A combined concrete formwork system and its construction method

A technology of concrete formwork and construction method, which is applied to the connection parts of formwork/formwork/work frame, formwork/formwork components, and basic structure engineering, etc. It can solve problems such as concrete cracking and inability to release concrete temperature stress, and achieve The effect of eliminating temperature stress, low cost, and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

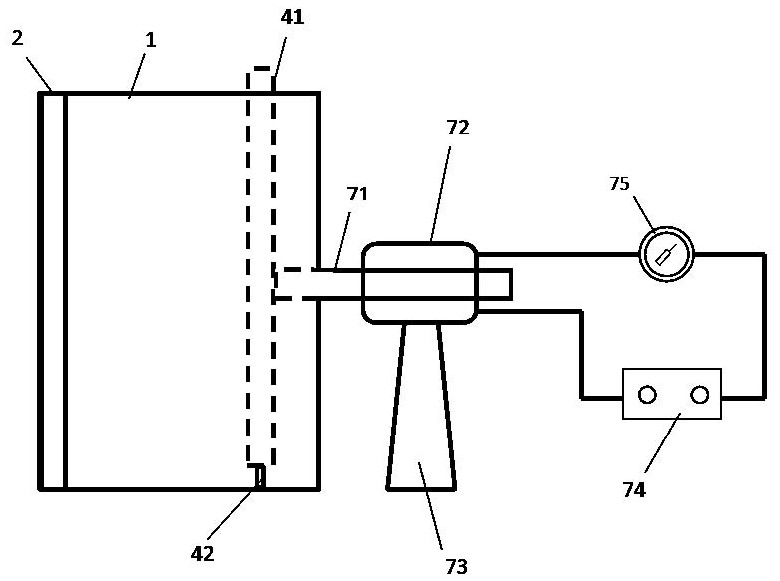

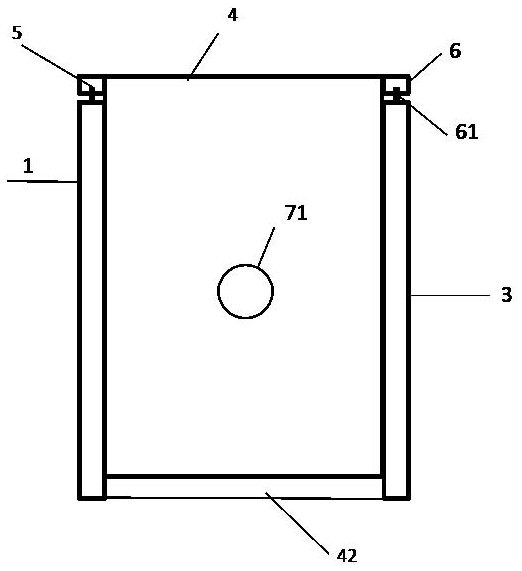

[0039] Combine below Figure 1 to Figure 4 , to describe in detail the combined concrete formwork system and construction method of the present invention.

[0040] Please refer to Figure 1 to Figure 4 , a combined concrete formwork system comprising:

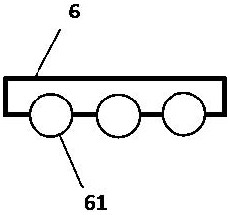

[0041] The bottomless box and the power system, the front side wall 1, the left side wall 2 and the rear side wall 3 of the bottomless box are all fixed, and the right side wall 4 is close to or away from the bottomless box under the action of the power system; no Both the top of the front side wall 1 and the rear side wall 3 of the bottom box are provided with slide rails 5; the right side wall 4 includes an upper steel mold 41 and a lower waterproof rubber strip 42 fixedly connected, and the top two ends of the upper steel mold 41 are hung symmetrically. The sliding assembly 6 is provided, the height of the sliding assembly 6 is consistent with the height of the waterproof rubber strip 42, and the sliding assembly 6 coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com