A plastering method for arc section walls

An arc-shaped section and arc-shaped technology is applied in the field of arc section wall plastering, which can solve the problem that the plastering surface of the arc-shaped wall is difficult to lay on the same arc, and it is difficult to lay the arc. The problem of shape wall and other problems can be ensured to ensure the structure size and the quality of plastering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

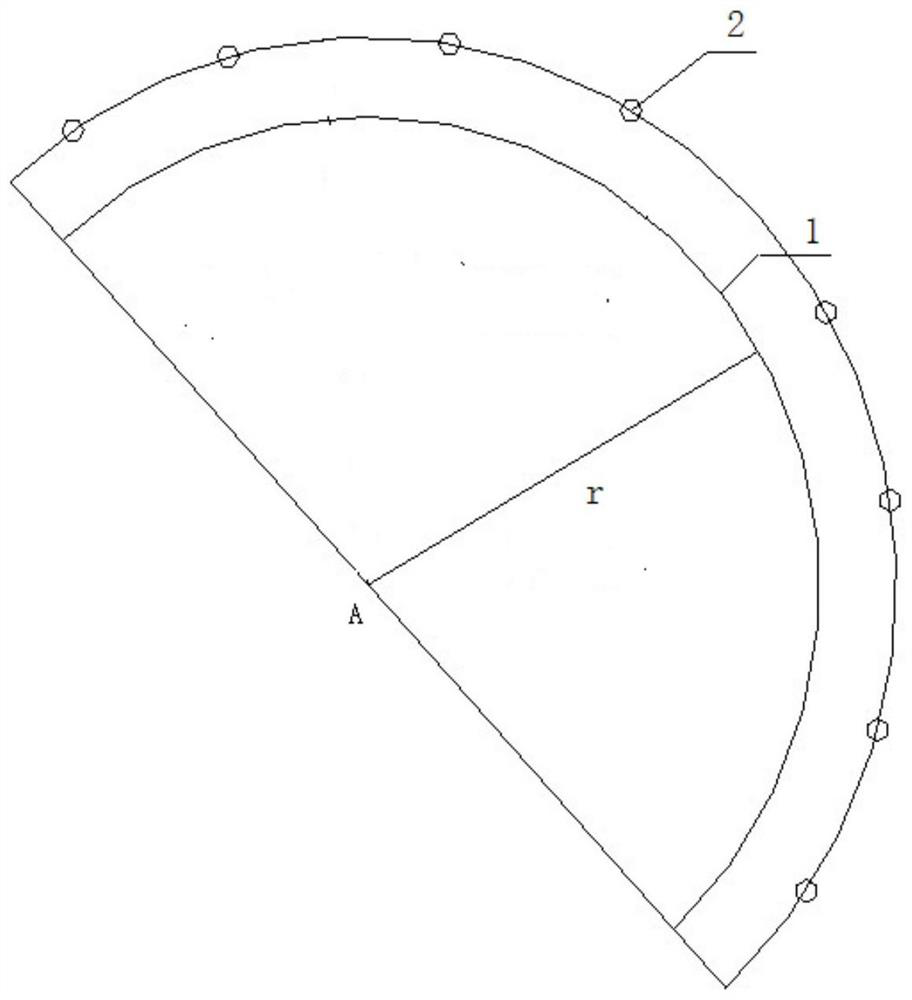

[0013] like figure 1 A kind of arc section wall plastering method of the present invention is shown, comprises the following steps:

[0014] Step 1. Determine the center point A of the arc-shaped wall on the electronic version of the drawing. If the radius of the arc-shaped wall is r, and the thickness of the wall to be plastered on the arc-shaped wall is X, then use the arc The center point A of the wall of the shape section is the center point, and the outer arc of the surface to be plastered is drawn with r+X as the radius; then multiple arc positioning points are evenly spaced on the outer arc and each arc is obtained The coordinates of the positioning point and the number of arc positioning points can be selected according to the actual value of X. The larger the value of X, the more the number of arc positioning points.

[0015] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com