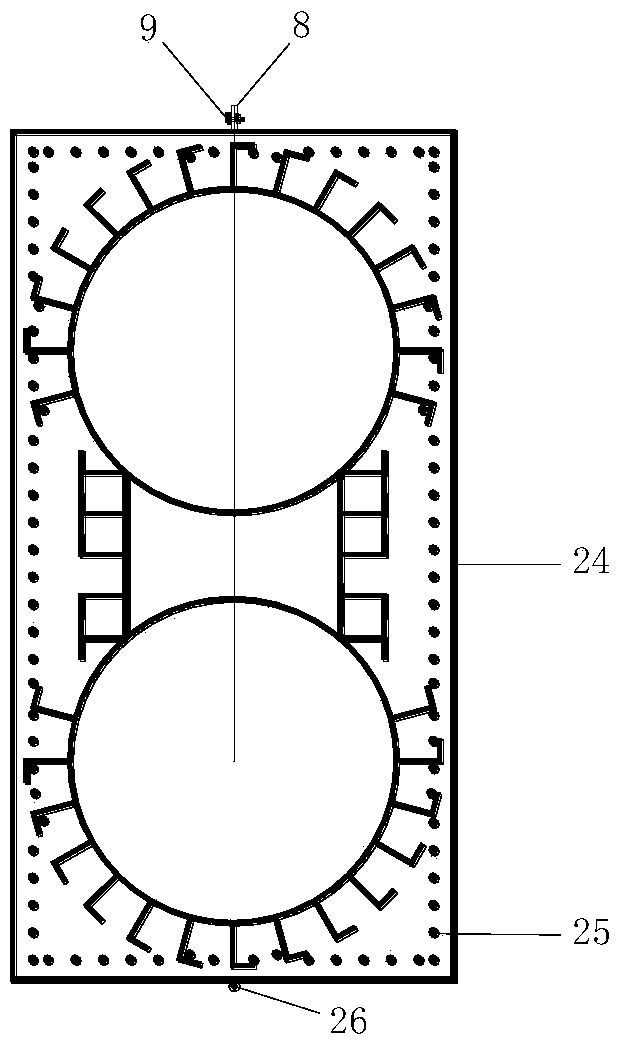

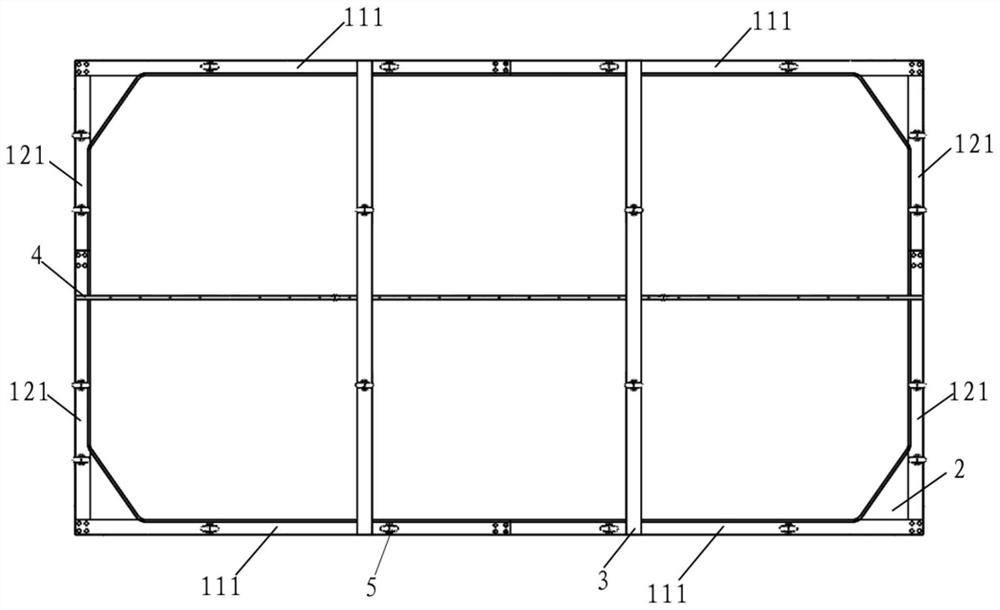

Self-assembling movable template for partition wall in main structure of subway station and half-cover excavation method section

PendingCN109610510ALow costSpeed up the construction progressArtificial islandsForms/shuttering/falseworksDouble rowFastener

The invention provides a self-assembling movable template for a partition wall in a main structure of a subway station and a half-cover excavation method section. A base is formed by welding channel steel, two first channel steel are arranged at parallel intervals in the length direction, a plurality of second channel steel are arranged at parallel intervals in the width direction, and the spacingbetween the two first channel steel is the same as the spacing between two adjacent second channel steel; both ends of the second channel steel are separately welded and fixed to the first channel steel; a bracket is erected with a plurality of steel pipes, the horizontal spacing is 1m, and the step spacing is 1.2m, so that a double-row scaffold is formed; the steel pipes which are erected in thevertical direction are used as vertical rods, the bottoms of the steel pipes are welded and fixed to the base, and other steel pipes are connected at crossing nodes by fasteners; the steel pipes erected in the horizontal direction are horizontal rods, the two ends of the steel pipes extend out of the bracket and are used for being fixed to transverse rib steel pipes of a panel to bear the weightof the panel; and the panel is a blockboard, and transverse ribs and vertical ribs are bound and fixed by iron wires.

Owner:中铁一局集团厦门建设工程有限公司 +1

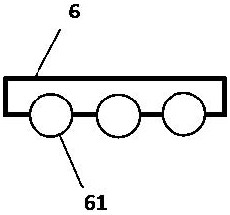

A plastering method for arc section walls

ActiveCN112343272BGuaranteed smoothGuarantee plastering qualityCovering/liningsClassical mechanicsStructural engineering

The invention discloses a method for plastering arc-shaped wall surfaces. The steps are: using the coordinate points outside the arc-shaped structure on the drawing to establish a set of coordinate systems based on the plastering thickness, and the two sets of coordinate systems are located at the same circle center. Stake out arc-shaped positioning points on the ground outside the wall by the total station. A series of ash cake points distributed at intervals are drawn upward on the wall by the laser level at the arc-shaped positioning point on the ground. Finally, use a level to detect whether the thickest points of any two ash cakes are on the same vertical plane. The method of the invention can ensure the quality of plastering, the smoothness of the entire large surface and the structural size.

Owner:中建桥梁有限公司 +1

Production method of non-developable surface structure of large bridge steel tower

ActiveCN102642118BLow production marginReduce consumptionThree-dimensional spaceStructure of the Earth

The invention discloses a production method of a non-developable surface structure of a large bridge steel tower. The method comprises the following steps of: constructing a simplified model of straight line instead of curve according to a curved surface structure by using Solidworks software, preparing a solid body, unfolding the solid body and drawing a curved surface flattening picture; pre-processing a board, blanking, marking out and digging according to the curved surface flattening picture, bending a bending line, detecting a sample plate, and carrying out flame finishing to obtain a split two-dimensional space curved surface; pre-processing the board, blanking, marking out and digging according to a curved surface flattening picture, bending a bending line, detecting a sample plate, carrying out flame finishing, dividing and marking out to carry out multiple divisions, weighting and matching in the field, cutting, assembling and welding to obtain a three-dimensional space curved surface; assembling and welding the split two-dimensional space curved surface and / or the three-dimensional space curved surface in the field, detecting flaw, and coping a welding line. The method provided by the invention is convenient and feasible, the production precise conforms to the design requirements and is simple to operate, hot rolling and a special mould are not adopted, the investment cost is low, and the change and the influence on the mechanical property of a steel material are avoided.

Owner:中铁宝桥(扬州)有限公司

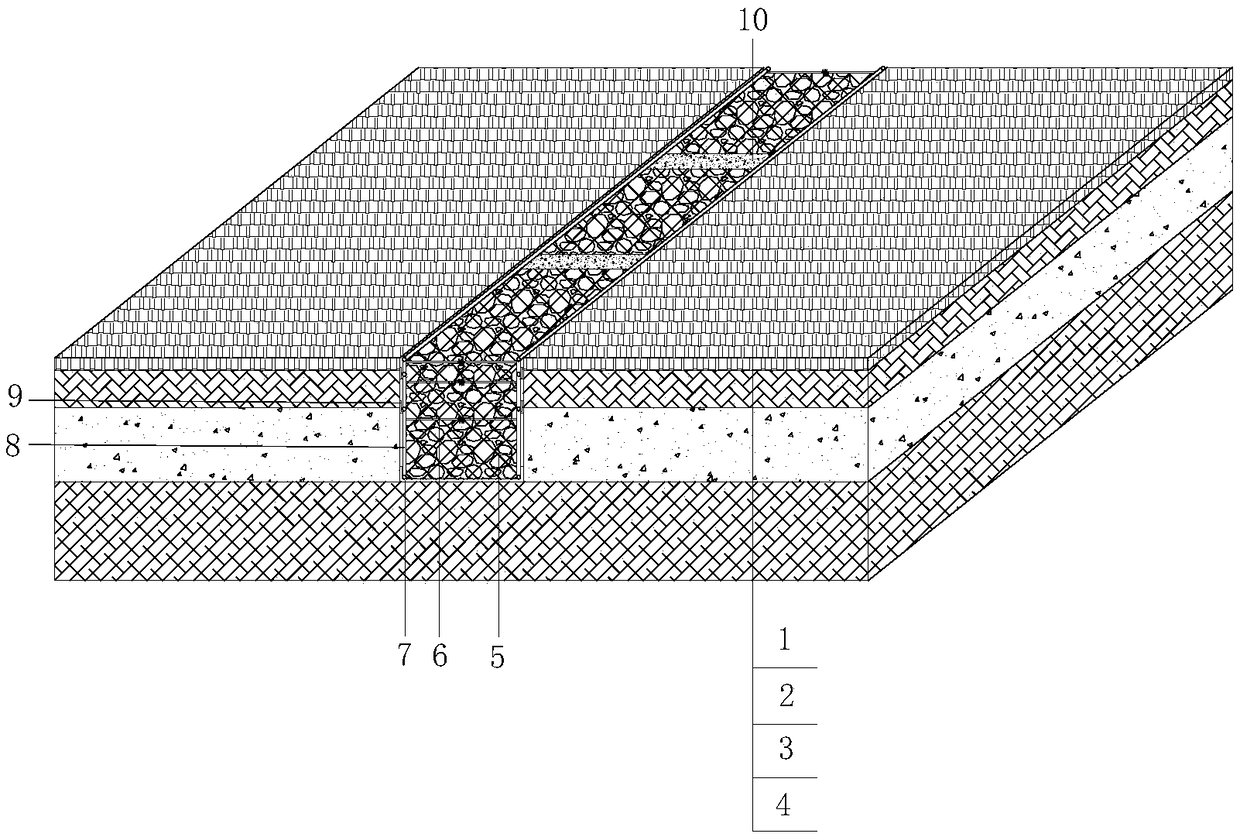

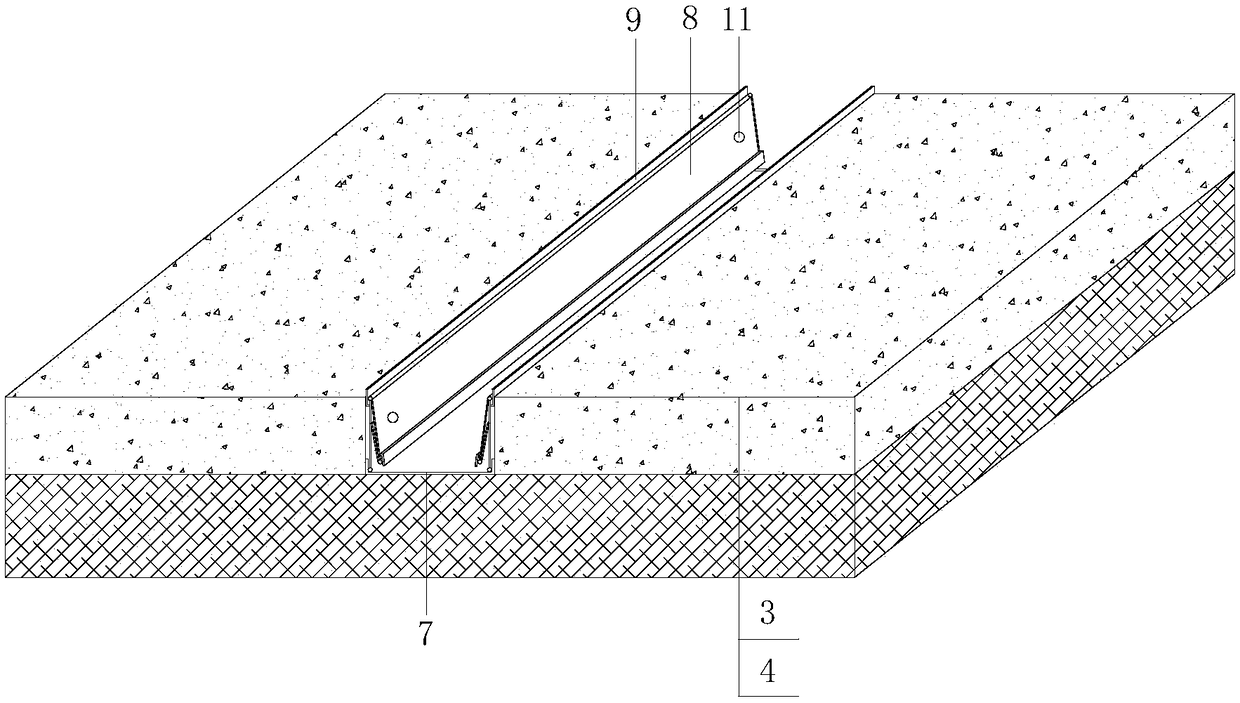

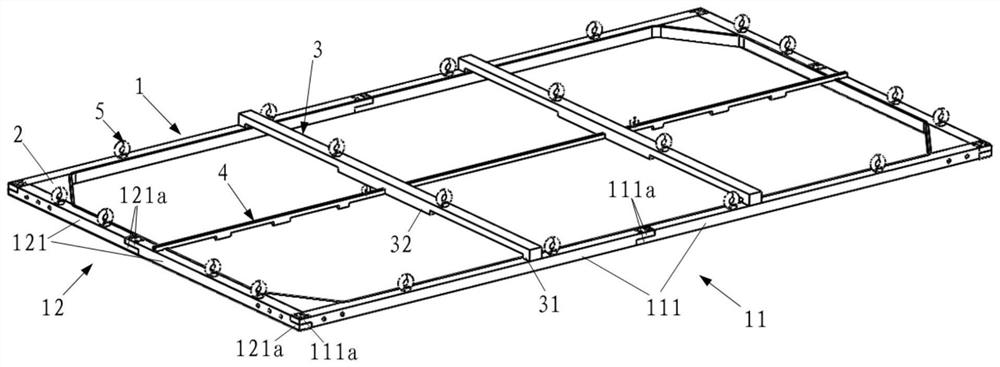

A combined concrete formwork system and its construction method

ActiveCN112709424BAvoid crackingGuaranteed structural sizeFoundation engineeringAuxillary members of forms/shuttering/falseworksArchitectural engineeringEngineering

The invention belongs to the technical field of large-volume concrete crack control, and in particular relates to a combined concrete formwork system and a construction method, aiming at controlling large-volume concrete cracks. It includes a bottomless box and a power system. The front side wall, left side wall and rear side wall of the bottomless box are fixed, and the right side wall approaches or moves away from the bottomless box under the action of the power system. The right side wall Including the fixedly connected upper steel mold and the lower water-stop rubber strip, the top of the upper steel mold is symmetrically cantilevered at both ends to set up sliding components and supporting power systems, so that the right side wall can slide on the slide rails on the top of the front and rear side walls, and the displacement can be achieved. f(x) Control the deformation of the absorbed concrete, eliminate the internal temperature stress of the concrete, and prevent the concrete from cracking; at the same time, through the displacement f(x) Controls the amount of left shift of the right side wall on the property's front and rear side walls f (x) max , which can effectively ensure that the size of the concrete structure meets the design requirements.

Owner:SHANGHAI CONSTRUCTION GROUP

Combined concrete formwork system and construction method thereof

ActiveCN112709424AAvoid crackingGuaranteed structural sizeFoundation engineeringAuxillary members of forms/shuttering/falseworksArchitectural engineeringMass concrete

The invention belongs to the technical field of mass concrete crack control, and particularly relates to a combined concrete formwork system and a construction method thereof. The combined concrete formwork system and the construction method thereof aim at controlling mass concrete cracks. The combined concrete formwork system comprises a bottomless box body and a power system, wherein the front side wall, the left side wall and the rear side wall of the bottomless box body are all fixed; the right side wall of the bottomless box body is close to or away from the bottomless box body under the action of the power system; the right side wall comprises an upper steel mold and a lower water stop rubber strip which are fixedly connected; sliding assemblies and matched power systems are symmetrically arranged at the two ends of the top of the upper steel mold in an overhanging mode, so that the right side wall slides on sliding rails at the tops of the front side wall and the rear side wall, the deformation of concrete is controlled and absorbed through the displacement f(x), the temperature stress in the concrete is eliminated, and the concrete is prevented from cracking; and meanwhile, the left displacement f(x) max of the right side wall on the characteristic front side wall and the characteristic rear side wall is controlled through the displacement f(x), and the structure size of the concrete can be effectively ensured to meet the design requirement.

Owner:SHANGHAI CONSTRUCTION GROUP

Arc-shaped wall plastering method

ActiveCN112343272AGuaranteed smoothGuarantee plastering qualityCovering/liningsVertical planeTotal station

The invention discloses an arc-shaped wall plastering method. The arc-shaped wall plastering method comprises the following steps of establishing a set of coordinate system according to the plasteringthickness on the basis of coordinate points on the outer side of an arc-shaped structure on a drawing, and enabling the two sets of coordinate systems to be located in the same center of a circle; lofting an arc-shaped positioning point on the ground outside a wall by a total station; leading a series of ash cake points which are distributed at intervals upwards on the wall from the ground arc-shaped positioning point by a laser level meter; and finally, detecting whether the thickest points of any two vertical ash cakes are located on the same vertical plane or not by a horizontal ruler. Byadopting the arc-shaped wall plastering method, the plastering quality can be guaranteed, the smoothness of the whole large surface is guaranteed, and the structural size can be guaranteed.

Owner:中建桥梁有限公司 +1

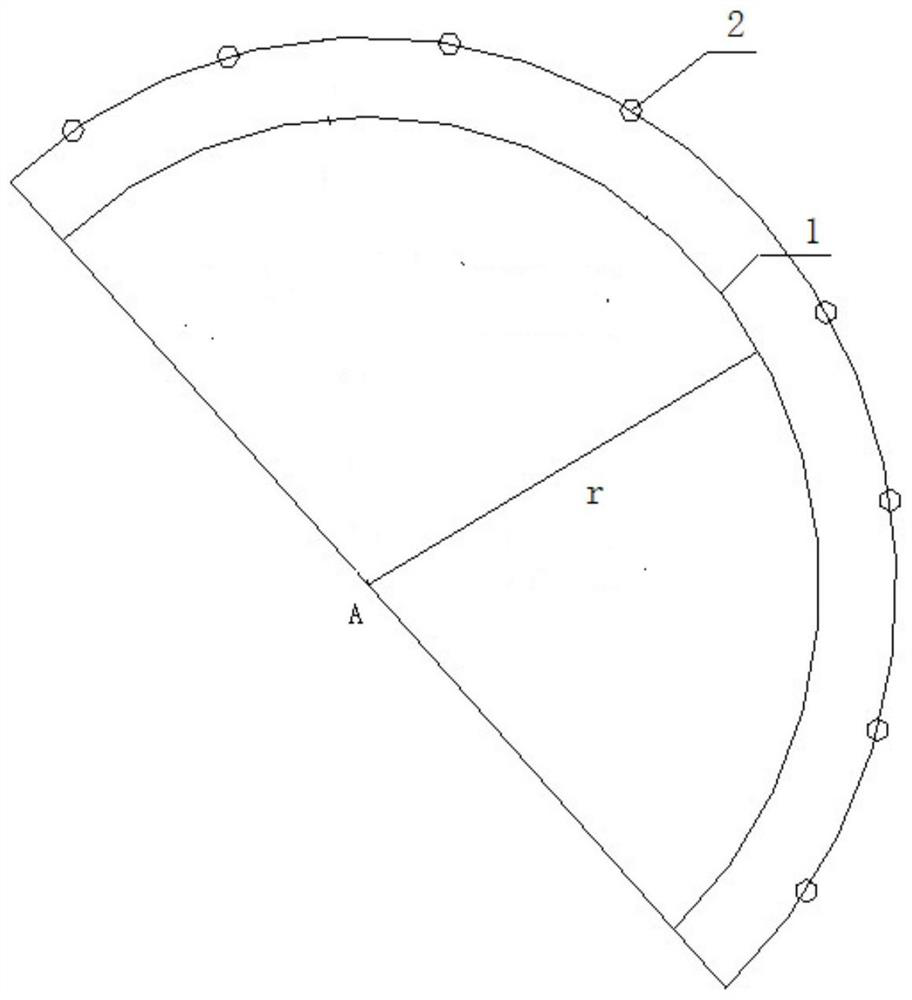

A new formwork trolley for the second lining of the large-section parking line in the underground excavation of the subway section

ActiveCN110080807BReasonable designSimple structureUnderground chambersTunnel liningTrackwayArchitectural engineering

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

A processing method for stable heat treatment of titanium alloy parts

ActiveCN104004982BGuaranteed structural sizeGuaranteed product performanceEffective solutionTitanium

The invention provides a stable heat treatment processing method for titanium alloy parts, which uses a stable heat treatment fixture to process titanium alloy parts, which effectively solves the problems of residual stress and uneven structure in titanium alloy parts after processing, thereby ensuring the structural size of titanium alloy parts and product performance.

Owner:吉林航空维修有限责任公司

Reservation and replacement of cast-in-place curb stones on asphalt concrete pavement and its construction method

ActiveCN108625249BImproving the construction quality of filling and rollingGuaranteed structural sizePaving gutters/kerbsRoads maintainenceStructural engineeringRoad surface

The invention relates to cast-in-place kerbstone for reserved replacement of an asphalt concrete pavement. The cast-in-place kerbstone comprises a reserved groove mold, a gravel dense screen bag, a lightweight rib separating block, a cast-in-place slip form system, the cast-in-place kerbstone and the asphalt concrete pavement. A cement stabilized macadam foundation is arranged on a subbase course,wherein a kerbstone indwelled groove is excavated on the cement stabilized macadam foundation by a separator kerbstone mould; in addition, a indwelled groove mold is arranged in the kerbstone indwelled groove; the lightweight rib separating block and the gravel dense screen bag are arranged in the indwelled groove mold; the cement stabilized macadam foundation is sequentially provided with a coarse-grained asphalt concrete layer and a fine-grained asphalt concrete layer from bottom to top. According to the cast-in-place kerbstone for the reserved replacement of the asphalt concrete pavement,disclosed by the invention, by adopting slip-form construction for the kerbstone, the construction method has the advantages of high construction speed, less required labor and no prefabricated site;the paved kerbstone has high integral structural strength and smooth and beautiful linetype.

Owner:HANGZHOU JIANGRUN TECH LIMITED

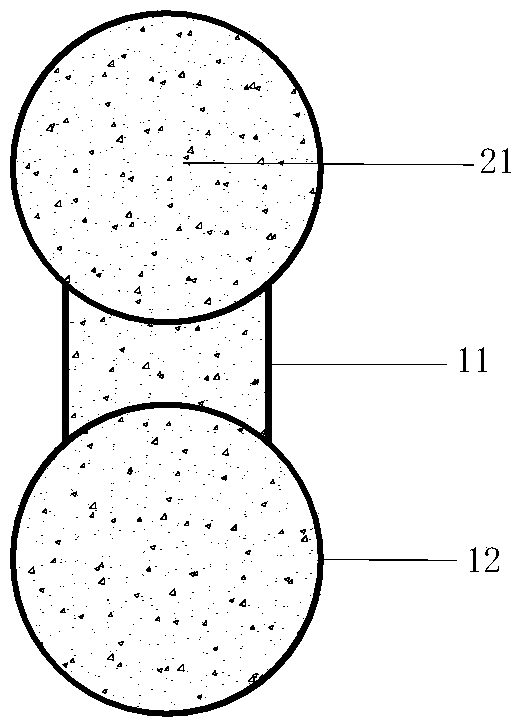

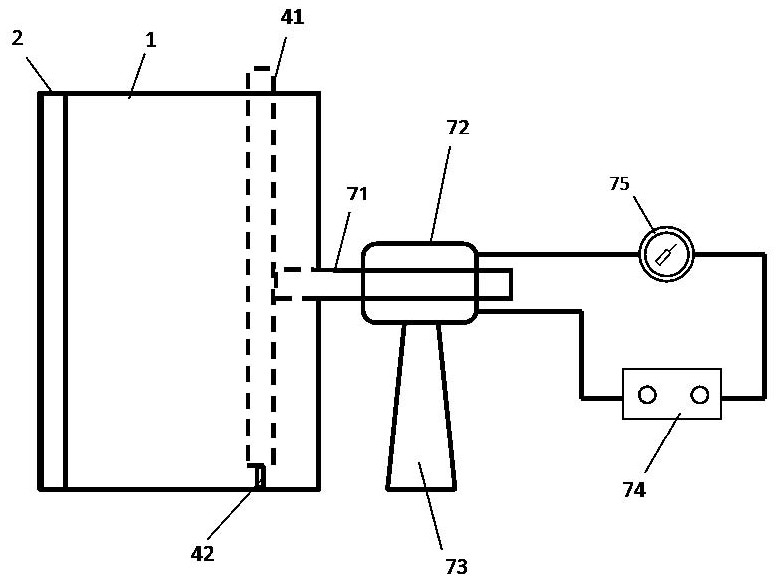

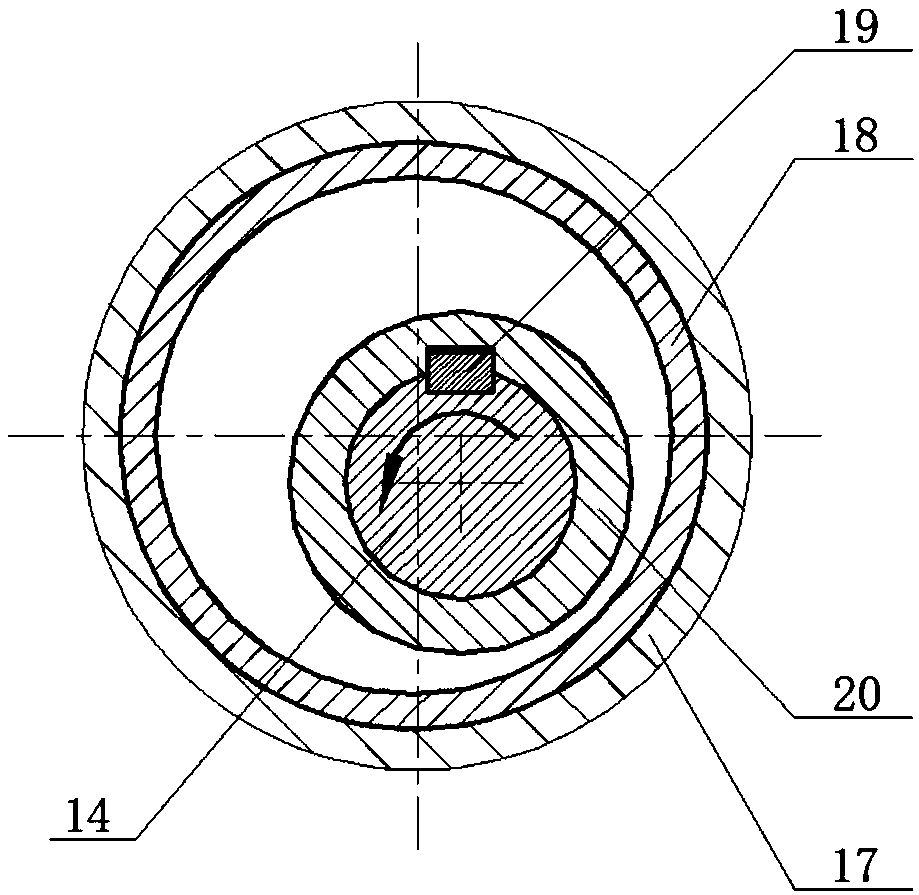

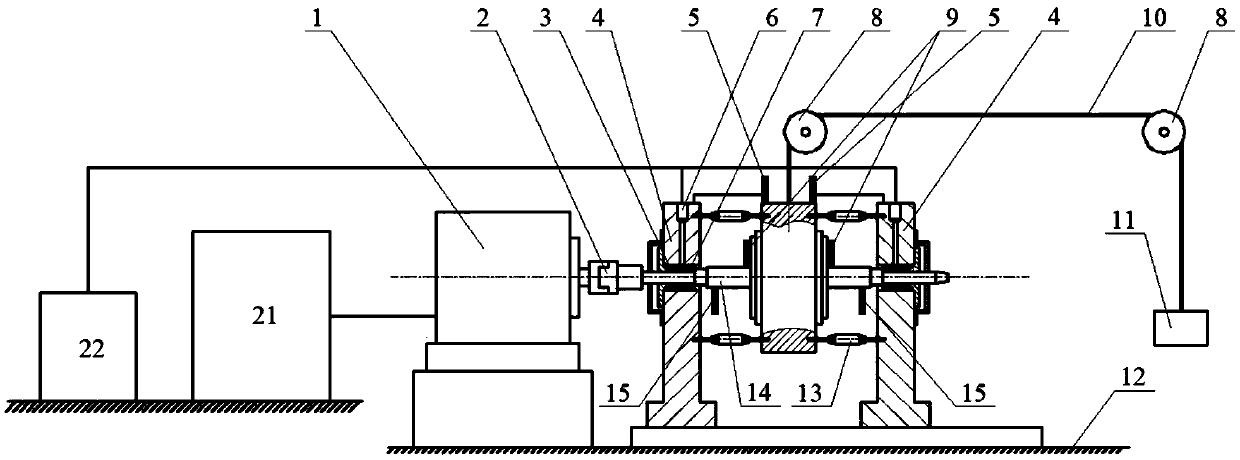

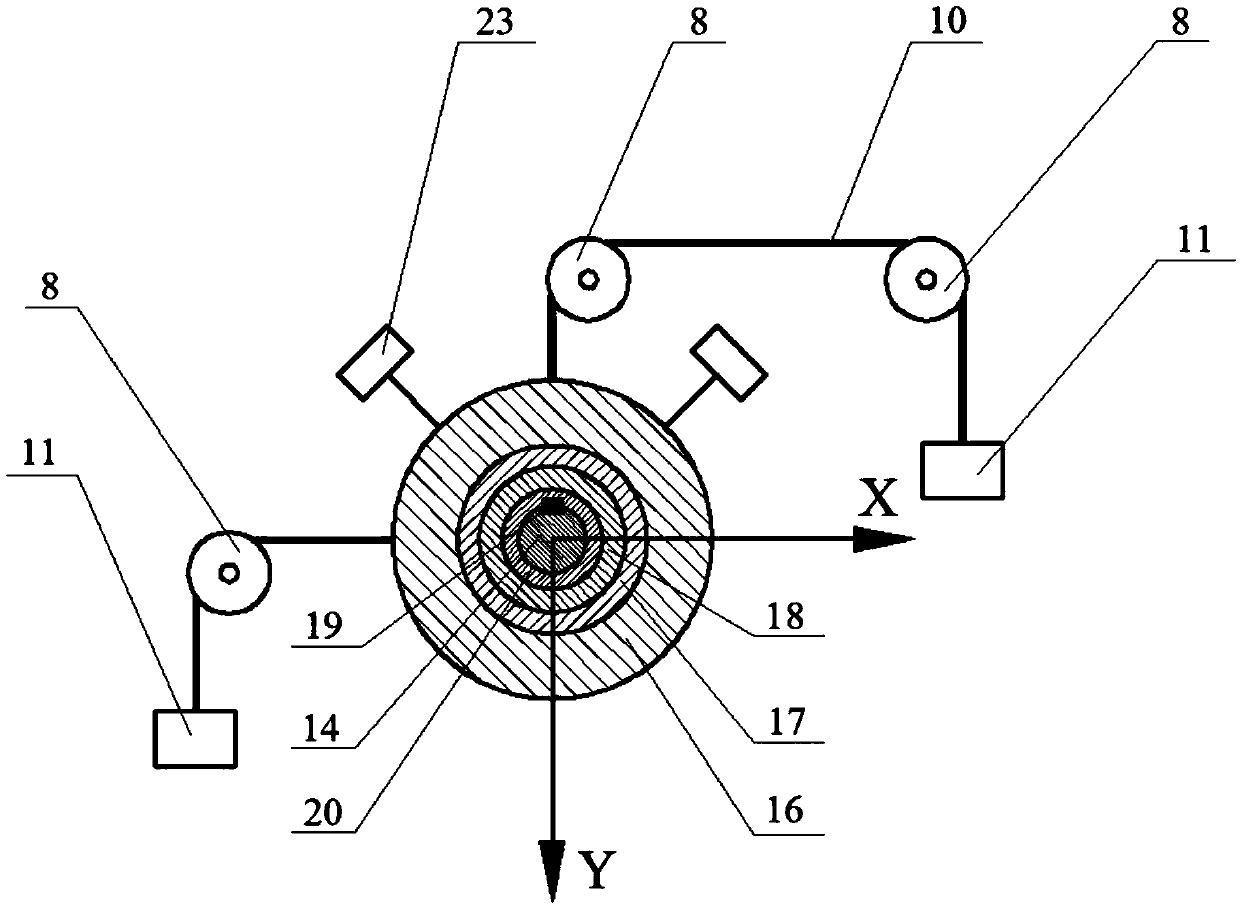

An experimental device and method for testing dynamic characteristics of a series of variable shaft diameter sliding bearings

ActiveCN108801635BGuaranteed structural sizeGuaranteed positioningMachine bearings testingVibration testingAudio power amplifierRolling-element bearing

Owner:XI AN JIAOTONG UNIV

An Easy-to-Remove Formwork Supporting Method of Deformation Seam

ActiveCN106481075BEasy to removeGuaranteed structural sizeForms/shuttering/falseworksEngineeringStructural dimension

The invention relates to an easy-to-dismantle deformation joint form erecting method which comprises the following steps: (1) mounting first wood glue plates which are 1 to 12mm thick on the two sides of a deformation joint respectively; (2) laying a first batten which is 50mm thick at the bottom of the deformation joint; (3) sequentially placing scaffold tubes in the deformation joint until the distance between the scaffold tubes and the upper surface is smaller than 100mm; (4) arranging a second batten above the scaffold tubes. The easy-to-dismantle deformation joint form erecting method has the beneficial effects that (1) easiness for dismantling is achieved; (2) such a combination is stiff enough, and the structural dimensions on the two sides of the deformation joints can be ensured; (3) the adopted materials are common for construction, and can be recycled; (4) the two sides of the deformation joints are simultaneously constructed, so that the construction speed is increased.

Owner:NORTH CHINA METALLURGICAL CONSTR ENG CONSTR +1

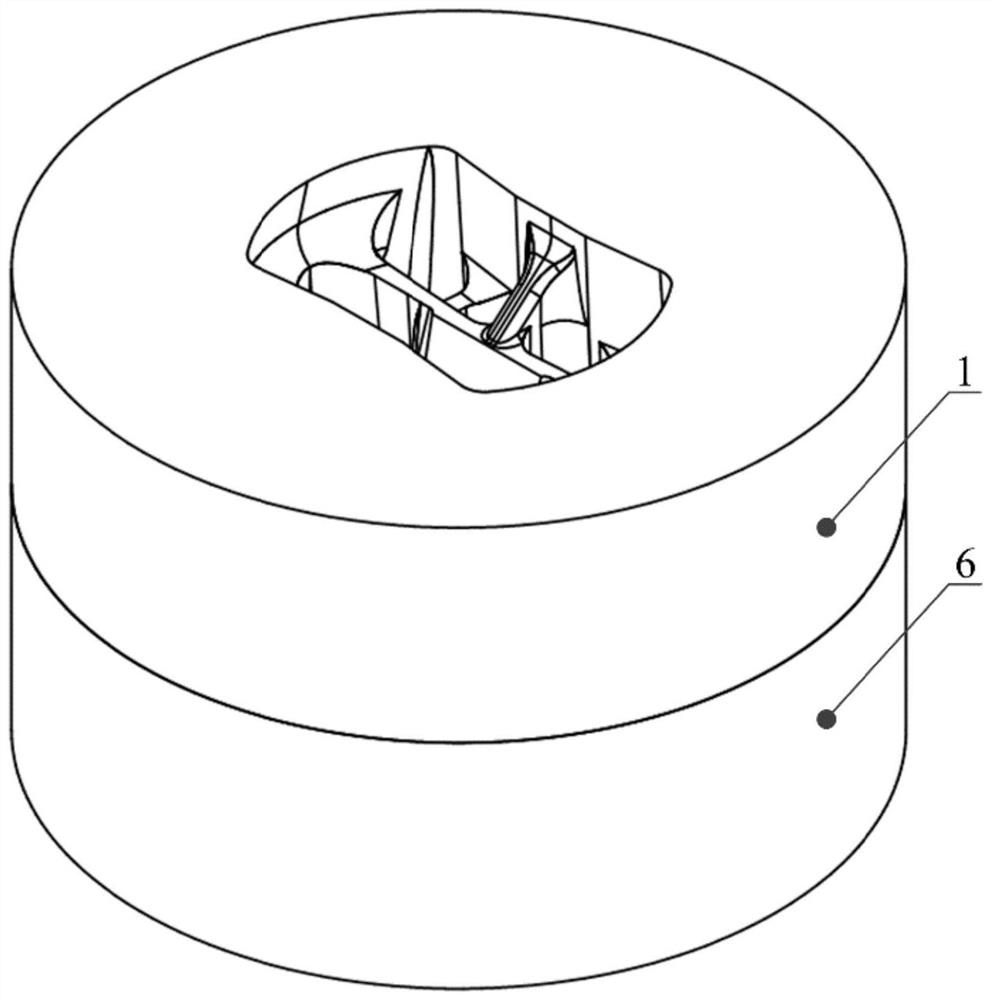

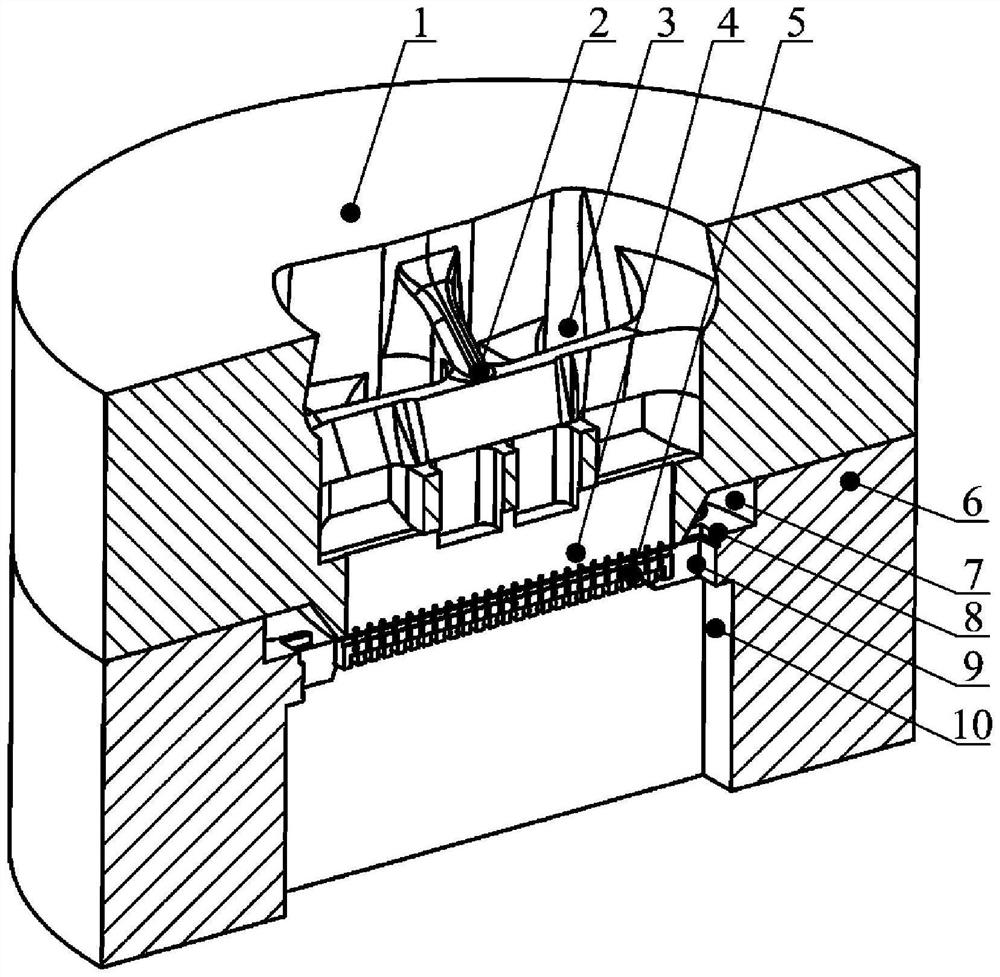

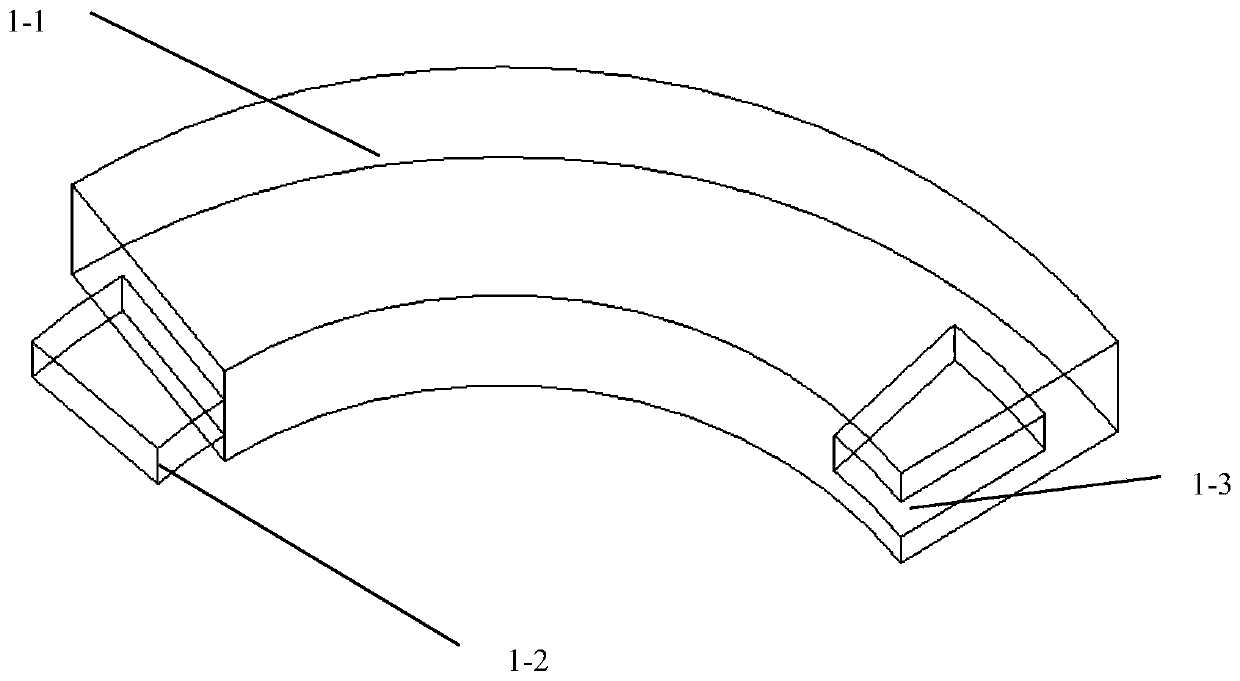

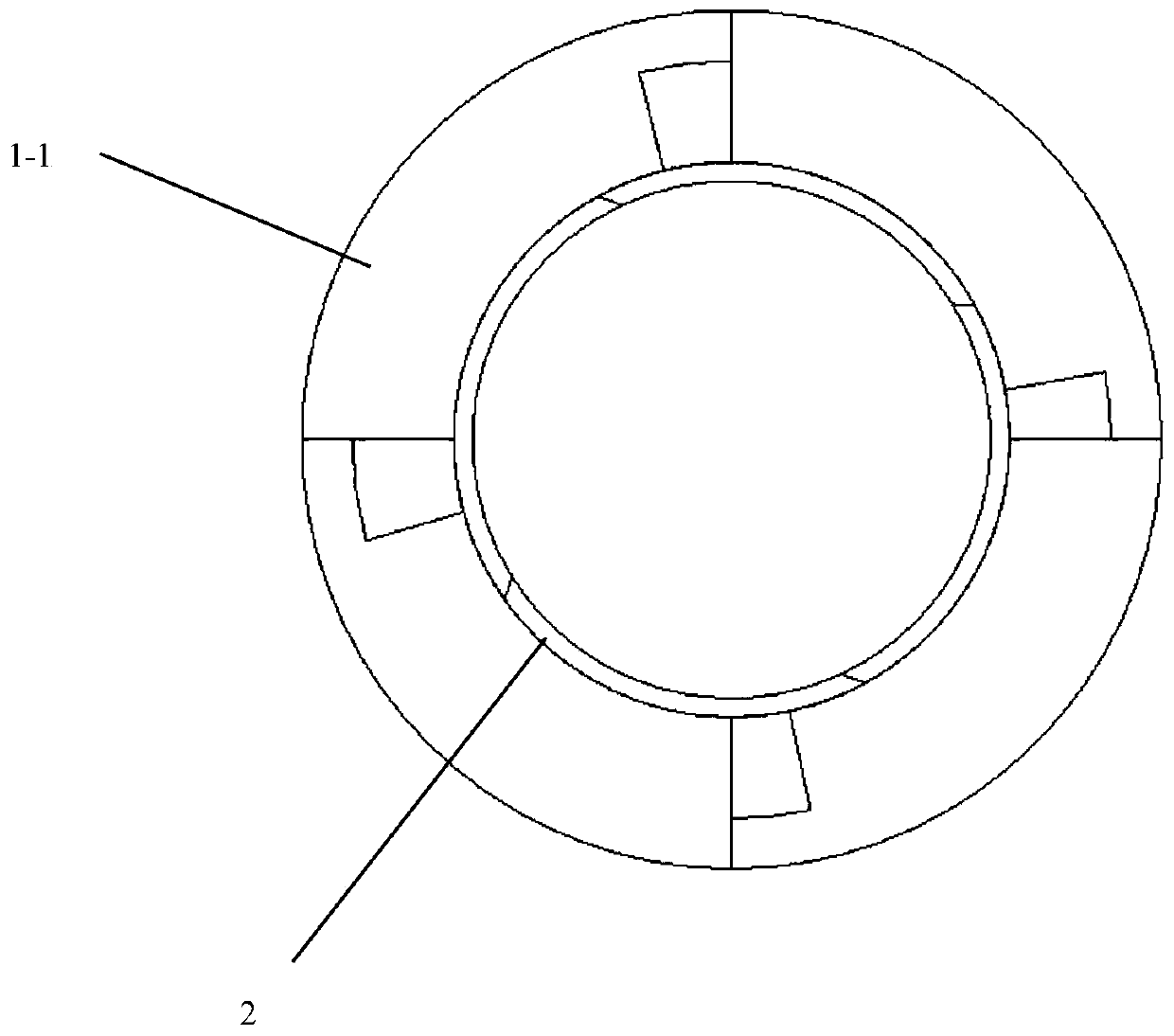

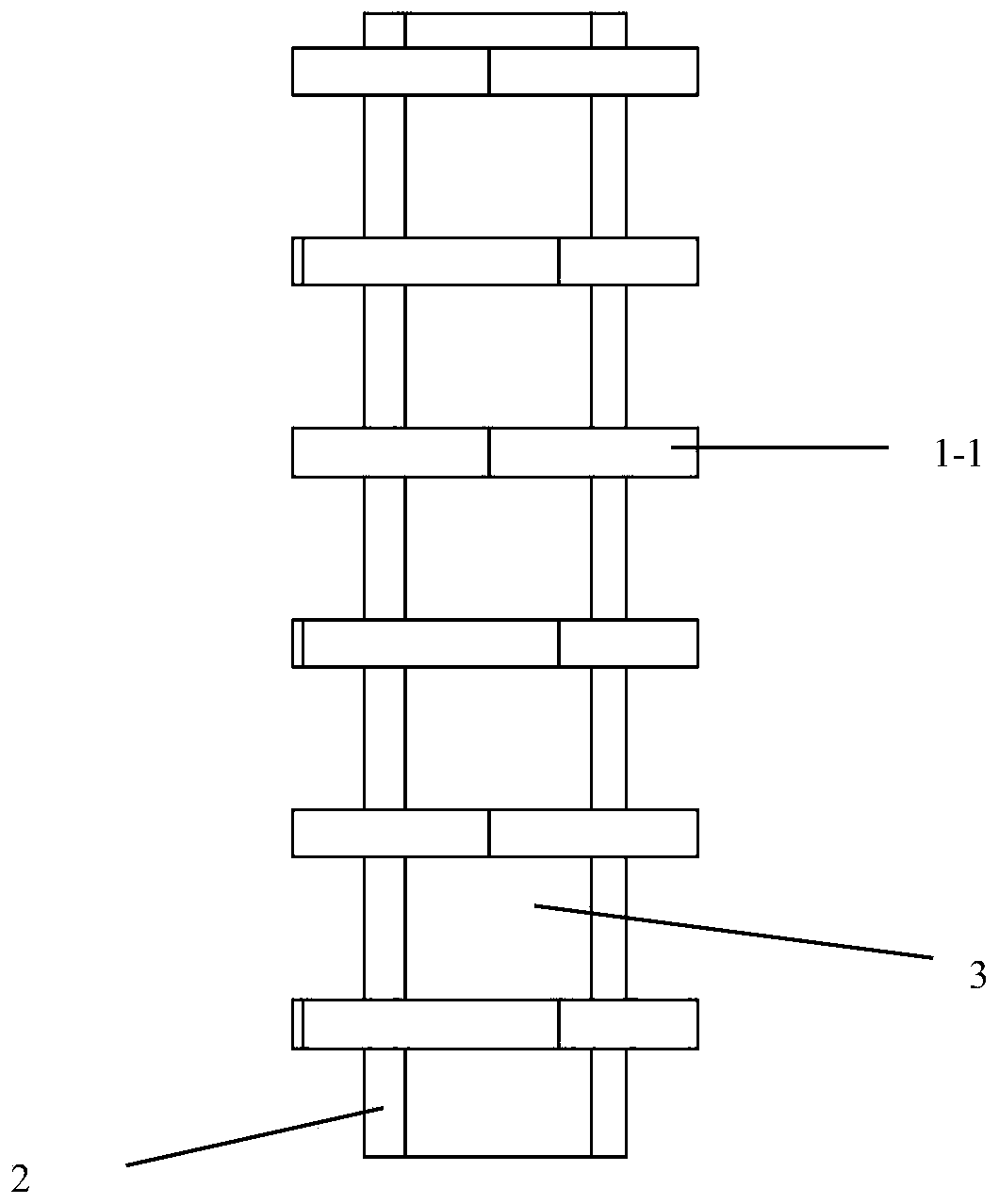

Large composite material product forming die

PendingCN114800958AEnsure structural stabilityGuaranteed structural accuracyPunchingMaterials science

The invention relates to a large composite material product forming die which comprises a die body (1), a connecting block (2), a correcting rod (3) and a punching tool rod (4). The mold main body (1) is of a regular annular structure; the multiple connecting blocks (2) are arranged at intervals in the circumferential direction of the mold body (1), and the connecting blocks (2) are located on the inner side of the mold body (1); a plurality of correcting rods (3) are arranged on the same side of the mold main body (1) at intervals; wherein two opposite ends of the correcting rod (3) are respectively connected with the mold main body (1); the punching tool rod (4) is perpendicular to the correcting rod (3), and the punching tool rod (4) and the correcting rod (3) are located on the same side of the die body (1); wherein two opposite ends of the punching tool rod (4) are respectively connected with the die main body (1).

Owner:NINGBO SHUXIANG NEW MATERIAL

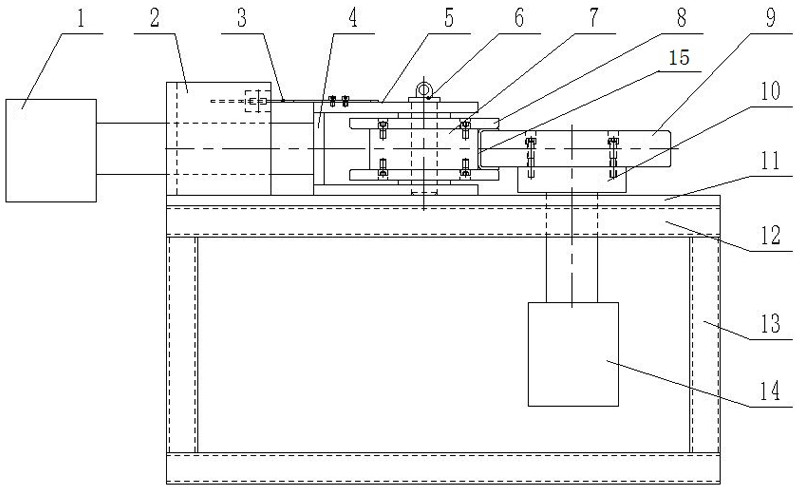

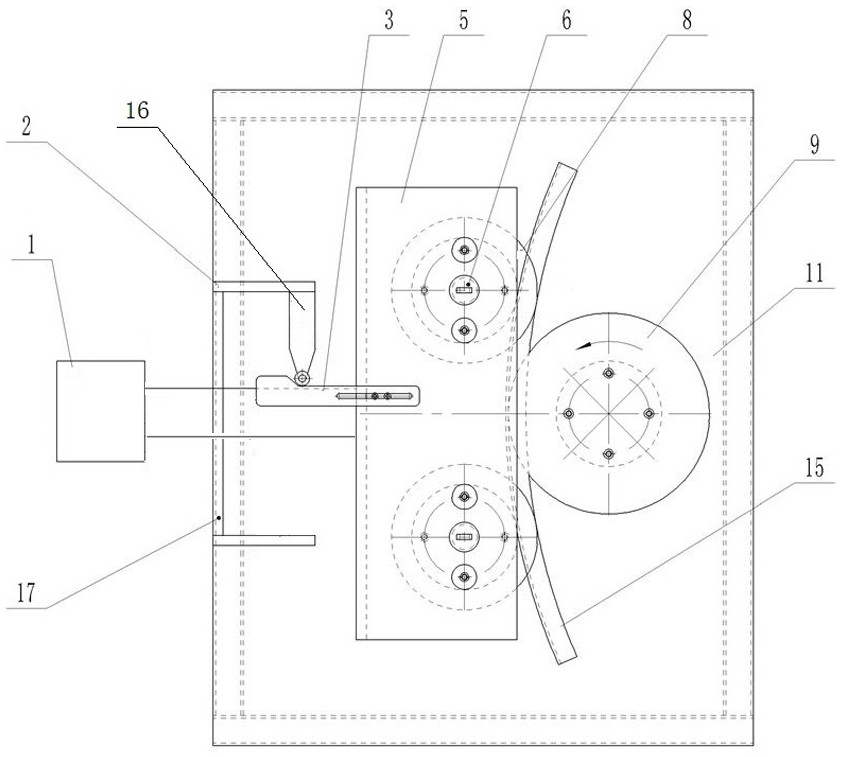

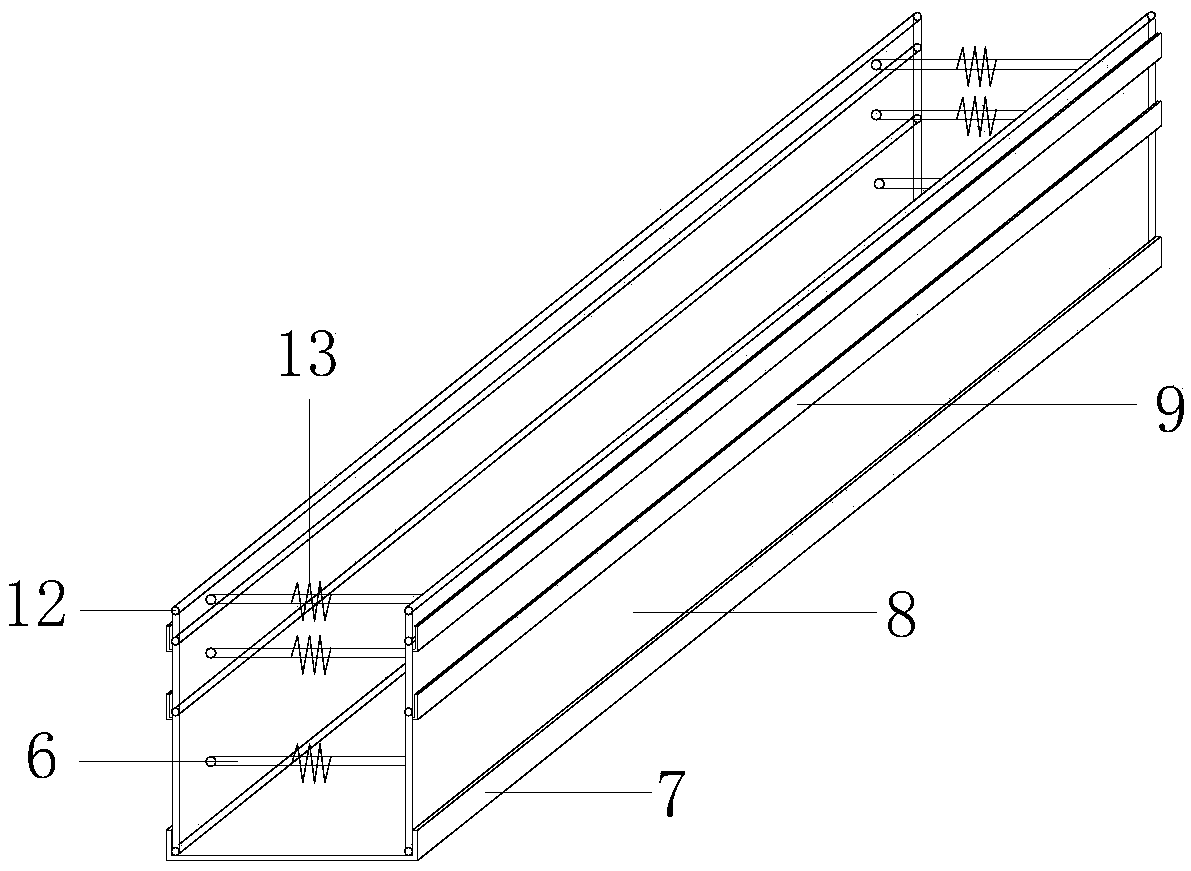

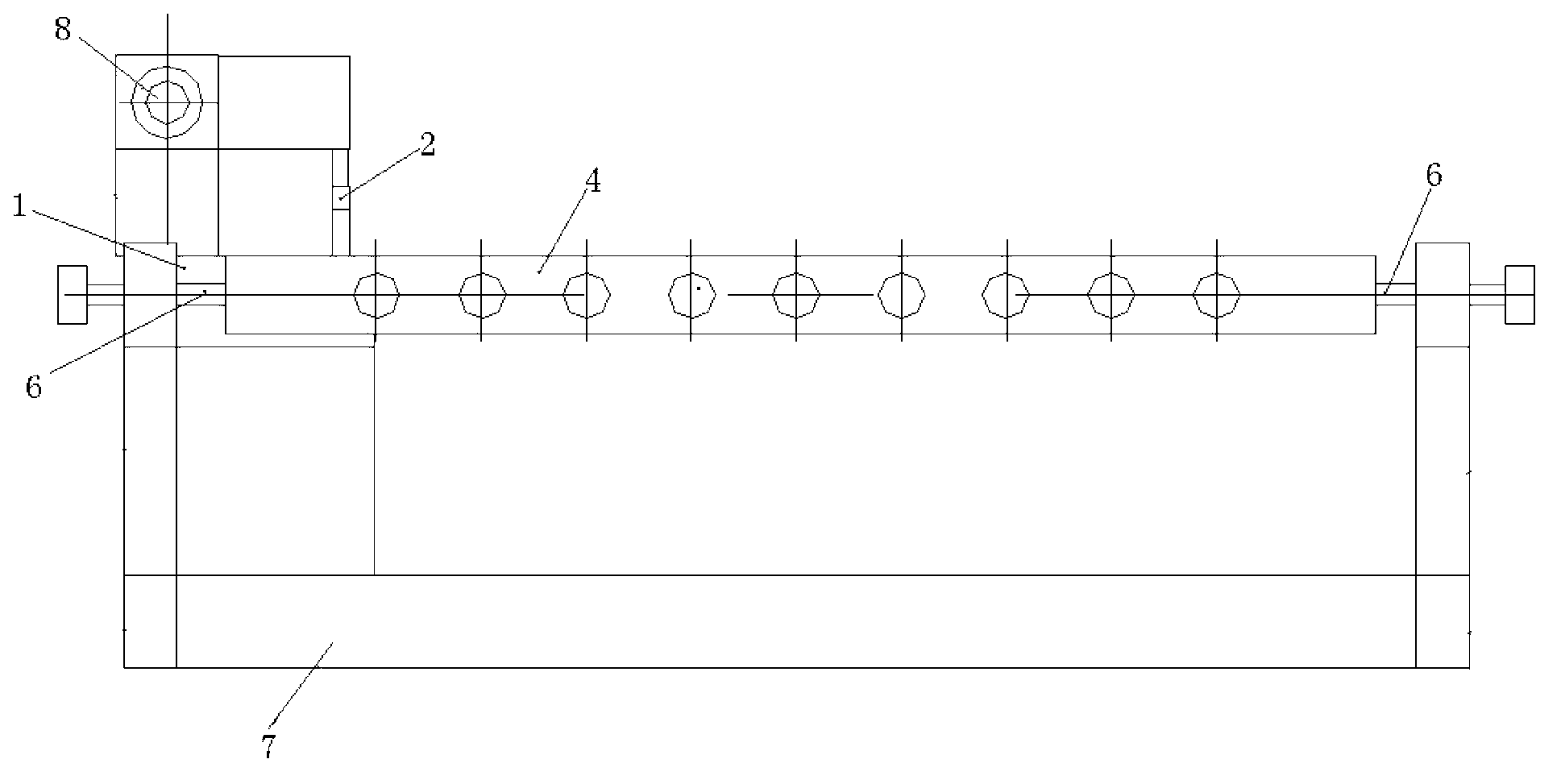

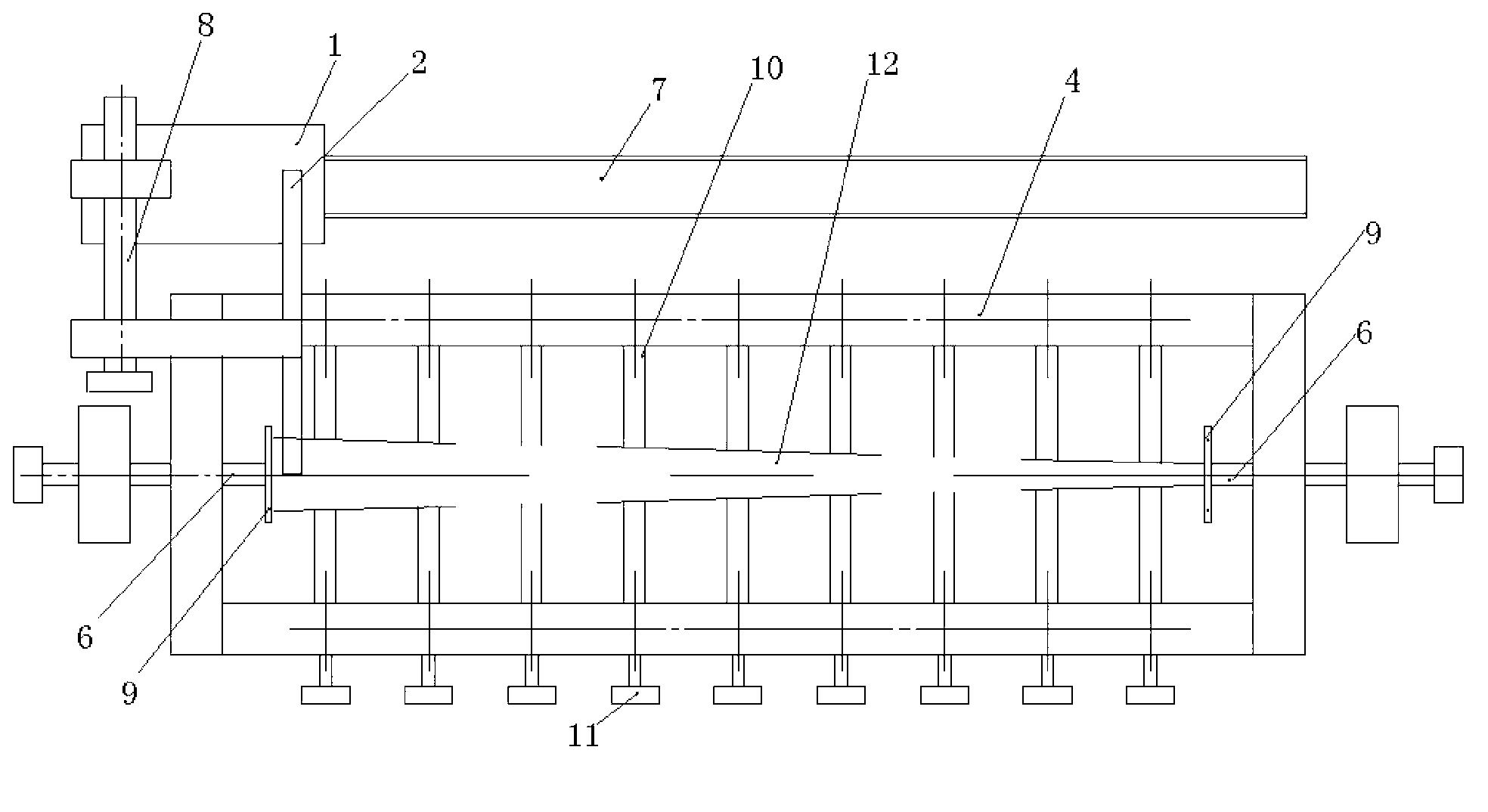

Welding plant for section-variable aluminum alloy long pipe fittings

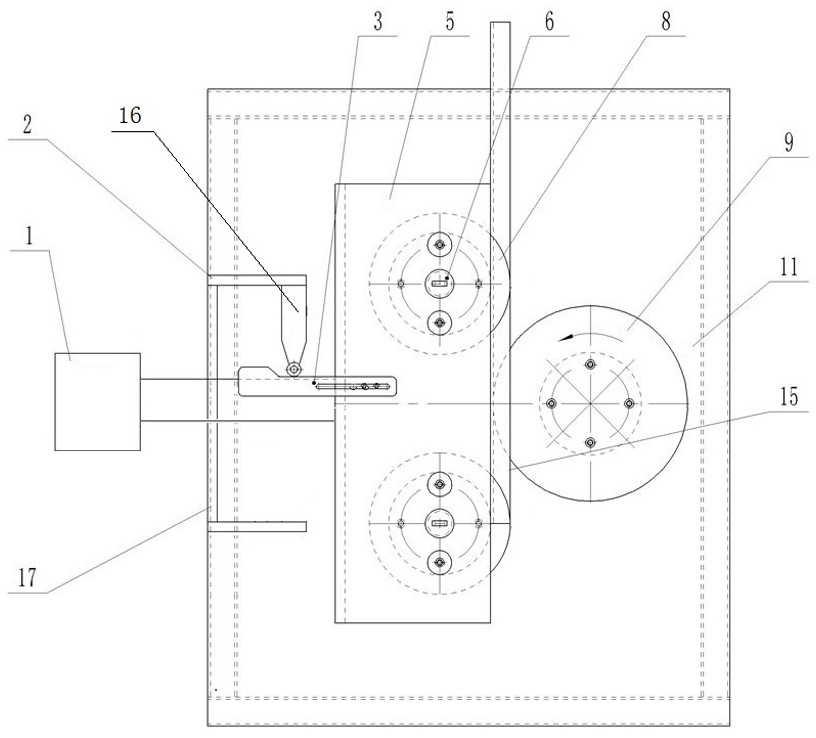

InactiveCN103056488AAvoid Welding DefectsGuaranteed structural sizeArc welding apparatusEngineeringTractor

The invention discloses a welding plant for section-variable aluminum alloy long pipe fittings. The welding plant comprises a rotary welding plant and an automatic welding tractor. The automatic welding tractor is provided with a full-automatic welding handle. The rotary welding plant comprises a base and a rotary frame, upright frames are respectively arranged at two ends of the base, two ends of the rotary frame are respectively mounted on the upright frames at the two ends of the base by hollow shafts, and workpiece clamping devices are respectively arranged on two sides of the rotary frame; rails are disposed on one side of the rotary welding plant, the automatic welding tractor is arranged on the guide rails, and a radial adjusting mechanism is arranged between the full-automatic welding handle and the automatic welding tractor; and elastic barriers are respectively arranged on the hollow shafts at two ends of the rotary frame. The welding plant has the advantages that the quality of products is improved under the condition without high-end welding equipment such as welding robots and special welding machines, the production efficiency is improved, and the repair rate and the rejection rate are reduced.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com