Production method of non-developable surface structure of large bridge steel tower

A technology of curved surface structure and bridge steel tower, which is applied in the field of non-developable curved surface structure of large bridge steel tower, can solve the problems of no production method, high investment cost, high precision, etc., and achieve the effect of saving steel consumption and low production margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

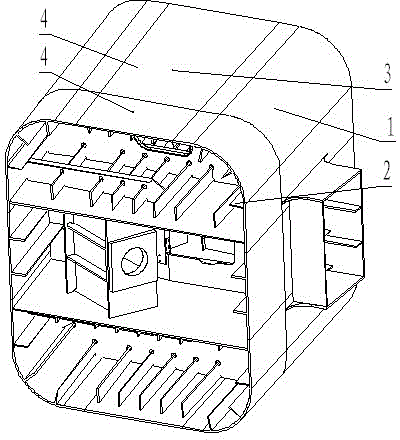

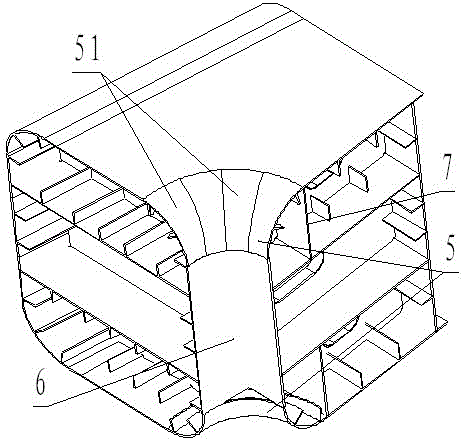

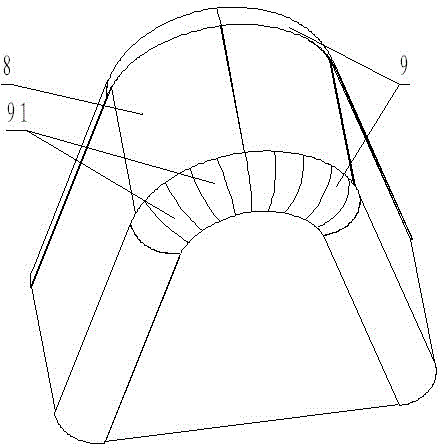

[0022] Such as figure 1 As shown, it is a schematic diagram of the corner structure of a large bridge steel tower body. The corner surface 1 in the figure is a split two-dimensional space surface. Entity, expand the entity to make surface expansion diagram, pre-process the plate, blank according to the surface development diagram, scribing, planing, processing long side bevel, marking bending line, press bending, sample bending arc inspection, flame trimming. Assembling ribs 2, trimming, making the two-dimensional space surface of the component body, sample inspection, trimming, assembling and welding the split two-dimensional space surface and the flat part 3 to form a box body 4, sample testing, trimming, box body and box Body ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com